High-temperature resistant quartz flexure accelerometer

An accelerometer and high temperature resistant technology, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring devices, etc., can solve the problems of poor output signal stability, large temperature coefficient of products, and failure to meet the requirements of use, so as to improve stability , good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 high temperature resistant quartz flexible accelerometer

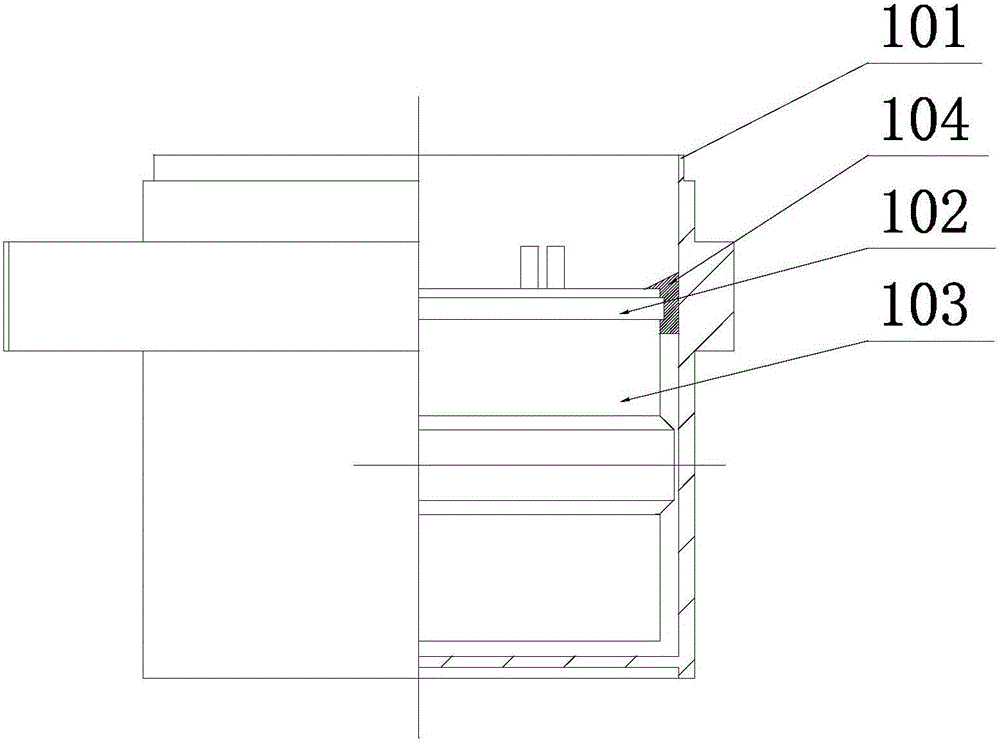

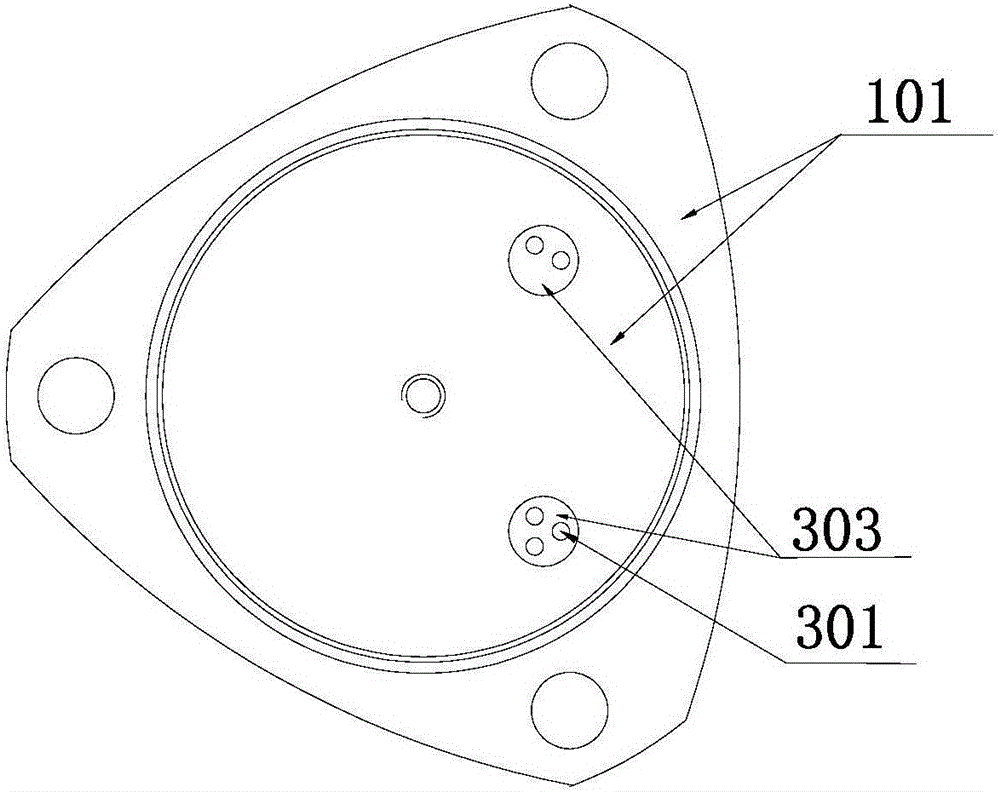

[0029] See attached figure 1 , the high temperature resistant quartz flexible accelerometer of the present invention comprises meter head 1 and servo circuit 2, meter head 1 and servo circuit 2 form electric connection by wire welding, the shell of servo circuit 2 and the shell 101 of meter head 1 pass laser welding machine Welded together to form a complete machine. The servo circuit 2 is a hybrid integrated circuit.

