Crystal growth furnace heater and sapphire crystal growth furnace

A crystal growth furnace and heater technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as uneven temperature field of sapphire crystal furnace, achieve firm and reliable connection parts, high reliability, and improve balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

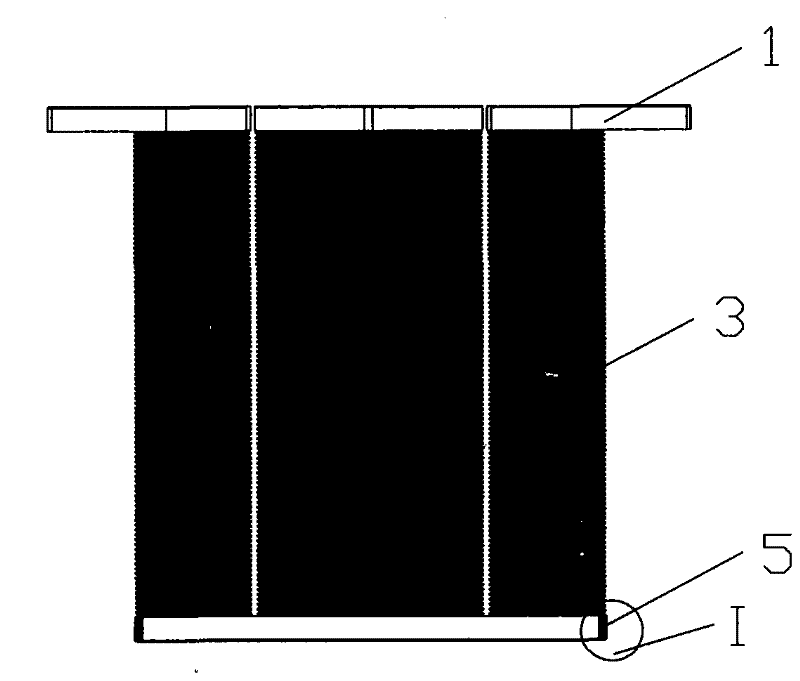

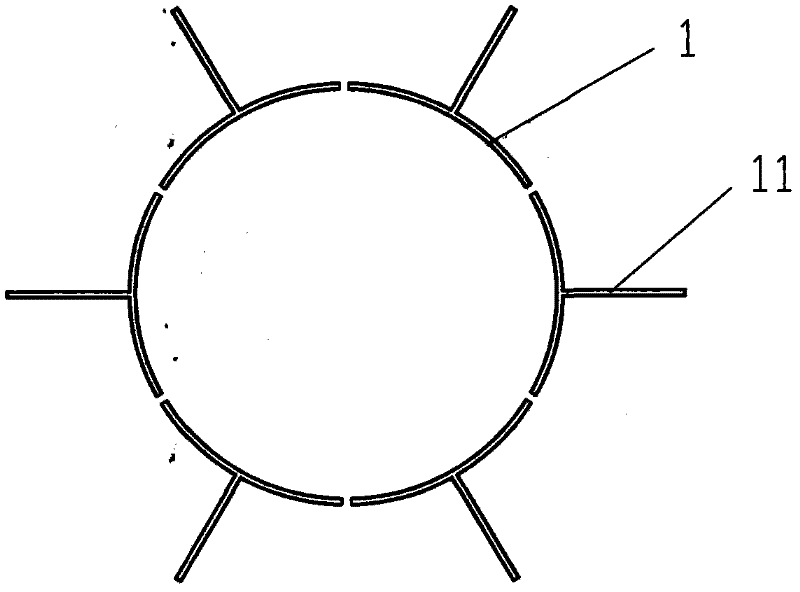

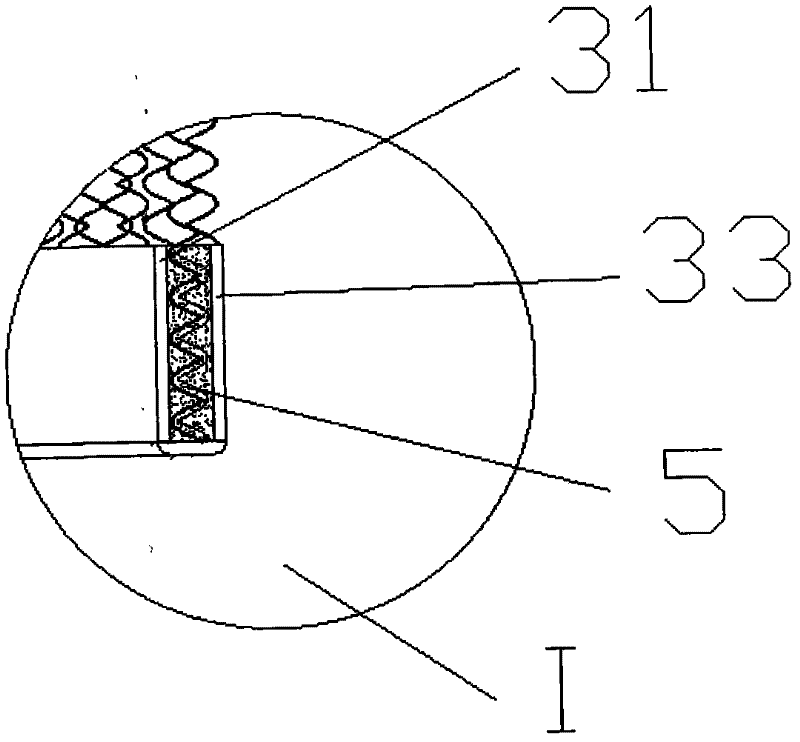

[0026] One aspect of the present invention provides a crystal growth furnace heater. The overall shape of the heater is cylindrical, such as figure 1 Shown is the front view of the heater. One end of the cylinder is provided with a plurality of electrodes 1, and according to an embodiment of the present invention, six electrodes 1 are provided. figure 2 It is a top view of the heater, six electrodes 1 are distributed in a ring, and every two electrodes 1 are divided into three groups, which are respectively connected to the output terminals of the three-phase power supply. For example, two adjacent electrodes 1 are divided into one group, and six electrodes 1 are divided into three groups a, b, and c, which are respectively connected to phase A, phase B, and phase C of the output terminals of the three-phase power supply.

[0027] According to an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com