Preparation method of samarium-cobalt (SmCo) system sintered materials

A sintered material, samarium cobalt technology, applied in the direction of magnetic materials, inductors/transformers/magnet manufacturing, magnetic objects, etc., can solve the problems of sintered magnet performance degradation, high thermal deformation, multi-energy loss, etc., to optimize the microstructure, ensure Magnetic properties, the effect of low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

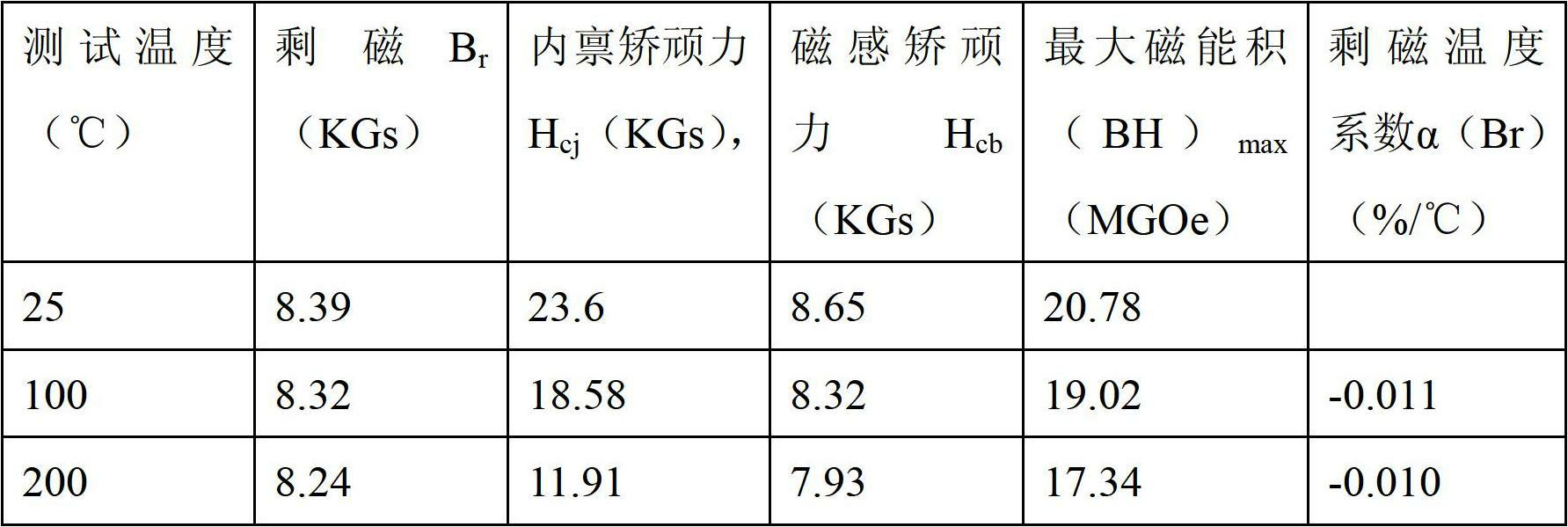

Embodiment 1

[0028] Raw materials were weighed according to the following weight fractions: samarium: 16.9%; cobalt: 49%; iron: 15.5%; copper: 6.3%; zirconium: 2.6%; dysprosium: 1.6%; gadolinium: 5.42%;

[0029] 1) Alloy smelting: mix Sm, Co with a purity greater than 99.9% and alloying elements according to the ratio, place the water-cooled copper crucible in the electric arc furnace, and evacuate to 10 -3 Pa or above, then pass high-purity argon gas at 0.1 atmospheric pressure, working voltage 30V, working current 630A, and repeatedly smelt 4 times under the protection of argon gas to obtain an alloy liquid with uniform composition;

[0030] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper plate or molybdenum plate at a speed of 0.6m / s to prepare an alloy cast strip;

[0031] 3) Magnetic powder preparation: carry out the hydrogenation and disproportionation reaction of the alloy casting strip, th...

