Magnetic field orientation three-dimensional printing anisotropic bonded permanent magnet and preparation method thereof

A technology of magnetocrystalline anisotropy and anisotropy, which is used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., and can solve problems that affect the arrangement and forming of droplets, complex process, and inability to achieve anisotropic bonding. Magnet 3D printing and other problems, to achieve the effect of eliminating the magnetic interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

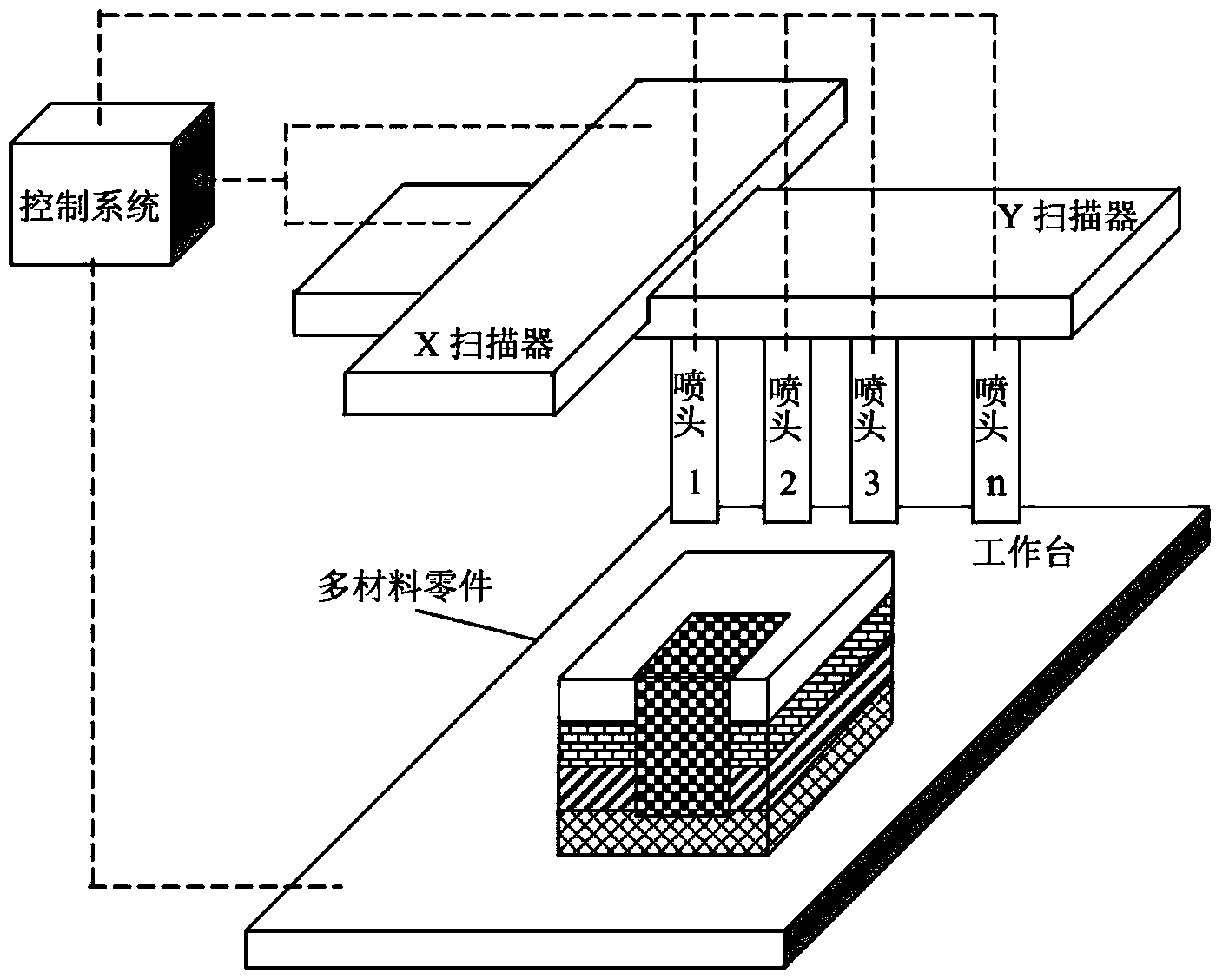

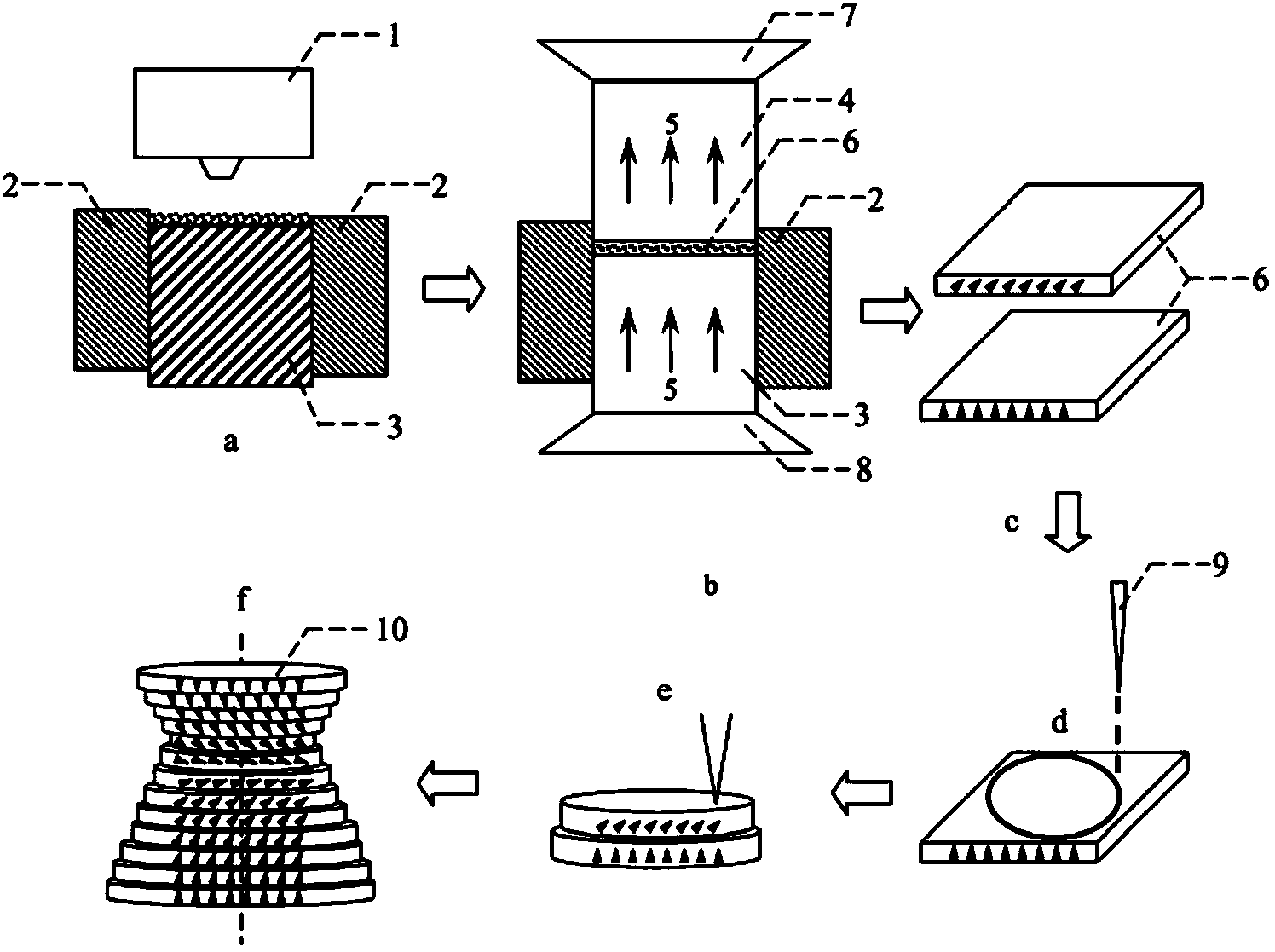

[0048] Such as figure 2 As shown, the preparation method of the magnetic field orientation three-dimensional printing anisotropic bonded magnet of the present invention comprises the following steps:

[0049] a) Powder loading: The magnet powder with magnetic crystal anisotropy is crushed by coarse crushing, jet milling or ball milling to a powder with an average particle size of 1-5um, and then mixed evenly with a binder. The binder is polyamide, One of unsaturated polyester and acrylate, mercaptan, ethylene copolymer, epoxy resin or metal tin; the volume ratio of powder to binder is 99.5:0.5~0.5:99.5; the mixed powder is supplied by The system is added to the mold to form an evenly distributed powder layer;

[0050] b) Orientation forming: the upper and lower pressing heads move the pre-pressed powder in opposite directions, and a magnetic field is applied through the upper and lower pole heads. The magnetic field strength is 0-2.2 tesla, so that the magnetic powder is ori...

