Millimetre micro-capsules and preparation method thereof

A microcapsule, millimeter-scale technology, applied in the field of microcapsule preparation, can solve problems such as difficult to achieve water volatilization rate, unsuitable for millimeter-scale capsules, narrow range of wall material selection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Adopt the method of Example 1 in CN 106540638A to prepare polymer water-in-capsules:

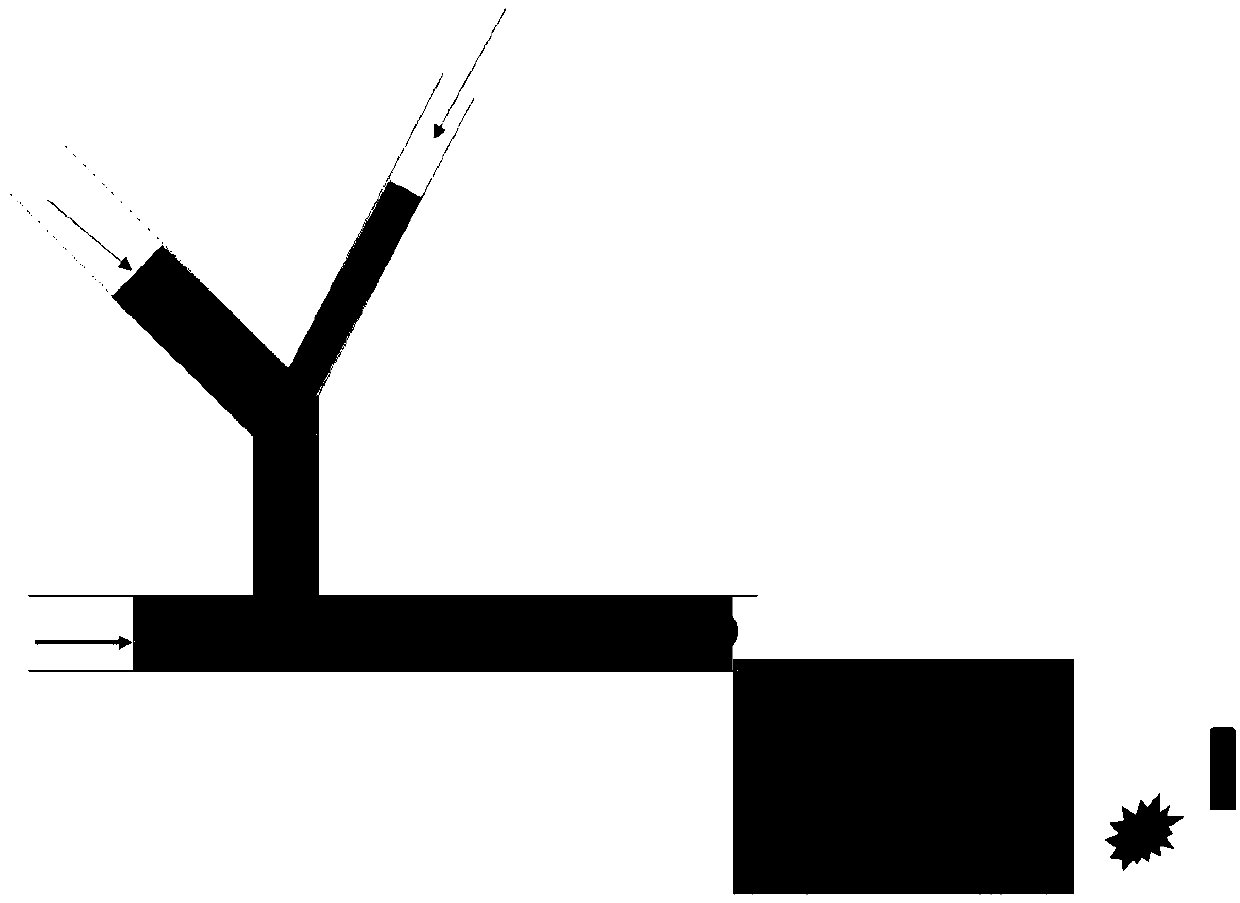

[0095] The inner phase (A) chooses pure water, the middle phase (B) chooses acrylic resin and diluent (Evergreen resin 6215-100 and tripropylene glycol diacrylate (TPGDA)) 1:4 mixed (containing 3% photoinitiator, 2 -Hydroxy-2-methyl-1-phenyl-1-propanone, 1173), the external phase (C) chooses water (containing 1% PVA). The distance between the pipe (1) and the pipe (3) is 3 mm, and the width of the curing channel is 1.5 mm. The internal phase (A), intermediate phase (B), and external phase (C) were pumped into pipelines (1), (2), ( In 3), a water-in-oil-in-water emulsion is generated through the action of shear force and gravity. After the emulsion flows to the curing channel (4), the mesophase is cured under the radiation of ultraviolet light to form a polymer-coated emulsion. water capsules.

