Plastic assembled engine model

A plastic assembly and engine technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of lack of complete structure, hidden safety hazards, etc., and achieve the effect of improving mechanical knowledge, no oil rust, safe operation and no danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

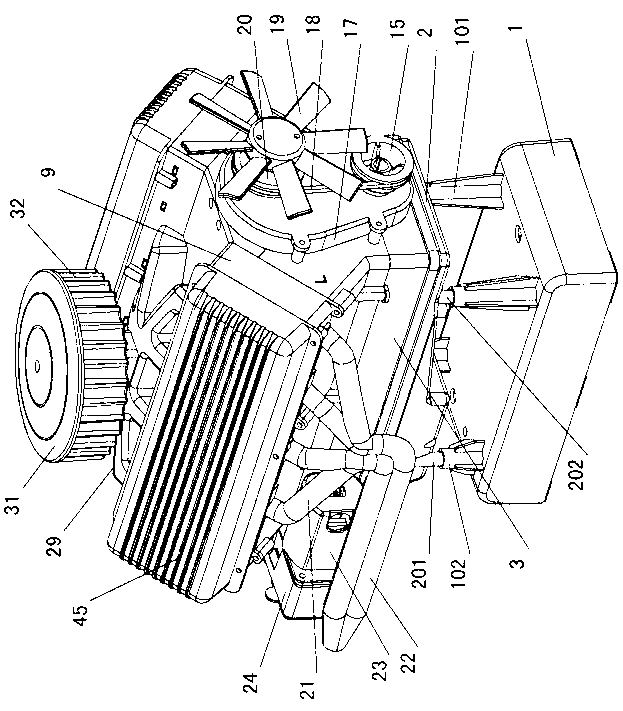

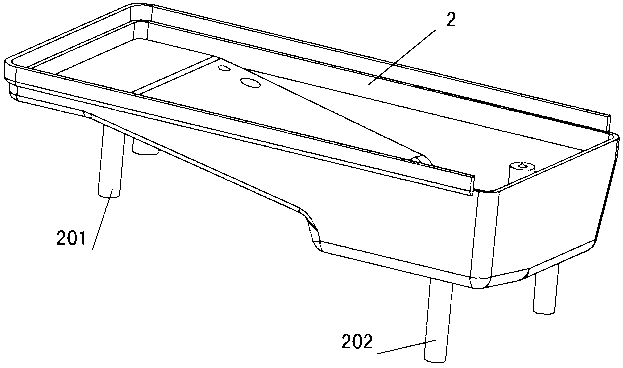

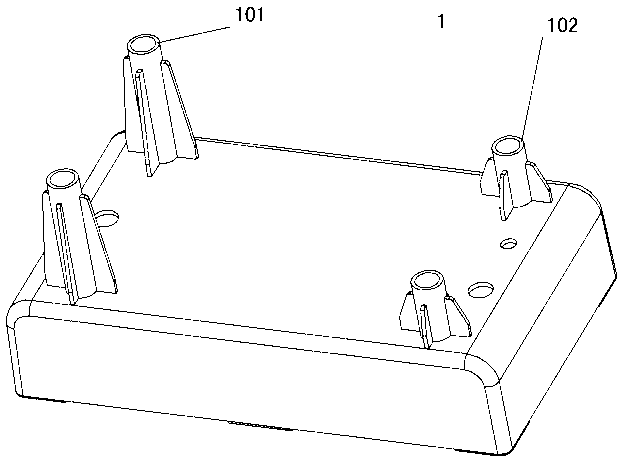

[0045] The present invention relates to a plastic assembled engine model, such as figure 1 — Figure 38 As shown, it is characterized in that: it includes an engine frame 1, on which a long connecting sleeve 101 and a short connecting sleeve 102 are formed, an oil tank panel 2 is installed on the engine frame, and a short insert 202 and a long insert are formed under the oil tank panel 2 Post 201, short and long inserting posts are connected with long and short connecting sleeves, low crankcase 3 is set on the oil tank panel 2, and bearing seat 301 is formed in the low crankcase 3, crankshaft 4 is installed in the bearing seat, machine shaft The large head 501 of the connecting rod 5 and the connecting rod head 6 are installed on the shaft 4. The small head 502 of the connecting rod is connected to the piston 8 through the piston pin 7. The piston 8 is composed of two semicircular bodies. Cylinder cavity 901 matches, cylinder seat 9 is V-shaped, cylinder top plate 10 and cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com