Samarium cobalt permanent magnet vacuum sintering furnace

A vacuum sintering furnace, permanent magnet technology, applied in furnaces, muffle furnaces, cooking furnaces and other directions, can solve the problems of long production cycle, unstable temperature zone, poor heat dissipation, etc., to improve product qualification rate, shorten cooling time, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

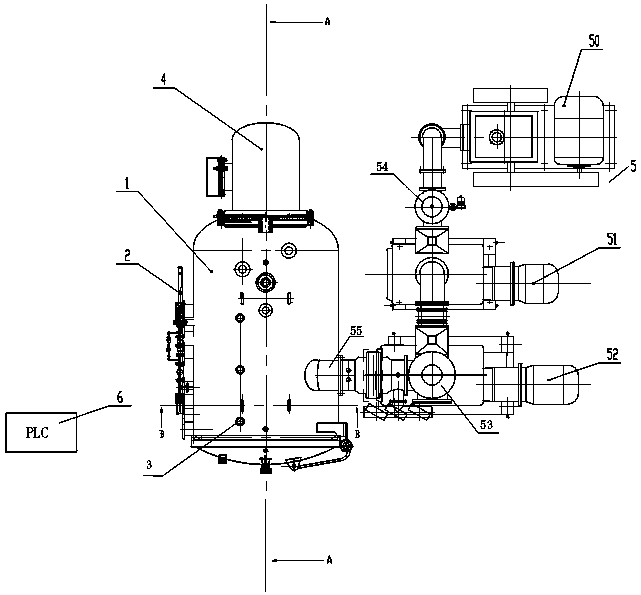

[0015] see figure 1 As shown, the permanent magnet vacuum sintering furnace includes a furnace body 1, a graphite electric heater 2, a temperature control device 3, a fan cooling coil 4, a vacuum system 5 and a program control system 6.

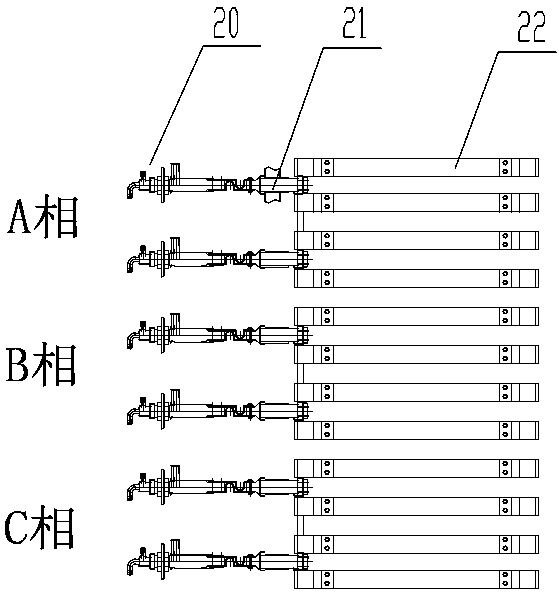

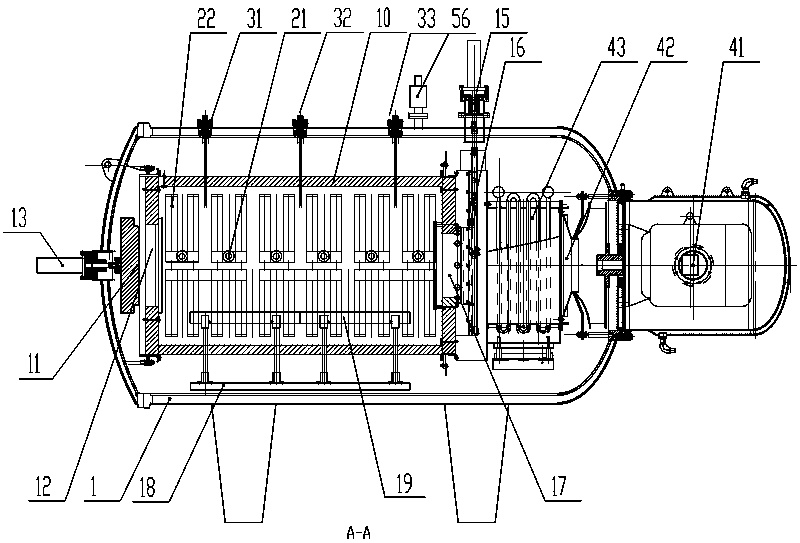

[0016] see Figure 2 ~ Figure 4 As shown, the furnace body 1 is equipped with a sintering furnace and a cold and heat exchanger. The sintering furnace body is composed of a heat insulation layer, a sealed furnace 10, a front door gasket 11 and a rear door gasket 17, which are respectively opened by the front door cylinder 13 and the rear door cylinder 15. Or close the sealed furnace 10.

[0017] The thermal insulation layer is composed of molybdenum sheet inner shell, thermal insulation cotton filled in the middle and stainless steel outer shell. The sealed furnace 10 is fixed with the inner wall of the furnace by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com