Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

A water-based lubricating fluid, sliding bearing technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of low service life, increased manufacturing difficulty, difficult to repair, etc., to achieve low cost and equipment fire hazards. The effect of low sex and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

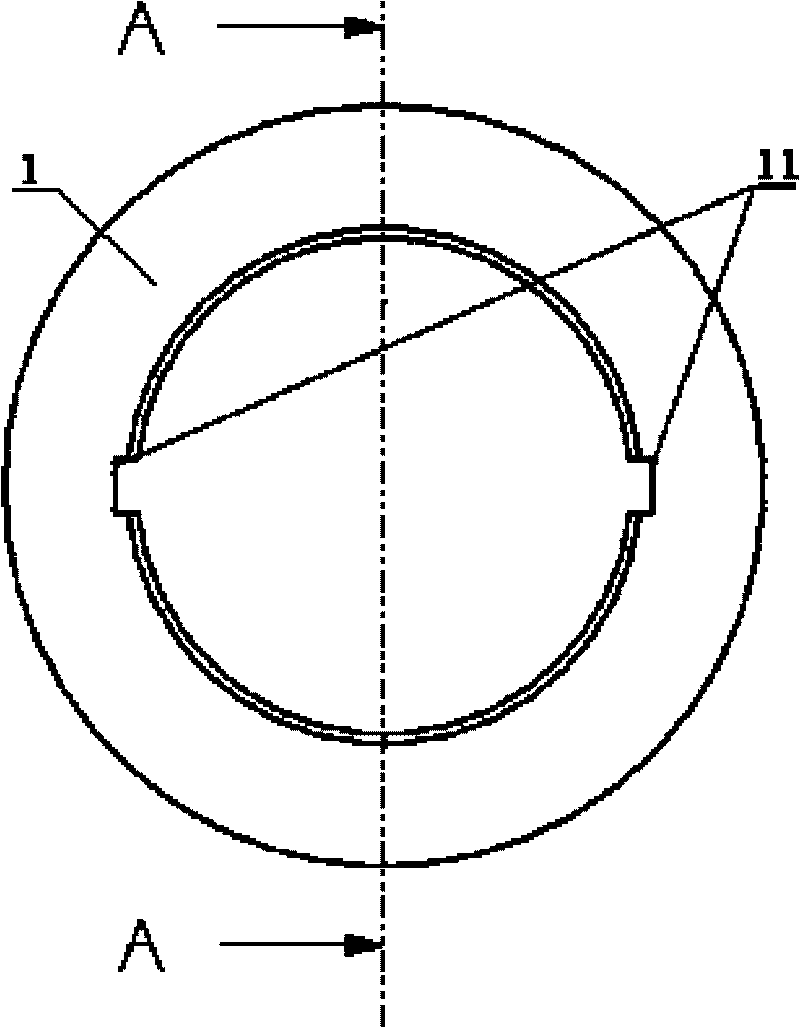

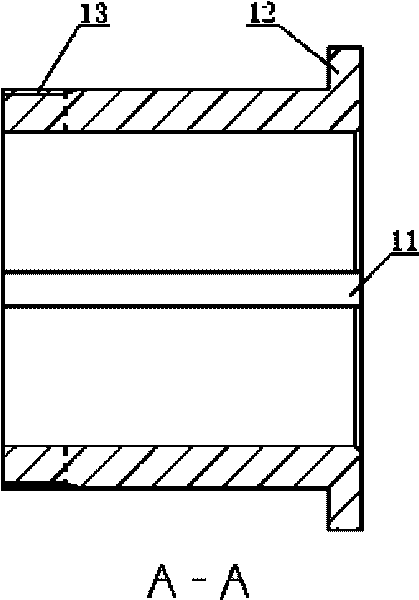

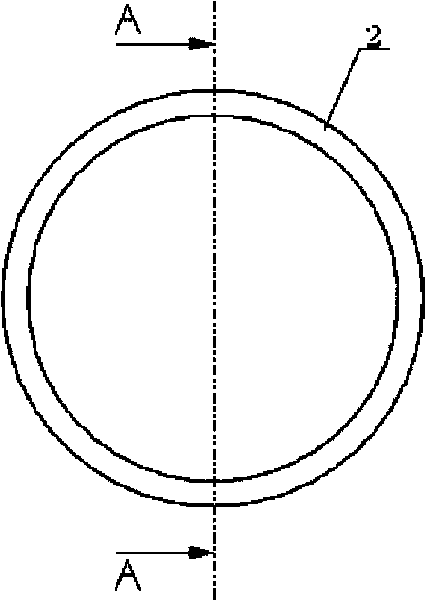

[0060] The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating fluid. It consists of a static ceramic bearing bush 3 and a bearing bush bush 4 fixed in a base, and a ceramic bushing installed on the shaft and rotating with the shaft. 2 and bearing bushing 1, bearing end cover 5 of special structure. During work, the lubricant enters the gap between the ceramic bushing 3 and the ceramic bushing 2, and the gap between the ceramic bushing 3 and the inner ceramic ring 52 of the bearing end cover 5 to form a bearing liquid film, so that the rotating shaft can work normally, and the liquid flows from the bearing bushing 4 and the ceramic ring 52. The bearing end cover 5 is lined with ceramic ring 52 in the gap on the matching surface, and the other end of the ceramic bearing bush 3 without the structure of the liquid-through groove 35 and the gap between the ceramic bushing 2 and the other end naturally leak out.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com