Patents

Literature

52results about How to "Reliable temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

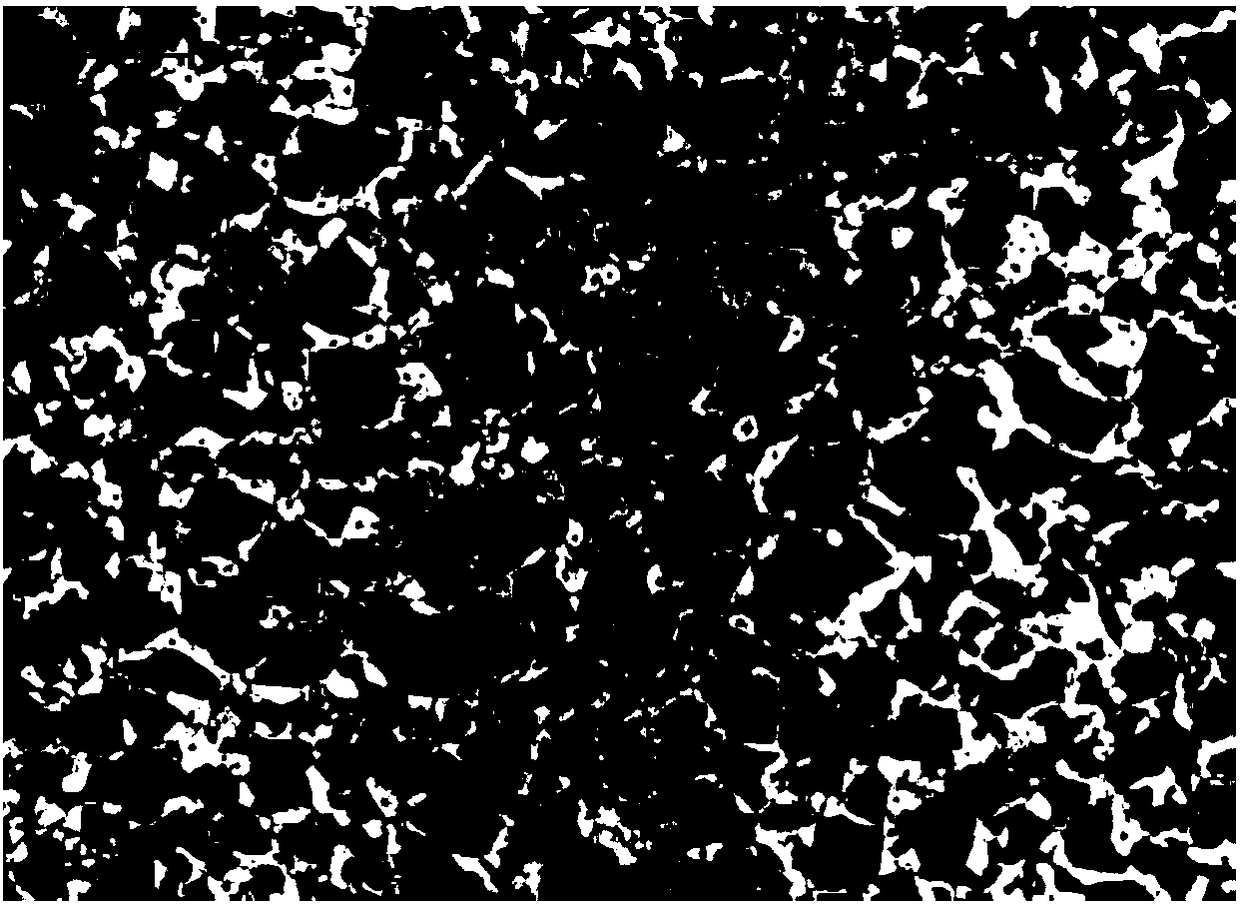

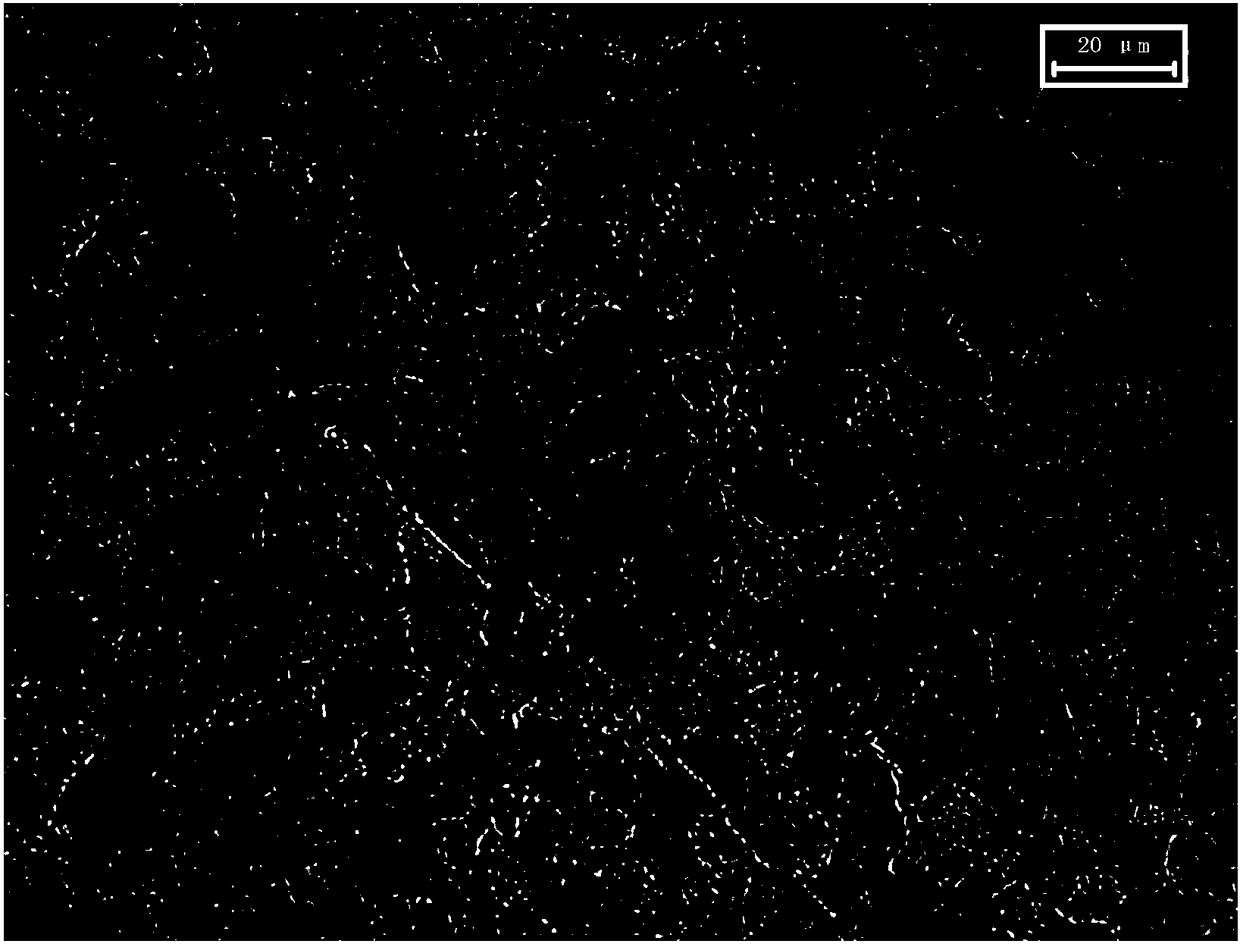

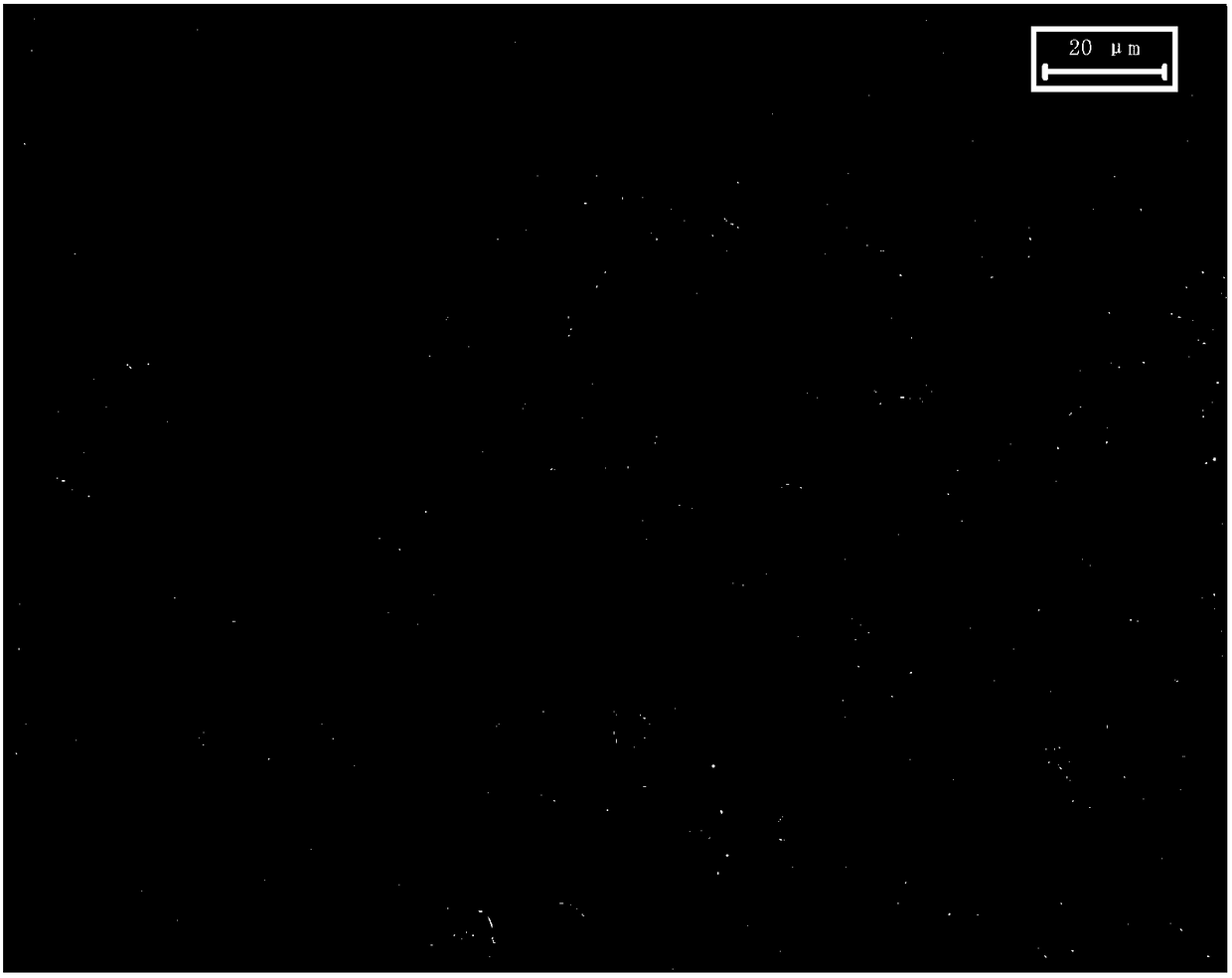

High-hardenability gear steel and manufacturing method thereof

The invention discloses high-hardenability gear steel. The high-hardenability gear steel comprises the chemical elements of, by mass, 0.19-0.25% of C, 0.15-0.35% of Si, 0.70-1.05% of Mn, 0.70-0.80% ofCr, 0.40-0.65% of Ni, larger than 0 and less than or equal to 0.20% of Cu, 0.33-0.40% of Mo, 0.020-0.050% of Al, 0.003-0.010% of Ti, 0.05-0.08% of b, 0.0001-0.0003% of B, 0.0080-0.0150% of N, and thebalance Fe and other inevitable impurities. The invention further discloses a gear which is obtained through the high-hardenability gear steel. In addition, the invention further discloses a manufacturing method of the high-hardenability gear steel. The high-hardenability gear steel is high in strength and good in toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

