A kind of rapid heating and constant temperature hot compress spirit and preparation method thereof

A warm and fast technology, applied in the direction of heating device for treatment, contraceptive device, cooling device for treatment and treatment, etc. Low cost, flexible use, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

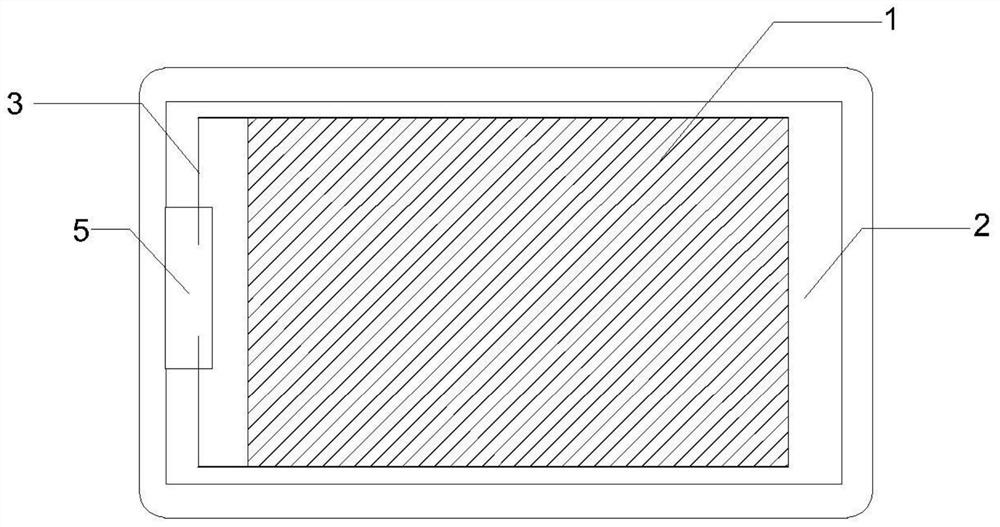

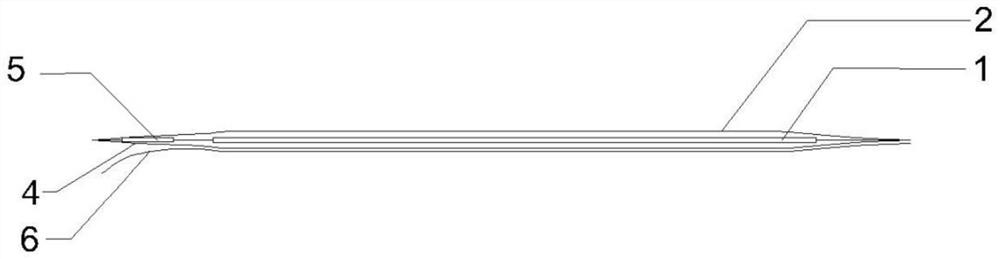

Method used

Image

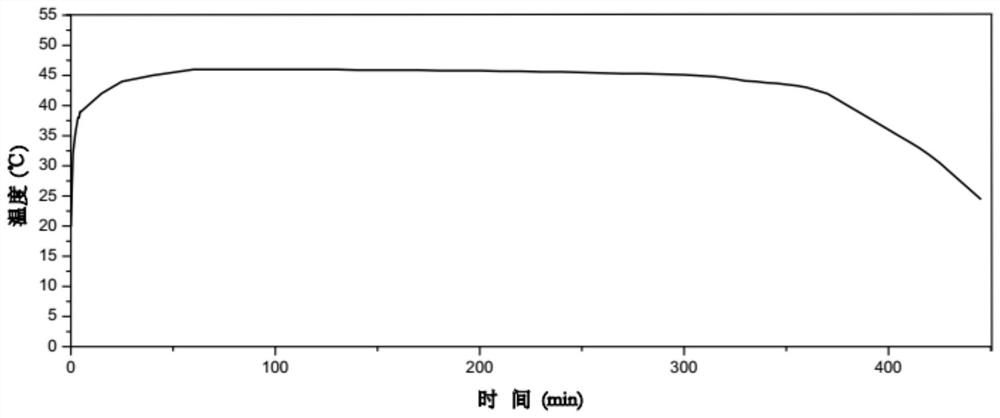

Examples

Embodiment 1

[0062] The preparation method of the self-temperature-controlling heating layer comprises the following steps:

[0063] (1) Pretreatment of conductive particles: soak and clean the acetylene carbon black powder with acetone, filter and distill under reduced pressure to remove acetone, then heat at 120°C for 100 minutes to remove volatile substances adsorbed on the surface of the acetylene carbon black powder;

[0064] (2) Melting: melt the low-density polyethylene particles, and at a temperature of 120°C, according to the ratio of raw materials (by mass parts, 25 parts of low-density polyethylene, 20 parts of stearic acid, 40 parts of myristic acid, acetylene 10 parts of carbon black, 5 parts of dioctyl phthalates), add myristic acid, stearic acid, step (1) pretreated acetylene carbon black and dioctyl phthalate while hot, vigorously stir and mix Homogenize to obtain a homogeneous mixture;

[0065] (3) Tablet pressing: Pour the mixture in step (2) onto the pre-made enamel pla...

Embodiment 2

[0076] The preparation method of the self-temperature-controlling heating layer comprises the following steps:

[0077] (1) Pretreatment of conductive particles: Soak and clean graphite powder with acetone, filter and distill under reduced pressure to remove acetone, then heat at 120°C for 120 minutes to remove volatile substances adsorbed on the surface of graphite powder;

[0078] (2) Melting: melt the ethylene vinyl acetate copolymer, and at a temperature of 100°C, according to the ratio of raw materials (in parts by mass, 20 parts of ethylene vinyl acetate copolymer, 17 parts of stearic acid, 33 parts of myristic acid, 25 parts of graphite powder, 5 parts of dioctyl phthalate), add myristic acid, stearic acid, step (1) pre-treated graphite and dioctyl phthalate while hot, vigorously stir and mix, obtain a homogeneous mixture;

[0079] (3) Tablet pressing: Pour the mixture in step (2) onto the pre-made enamel plate, and pre-set copper wires on both sides of the slurry, lig...

Embodiment 3

[0090] The preparation method of the self-temperature-controlling heating layer comprises the following steps:

[0091] (1) Pretreatment of conductive particles: fully stir and wash the copper powder with 10% citric acid aqueous solution, filter and dry after washing for 10 hours;

[0092] (2) Melting: Melt the low-density polyethylene particles, and at a temperature of 120°C, according to the ratio of raw materials (in parts by mass, 15 parts of low-density polyethylene, 30 parts of stearic acid, 35 parts of myristic acid, copper 15 parts of powder, 3 parts of dioctyl phthalates, 2 parts of isopropyl three isostearyl phthalates), add myristic acid, stearic acid, step (1) copper powder after pretreatment while hot , dioctyl phthalate and isopropyl triisostearyl phthalate, stirred vigorously to obtain a homogeneous mixture;

[0093] (3) Tablet pressing: Pour the mixture in step (2) onto the pre-made enamel plate, and pre-set copper wires on both sides of the slurry, lightly pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com