High performance mechanical canned motor pump

A high-performance mechanical and canned pump technology, which is applied to mechanical equipment, pumps, and parts of pumping devices for elastic fluids, can solve the problems of medium leakage, inconvenient maintenance, and high cost, and ensure the sealing performance and use Life, improve the axial bearing capacity, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

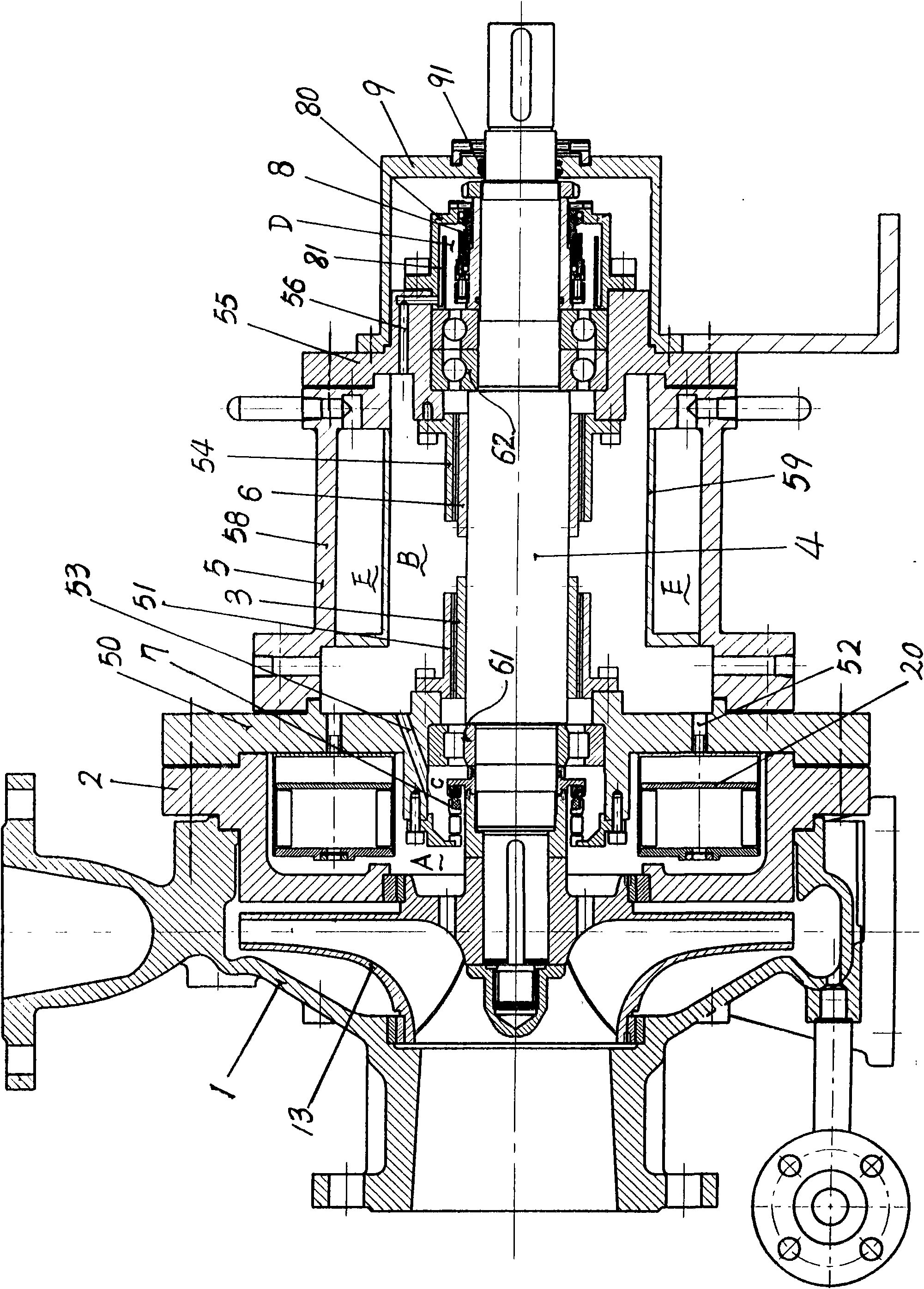

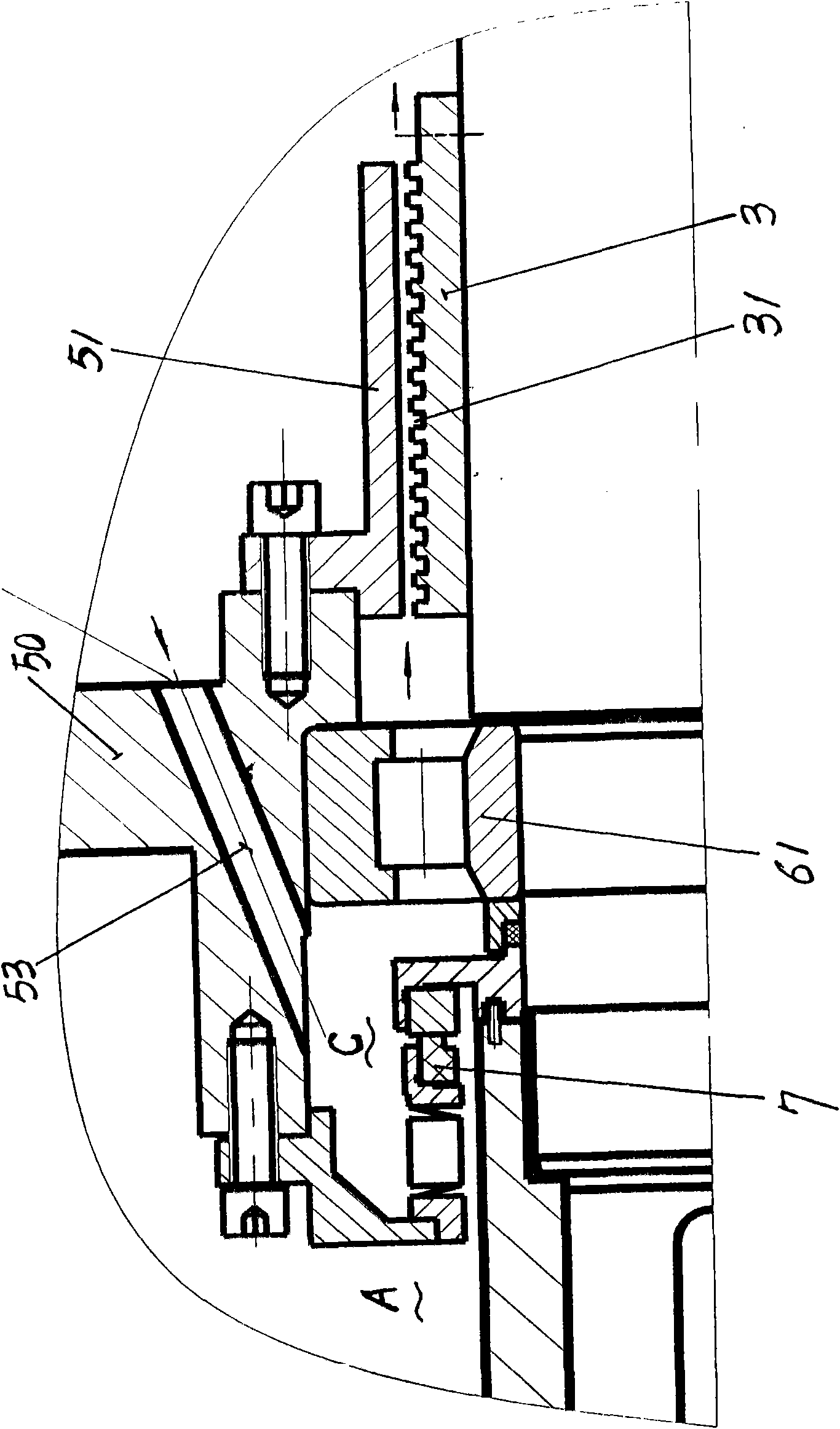

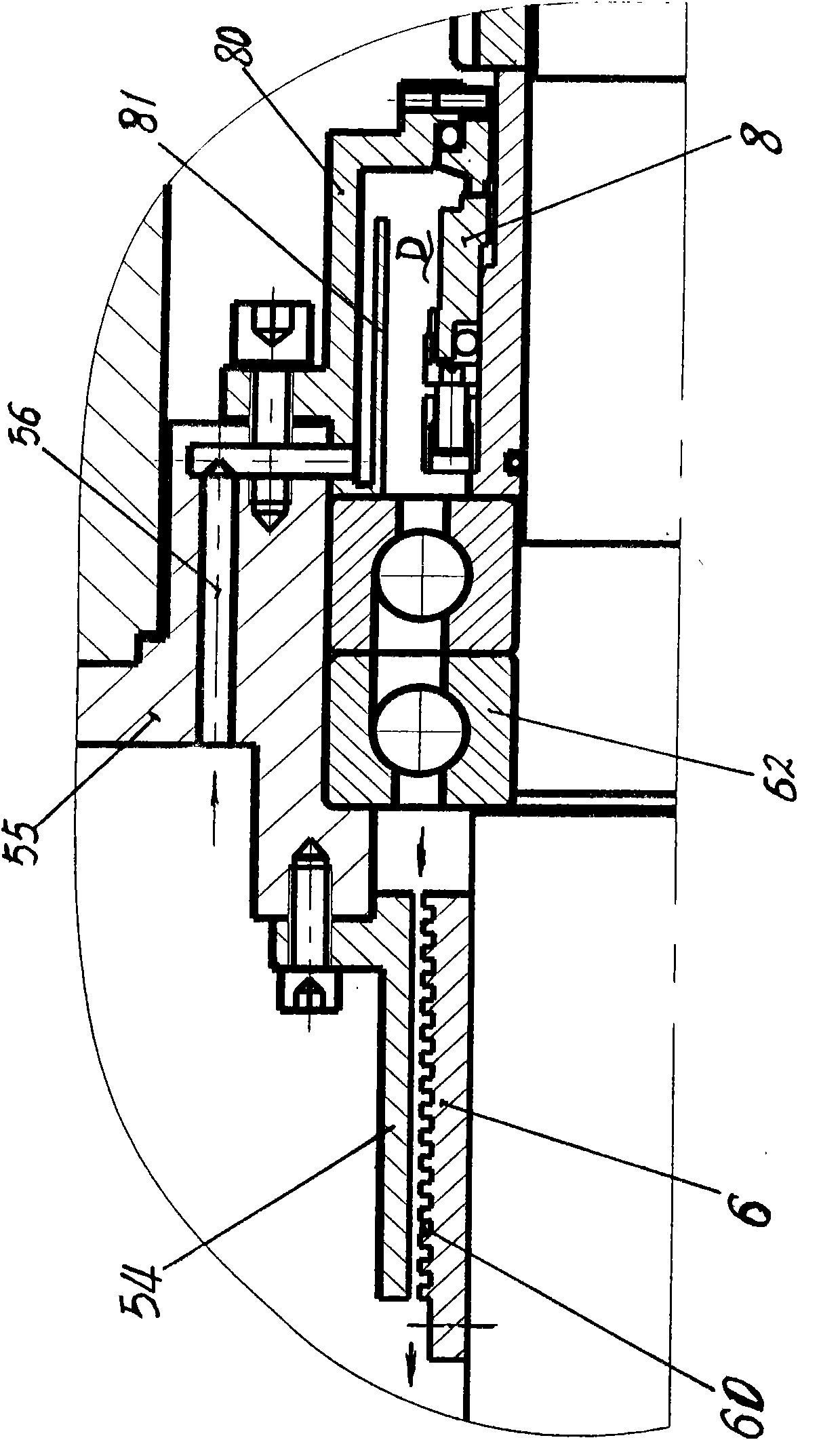

[0010] Shown in the embodiment of the accompanying drawings is a centrifugal pump. The present invention includes a pump body 1, an impeller 13, a pump cover 2, a pump shaft 4, and a bearing housing 5. The bearing housing 5 is composed of a front end plate 50, a cylinder body 58, and a rear end plate 55. The pump shaft 4 is connected with rolling bearings 61, 62 The front and rear end plates of the bearing box 5 are rotated and installed. In the inner cavity A of the pump cover 2, a mechanical seal device is provided between the front end plate 50 of the bearing box and the hub of the pump wheel or the pump shaft 4 ----- the front end mechanical seal device 7. There is another mechanical seal device between the rear end plate 55 of the bearing box and the pump shaft 4 - the rear end mechanical seal device 8, and the front and rear end mechanical seal devices 7 and 8 form the inner cavity B of the bearing box 5 The airtight inner cavity is filled with cooling lubricating oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com