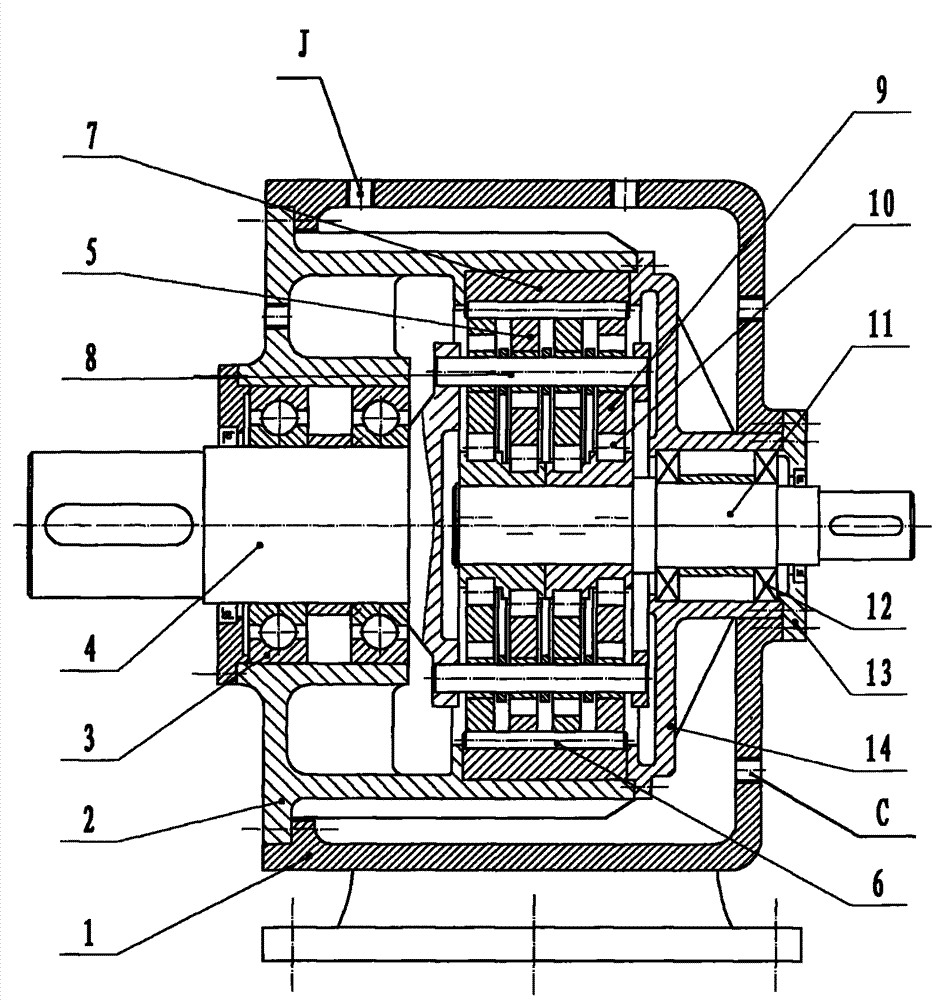

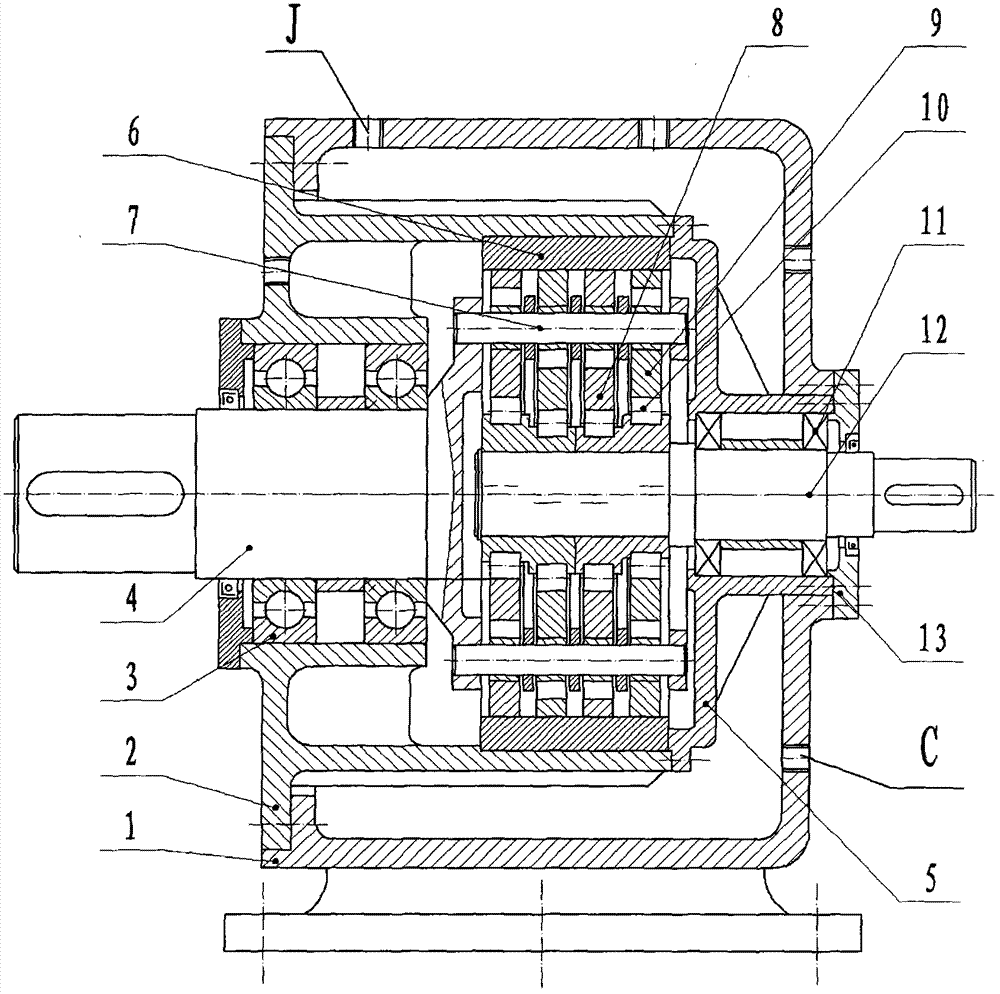

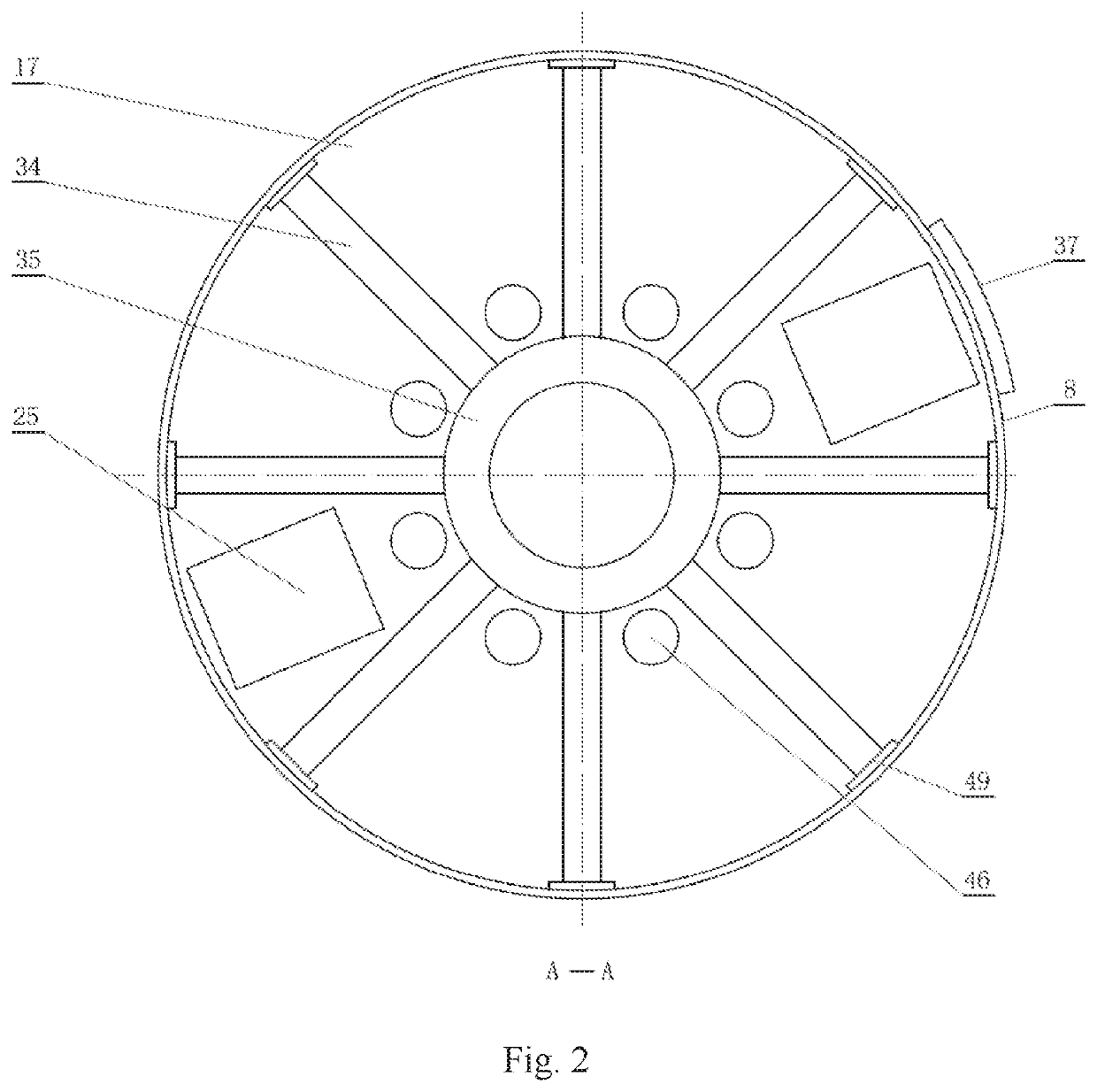

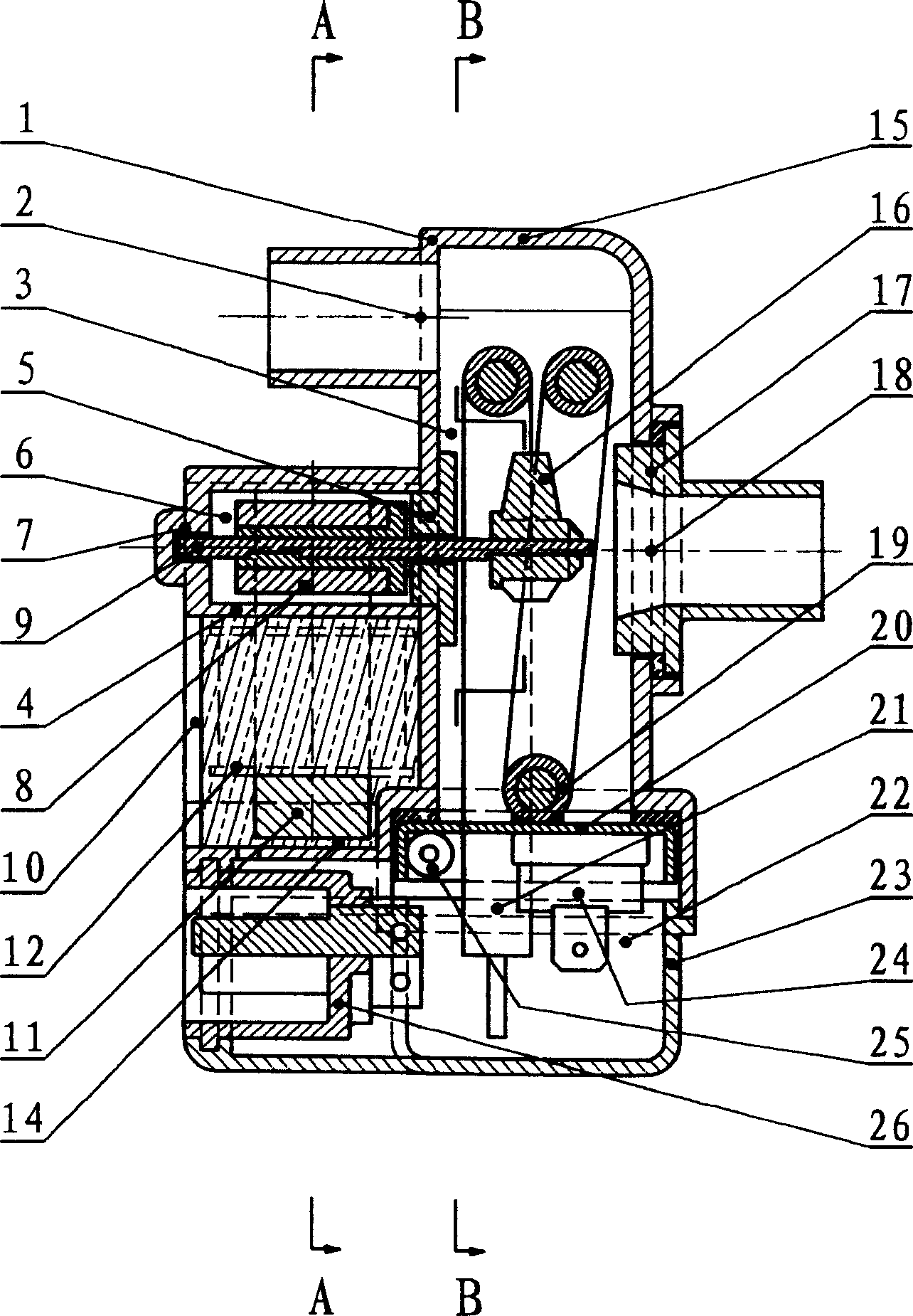

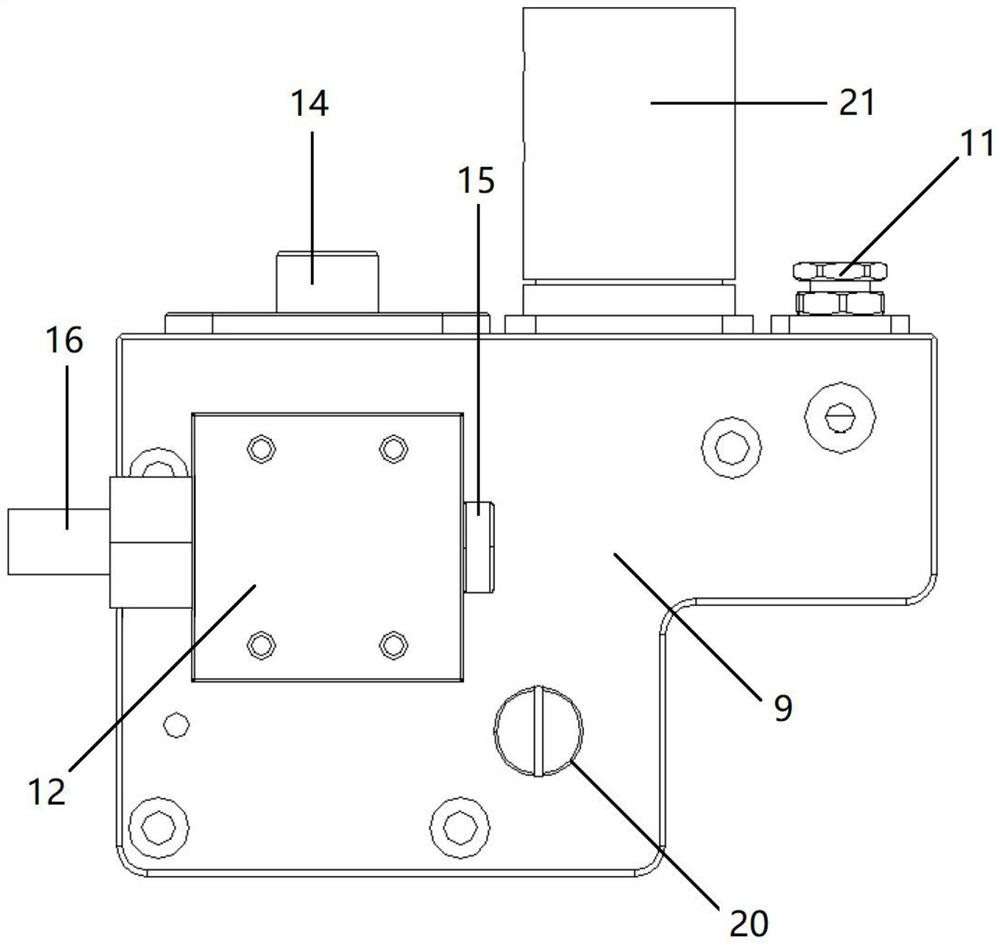

Box body interlayer water cooling high thermal power dynamic balance cycloidal reduction box

InactiveCN104728351ASimple structureLow costGearboxesGear lubrication/coolingDynamic balanceWater flow

The invention relates to cycloidal reducers. A box body interlayer water cooling high thermal power dynamic balance cycloidal reduction box comprises a box body, an input shaft, a transmission mechanism and an output shaft, wherein the input shaft, the transmission mechanism and the output shaft are arranged in the box body and are in successive transmission. The box body interlayer water cooling high thermal power dynamic balance cycloidal reduction box is characterized in that a connecting part of an inner cylinder and a circular end cover is arranged in the box body, a flange of the inner cylinder is connected with the output end face of the box body, an outer circle of the input end of the circular end cover is in close fit with an inner hole of the input end of the box body, the input end face of the circular end cover and the input end of the box body are in seal connection through the same annular pad, the inner wall of the box body and the outer wall of the connecting part of the inner cylinder and the circular end cover form an interlayer, water inlet valves communicated with the airtight interlayer are arranged on the top of the box body, drain valves communicated with the airtight interlayer are arranged on the lateral part of the box body, the input shaft is supported in the circular end cover through a bearing, the output shaft is supported in the inner cylinder through a bearing, and the transmission mechanism comprises four cycloidal gears, pin wheel housings, needle pins, eccentric bearings and pins. The box body interlayer water cooling high thermal power dynamic balance cycloidal reduction box has the technical advantages that heat in an airtight interlayer water sleeve is exhausted from a water outlet valve and dissipated to the outside of the box body, the structure is simple and manufacturing cost is low; the water flow rate is adjusted so that thermal power can be close to mechanical power, and dynamic balance of operation can be achieved.

