A Method for Isothermal Superplastic Deformation of Micro/Nano Particle Reinforced Titanium Matrix Composites

A titanium-based composite material and particle-reinforced technology, applied in the field of warm superplastic deformation, can solve the problems of difficult processing and forming, large deformation resistance, etc., and achieve the effect of improving material forming rate, excellent superplastic performance, and meeting high performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

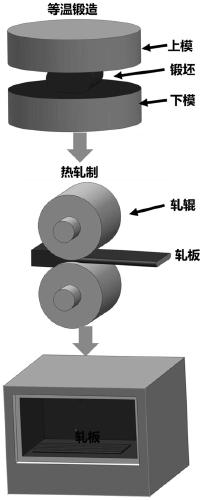

[0032] This embodiment provides a method for superplastic deformation of micro / nano particle reinforced titanium-based composite materials, and the schematic diagram of the process flow is as followsfigure 1 As shown, the specific steps are as follows:

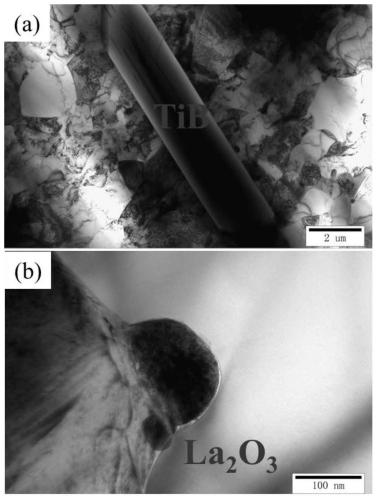

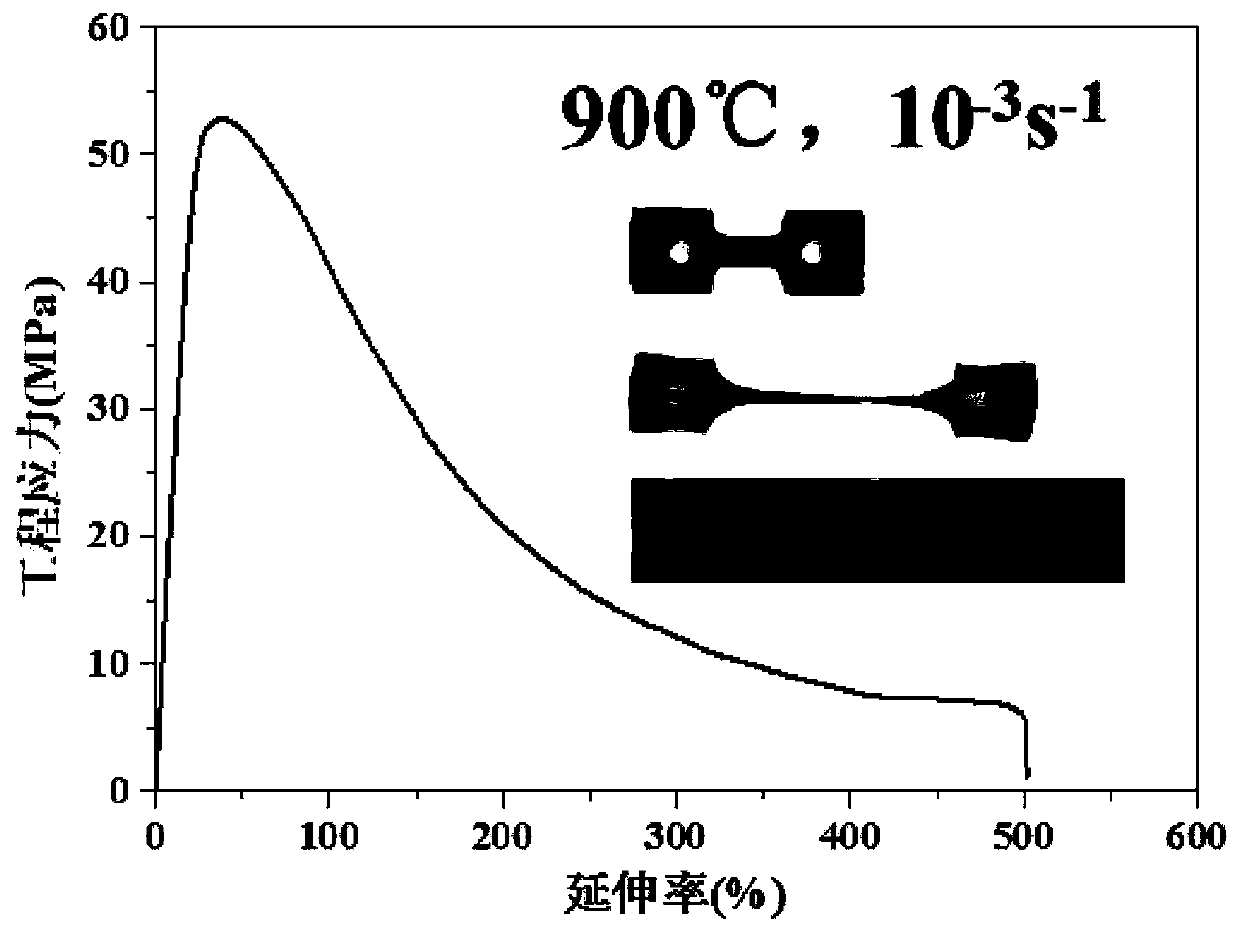

[0033] Preparation of TiB and La by in situ autogenous technique 2 o 3 Micro / Nano Particle Reinforced Titanium Matrix Composites, TiB and La 2 o 3 The volume fractions are 2.5vol.% and 0.1vol.%, respectively. In order to ensure that the composition of the prepared composite material is uniform, the composite material is subjected to vacuum self-consumption melting for three times, and then the head is cut to remove defects such as surface scale and shrinkage cavity. Microstructure photographs of composite materials as figure 2 As shown; the titanium-based composite material is heated to the β single-phase region (1160°C) and held for 60 minutes, and the billet forging is carried out in the β single-phase region (1160°C), a...

Embodiment 2

[0035] This embodiment provides a method for superplastic deformation of micro / nano particle reinforced titanium-based composite materials, the specific steps are as follows:

