Releasing agent and preparation method thereof

A technology of release agent and weight percentage, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory demoulding effect, blank product pass rate and poor forming quality, etc., to improve product forming qualification The effect of improving the rate, improving the surface quality, and increasing the product forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

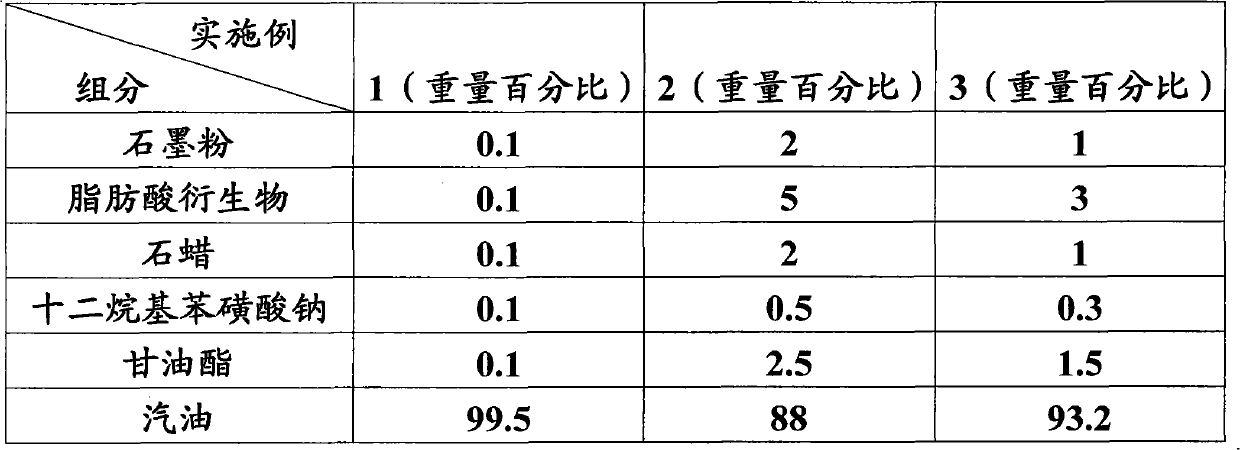

[0018] A release agent used in the forming process of magnetic materials, which consists of the following components: graphite powder with a weight percentage of 0.1, fatty acid derivatives with a weight percentage of 0.1, paraffin wax with a weight percentage of 0.1, and dodecane with a weight percentage of 0.1 A mixture of sodium alkylbenzene sulfonate, 0.1 weight percent glyceride, and 99.5 weight percent gasoline. The mixture mixed according to the above ratio is heated to a temperature of 60-100° C., mixed and dissolved for 30-45 minutes, and the mold release agent in the forming process of the magnetic material is obtained.

Embodiment 2

[0020] A release agent used in the forming process of magnetic materials is composed of the following components: graphite powder with a weight percentage of 2, fatty acid derivatives with a weight percentage of 5, paraffin wax with a weight percentage of 2, and dodecane with a weight percentage of 0.5 A mixture of sodium alkylbenzene sulfonate, 2.5% by weight glyceride, and 88% by weight gasoline. The mixture mixed according to the above ratio is heated to a temperature of 60-100° C., mixed and dissolved for 30-45 minutes, and the mold release agent in the forming process of the magnetic material is obtained.

Embodiment 3

[0022] A release agent used in the forming process of magnetic materials is composed of the following components: graphite powder with a weight percentage of 1, fatty acid derivatives with a weight percentage of 3, paraffin wax with a weight percentage of 1, and dodecane with a weight percentage of 0.3 A mixture of sodium alkylbenzene sulfonate, 1.5 weight percent glyceride, and 93.2 weight percent gasoline. The mixture mixed according to the above ratio is heated to a temperature of 60-100° C., mixed and dissolved for 30-45 minutes, and the mold release agent in the forming process of the magnetic material is obtained.

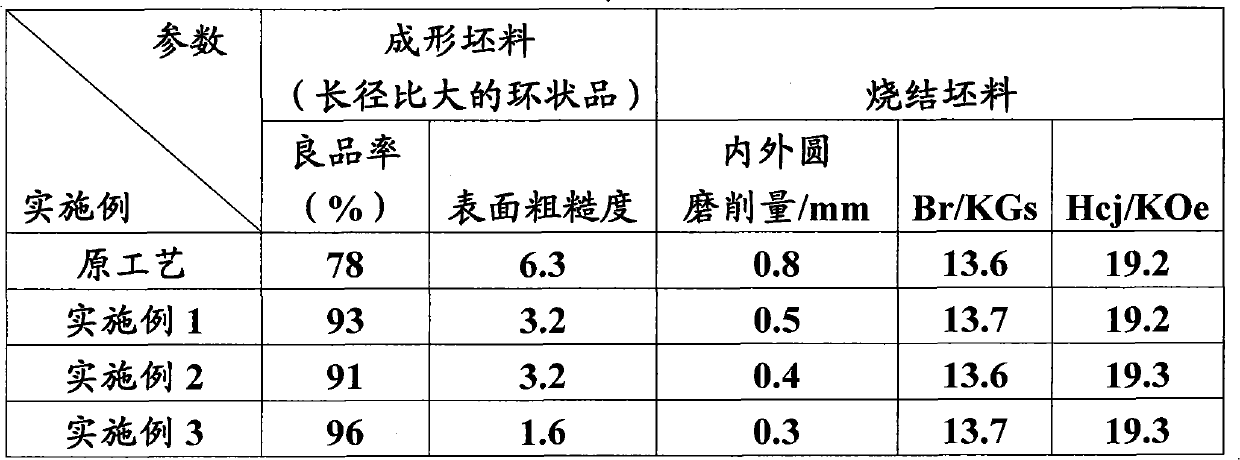

[0023] The composition of the components of each of the above examples is shown in Table 1 below. In addition, see Table 2 for the product technical parameters of the various embodiments.

[0024] Table 1

[0025]

[0026] Table 2

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com