Owner:吴小杰

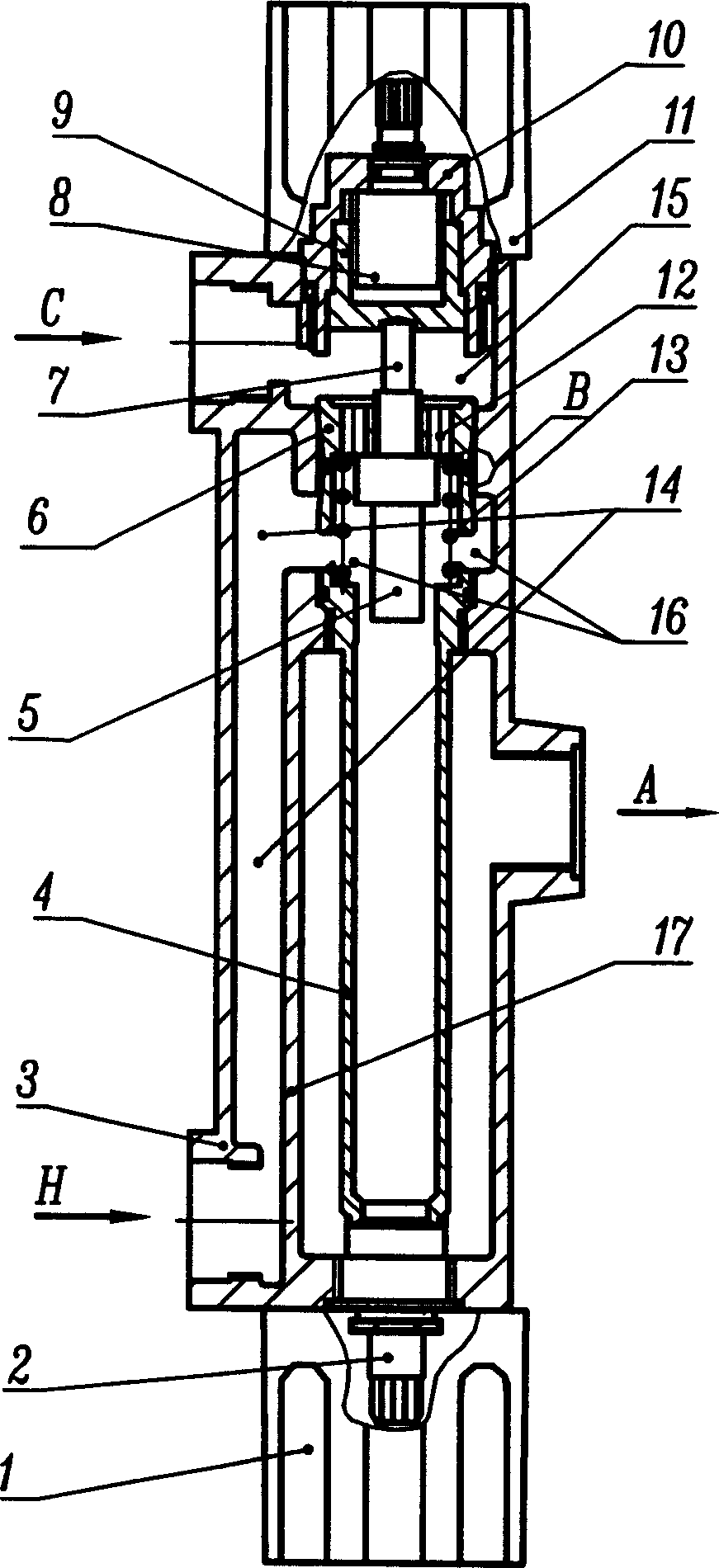

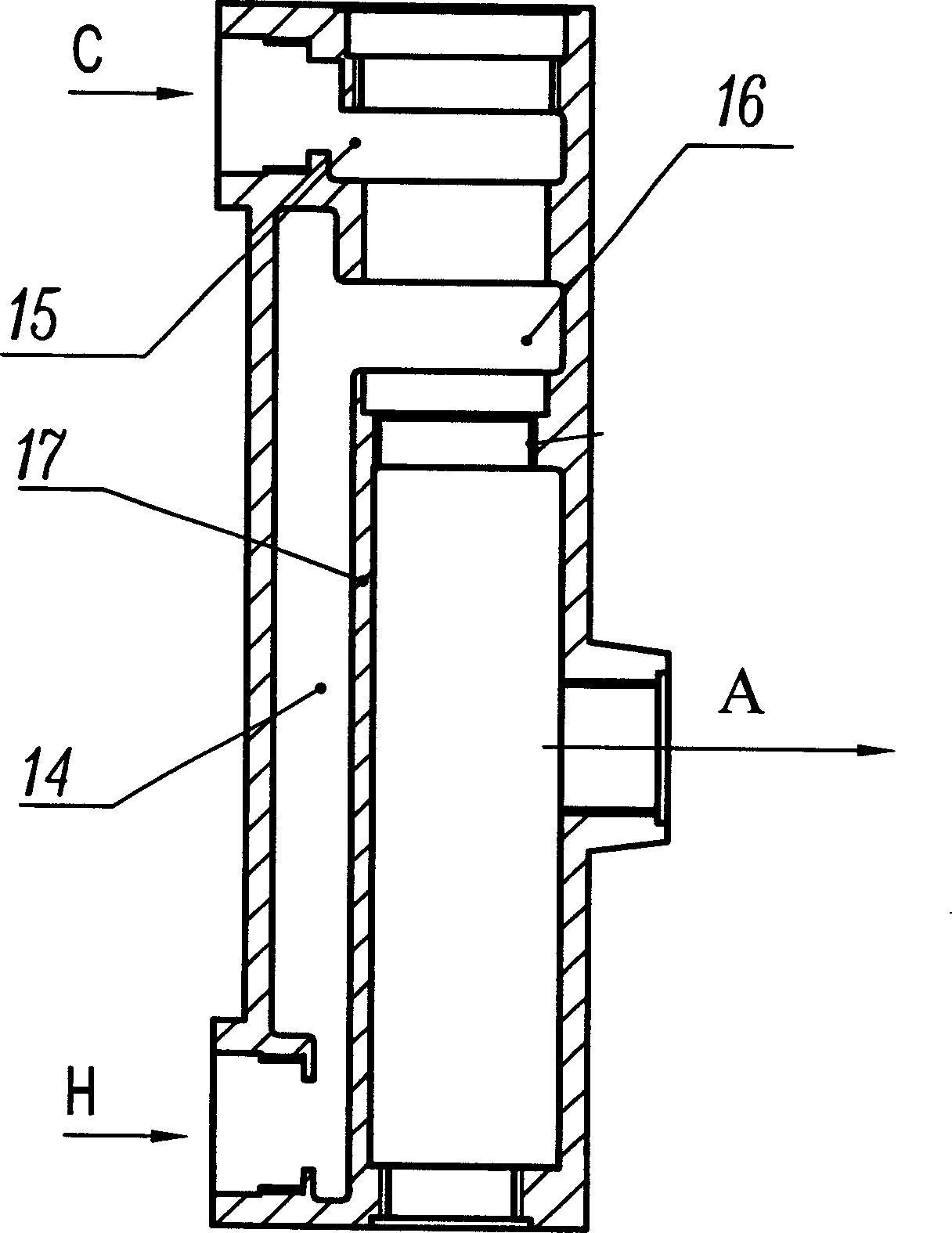

Water tap capable of keeping constant output-water temperature

InactiveCN1837657AReasonable structureSimple structureOperating means/releasing devices for valvesMultiple way valvesRegulation temperatureTemperature control

The invention relates to a water tap with automatic constant water temperature, which can automatically constant the temperature cold-hot mixed water. Wherein, the frame (3) contains a water tube (4); the frame comprises the water inlets H, C and the water outlet A; the switch hand wheel (1) is mounted on one end of frame which contains a ceramic switch (2); the outlet temperature adjusting hand wheel (11) is mounted on another end is frame which contains the temperature adjusting screw (8) that mounted inside the six-angle temperature adjusting nut (9); said nut is mounted inside the adjusting fixing nut (1); the temperature control element (5) is screwed inside the piston (6) which has a water through hole (12); one end of temperature control pushing rod (7) is mounted inside the six-angle temperature adjusting nut while another end is inside the temperature control element; one end of temperature control spring (13) is mounted on one end of piston while another end is connected to another plane of water tube. The invention can automatically control the temperature of water.

