Environment-friendly aqueous putty

A kind of atomic ash and water-based technology, applied in the direction of filling slurry, etc., can solve the problems that the air-drying performance is greatly affected by the construction environment temperature, it is difficult to meet the domestic market demand, and the matching of the primer is not good, so as to achieve good matching, Superior construction performance, fine touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

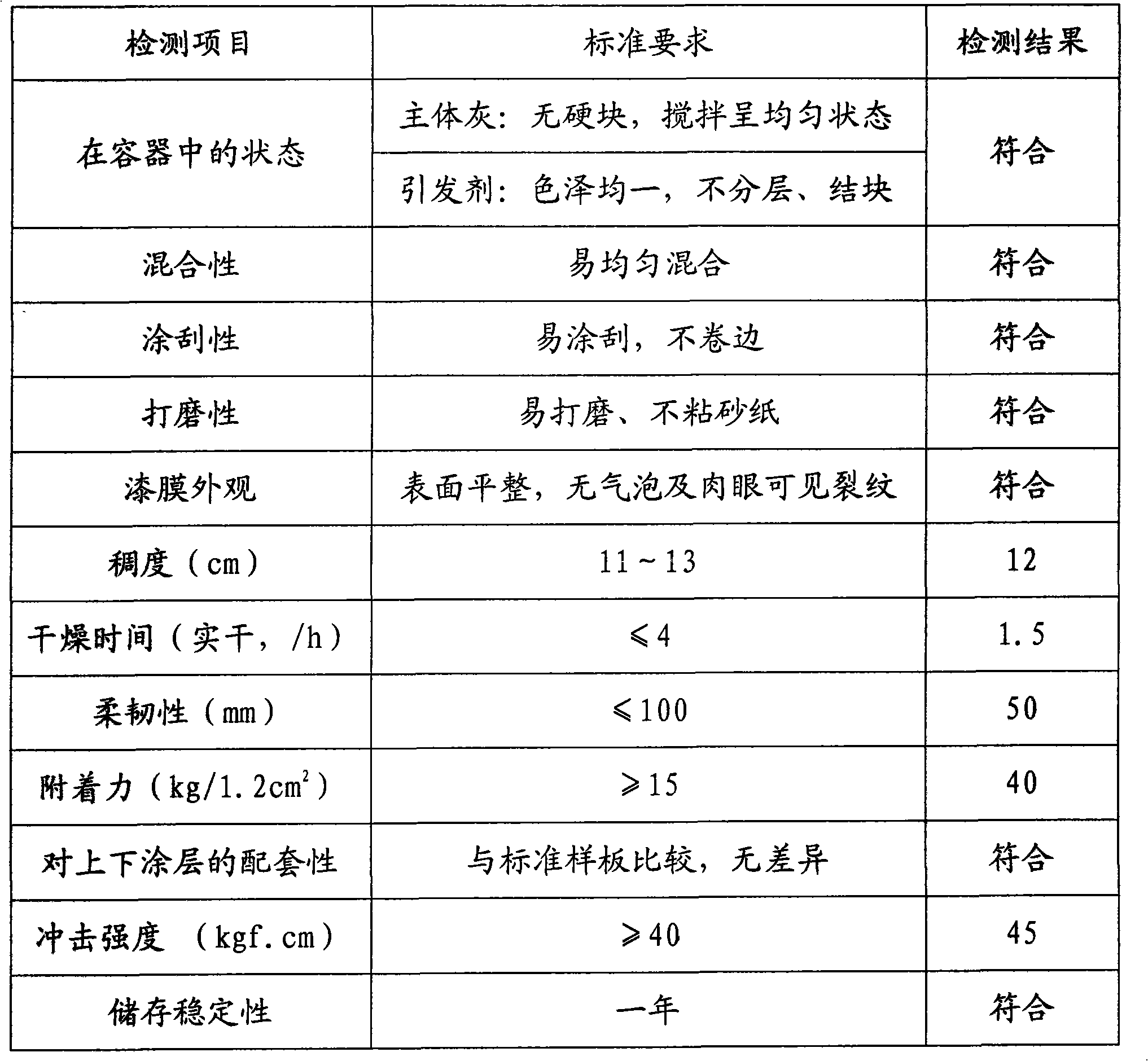

Image

Examples

Embodiment approach 1

[0038] Main body ash: put 40 parts of air-drying water-based unsaturated polyester resin into the reaction kettle according to the weight ratio, and put in 2 parts of deionized water and acrylonitrile-acrylate-styrene copolymer respectively under stirring at a speed of 400 rpm 0.2 parts, 0.3 parts of dimethylaniline, 1 part of BYK-966, 0.002 parts of methyl ethyl ketone oxime, 0.002 parts of polytetrafluoroethylene wax, 0.02 parts of BYK-4500, 0.02 parts of methyl paraben and stir for 10 minutes; put into the structure reinforcement 30 parts of agent (by weight: hollow ceramic microspheres: silicon dioxide: expanded micropowder = 10:3:8 homogeneous mixture), stirred for 8 minutes; finally dropped into 26.456 parts of talcum powder, and stirred at 800 rev / min of rotating speed 10 minutes, at 1500 rev / min, stir for 15 minutes, and grind with a colloid mill to make the finished main body ash.

[0039] Initiator: 50 parts of benzoyl peroxide, 43 parts of dibutyl phthalate, 7 parts...

Embodiment approach 2

[0042] Main body ash: put 41 parts of air-drying water-based unsaturated polyester resin into the reaction kettle according to the weight ratio, and put in 3 parts of deionized water and acrylonitrile-acrylate-styrene copolymer respectively under stirring at a speed of 400 rpm 0.5 parts, 0.5 parts of triethylenetetramine, 1.5 parts of BYK-980, 0.004 parts of dimethylglyoxime, 0.003 parts of polyethylene wax, 0.05 parts of Silok-628, 0.05 parts of ethylparaben, stir for 10 minutes; put into the structure 25 parts of reinforcing agent (by weight: hollow ceramic microspheres: silicon dioxide: expanded micropowder = 5: 3: 10 homogeneous mixture), stirred for 8 minutes; finally dropped into 15 parts of barium sulfate, 13.393 parts of talcum powder, Stir for 10 minutes at 800 rpm, and 15 minutes at 1500 rpm, and grind with a colloid mill to make the finished main ash.

[0043] Initiator: 45 parts of benzoyl peroxide, 50 parts of dibutyl phthalate, 5 parts of silicon dioxide, stir an...

Embodiment approach 3

[0046]Main body ash: put 38 parts of air-drying water-based unsaturated polyester resin into the reaction kettle according to the weight ratio, and put in 4 parts of deionized water, 0.8 parts of polymethyl methacrylate, and two parts respectively under stirring at a speed of 400 rpm 0.6 parts of methylaniline, 3 parts of BYK-920, 0.005 parts of methyl ethyl ketone oxime, 0.005 parts of polyamide wax, 0.1 parts of BYK-4500, 0.1 parts of methylparaben, stirred for 10 minutes; For: hollow ceramic microspheres: silicon dioxide: expanded micropowder = 8:3:7 homogeneous mixture) 28 parts, stirred for 8 minutes; finally put in 5 parts of filler titanium dioxide, 6 parts of barium sulfate, 14.39 parts of talcum powder, at a speed of 800 Stir for 10 minutes at 1500 rpm, 15 minutes at 1500 rpm, and grind with a colloid mill to make the main ash.

[0047] Initiator: 48 parts of benzoyl peroxide, 49 parts of dibutyl phthalate, 3 parts of silicon dioxide, stir and grind into a uniform pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com