Embodiment 1

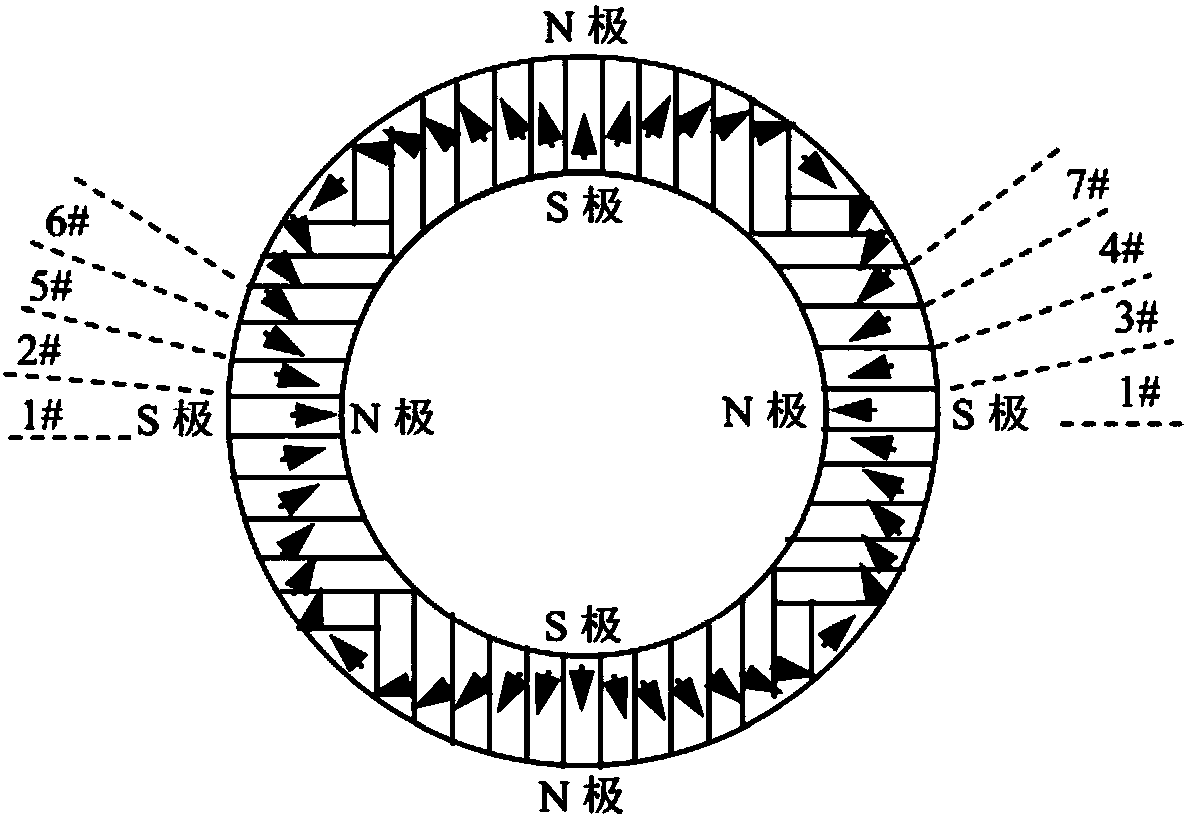

[0057] A four-pole radiation-oriented bonded permanent magnet ring was prepared by three-dimensional printing.

[0058] Such as figure 2 As shown, the three-dimensional printing molding process of embodiment 1 comprises the following steps:

[0059] a) Powder loading: Nd with magnetocrystalline anisotropy 2 Fe 14 B Magnet powder, crushed by coarse crushing, jet milling or ball milling to a powder with an average particle size of 3um, mixed with thermosetting epoxy resin at a volume ratio of 95:5; the mixed powder is added to the mold by the feeding system , forming a powder layer with a thickness of 10um and uniform distribution;

[0060] b) Orientation molding: the upper and lower pressing heads move the pre-pressed powder in opposite directions, and a magnetic field is applied through the upper and lower pole heads. The magnetic field strength is 1.8 Tesla, so that the magnetic powder is oriented along the direction of the magnetic field, and then pressed to form a speci...

Embodiment 2

[0067] A composite permanent magnetic gradient functional material block was prepared by a three-dimensional printing process.

[0068] Such as figure 2 As shown, the three-dimensional printing molding process of embodiment 2 comprises the following steps:

[0069] a) Powder loading: Sm with magnetocrystalline anisotropy 2 co 17 The powder crushed to an average particle size of 3um by coarse crushing, jet milling or ball milling is mixed evenly with thermosetting epoxy resin at a volume ratio of 95:5; the mixed powder is added to the molding mold by the feeding system, Form a powder layer with a thickness of 15um and uniform distribution;

[0070] b) Orientation forming: the upper and lower indenters move towards each other, pre-press the powder, apply a magnetic field through the upper and lower pole heads, the magnetic field strength is 2.2 Tesla, orient the magnetic powder along the direction of the magnetic field, and then carry out molding and pressing to form a orie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com