Organic silicon polyurethane composite modified alkyd resin coating composition and preparation method thereof

A technology of alkyd resin and compound modification, which is applied in the field of coatings, can solve the problems that cannot meet the requirements of long life of steel structure, heavy anti-corrosion, limited improvement of weather resistance and anti-aging performance, and decreased adhesion, so as to achieve excellent adhesion, The effect of reducing the preparation cost and improving the comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

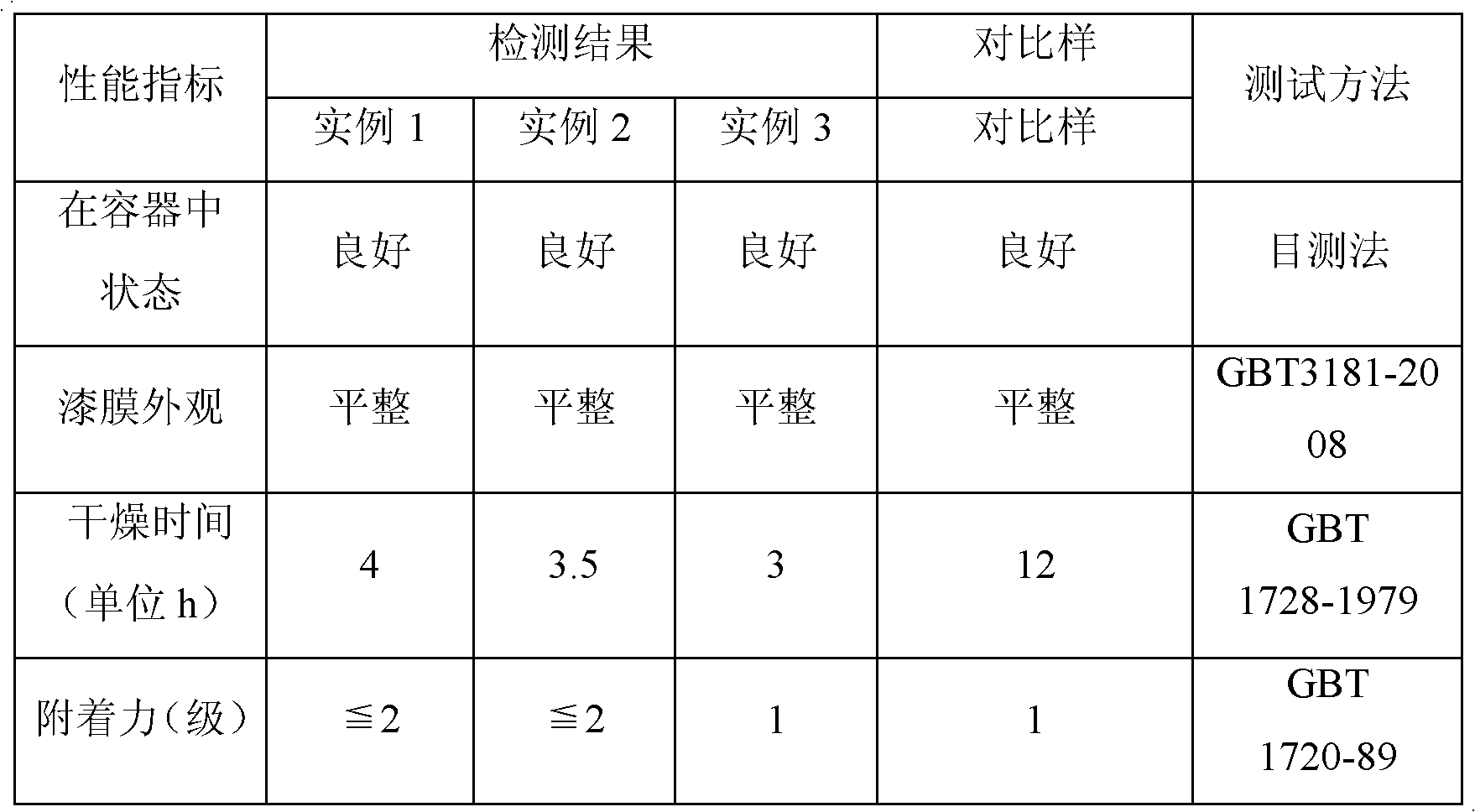

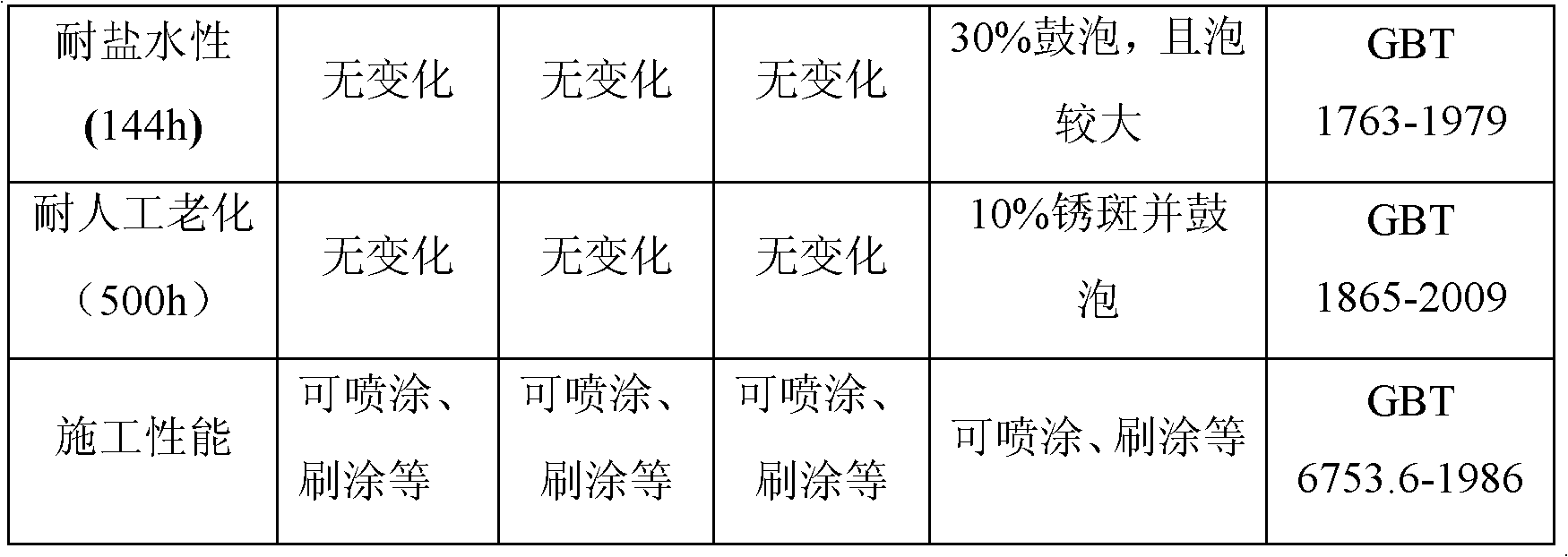

Examples

Embodiment 1

[0046] The organosilicon polyurethane composite modified alkyd resin coating composition that this embodiment provides:

[0047]Curing agent component, namely A component: 12 parts of isocyanate, 30 parts of polysiloxane (hydroxyl value 6), 2.0 parts of catalyst, 56 parts of solvent, by weight fraction;

[0048] Hydroxyl component, that is, component B: 28 parts of alkyd resin, 27 parts of solvent, 18 parts of pigment and filler, 11 parts of wetting and dispersing agent, 7 parts of leveling agent, and 9 parts of anti-skinning agent, calculated by weight fraction;

[0049] A component: B component=1: 6, by weight fraction;

[0050] The steps for preparing the A component are:

[0051] Step 1: Weighing according to weight fraction, isocyanate 12, polysiloxane 30, catalyst 2.0, solvent 56, the total weight fraction of each component is 100;

[0052] Step 2: Add 30 parts of polysiloxane in step 1 into the reaction kettle, heat up to 110-120°C and dehydrate for 1-3 hours under a ...

Embodiment 2

[0064] The organosilicon polyurethane composite modified alkyd resin coating composition that this embodiment provides:

