A kind of sponge material and its preparation method and application

A sponge and cross-linking reaction technology, applied in bandages, medical science, etc., can solve the problems of difficulty in maintaining the cross-linking reaction of polyvinyl alcohol and chitosan, difficulty in reflecting the treatment effect of the affected area, and hindering the smooth progress of the foaming process, etc., to achieve Excellent therapeutic effect, high water absorption, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

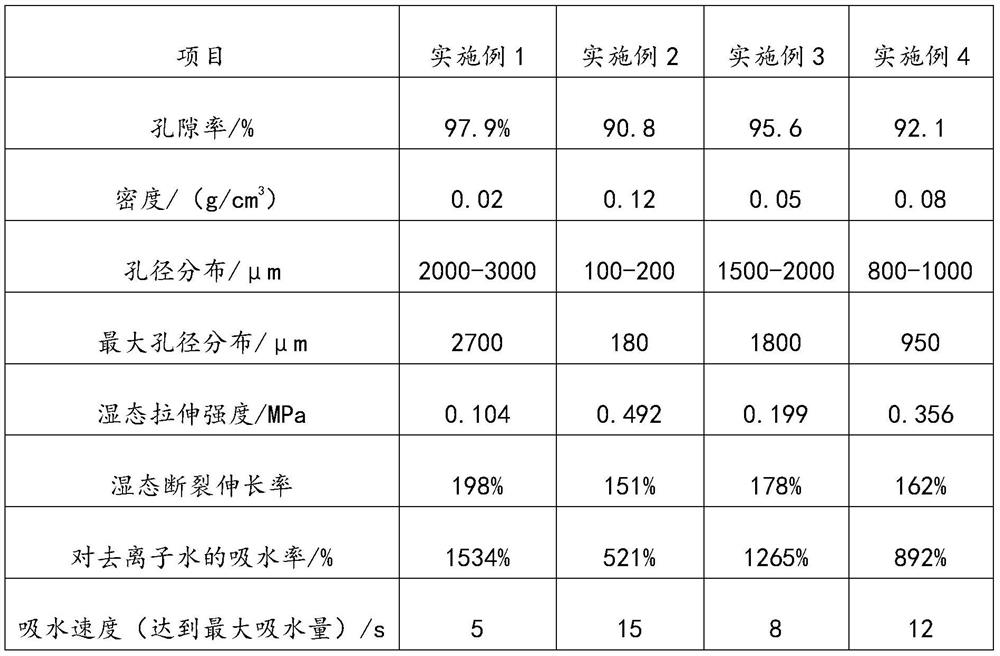

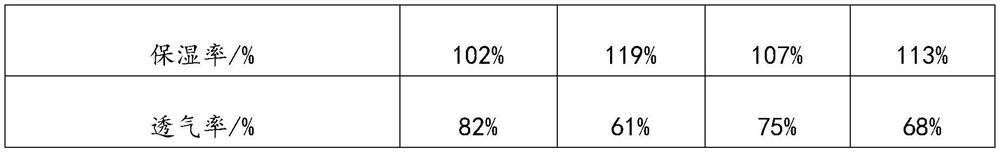

Examples

preparation example Construction

[0047] The specific embodiment of the present invention provides a kind of preparation method of sponge material, comprising:

[0048] Add catalyst and cross-linking agent into the polyvinyl alcohol solution, stir for cross-linking reaction and foaming, add chitosan solid, continue stirring for cross-linking reaction and foaming, and solidify to obtain a sponge material.

[0049] Both polyvinyl alcohol and chitosan contain hydroxyl groups in their molecular chains, and both have the ability to undergo condensation reactions with crosslinking agents. When solid powdered chitosan is added to the polyvinyl alcohol foaming system, it also dissolves on the surface of its particles, and the local microscopic dissolution and crosslinking agent undergo a homogeneous crosslinking reaction, so that the polyvinyl alcohol and chitosan macroscopically Mixed foaming is possible.

[0050] Chitosan powder is added during the foaming process of polyvinyl alcohol. When the foaming is completed...

Embodiment 1

[0097] A preparation method of a sponge material, comprising:

[0098] a. Polyvinyl alcohol (polymerization degree is 400; alcoholysis degree is 88%) is dissolved in water at 70° C. and a stirring speed of 200 rpm, and a polyvinyl alcohol aqueous solution having a mass concentration of 10% is prepared;

[0099] b. Add dilute H to polyvinyl alcohol solution 2 SO 4 Aqueous solution (mass fraction is 36%, H 2 SO 4 The consumption is 7% of polyvinyl alcohol solution and chitosan solid gross mass) and formaldehyde (consumption is 60% of polyvinyl alcohol solution and chitosan solid gross mass), at 65 ℃, under the stirring speed of 1000rpm, carry out Cross-linking reaction and foaming for 60 minutes;

[0100] c. add chitosan (molecular weight is 10 2 ; degree of deacetylation is 50%) solid (particle diameter is 80 orders, the mass ratio of polyvinyl alcohol and chitosan solid is 1:0.1), at 65 ℃, under the stirring speed of 1000rpm, continue to stir and carry out cross-linking r...

Embodiment 2

[0103] A preparation method of a sponge material, comprising:

[0104] a. Polyvinyl alcohol (polymerization degree is 2600; alcoholysis degree is 99%) is dissolved in water at 95° C. and a stirring speed of 50 rpm, and a polyvinyl alcohol aqueous solution having a mass concentration of 40% is prepared;

[0105] b. Add dilute H to polyvinyl alcohol solution 2 SO 4 Aqueous solution (mass fraction is 36%, H 2 SO 4 The consumption is 3% of polyvinyl alcohol solution and chitosan solid gross mass) and formaldehyde (consumption is 20% of polyvinyl alcohol solution and chitosan solid gross mass), at 20 ℃, under the stirring velocity of 200rpm, carry out Cross-linking reaction and foaming for 20 minutes;

[0106] c. add chitosan (molecular weight is 10 6 ; degree of deacetylation is 95%) solid (particle diameter is 140 orders, the mass ratio of polyvinyl alcohol and chitosan solid is 1:0.4), at 20 ℃, under the stirring speed of 200rpm, continue to stir and carry out cross-linking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com