[0036] Preparation of TiB and La by in situ autogenous technique 2 o 3 Micro / Nano Particle Reinforced Titanium Matrix Composites, TiB and La 2 o 3 The volume fractions are 2.5vol.% and 0.5vol.%, respectively. In order to ensure that the composition of the prepared composite material is uniform, the composite material is subjected to vacuum self-consumption smelting for three times, and then the head is cut to remove defects such as surface oxide skin and shrinkage cavity; The titanium-based composite material was heated to the β single-phase region (1200°C) and held for 50 minutes, and the billet forging was carried out in the β single-phase region (1200°C). 60% to eliminate the original coarse grains, and then machining to remove the scale and defects on the surface of the initial forging billet; th...

Embodiment 3

[0038] This embodiment provides a method for superplastic deformation of micro / nano particle reinforced titanium-based composite materials, the specific steps are as follows:

[0039] Preparation of TiB and Y by in situ self-generation technique 2 o 3 Micro / Nano Particle Reinforced Titanium Matrix Composites, TiB and Y 2 o 3 The volume fractions are 2.5vol.% and 0.5vol.%, respectively. In order to ensure that the composition of the prepared composite material is uniform, the composite material is subjected to vacuum self-consumption smelting for three times, and then the head is cut to remove defects such as surface oxide skin and shrinkage cavity; The titanium-based composite is heated to the β single-phase region (1200°C) and held for 60 minutes, and the billet forging is carried out in the β single-phase region (1200°C). The hydraulic press mold temperature used is always kept at 900-980°C, and the deformation is 60% to eliminate the original coarse grains, and then mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com