Solid oxide fuel battery cell

A solid oxide, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of undisclosed air electrode current collectors, and achieve high power generation performance and good power generation durability. , to ensure the effect of tightness

Inactive Publication Date: 2013-07-03

TOTO LTD

View PDF13 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this prior art does not disclose an air electrode current collector containing silver, palladium, and a perovskite-type oxide in specific content ratios.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0058] In the following examples, the following measurement methods and evaluation methods were used.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

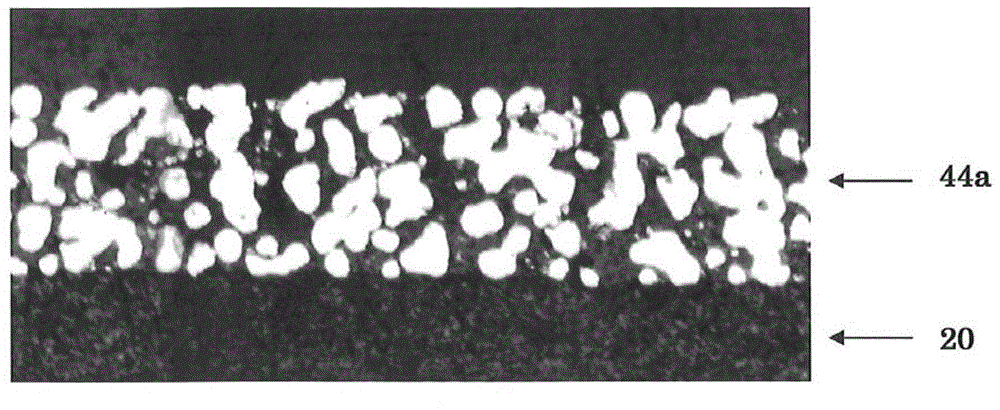

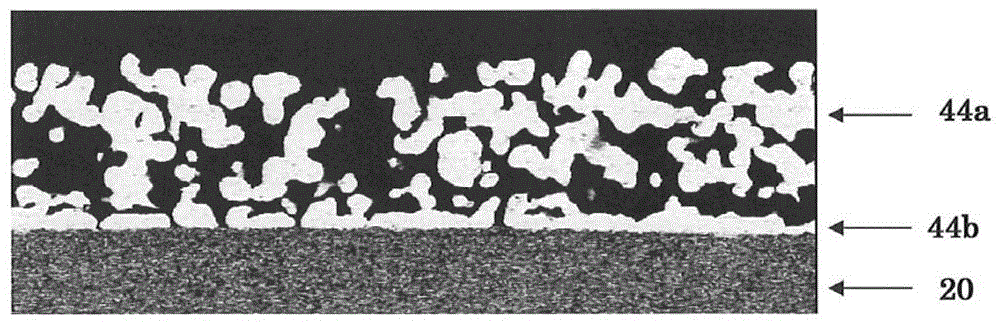

There is provided a solid oxide fuel battery cell that has a high initial power generation performance and a good power generation durability while ensuring adhesion between an air electrode layer and a current collector layer. The solid oxide fuel battery cell includes at least a solid electrolyte, a fuel electrode layer provided on one surface side of the solid electrolyte, an air electrode layer provided on the other surface side of the solid electrolyte, and a current collector layer provided on the surface of the air electrode layer, wherein the air electrode layer is formed of an oxide selected from the group consisting of lanthanum ferrite perovskite oxides, lanthanum cobalt perovskite oxides, and samarium cobalt perovskite oxides, and the current collector layer is a porous layer including silver, palladium, and an oxide and has an average porosity of 20% to 70% in a portion other than a portion near a boundary between the current collector layer and the air electrode layer and, in the near-boundary portion, an average porosity of not less than 50% of the average porosity of the portion other than the near-boundary portion.

Description

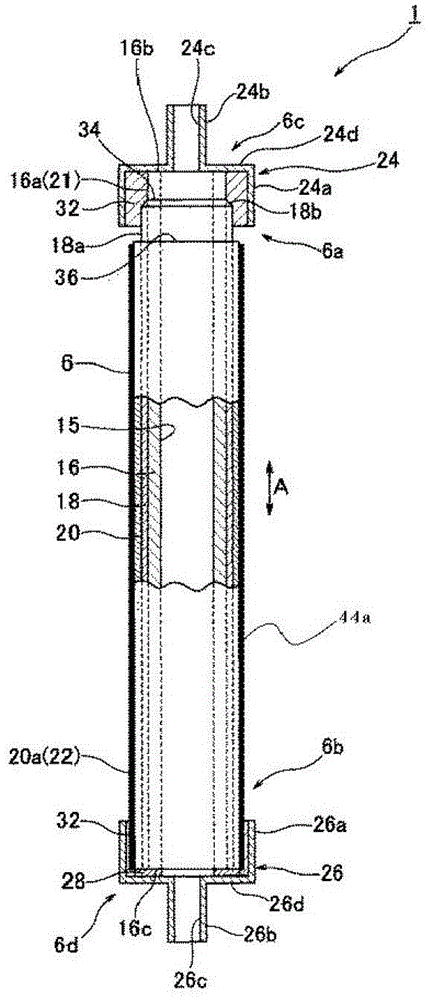

technical field [0001] The present invention relates to a single solid oxide fuel cell and a fuel cell system including the single solid oxide fuel cell. Background technique [0002] Conventionally, a fuel cell having a tubular fuel cell is known (for example, Japanese Patent Laid-Open No. 2007-95442 (Patent Document 1)). The air electrode of this conventionally known solid oxide fuel cell is formed by coating silver paste, and the silver is exposed to the air. [0003] Furthermore, Japanese Patent Application Laid-Open No. 2005-50636 (Patent Document 2) describes a flat solid oxide fuel cell in which the air electrode contact material inside the solid oxide fuel cell is isolated. The object and the air pole are sandwiched. The air electrode contact material contains at least silver powder or silver alloy powder and perovskite oxide powder. It is described that the preferred mixing ratio is in the range of silver powder or silver alloy powder:perovskite oxide powder=90:1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M8/12H01M8/02

CPCH01M4/8889H01M4/9033H01M8/0232H01M8/0236H01M8/0243H01M2008/1293H01M4/9058H01M4/9066Y02E60/50H01M4/8657H01M12/06

Inventor 新美泰之川上晃安藤茂让原正义西水亮市

Owner TOTO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com