Owner:温邦绥

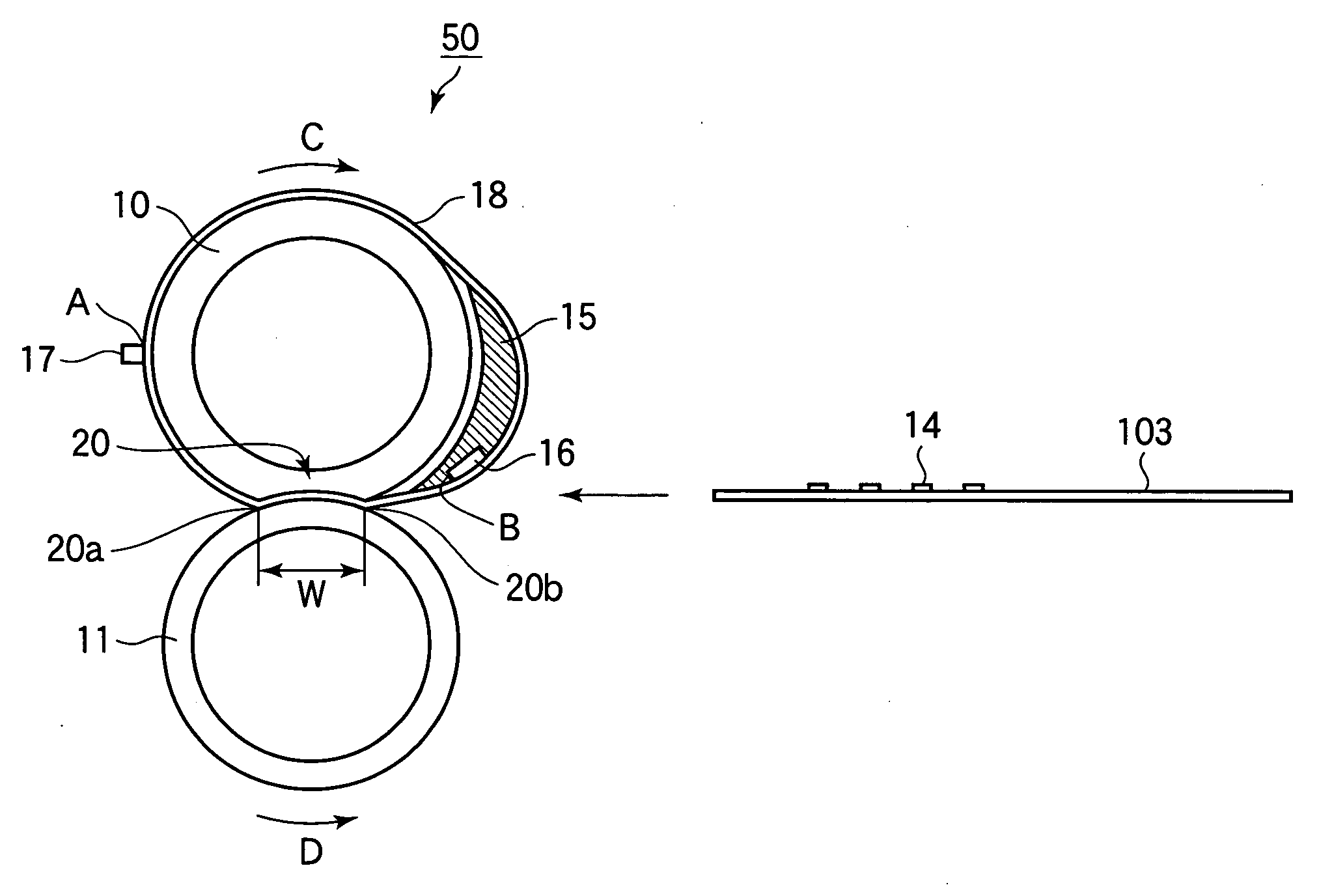

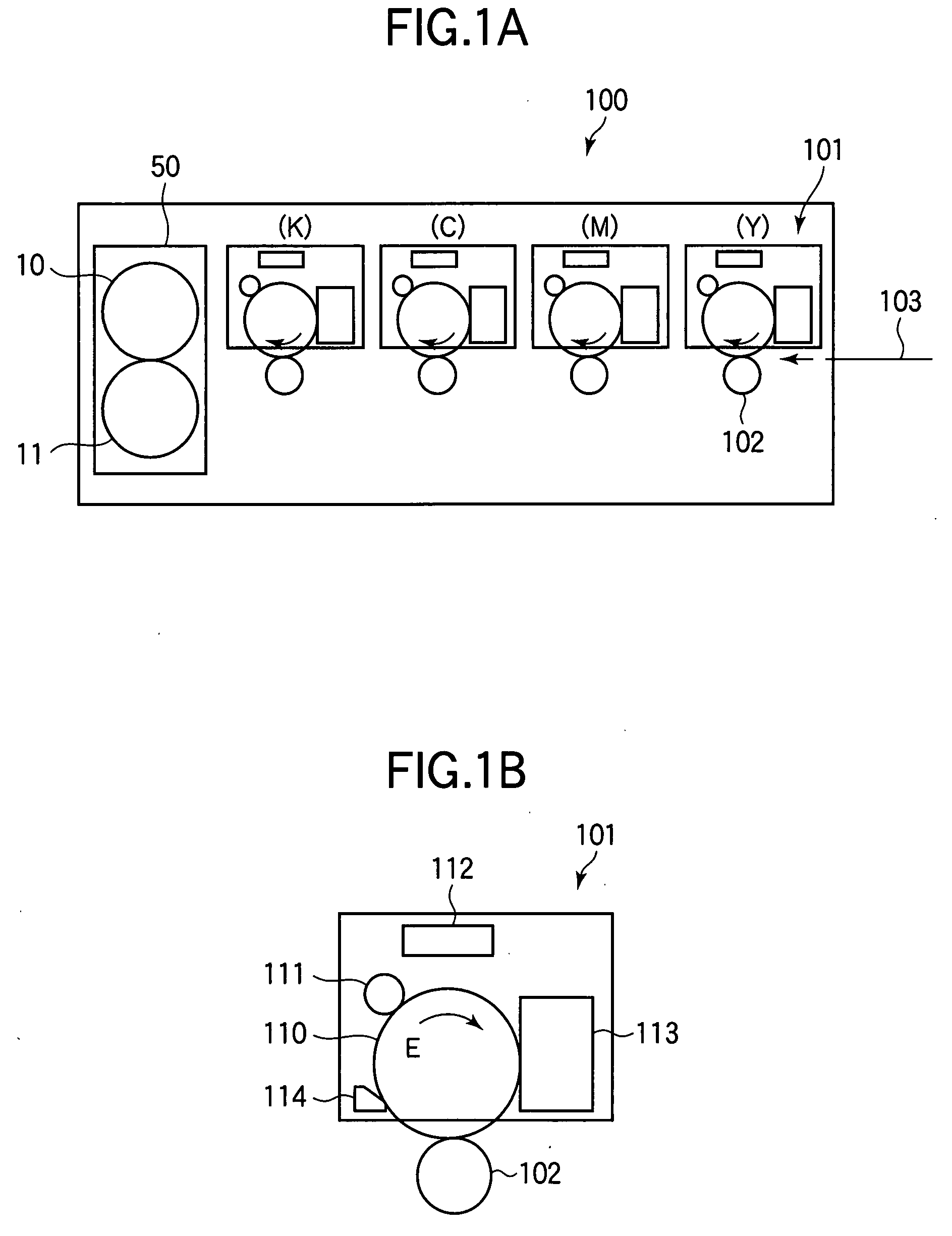

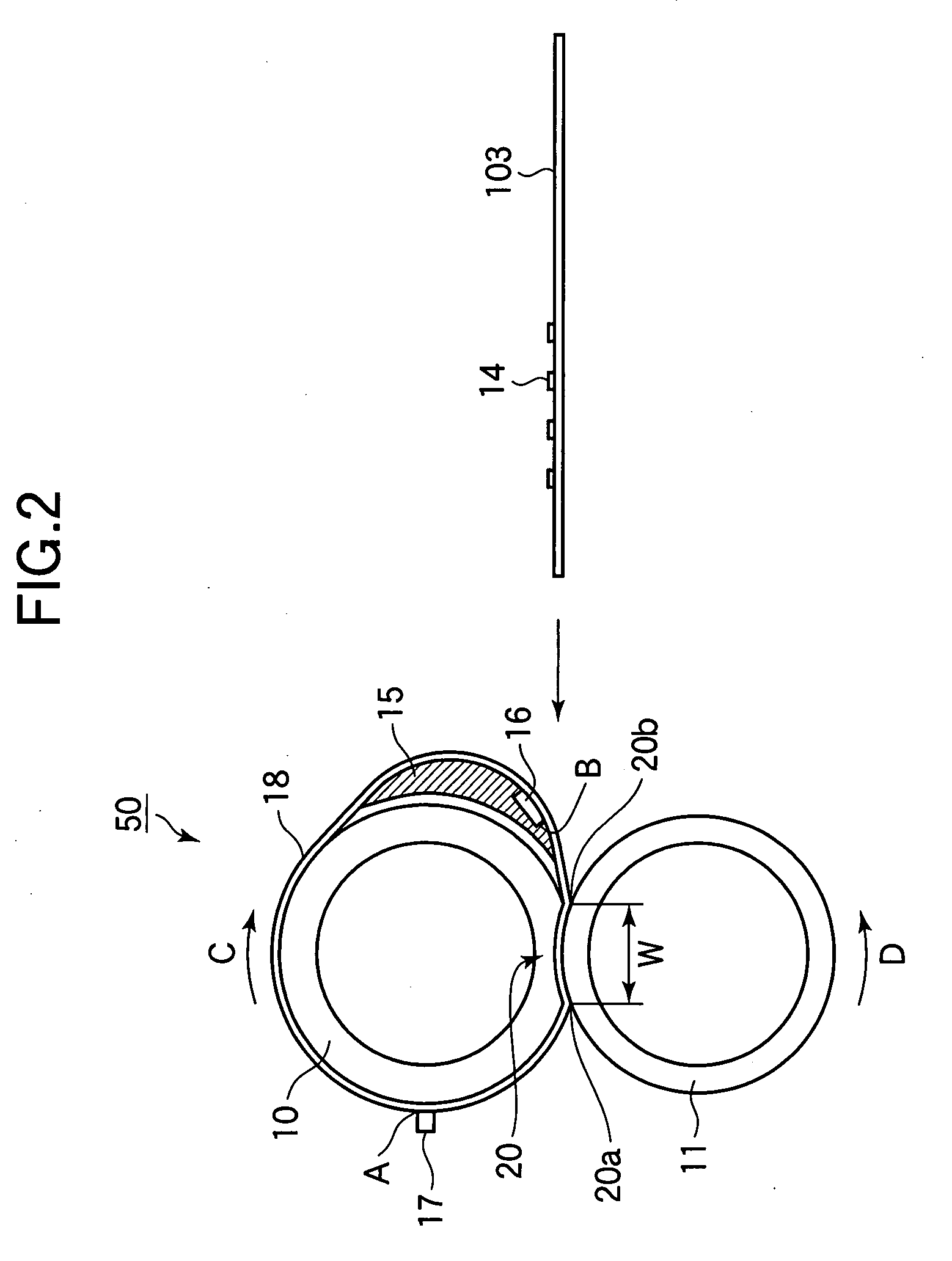

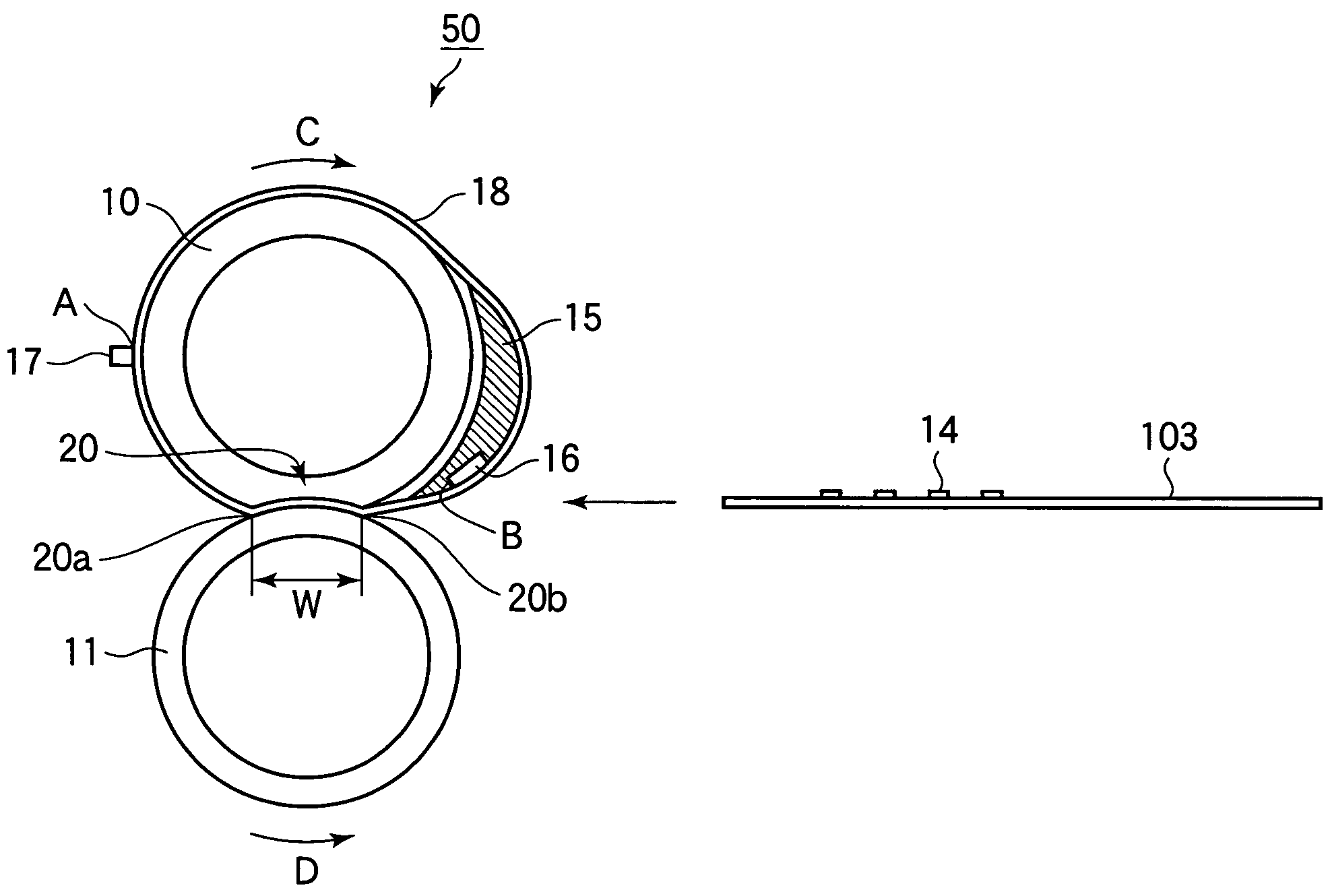

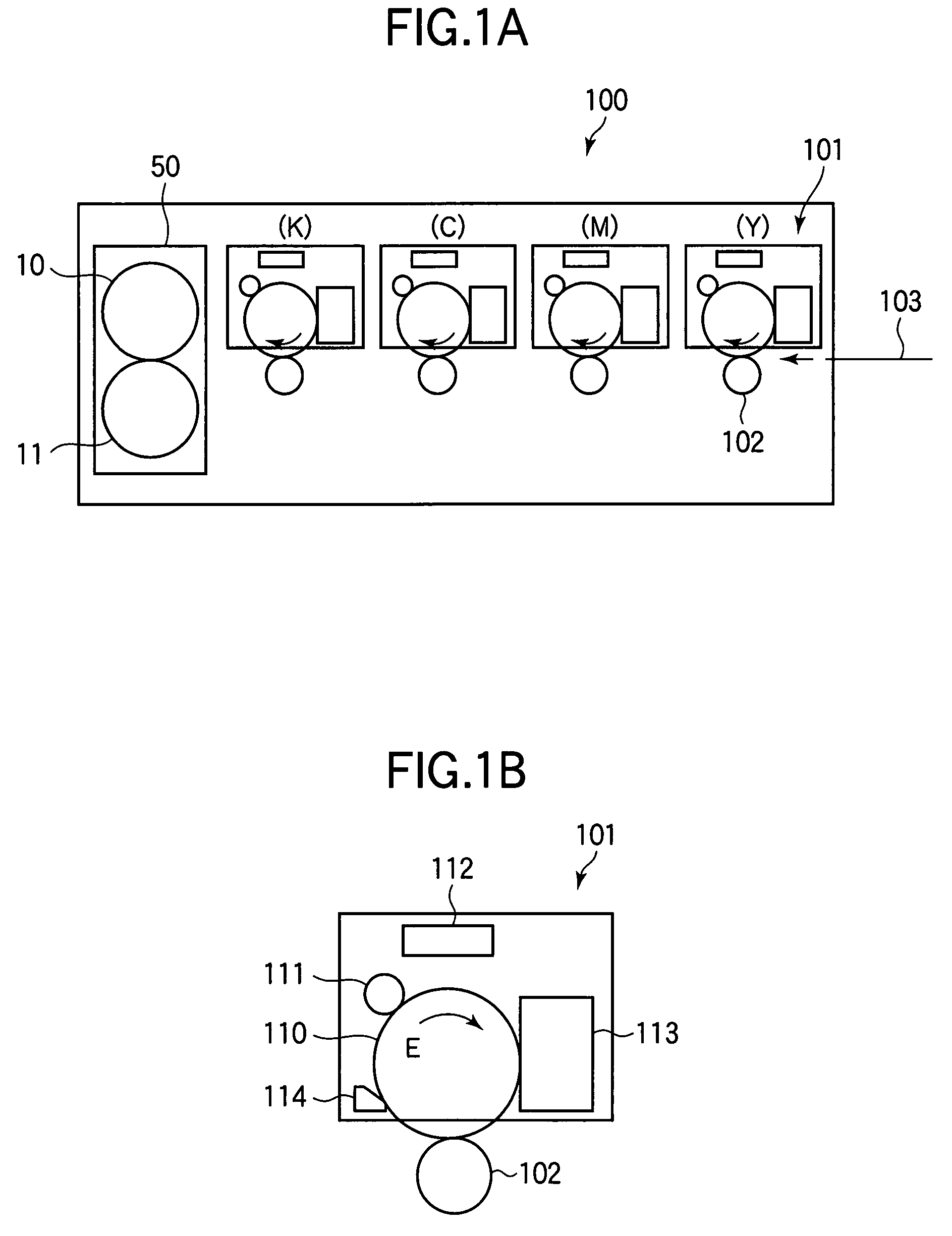

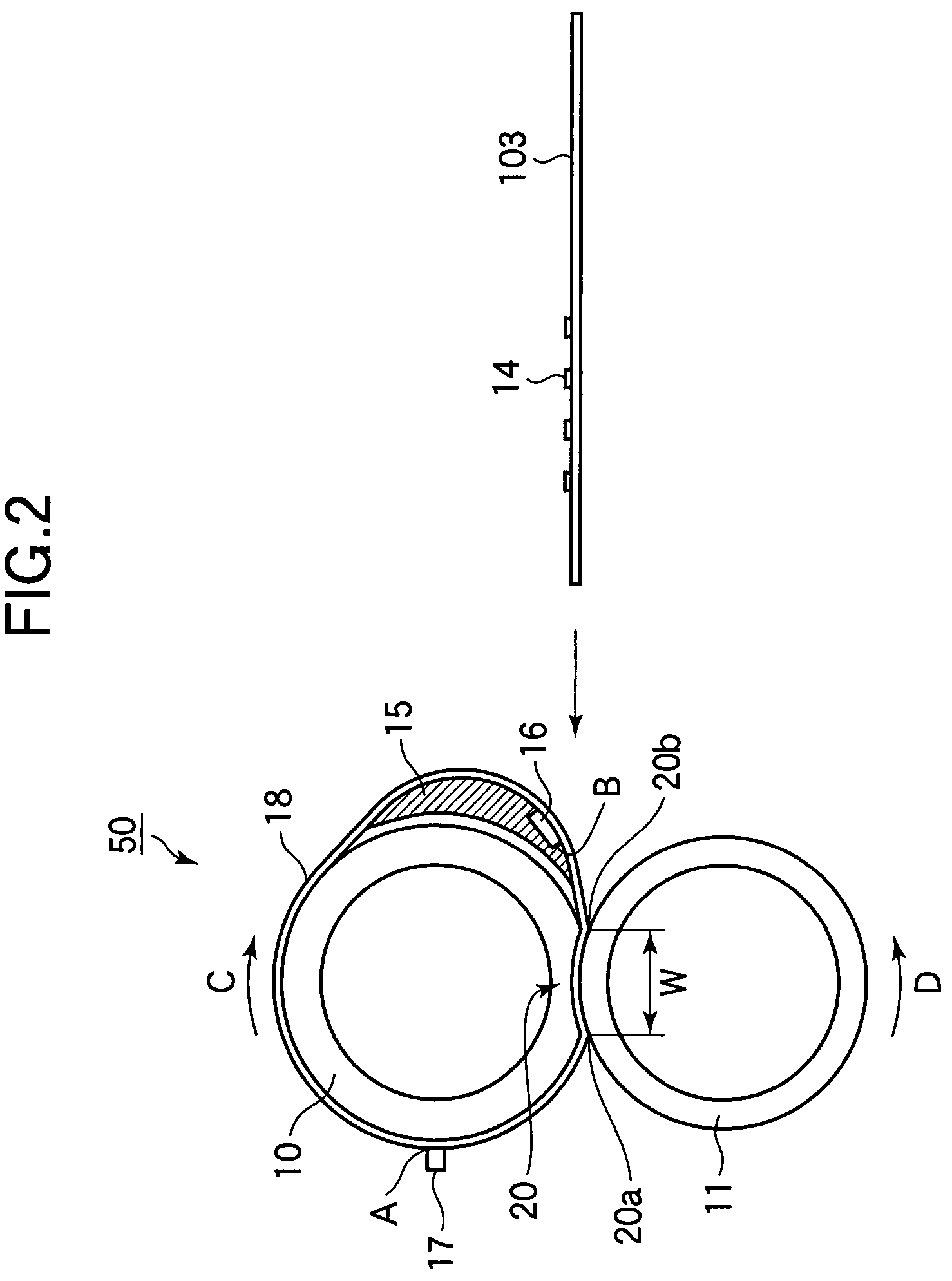

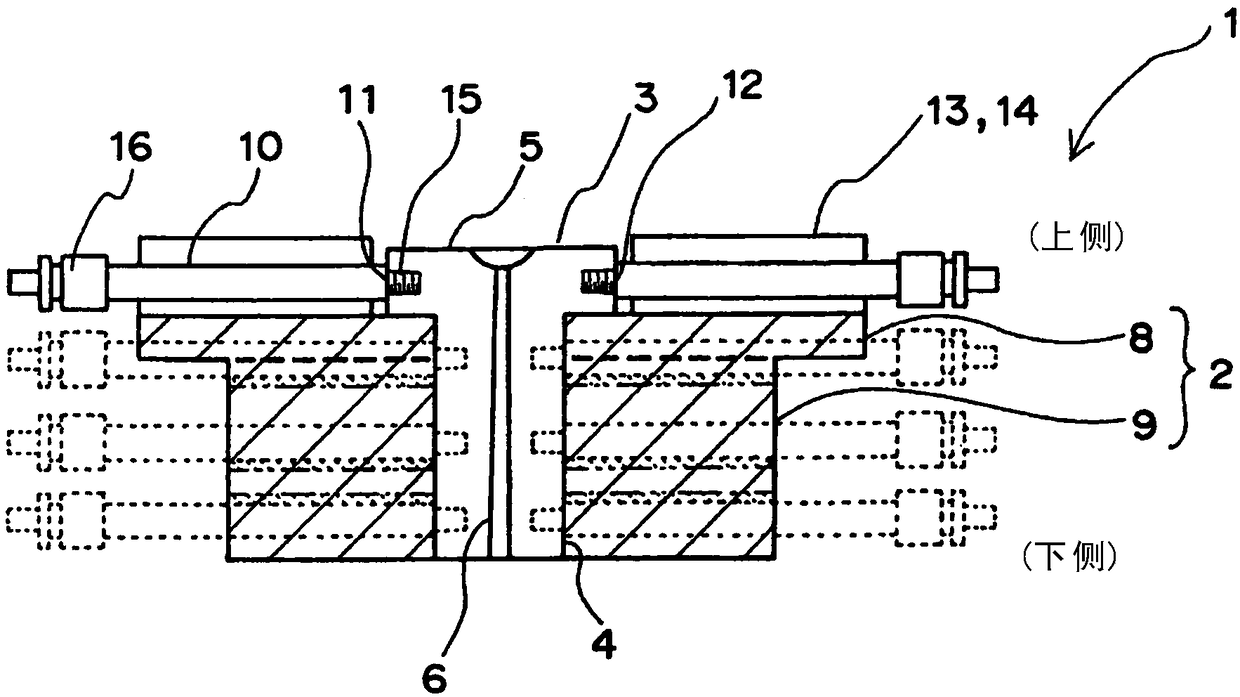

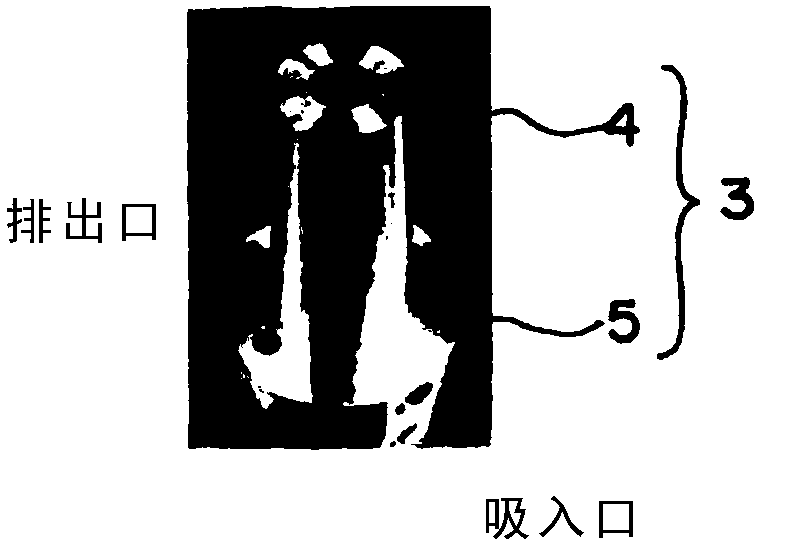

Fixing apparatus and image forming apparatus

InactiveUS20070280757A1Reliable temperature controlStable removalElectrographic process apparatusHeating elementEngineering

A fixing apparatus includes an endless belt, a fixing roller, a pressure roller, a sheet heating element, and a support. The fixing roller and support are positioned on the inside of the endless belt. The endless belt is entrained about the fixing roller and the support. The support supports the sheet heating element. The pressure roller is positioned on the outside of the endless belt. The pressure roller cooperates with the fixing roller to hold the endless belt between the fixing roller and the pressure roller in sandwiched relation such that a nip is formed between the endless belt and the pressure roller. The sheet heating element is in contact with the inside of the endless belt and heats the endless belt. The sheet heating element is disposed in an area outside of the nip.

