Aqueous dispersed alkyd blend colored paint and preparation method thereof

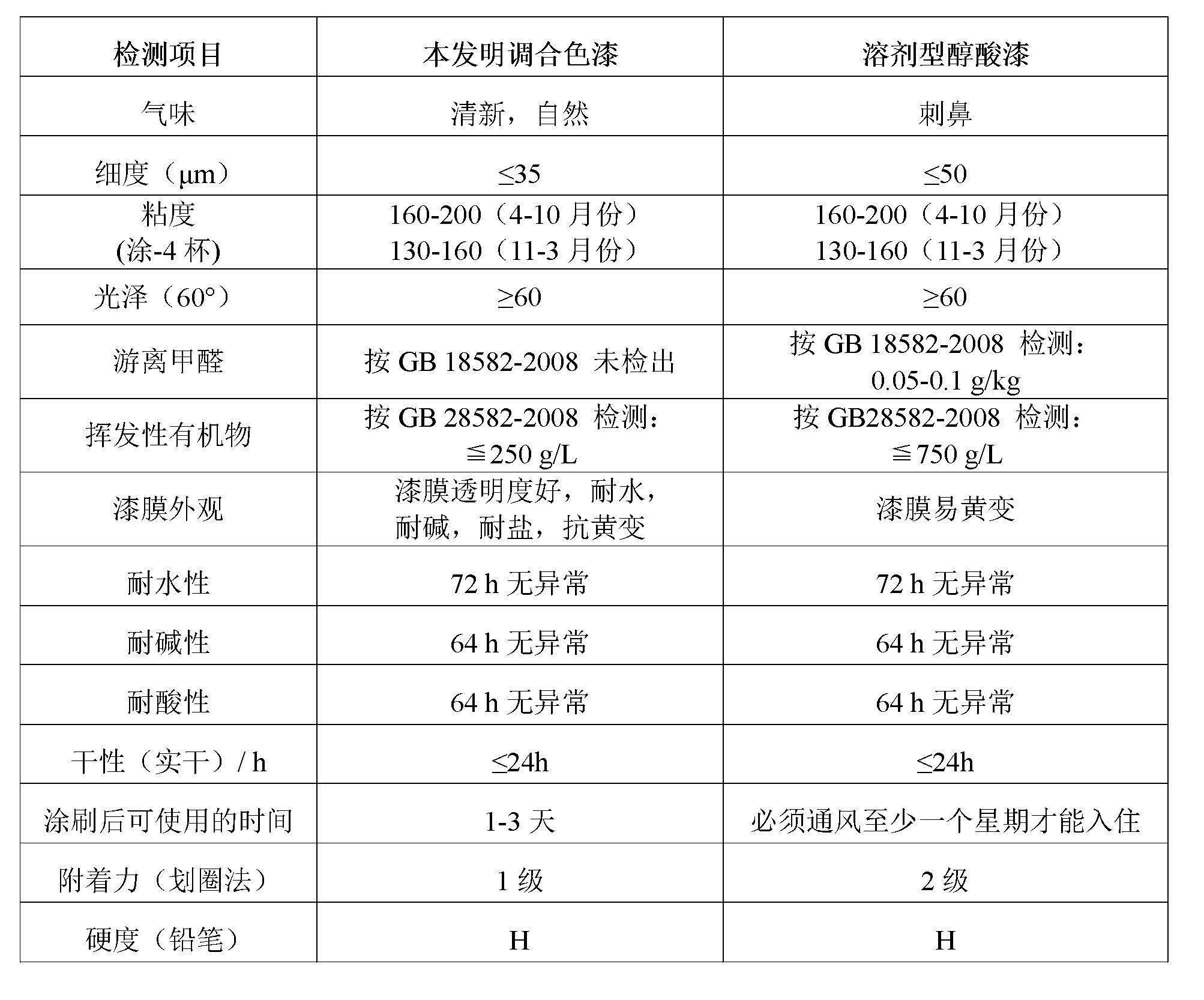

A dispersing and blending technology, used in the field of coatings, can solve the problems of slow drying and poor hardness of film formation, and achieve the effects of low volatile organic content, low odor and fast drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First add 42kg of medium-oil alkyd resin (Jiangsu Champion Paint Industry Co., Ltd.) and 4 kg of mixed trimethylbenzene, start stirring (300 rpm), then add 6 kg of iron oxide yellow, 3.3 kg of medium chrome yellow, and 0.8 kg of rutile titanium dioxide , 5 kg superfine calcium carbonate, 5.5 kg precipitated barium sulfate, 0.35 kg BYK104S wetting agent, 0.5kg BYK141 defoamer, 0.6 kg 160 organobentonite and stir at an accelerated rate (900 rpm) for 15 minutes until evenly stirred (no powder on the edge of the pot) The material is attached, and there is no agglomeration in the pot);

[0038] Inhale the resulting mixture into a sand mill for sand grinding until the fineness is less than 35 microns;

[0039] Then start stirring (300 rpm) and add 5 kg C9 petroleum resin, 22 kg water-based additive (the water-based additive is the additive disclosed in Example 1 of the invention patent with the publication number CN 101230217A, Jiangsu Champion Paint Industry Co., Ltd.), 0.86...

Embodiment 2

[0042]First add 44kg of medium-oil alkyd resin (Jiangsu Champion Paint Industry Co., Ltd.) and 4 kg of 200# gasoline, start stirring (300 rpm), then add 0.64kg of phthalocyanine blue, 0.26kg of easily dispersible iron blue, and 3.5 kg of rutile Titanium dioxide, 6 kg ultra-fine calcium carbonate, 6.5 kg precipitated barium sulfate, 0.35 kg BYK104S wetting agent, 0.5 kg BYK052 defoamer, 0.6 kg 160 organic bentonite, accelerated stirring (900 rpm) for 15 min, until evenly stirred (pot edge No powder adhesion, no agglomeration in the pot);

[0043] Inhale the resulting mixture into a sand mill for sand grinding until the fineness is less than 35 microns;

[0044] Then start stirring (300 rpm) and add 5 kg C9 petroleum resin, 22.94 kg water-based additive (the water-based additive is the additive disclosed in Example 1 of the invention patent with the publication number CN 101230217A, Jiangsu Champion Paint Industry Co., Ltd.), 0.86 kgV-668 drier (Haimen Haifeng Chemical Auxiliar...

Embodiment 3

[0047] First add 46 kg of medium-oil alkyd resin (Jiangsu Champion Paint Industry Co., Ltd.) and 4kg of aromatic solvent oil S-1000#, start stirring (300 rpm), then add 4.74 kg of medium-pigment carbon black N234, 5.5 kg of ultra-fine carbonic acid Calcium, 6 kg of precipitated barium sulfate, 0.35 kg of BYK104S wetting agent, 0.5 kg of BYK052 defoamer, 0.6 kg of 160 organic bentonite, accelerated stirring (900 rpm) for 15 min, until evenly stirred (no powder adhered to the edge of the pot, no into agglomerates);

[0048] Inhale the resulting mixture into a sand mill for sand grinding until the fineness is less than 35 microns;

[0049] Then start stirring (300 rpm) and add 5 kg of C9 petroleum resin liquid, 22 kg of water-based additives (the water-based additives are the additives disclosed in Example 1 of the invention patent with the publication number CN 101230217A, Jiangsu Champion Paint Industry Co., Ltd.), 0.94 kg V-668 drier (Haifeng Chemical Auxiliary Co., Ltd., Hai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com