Line heating automatic forming method based on curve surface unfolding

A technology of water-fire bending and forming method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of immature heating parameters, changes, application of automation equipment, etc., to improve detection methods and reduce labor intensity. , the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

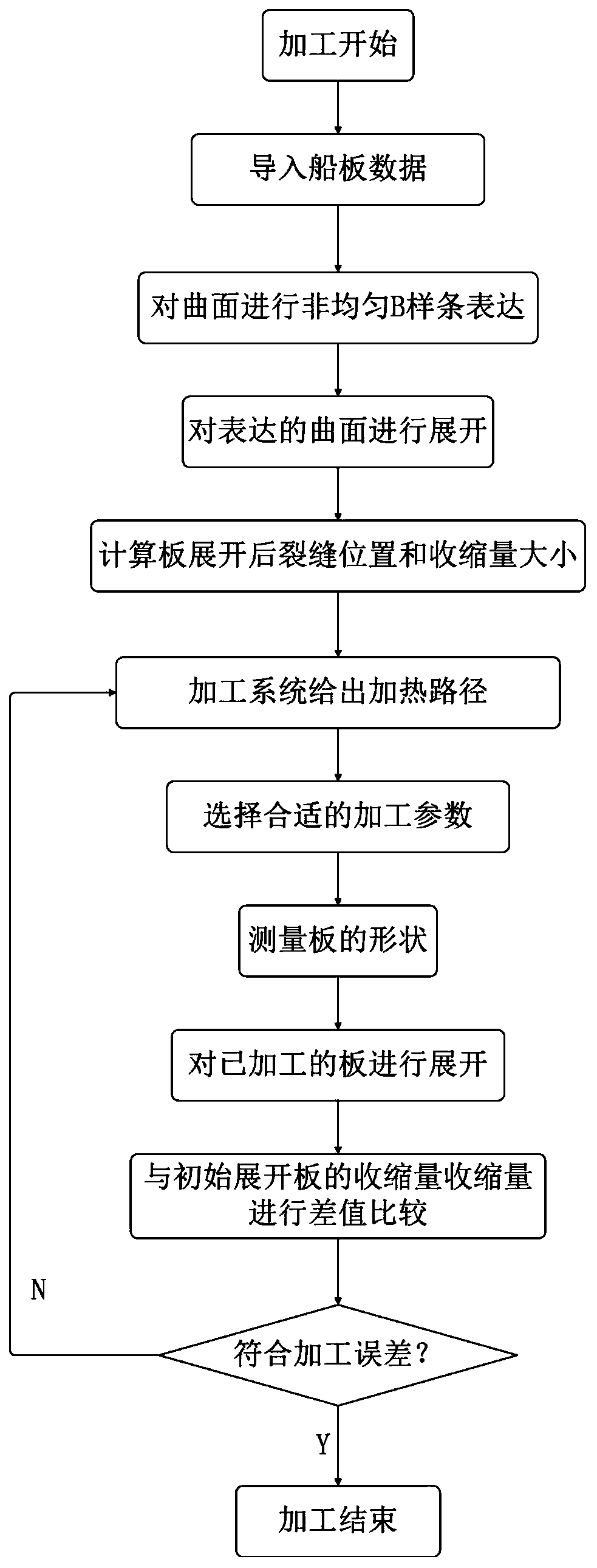

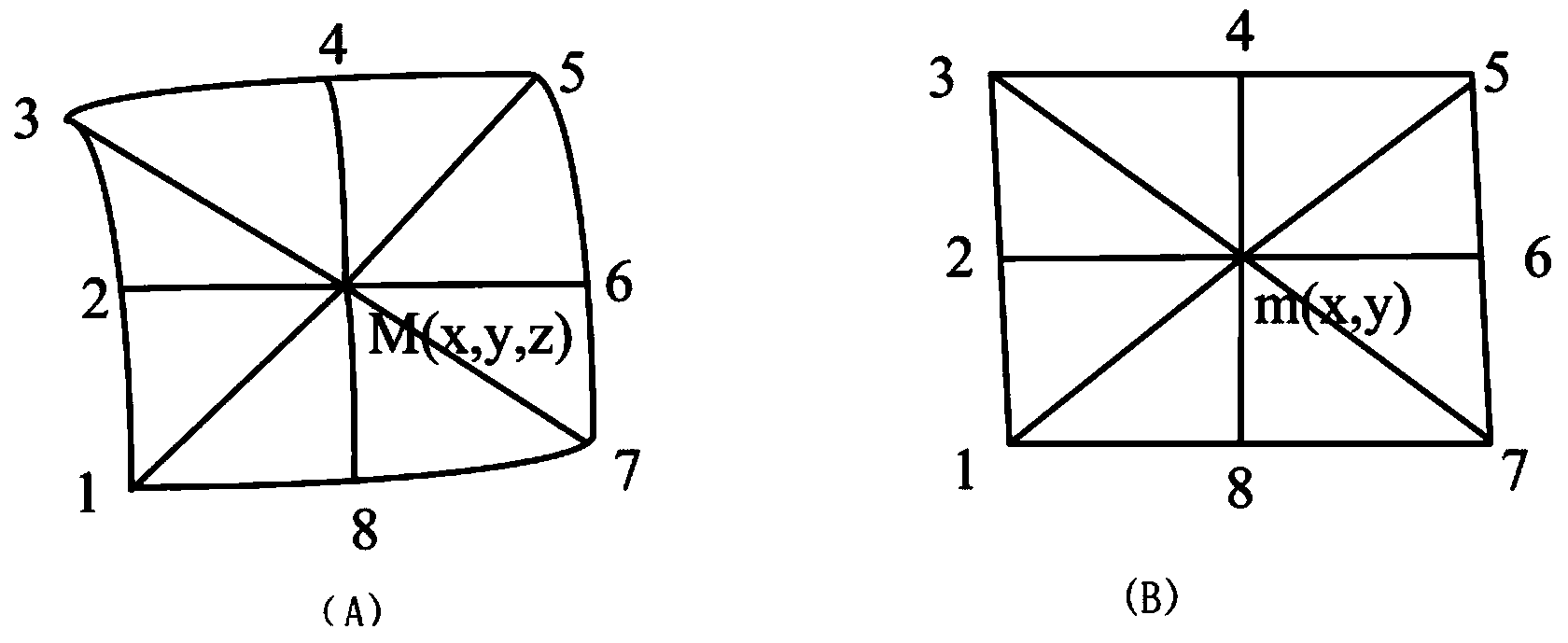

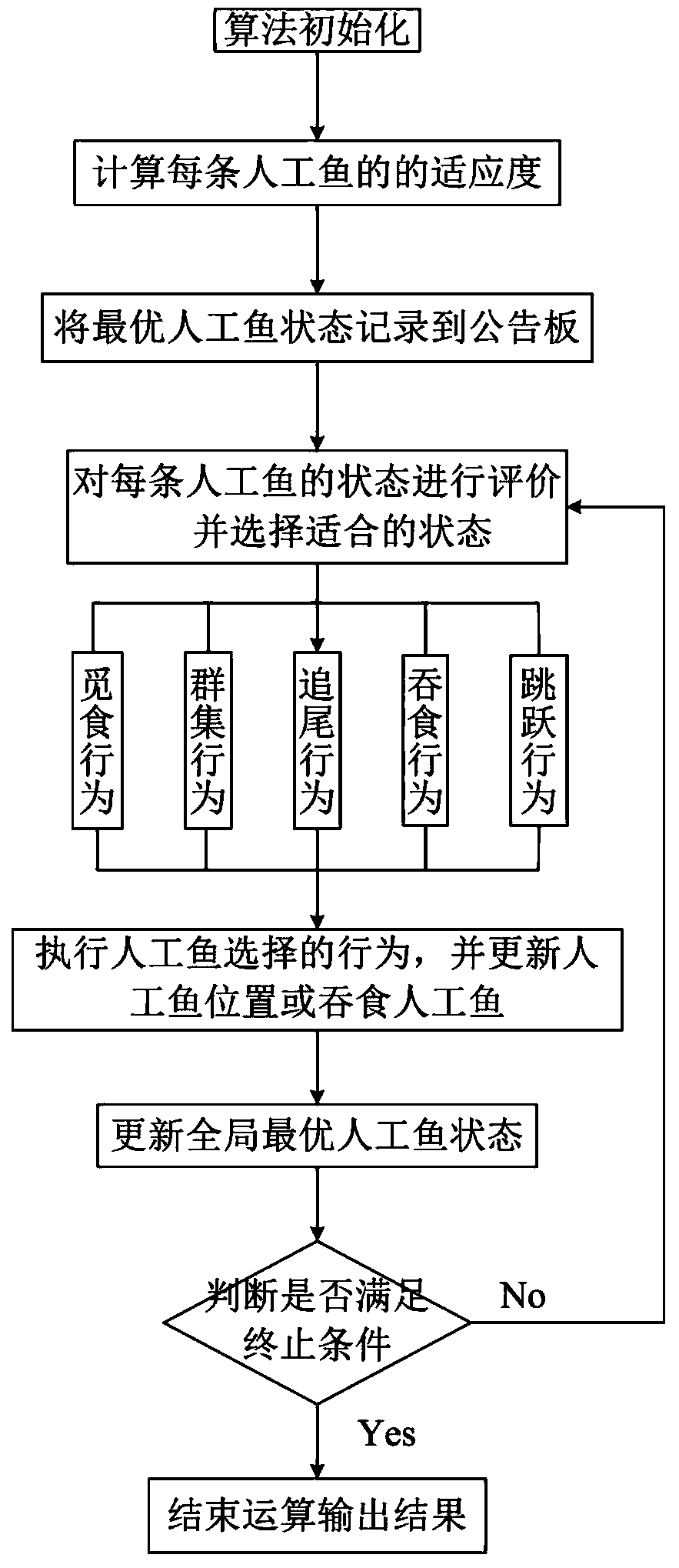

[0041] Such as figure 1 As shown, the technological process of the water-fired bending plate automatic forming system based on curved surface expression in the present invention is: 1) import a certain real ship plate Tribon data; 2) carry out non-uniform B-spline expression to the imported ship shell plate to fit This is the surface of the real ship plate; 3) The initial triangle expansion is performed on the surface, and the initial expansion data is used as the initial value of iteration, and the data of all expansion points can be obtained by iteratively solving with the improved multi-behavior global fish swarm algorithm; 4) Calculate the amount of shrinkage at the cracks of the unfolded plate, and use the inference computer system to calculate and give the heating line path layout; 5) According to the already arranged heating lines, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com