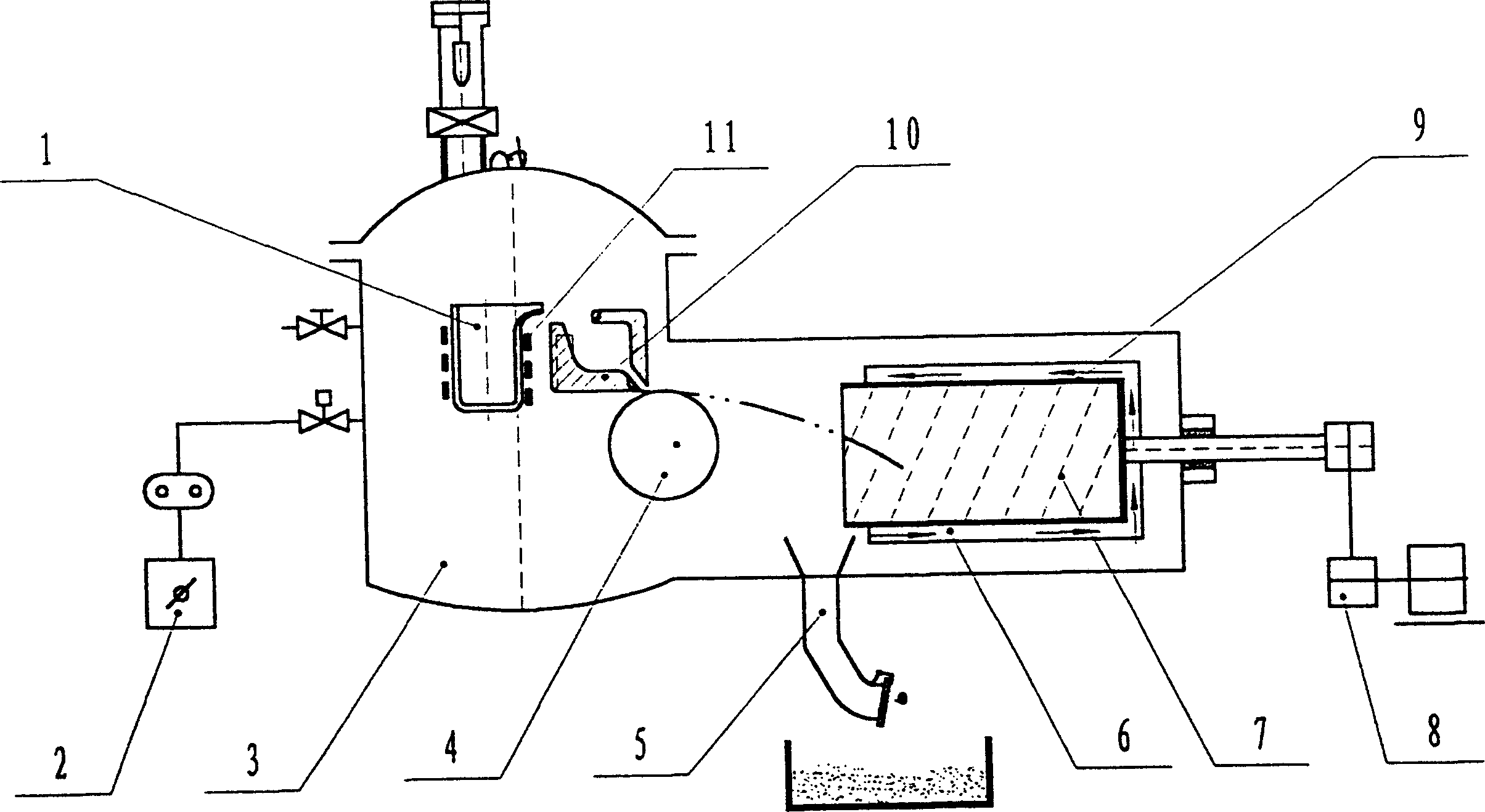

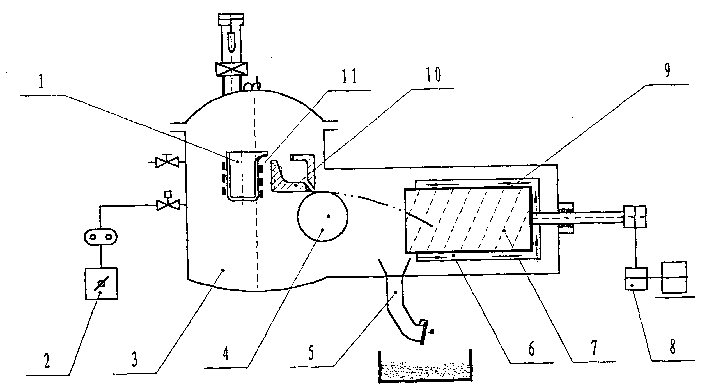

Vacuum smelting quick condensation furnace

A vacuum melting and rapid-setting technology, applied in furnaces, crucible furnaces, furnace types, etc., which can solve the problems of slow cooling rate, flake bonding, large grain size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] As can be seen in Figure 1, after the alloy material is added to the crucible 1, the vacuum furnace shell 3 is closed, the vacuum system 2 is started, and the entire furnace body is in a vacuum state or under a protective atmosphere. The heater coil 11 starts to generate heat. Under the medium frequency induction, the alloy material in the crucible 1 is heated and melted. By adjusting the angle of the crucible 1, the smelted alloy melt flows to the tundish 10 and lands on the rotor set under the side of the tundish. On the wheel 4, there is a circulating cooling medium in the runner 4, so that the alloy melt is rapidly cooled to form alloy flakes, and the flake alloy flakes are thrown into the drum 9 under the action of the centrifugal force generated by the rotating runner 4, and the drum 9 The outer wall is covered with a cooling device 6 and the inner wall is fixed with a spiral piece 7 for stirring, which can make the alloy flakes in the drum 9 turn continuously, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com