Ceramic photo-curing 3D printing system and method

A 3D printing and light curing technology, applied in the field of additive manufacturing in mechanical manufacturing, it can solve the problems of complex process, increased cost, and relatively high requirements for projection resolution, so as to improve the forming rate, prevent slurry precipitation, and ensure reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

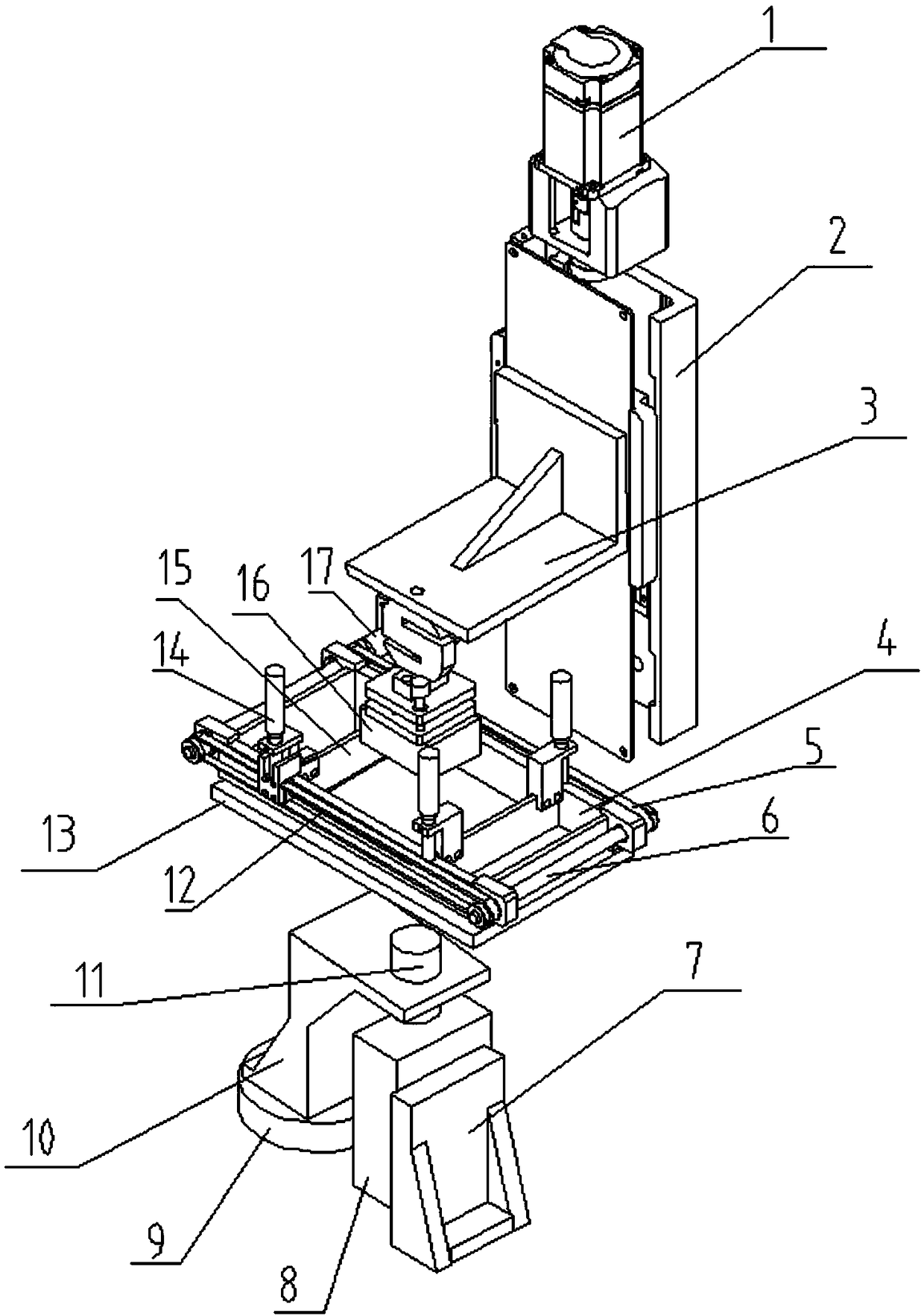

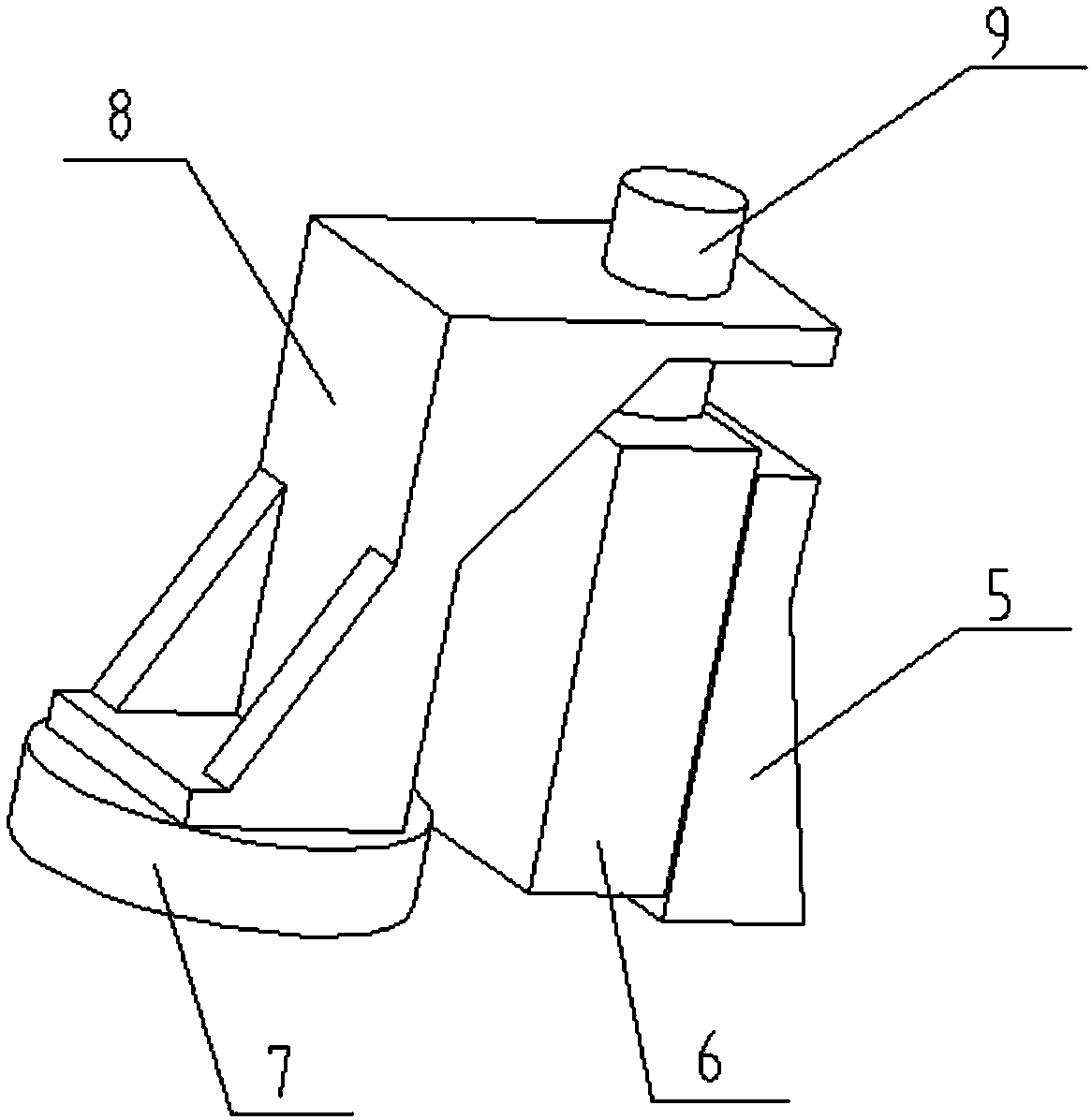