Owner:OKI DATA CORP

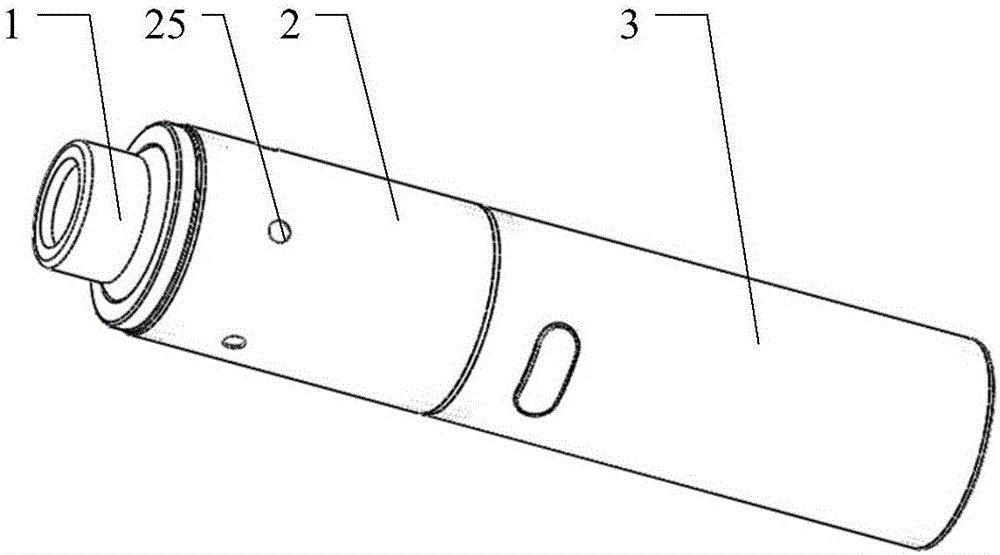

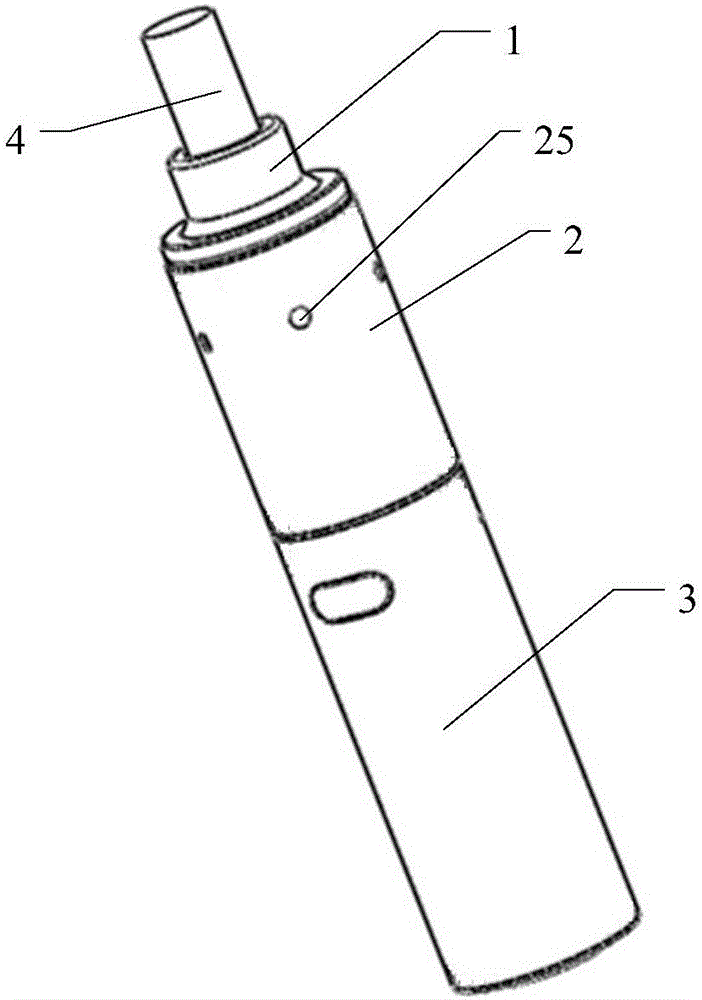

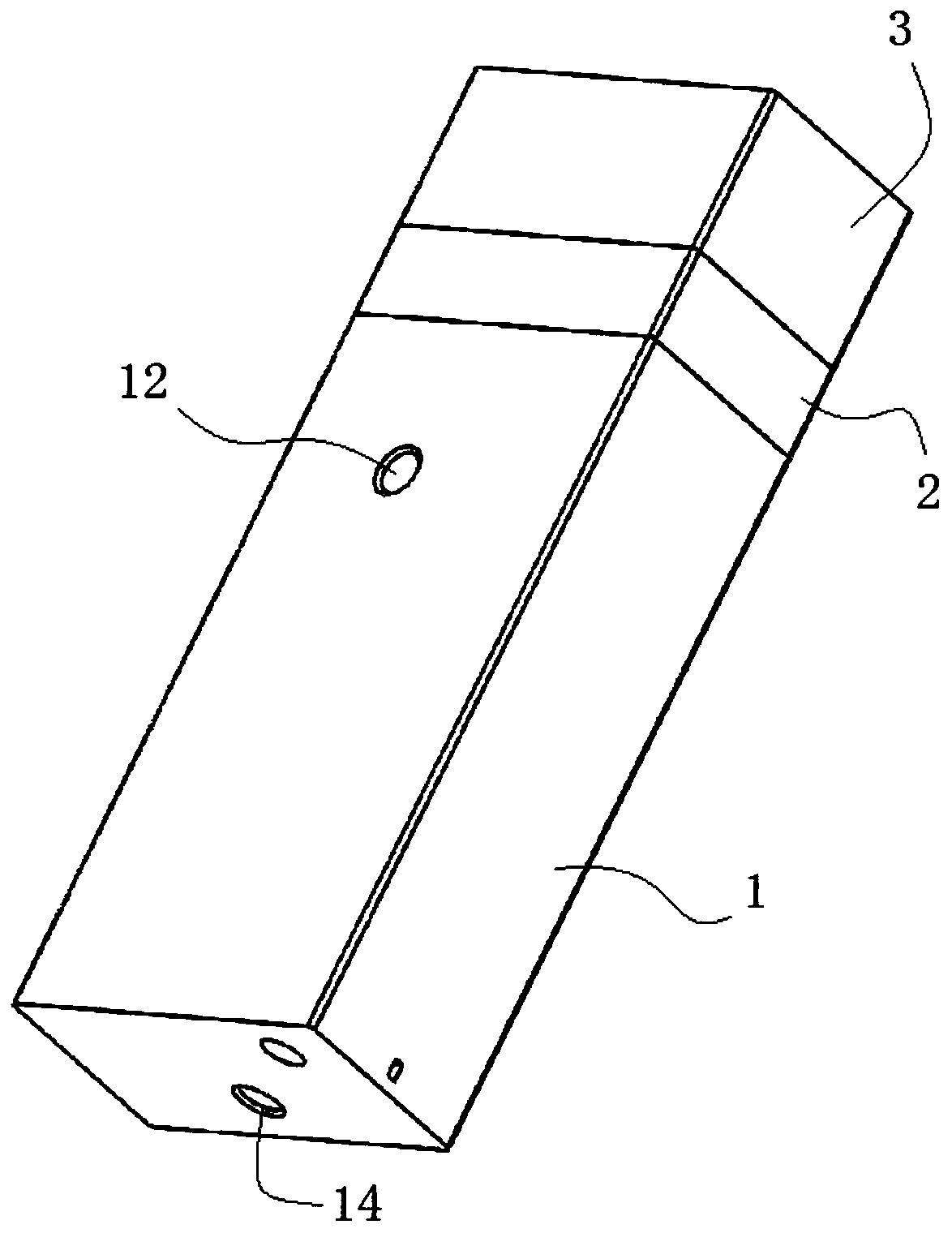

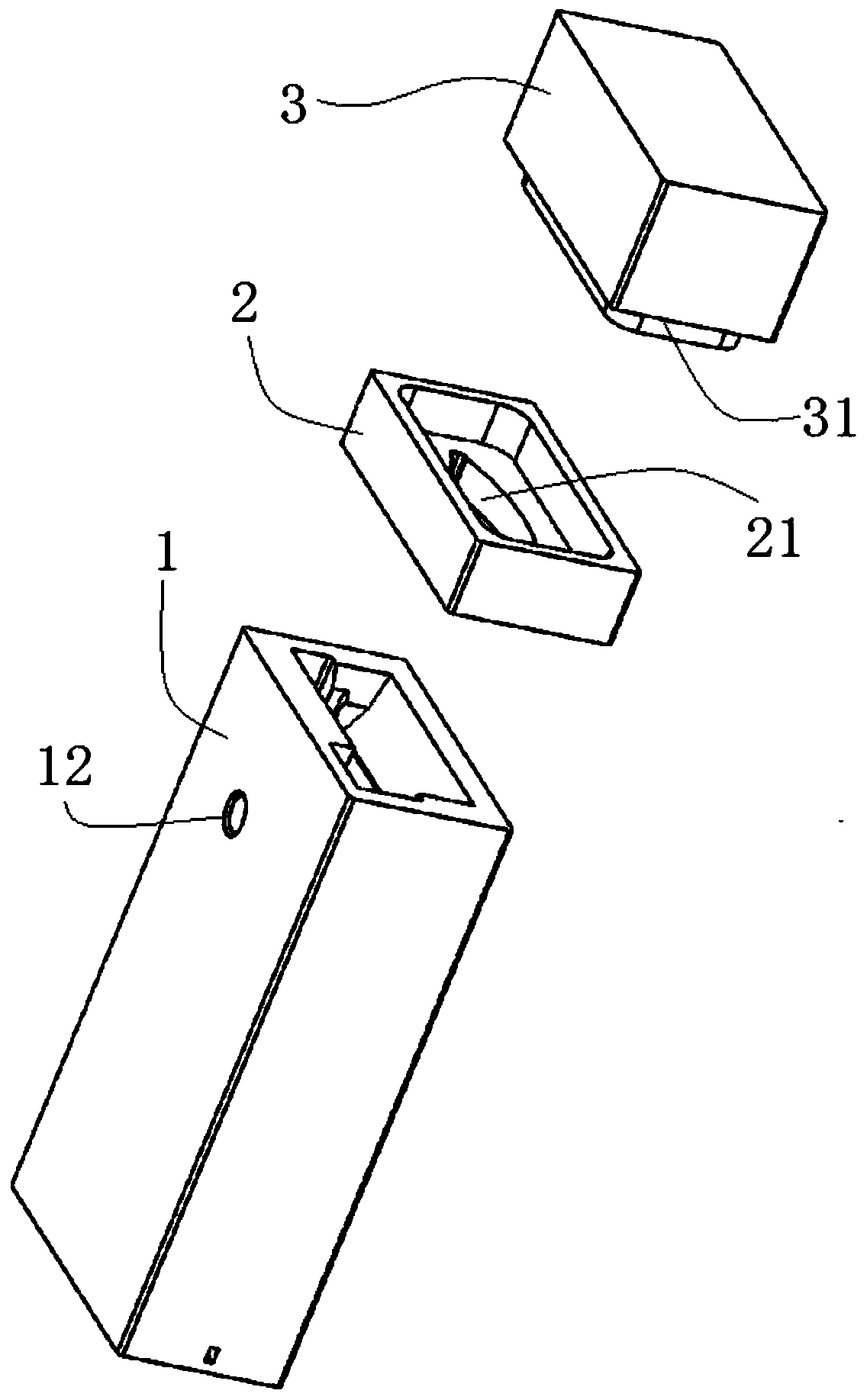

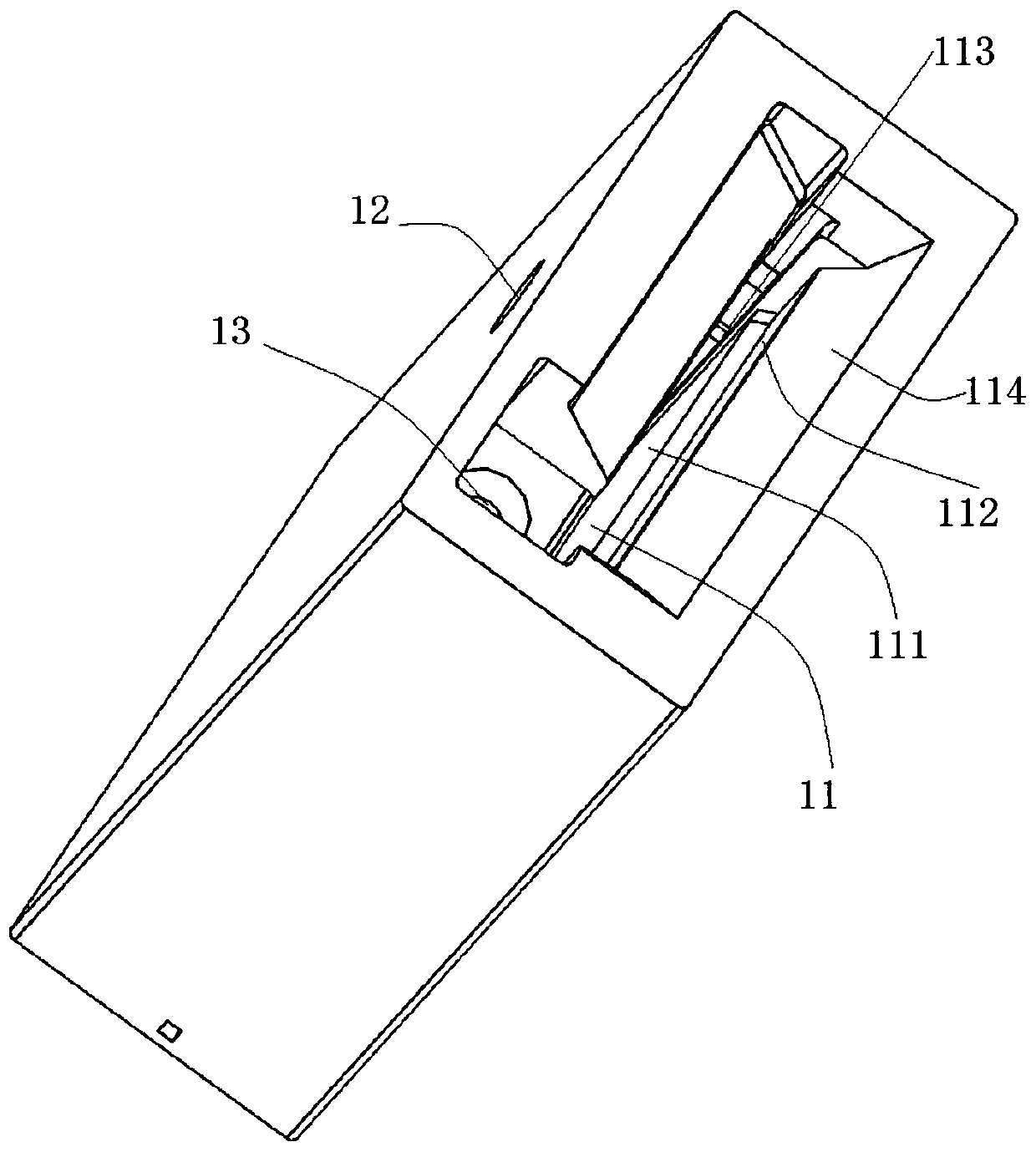

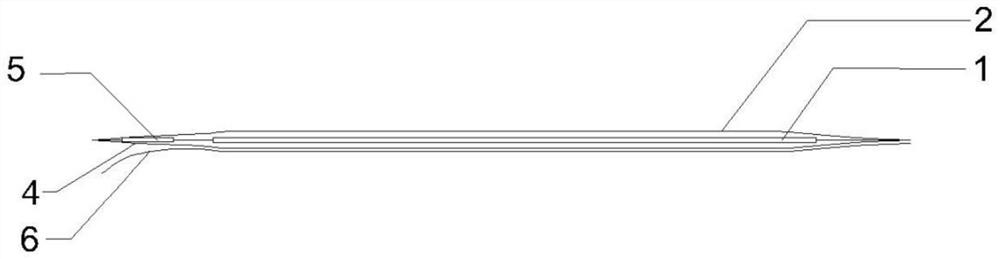

Flue-cured tobacco electronic cigarette

The invention provides a flue-cured tobacco electronic cigarette. The flue-cured tobacco electronic cigarette comprises a suction nozzle, an atomizing tube and a battery tube, the atomizing tube is internally provided with a cigarette liner and a cigarette liner bracket, the cigarette liner bracket is located at the bottom of the cigarette liner, and the middle of the cigarette liner is provided with a thermal conductive rod; the cigarette liner bracket is provided with a control circuit board and a heating component electrically connected to the control circuit board, and the heating component is connected to the thermal conductive rod; the battery tube is located below the atomizing tube, and positive and negative ends of the battery tube are electrically connected to the control circuit board respectively; the surface of the atomizing tube is provided with an air inlet hole, an air inlet gap is arranged between the cigarette liner and the cigarette liner bracket, and air flow entering from the air inlet hole enters the cigarette liner through the air inlet gap; the suction nozzle is locate above the atomizing tube; a cigarette is inserted into the cigarette liner from the suction nozzle, and the thermal conductive rod is inserted into the cigarette liner to conduct heating. According to the technical scheme, through the flue-cured tobacco electronic cigarette, the smoking effect and flavor are better; after the flue-cured tobacco electronic cigarette is used, the cigarette is pulled out directly, and the cigarette liner is clean internally and easy to wash.

Owner:SHENZHEN DORTEAM TECH LTD

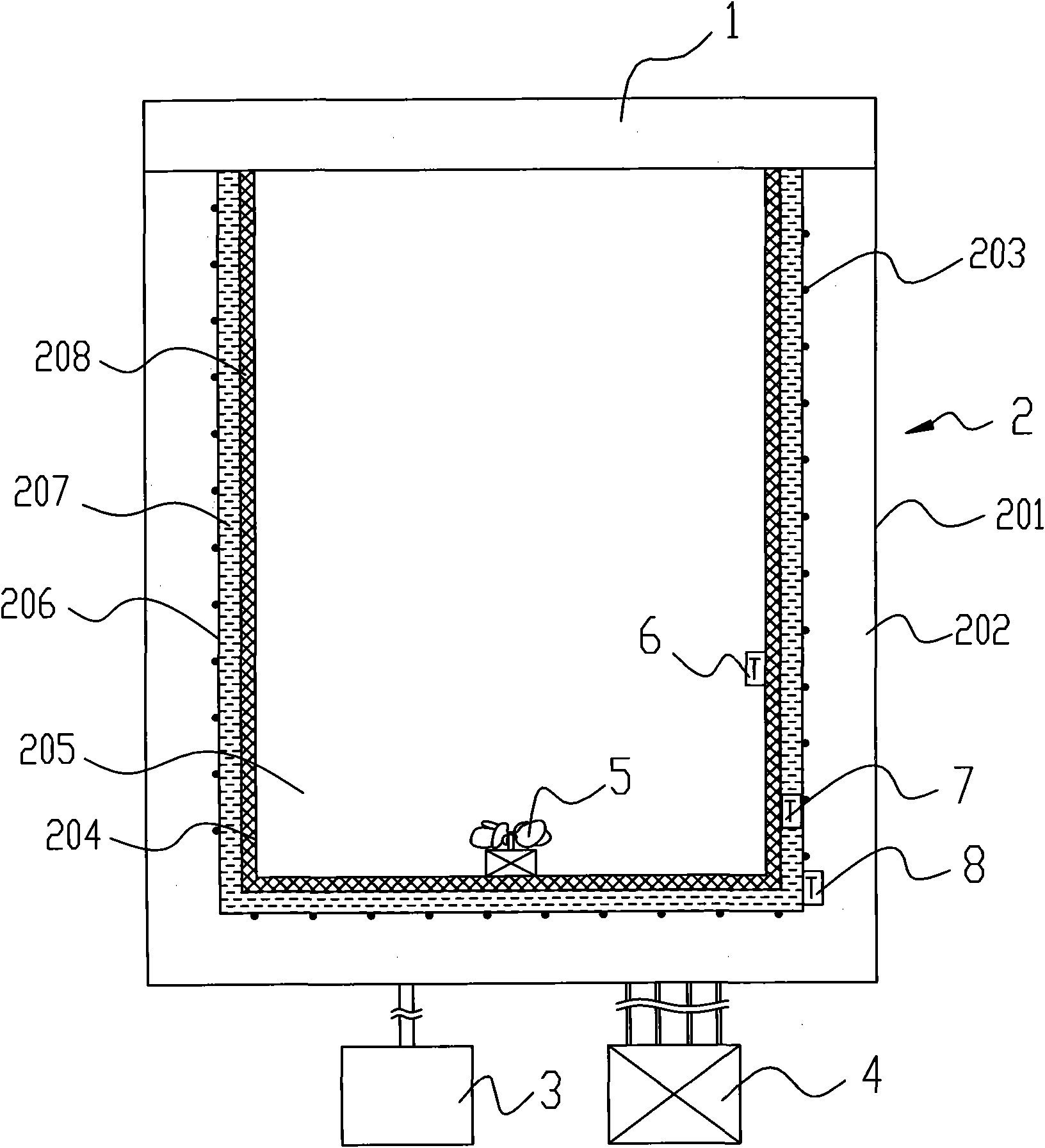

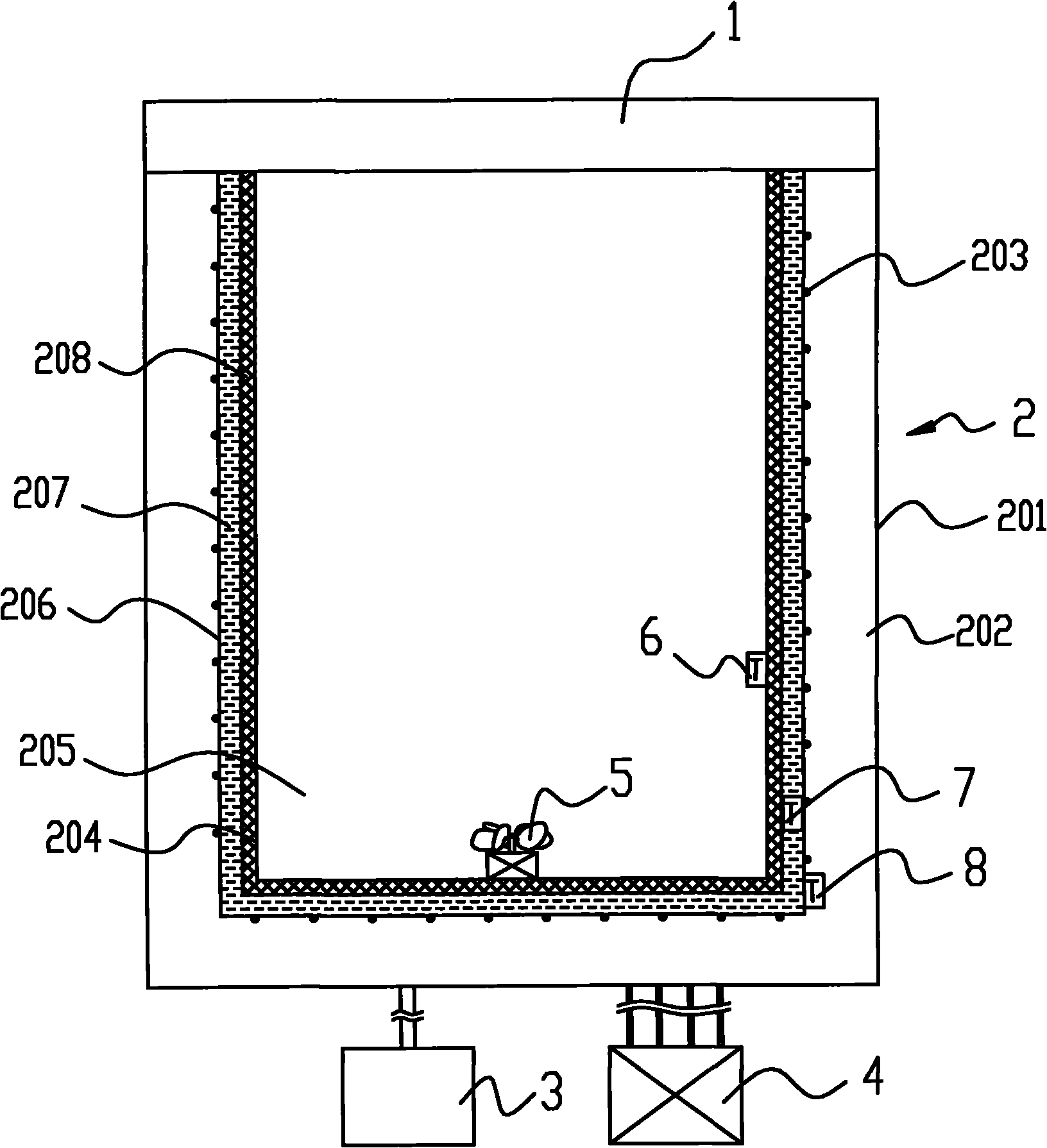

Novel thermotank

ActiveCN102161401AUniform temperatureImprove consistencyShock-sensitive articlesPlate heat exchangerHeat conducting

The invention discloses a novel thermotank. The novel thermotank comprises a door body, a tank body and a refrigerating and / or heating system and is characterized in that: a shell, an insulating layer, a heat exchanger, an inner container and a storage chamber formed by the inner container are arranged from outside to inside according to the cross section structure of the tank body; and a heat-conducting medium layer is arranged between the heat exchanger and the inner container. In the refrigerating or heating process, a heat-conducting medium absorbs cold or heat, and the whole heat-conducting medium layer transmits the cold or heat quickly until the temperature is uniform and then transmits the cold or heat to the whole inner container uniformly, so that the temperature of each part ofthe whole storage chamber is balanced and has high consistency, and the temperature is controlled more accurately and reliably.