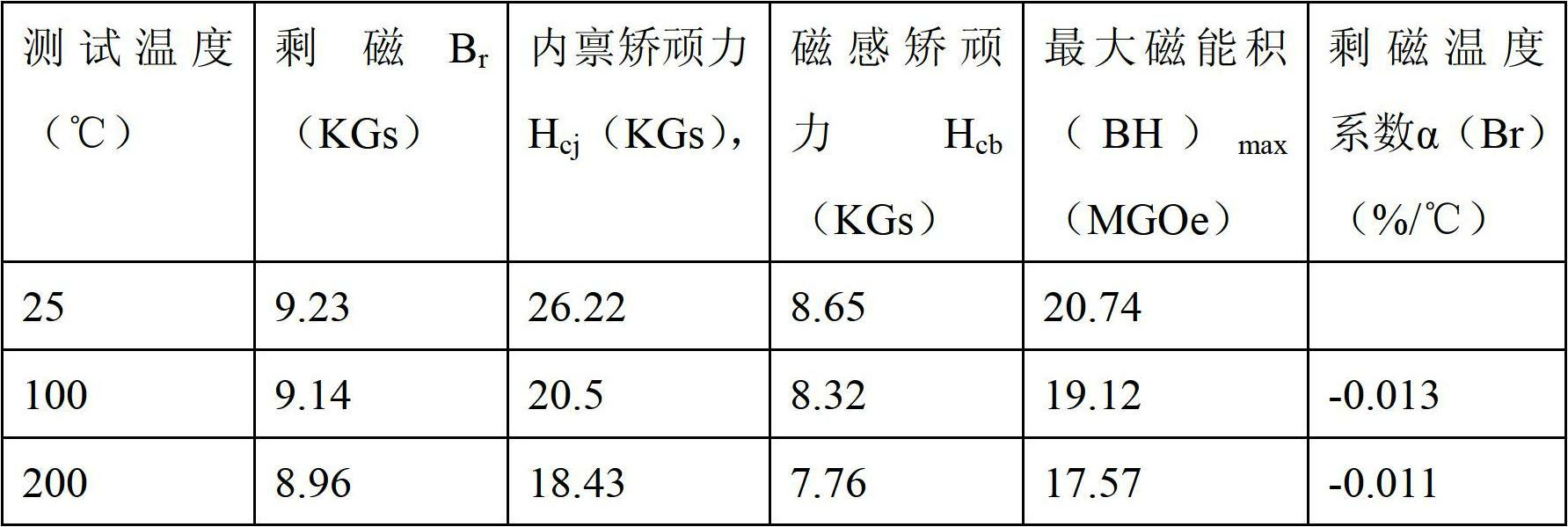

Embodiment 2

[0039] Raw materials were weighed according to the following weight fractions: samarium: 20.78%; cobalt: 51.81%; iron: 13.93%; copper: 6.34%; zirconium: 1.71%; dysprosium: 5.43%.

[0040] 1) Alloy smelting: mix Sm, Co with a purity greater than 99.9% and alloying elements according to the ratio, place the water-cooled copper crucible in the electric arc furnace, and evacuate to 10 -3 Pa, then introduce high-purity argon gas at 1.2 atmospheric pressure, working voltage 45V, working current 750A, and repeatedly smelt 4 times under the protection of argon gas to obtain an alloy liquid with uniform composition;

[0041] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper plate or molybdenum plate at a speed of 0.6m / s to prepare an alloy cast strip;

[0042] 3) Magnetic powder preparation: carry out the hydrogenation and disproportionation reaction of the alloy cast strip, the hydrogenation di...

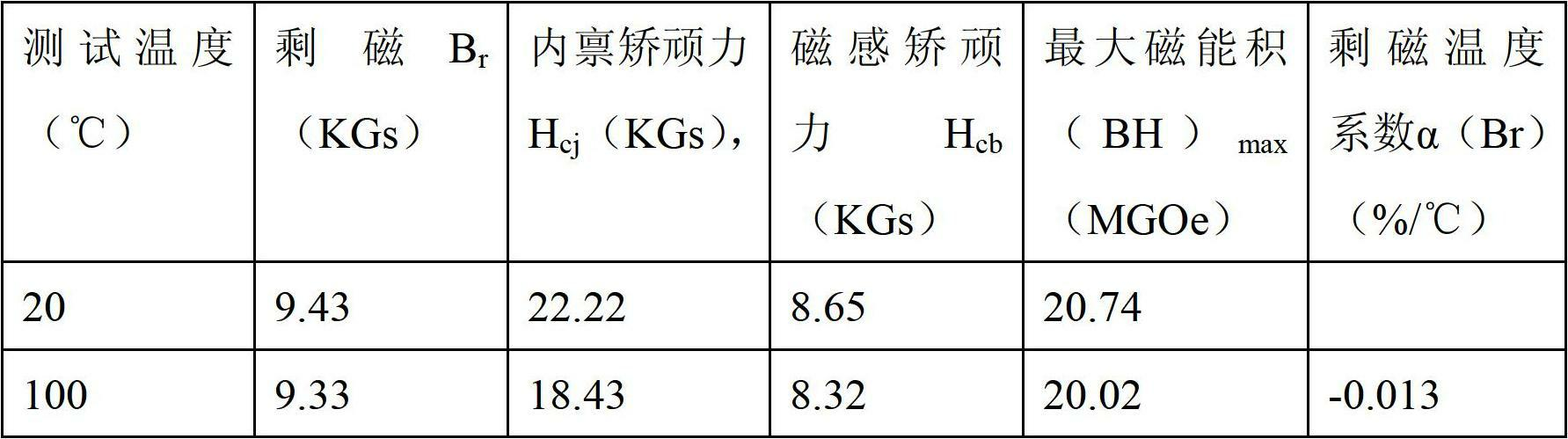

Embodiment 3

[0050] Raw materials were weighed according to the following weight fractions: samarium: 16.9%; cobalt: 49%; iron: 15.5%; copper: 6.3%; zirconium: 2.6%; dysprosium: 1.6%; gadolinium: 5.8%;

[0051] 1) Alloy smelting: mix Sm, Co with a purity greater than 99.9% and alloying elements according to the ratio, place the water-cooled copper crucible in the electric arc furnace, and evacuate to 10 -3 Pa, then pass high-purity argon gas at 1.0 atmospheric pressure, working voltage 35V, working current 700A, and repeatedly smelt 3 times under the protection of argon gas to obtain an alloy liquid with uniform composition;

[0052] 2) Rapid quenching: casting the uniformly smelted alloy liquid onto a rotating water-cooled copper roll, water-cooled molybdenum roll, copper disc or molybdenum disc at a speed of 0.4m / s to prepare an alloy cast strip;

[0053] 3) Magnetic powder preparation: carry out the hydrogenation and disproportionation reaction of the alloy casting strip, the hydrogenat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com