White wood wax oil for woodware and preparation method thereof

A wood wax oil, white technology, used in wood processing appliances, wood impregnation, wood impregnation, etc., can solve the problems of poor weather resistance and application limitations, and achieve the effects of good water resistance, convenient construction, and avoiding uneven water content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

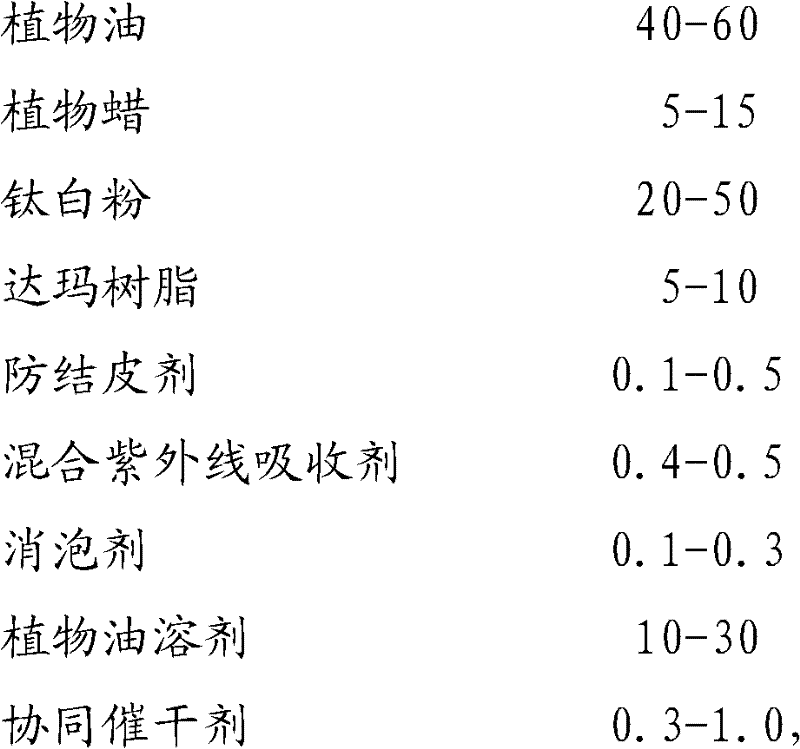

[0055] The composition and weight parts of white wood wax oil described in the present embodiment are as follows:

[0056]

[0057] The preparation method of white wood wax oil described in the present embodiment is as follows:

[0058] (1) 34 parts of soybean oil and 20 parts of sunflower oil are mixed and added to the reaction kettle. Under the condition of nitrogen protection, 8 parts of carnauba wax, 2.3 parts of beeswax and 5 parts of dammar resin are added to the above vegetable oil, mixed and stirred, and the temperature is raised. React at 220°C to 250°C for 8 hours, then cool to 30°C to 60°C;

[0059] (2) Add 30 parts of titanium dioxide and 0.3 parts of calcium drier to the mixture obtained in step 1, disperse and grind at a high speed of 1500-2000 rpm for 15-30 minutes, and then add 0.05 parts of cobalt to dry 0.5 parts of oily UV absorber and hindered amine light stabilizer, 0.2 parts of defoamer, mixed and stirred for 5-10 minutes, and finally added 0.3 parts ...