Owner:AUCMA

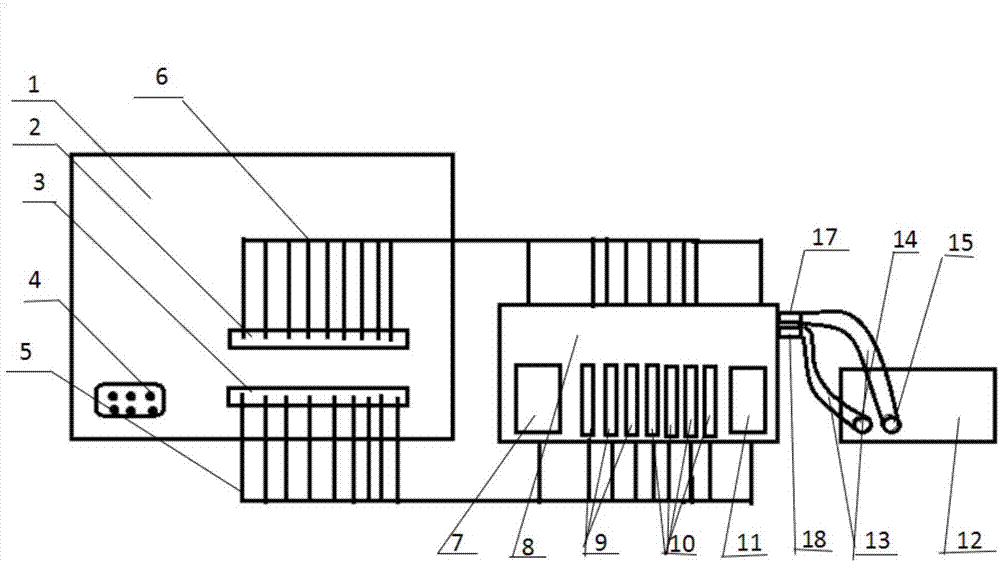

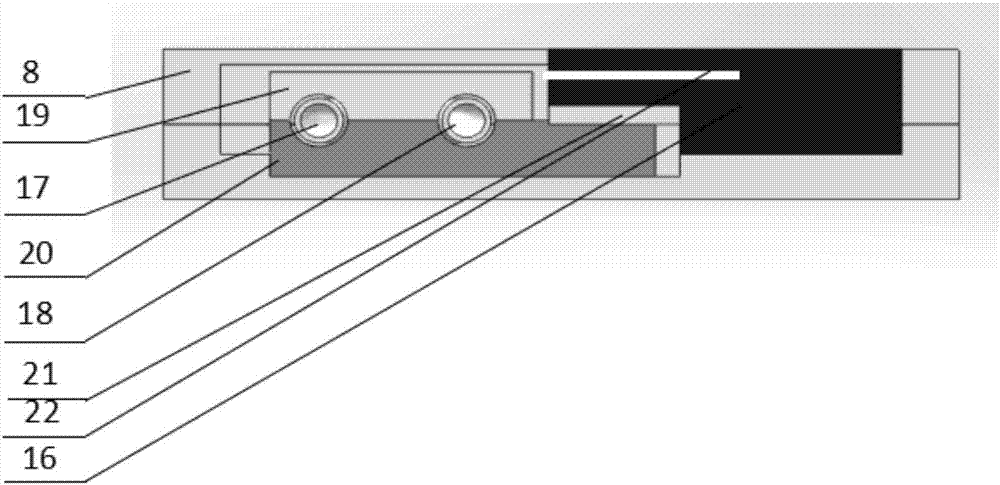

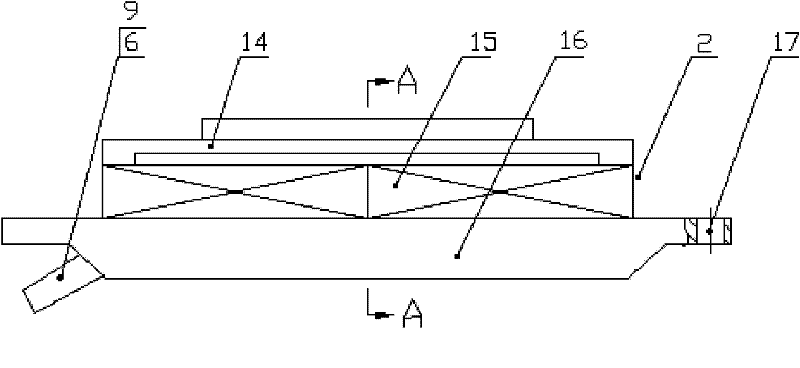

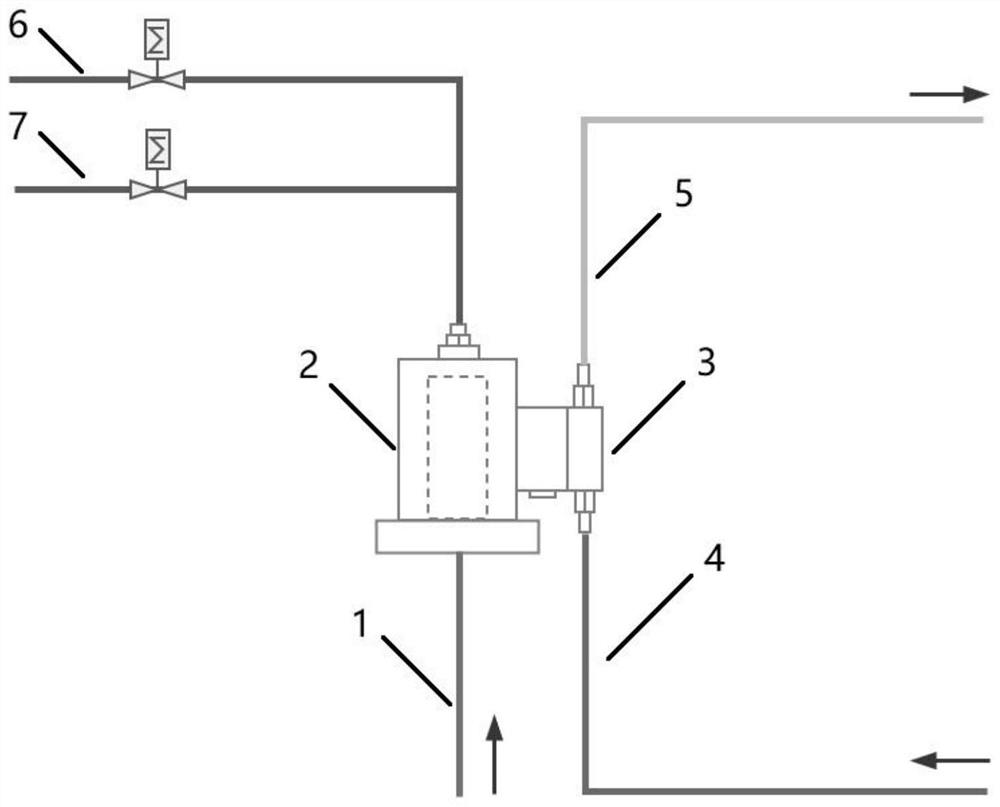

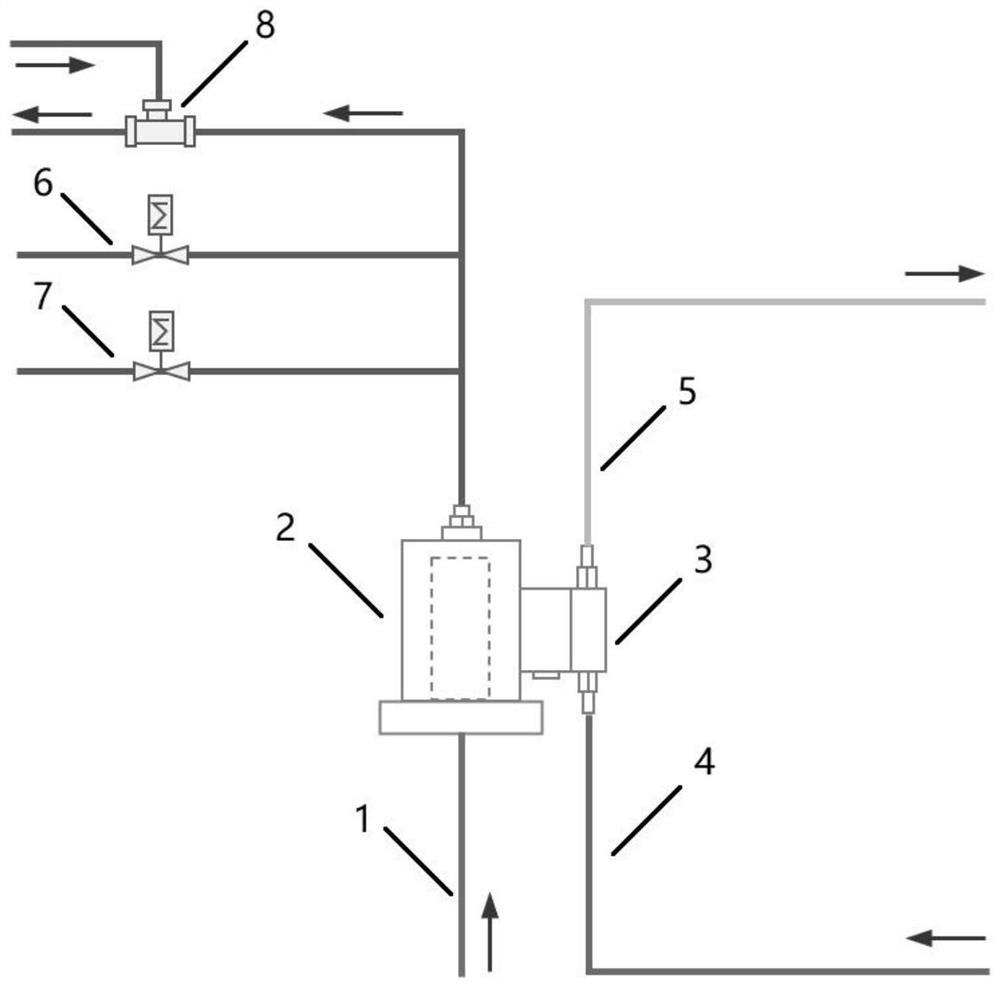

Sectional-type micro-fluidic chip temperature control apparatus

The invention discloses a temperature control platform for sectionally controlling a temperature of a micro-fluidic chip. The temperature control platform comprises a temperature control platform body, an intelligent temperature regulator and a constant-temperature circulator, wherein the temperature control platform body consists of a housing, a cool plate, a hot plate, a semiconductor refrigerating sheet with a cool surface facing upwards, a heater, a heat radiator and a metal conduit from the external to the internal, and the cool plate and the hot plate are provided with a temperature measurer. By utilizing the high-performance micro semiconductor refrigerating sheet and the ceramic heating sheet, the size of the sectional-type micro-fluidic chip temperature control apparatus is greatly reduced, and for the characteristic of the small area of the micro-fluidic chip, the practicability of the temperature control platform is improved; by adopting the commercial temperature controller Tempco TEC-220, according to the temperature data of the hot plate and the cool plate collected by a platinum electrode, the high precision automatic temperature control is realized by precisely controlling the operation and stopping of the semiconductor refrigerating sheet and the ceramic heating sheet; and by adopting the HX-1050 constant-temperature circulator, the temperature of the circulating liquid is kept at 60 DEG C below zero to 50 DEG C, the heat radiation requirement of the apparatus can be met, the experiment energy consumption can be reduced, the application cost is decreased, and the temperature control platform is suitable for realizing experiments such as biological PCR, liquid drop and capsule solidification and melting, crystal phase changing, material synthesis by controlling temperature in the micro-fluidic chip.

Owner:GUANGDONG UNIV OF TECH +1

Rapid constant temperature high definition dyeing structural unit and high definition dyeing method

PendingCN110286022AInconvenient to realizeAvoid inconveniencePreparing sample for investigationEngineeringMechanical engineering

The present invention relates to a rapid constant temperature high definition dyeing structural unit and a high definition dyeing method. The rapid constant temperature high definition dyeing structural unit comprises a reaction chamber body, wherein the reaction chamber body is provided with a dyeing chamber; distance between front sidewall and rear sidewall of the dyeing chamber is greater than thickness of a slide, left side wall and right side wall of the dyeing chamber are provided with a slide guide groove respectively, bottom of the reaction chamber body is provided with a liquid inlet and outlet hole, the liquid inlet and outlet hole is connected to a liquid inlet and outlet pipe, alternatively, bottom of the reaction chamber body is provided with a liquid outlet hole, one side wall of the reaction chamber body is provided with a liquid inlet hole, the liquid outlet hole is used to connect with the liquid outlet pipe, and the liquid inlet hole is used to connect with the liquid inlet pipe; and the side wall of the reaction chamber body is provided with a controllable constant temperature heating module. The method uses a controllable constant temperature heating module to directly heat the reaction chamber body, thereby overcoming shortcomings of the existing air heating or reagent heating. In addition, when the slide is inserted, the method does not need to distinguish front side and back side, and has convenient operation.

Owner:ZHENGZHOU ZHONGPU MEDICAL INSTR CO LTD

Fixing apparatus and image forming apparatus

InactiveUS7664449B2Reliable temperature controlStable removalElectrographic process apparatusEngineeringHeating element

A fixing apparatus includes an endless belt, a fixing roller, a pressure roller, a sheet heating element, and a support. The fixing roller and support are positioned on the inside of the endless belt. The endless belt is entrained about the fixing roller and the support. The support supports the sheet heating element. The pressure roller is positioned on the outside of the endless belt. The pressure roller cooperates with the fixing roller to hold the endless belt between the fixing roller and the pressure roller in sandwiched relation such that a nip is formed between the endless belt and the pressure roller. The sheet heating element is in contact with the inside of the endless belt and heats the endless belt. The sheet heating element is disposed in an area outside of the nip.