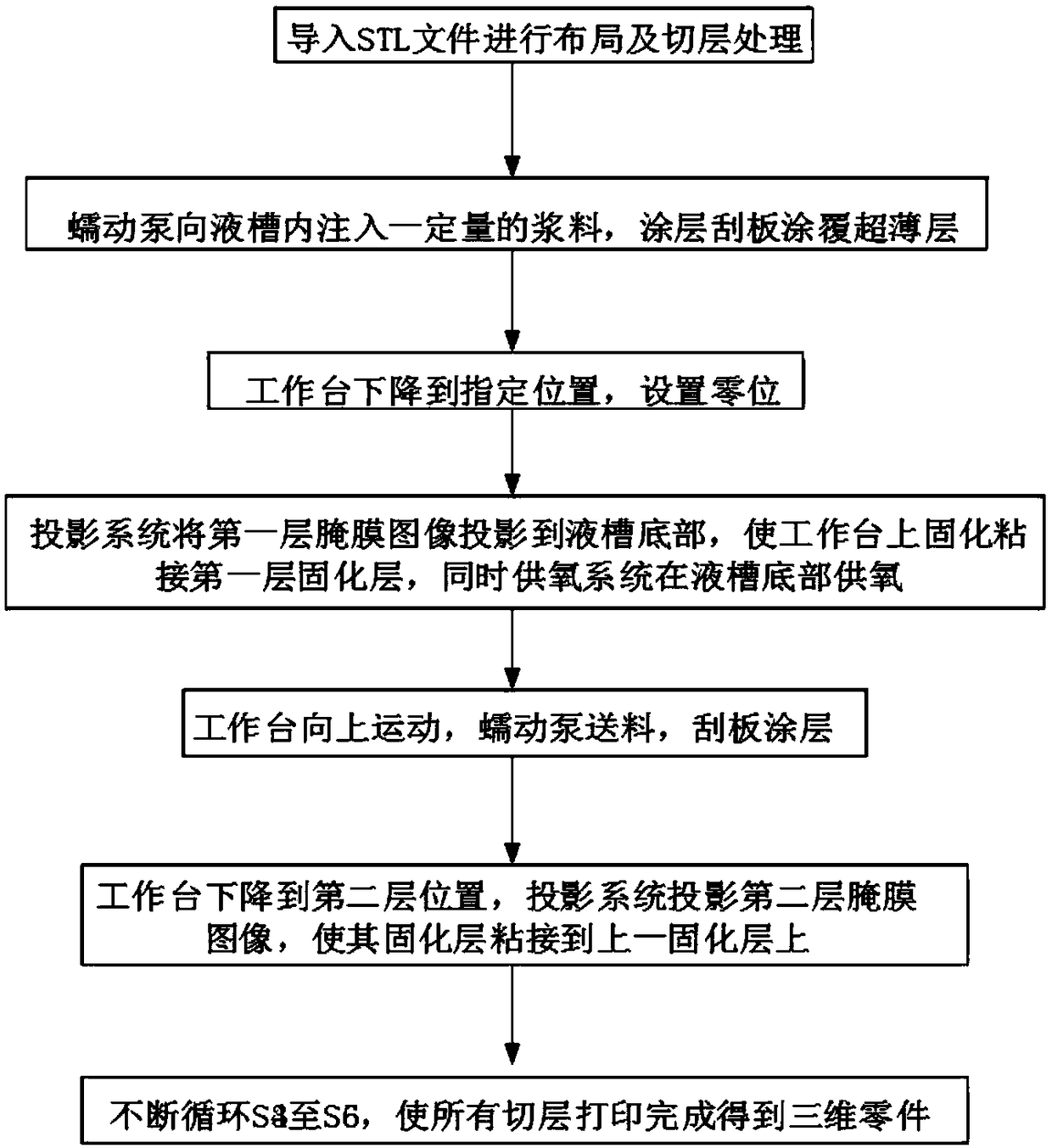

[0031] refer to figure 1 and figure 2 , the ceramic photocuring 3D printing system described in the present invention includes a DLP projection system, a computer, a liquid tank 4, a transparent bottom plate 13, an elastic separation film, a workbench 16, a coating scraper 15 located in the liquid tank 4, and is used to drive The driving device for the coating scraper 15 to move in the liquid tank 4, the liquid supply system for providing the light-cured slurry in the liquid tank 4, and the Z-axis control system for controlling the movement of the workbench 16 in the vertical direction; the liquid The tank 4 is located on the transparent base plate 13, the elastic separation film is located between the transparent base plate 13 and the liquid tank 4, and the workbench 16 is located directly above the liquid tank 4; the DLP projection system includes a DLP projection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com