[0096] Its preparation adopts micro / millifluidic chip, and its structure includes: sampl...

Embodiment 2

[0111] Embodiment 2: Effect of different oil phase viscosities on the performance of millimeter-scale microcapsules

[0112] In this example, the influence of different oil phase viscosities on the performance of millimeter-sized microcapsules was tested.

[0113] The specific preparation process is as follows:

[0114] 1. Preparation of the aqueous phase system: the inner aqueous phase is an aqueous solution of carboxymethyl cellulose with a concentration of 1%, and the outer aqueous phase is used as a mobile phase.

[0115]2. Preparation of light-curing materials (mass ratio): mix bisphenol A epoxy acrylic resin with dipropylene glycol diacrylate, 27 parts of tetrahydrofuran acrylate, 3 parts of 2-hydroxy-methylphenylpropane-1- Ketones are mixed evenly, wherein different parts of dipropylene glycol diacrylate are added to control the configuration of oil phases with different viscosities;

[0116] 3. Construction of the microfluidic device: connect the thicker side of the ...

Embodiment 3

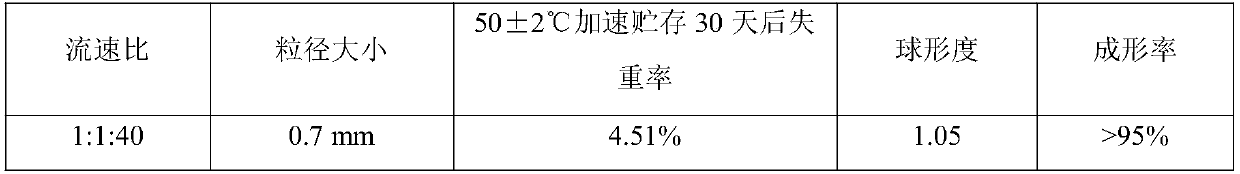

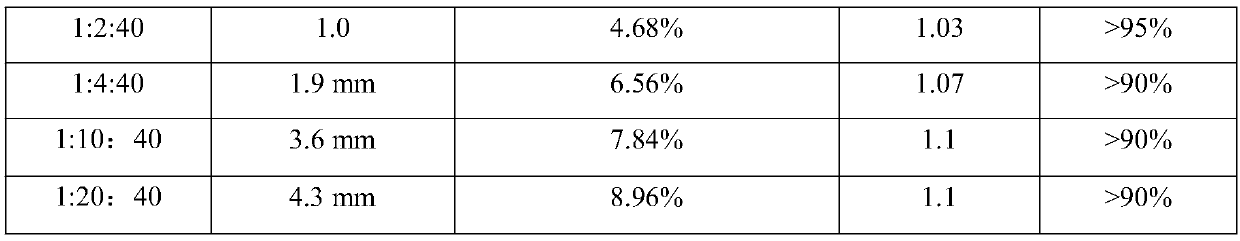

[0122] Embodiment 3: the impact of different flow rate ranges on the performance of millimeter-scale microcapsules

[0123] In this example, the effects of different flow rate ranges on the performance of millimeter-scale microcapsules were tested.

[0124] The specific preparation process is as follows:

[0125] 1. Preparation of the aqueous phase system: the inner aqueous phase is an aqueous solution of carboxymethyl cellulose with a concentration of 1%, and the outer aqueous phase is used as a mobile phase.

[0126] 2. Preparation of light-curing material (mass ratio): configure an oil phase with a viscosity of 200, specifically 40 parts of bisphenol A epoxy acrylic resin: dipropylene glycol diacrylate: tetrahydrofuran acrylate: 2-hydroxy- Mix the methyl phenylpropan-1-one evenly according to the ratio of 50:20:27:3.

[0127] 3. Construction of the microfluidic device: connect the thicker side of the Y-shaped connector to a silicone tube with an inner diameter of 1.2mm wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com