[0030] The watch head 1 includes a watch core 103, a housing 101 and an isolation ring 102. The watch core 103 is bonded with an isolation ring 102 with a 180°C high temperature resistant adhesive 104, and the isolation ring 102 is fixed to the housing 101 by bonding the 180°C high temperature resistant adhesive 104. Inside.

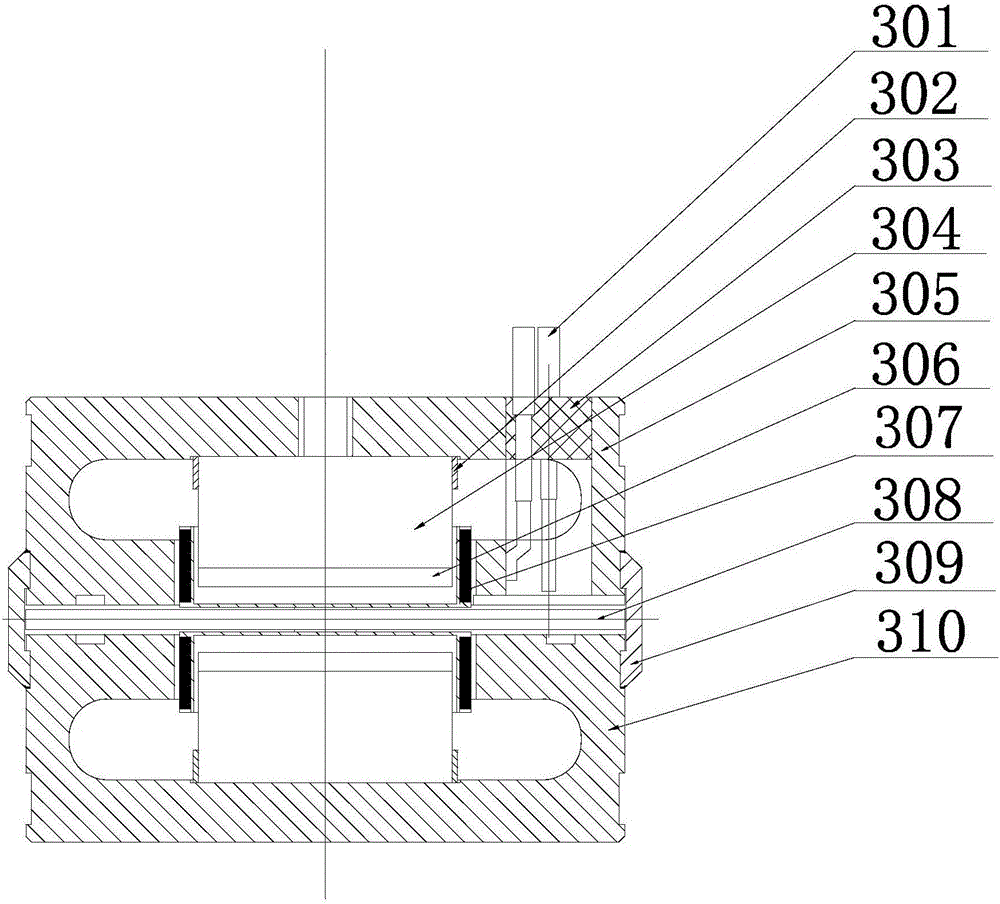

[0031] The watch movement 103 includes a quartz pendulum assembly, an upper torquer and a lower torquer, the quartz pendulum assembly is placed between the ...

Embodiment 2

[0037] Example 2 Detection of High Temperature Resistance of High Temperature Resistant Quartz Flexible Accelerometer

[0038] The test samples are the high temperature resistant quartz flexible accelerometer of embodiment 1 and the original product.

[0039] The two products in Table 1 are the test data of the original high temperature accelerometer of our company.

[0040] The two products in Table 2 are 4308-006 and 4308-007 in Table 1. Dissect and disassemble the meter head part, and replace the magnetic steel used in the upper and lower torque devices with the changed composition. The rest of the production process and testing methods have not changed. Among them, the original 4308-006 corresponds to the new product number 4312-0006, and the original 4308-007 corresponds to the new product number 4312-0007.

[0041] Detection method:

[0042] Refer to the test method and test data calculation method in 6.3.4 "Four-point overturn test" in the "GJB 1037A Single-axis pendu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com