Embodiment 2

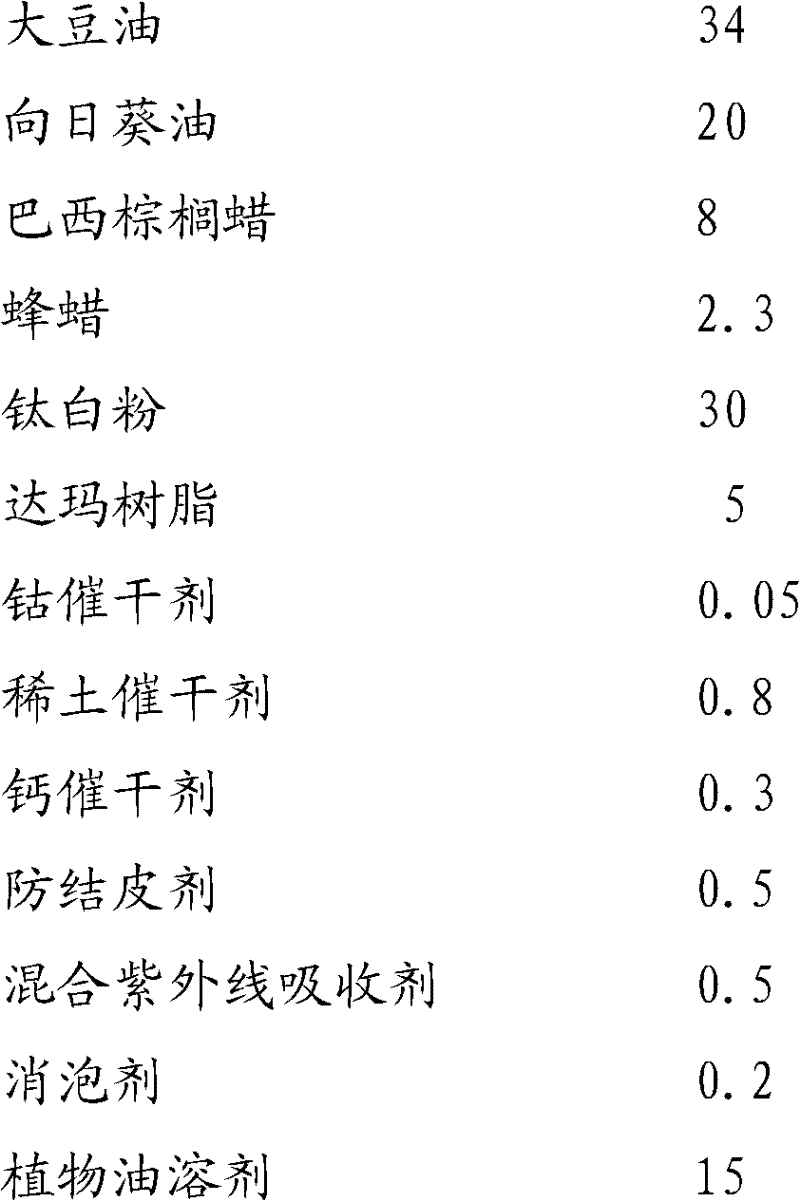

[0061] The composition and weight parts of white wood wax oil described in the present embodiment are as follows:

[0062]

[0063] The preparation method of white wood wax oil described in the present embodiment is as follows:

[0064] (1) Take 60 parts of soybean oil in a reaction kettle, add 8 parts of carnauba wax and 8 parts of dammar resin into the above vegetable oil under the condition of nitrogen protection, mix and stir, heat up to 200°C-250°C for 8 hours, and cool to 30℃~60℃;

[0065] (2) Add 35 parts of titanium dioxide and 0.6 parts of calcium drier to the mixture obtained in step 1, disperse and grind at a high speed of 1500-2000 rpm for 15-30 minutes, and then add 0.03 parts of cobalt to dry 0.5 parts of ultraviolet absorber and hindered amine light stabilizer, 0.2 parts of defoamer, mixed and stirred for 5-10 minutes, and finally added 0.2 parts of anti-skinning agent, vegetable oil solvent 15 portion, and stirred at a medium speed for 5 minutes to obtain ...

Embodiment 3

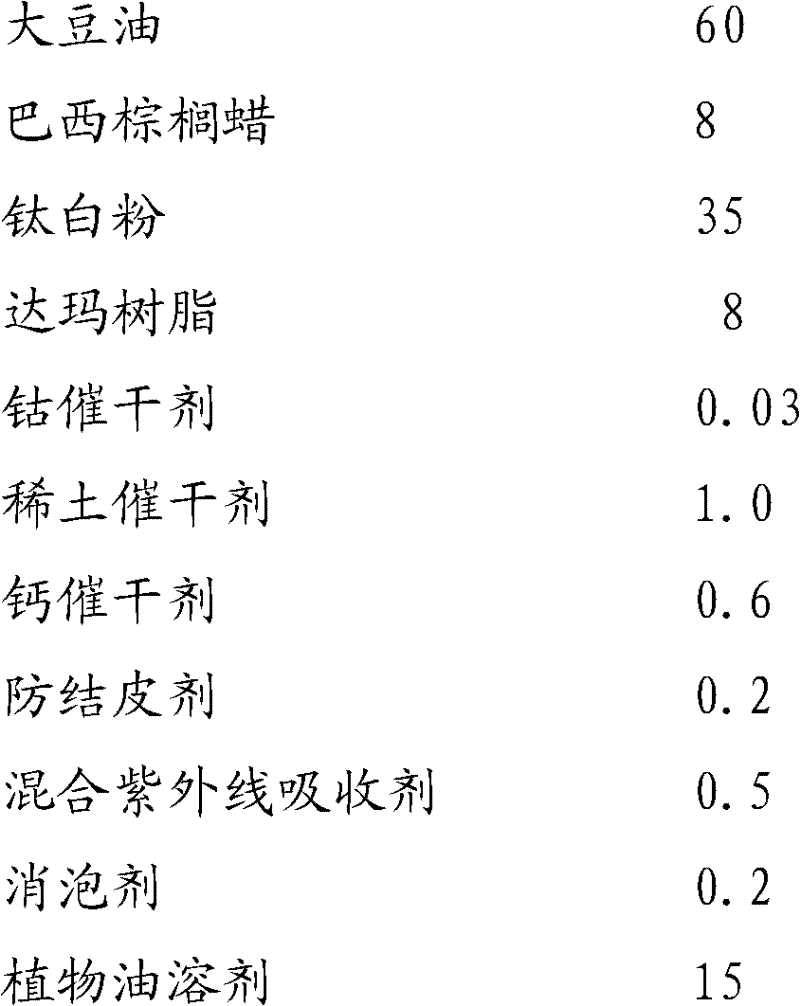

[0067] The composition and weight parts of white wood wax oil described in the present embodiment are as follows:

[0068]

[0069] The preparation method of white wood wax oil described in the present embodiment is as follows:

[0070] (1) 45 parts of soybean oil and 15 parts of sunflower oil are mixed and added to the reaction kettle. Under the condition of nitrogen protection, 10 parts of candelilla wax and 10 parts of dammar resin are added to the above vegetable oil, mixed and stirred, and the temperature is raised to 220 ℃~250℃ for 8 hours, then cooled to 30℃~60℃;

[0071] (2) Add 30 parts of titanium dioxide and 1.0 part of zinc drier to the mixture obtained in step 1, disperse and grind at a high speed of 1500-2000 rpm for 15-30 minutes, and then add 0.02 parts of cobalt to dry 1.2 parts of rare earth drier, 0.5 parts of UV absorber and hindered amine light stabilizer, 0.2 parts of defoamer, mixed and stirred for 5-10 minutes, and finally added 0.2 parts of anti-sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com