[0065] Curing agent component, namely A component: 20 parts of isocyanate, 33 parts of polysiloxane (hydroxyl value 8), 2.0 parts of catalyst, 45 parts of solvent, by weight fraction;

[0066] Hydroxyl component, that is, component B: 31 parts of alkyd resin, 21.5 parts of solvent, 20 parts of pigment and filler, 9.5 parts of wetting and dispersing agent, 9 parts of leveling agent, 9 parts of anti-skinning agent, calculated by weight fraction;

[0067] A component: B component=1: 6, by weight fraction;

[0068] Preparation process of component A:

[0069] Identical to the preparation process of A component among the embodiment 1;

[0070] The preparation process of component B:

[0071] Identical to the preparation process of B component among the embodiment 1;

[0072] Component A and component B are uniformly mixed according to the weight ratio of 1:6...

Embodiment 3

[0074] The organosilicon polyurethane composite modified alkyd resin coating composition that this embodiment provides:

[0075] Curing agent component, i.e. component A: 16 parts of isocyanate, 40 parts of polysiloxane (hydroxyl value 6), 2.0 parts of catalyst, 42 parts of solvent, by weight fraction;

[0076] Hydroxyl component, that is, component B: 35 parts of alkyd resin, 26 parts of solvent, 15 parts of pigment and filler, 8 parts of wetting and dispersing agent, 7 parts of leveling agent, 9 parts of anti-skinning agent, calculated by weight fraction;

[0077] A component: B component=1: 6, by weight fraction;

[0078] Preparation process of component A:

[0079] With the preparation technology of A component among the embodiment 1;

[0080] The preparation process of component B:

[0081] With the preparation technology of B component among the embodiment 1;

[0082] Component A and component B are uniformly mixed according to the weight ratio of 1:6 to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com