Preparation method of waterborne alkyd enamel

A water-based alkyd and water-based alkyd resin technology, used in the field of paint, can solve problems such as environmental and human body damage, and achieve the effects of excellent salt water resistance, excellent weather resistance and high gloss

Inactive Publication Date: 2015-04-08

成都拜迪新材料有限公司

View PDF2 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With people's increasing awareness of environmental protection, the requirements for environmental protection of coating products are also getting stronger and strong

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

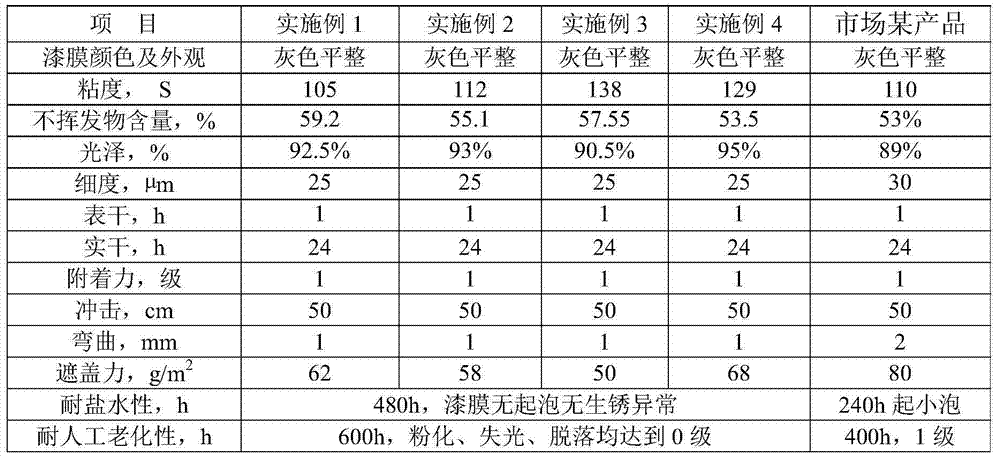

The invention discloses a preparation method of waterborne alkyd enamel. The preparation method comprises the following components in percentage by mass: 45%-55% of waterborne alkyd resin, 10%-15% of rutile type titanium dioxide, 0.3%-1% of carbon black, 10%-15% of precipitated barium sulphate, 0.2%-0.5% of a waterborne dispersing agent, 0.1%-0.2% of a waterborne antifoaming agent, 0.1%-0.2% of a waterborne foam inhibitor, 1%-2% of hydrated magnesium silicate, 0.8%-1.2% of waterborne drier, 0.2%-0.4% of a waterborne anti-skinning agent, 0.5%-1% of a water-based thickener, 2%-4% of a neutralizer, 2%-4% of a hydrotropy agent, 2%-4% of a coalescing agent, 0.1%-0.2% of a waterborne flatting agent and 8%-9.6% of deionized water. The method comprises the following technological steps: stirring the waterborne alkyd resin evenly, and testing and adjusting the pH value; diluting the foam inhibitor with the deionized water, then adding to a production cylinder, stirring, and adding the rutile type titanium dioxide and the like, dispersing and then grinding; adding a compound drier and the like, and stirring; adjusting the viscosity with the deionized water; and adjusting the pH value of the product with the neutralizer. The waterborne alkyd enamel has the advantages of being high in drying rate, high in glossiness, excellent in weather fastness, excellent in salt water resistance, and free of a blistering or rusting phenomenon after being soaked in a 3% sodium chloride solution for 480 hours.

Description

technical field [0001] The invention relates to the field of lacquer making, in particular to a preparation method of water-based alkyd enamel. Background technique [0002] With people's increasing awareness of environmental protection, the requirements for environmental protection of coating products are also getting stronger and stronger. Now 80% of steel structure manufacturers in the market still use traditional oily alkyd enamel, which causes harm to the environment and human body. caused great damage. The invention provides a pure water-based alkyd enamel, which completely meets the standard of the oil-based alkyd enamel in terms of drying speed, gloss and weather resistance. Suitable for steel surface protection products such as steel structures, bridges, guardrails, vehicles, pipelines, doors and windows. Contents of the invention [0003] The invention proposes a method for preparing water-based alkyd enamel. The prepared product has the characteristics of fast...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D167/08C09D7/12C09D5/23C09D5/08

CPCC09D167/08C08K3/04C08K3/22C08K3/30C08K3/34C08K5/06C08K13/02C08K2003/2241C08K2003/3045C09D5/08C09D7/61C09D7/63H01F41/16

Inventor 任明华江拥孙迎春

Owner 成都拜迪新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com