Owner:OKI DATA CORP

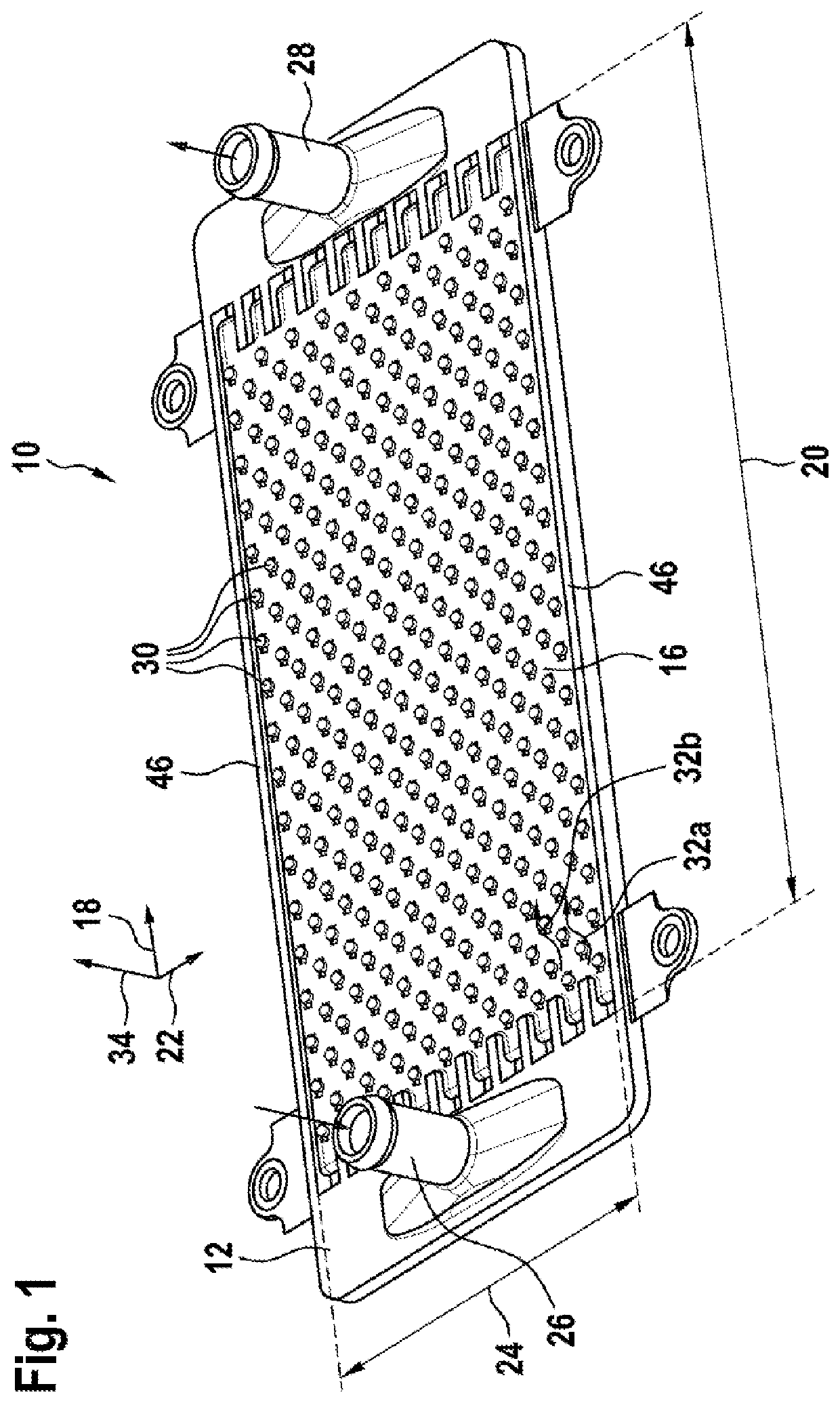

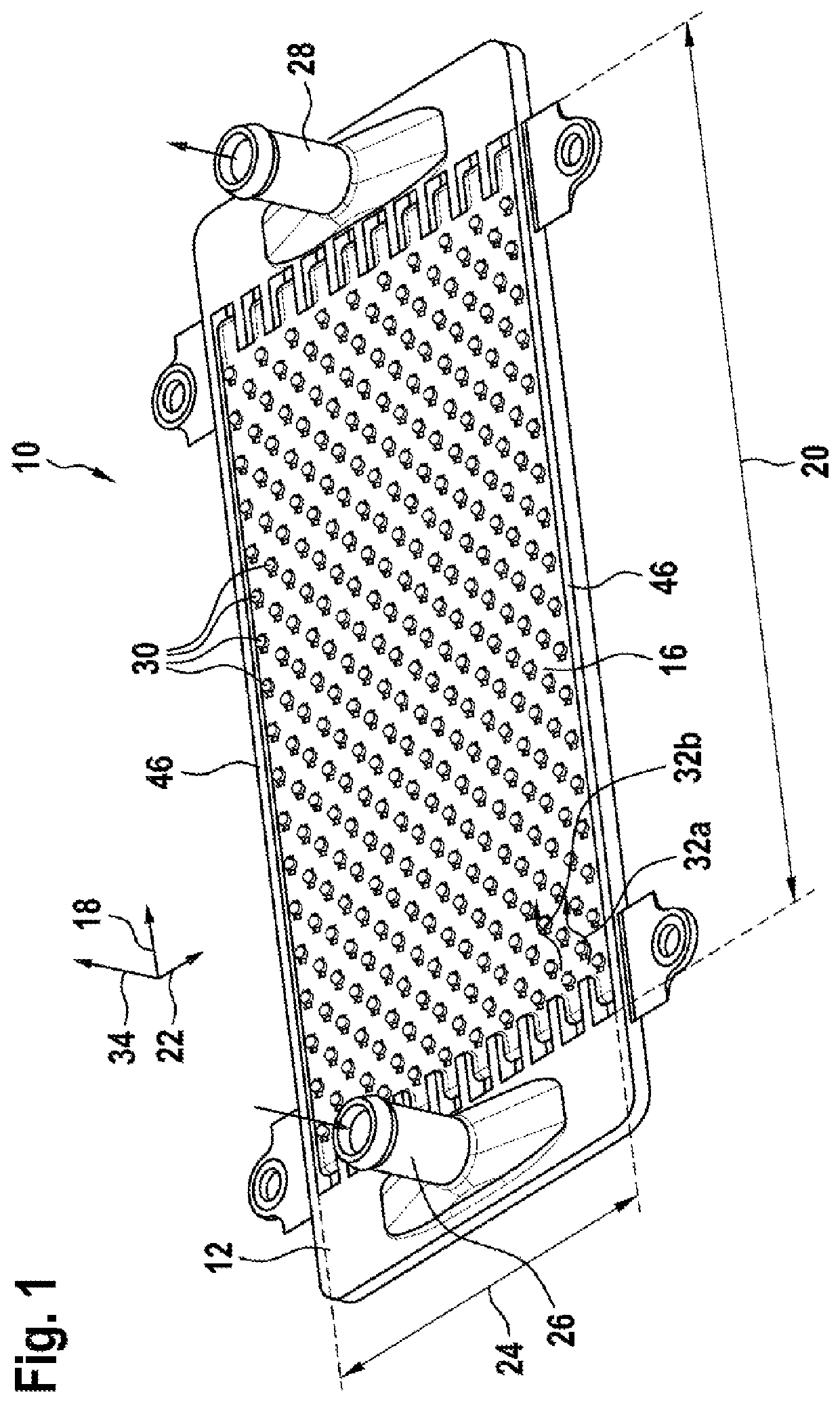

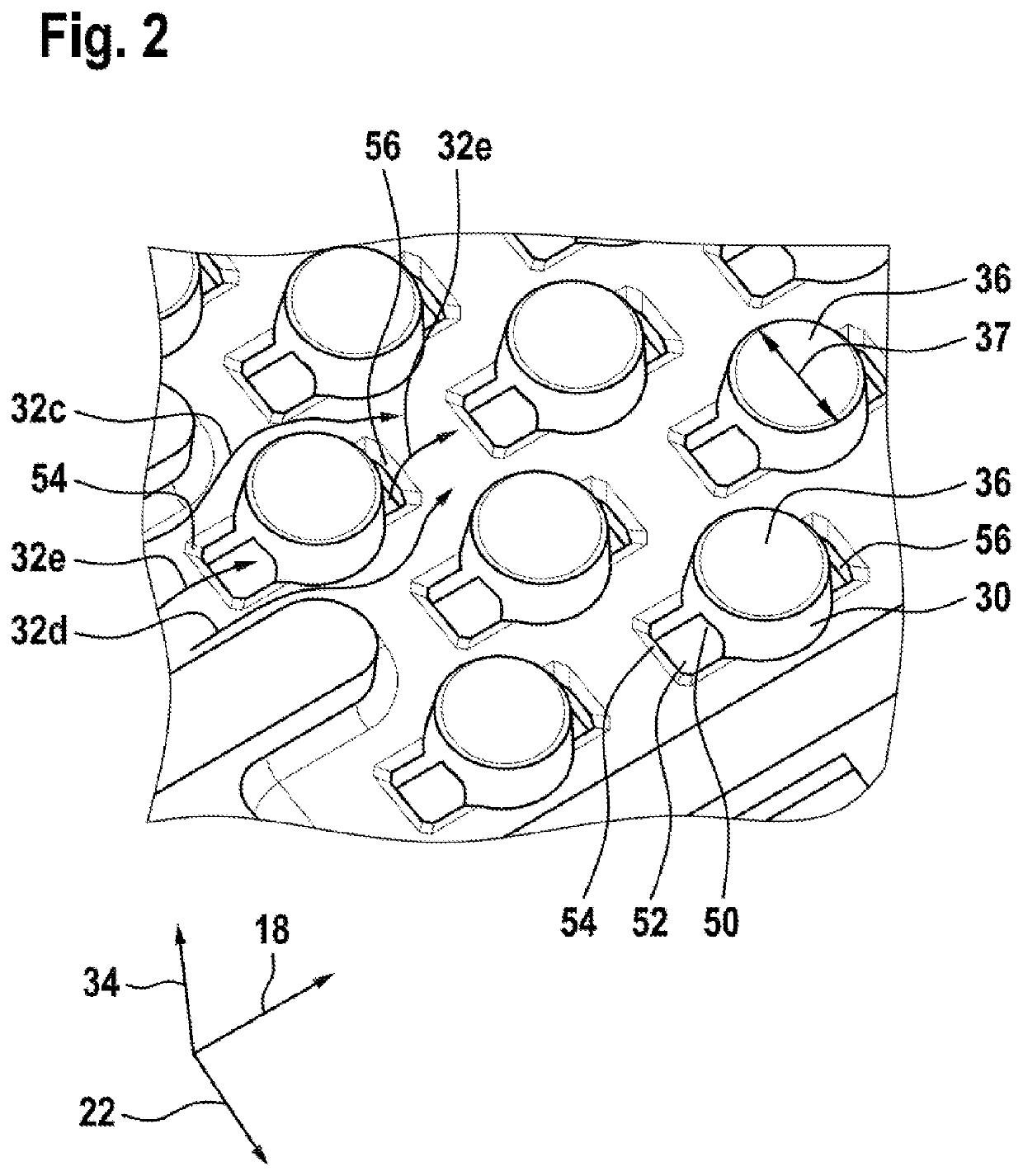

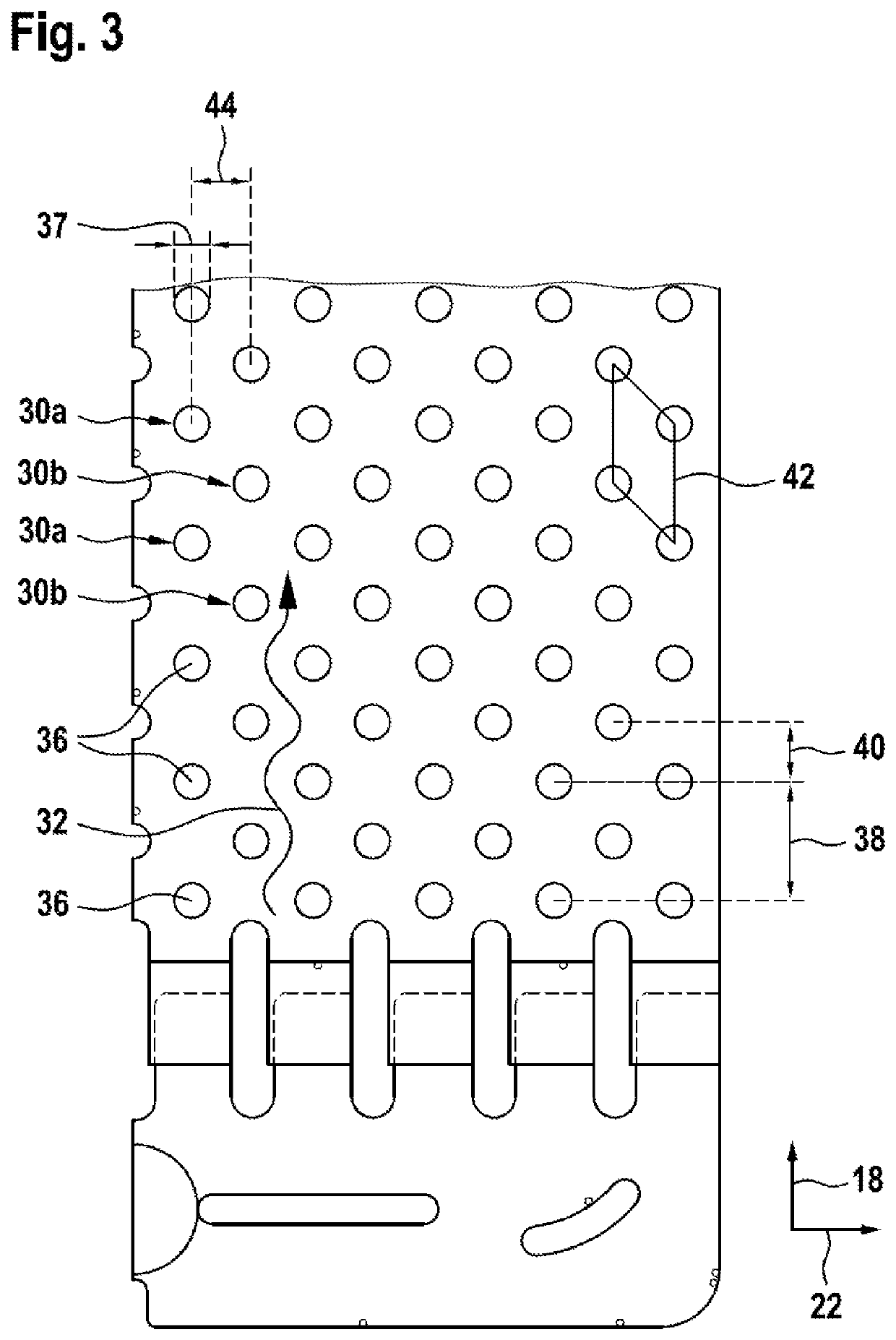

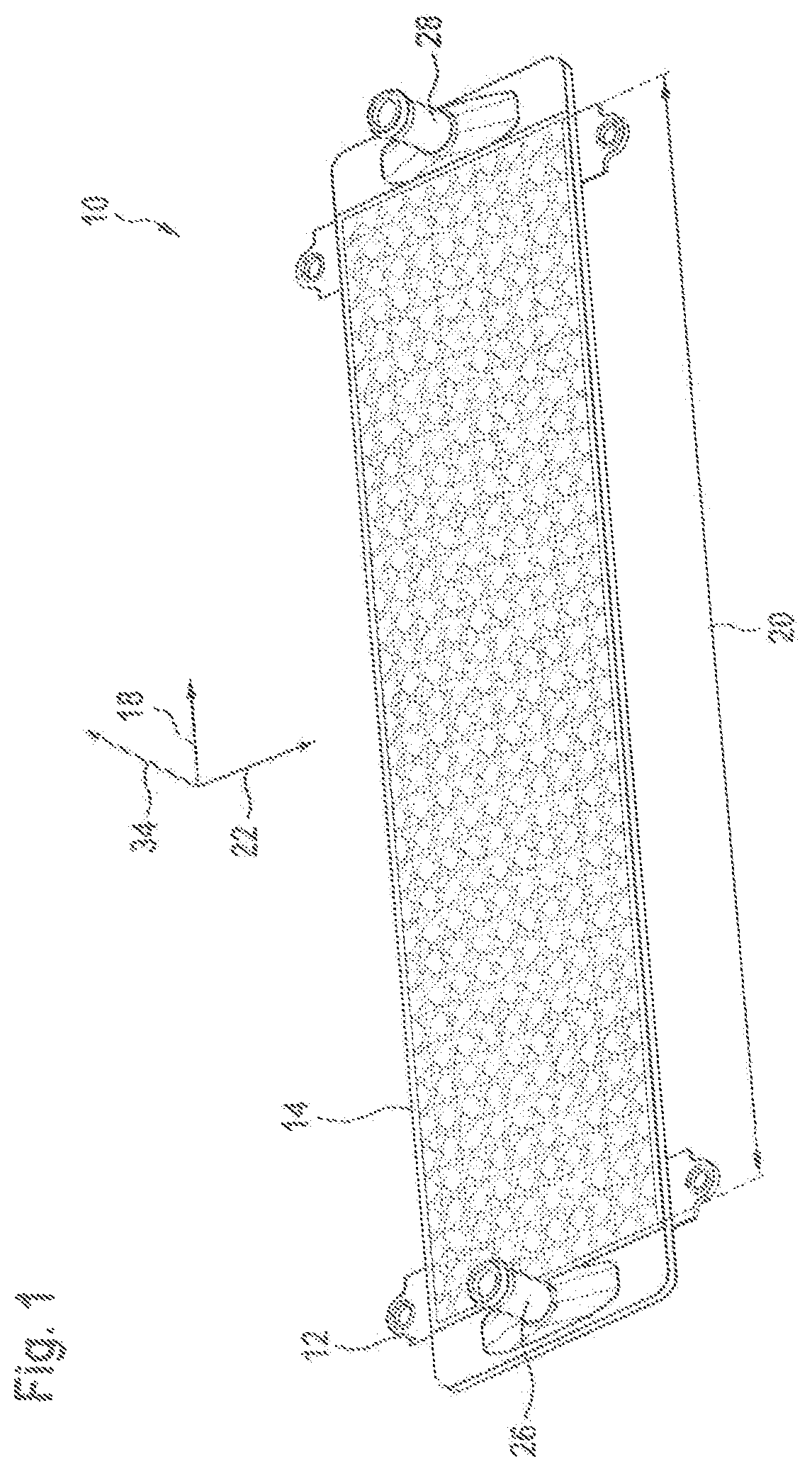

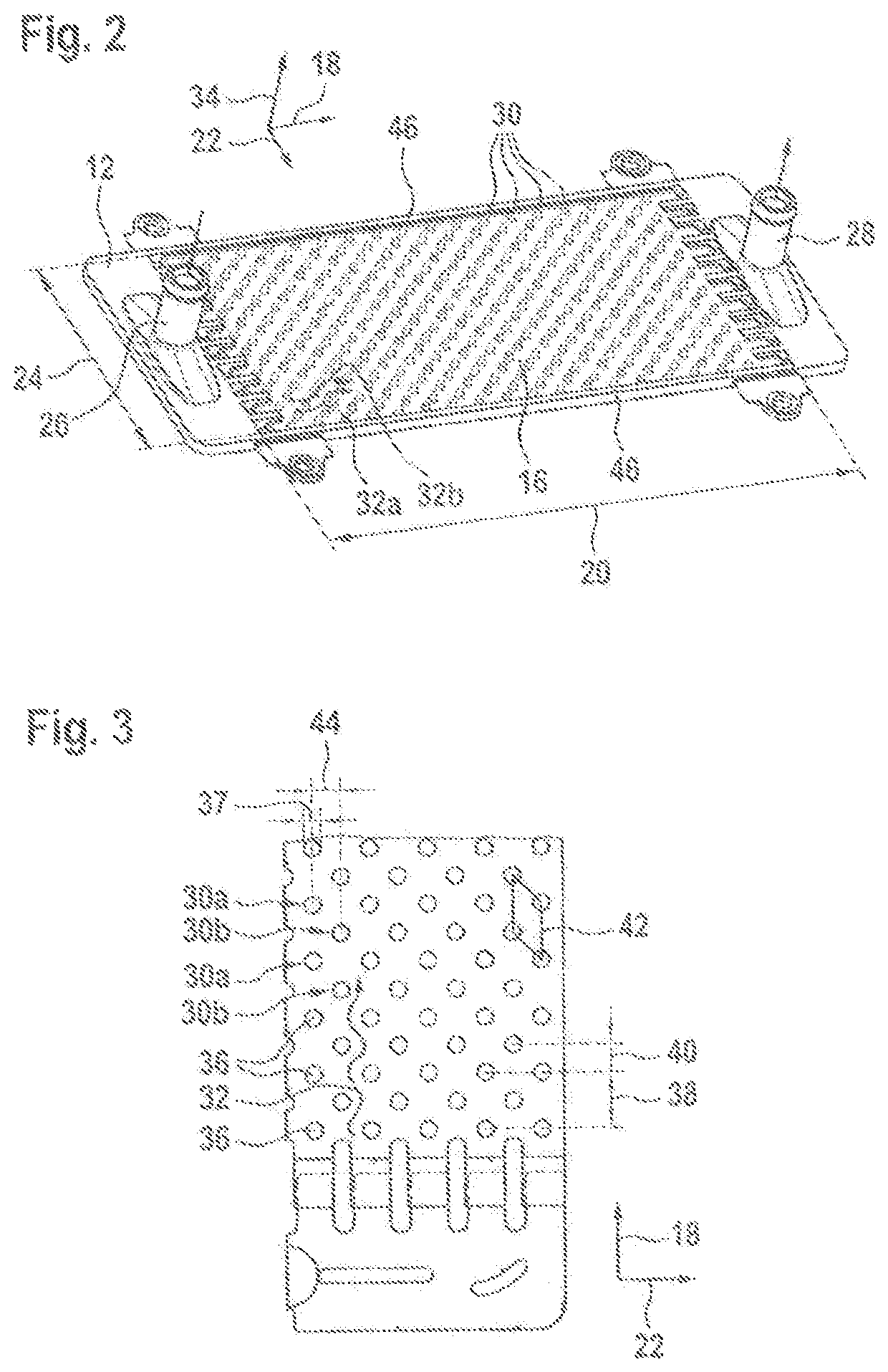

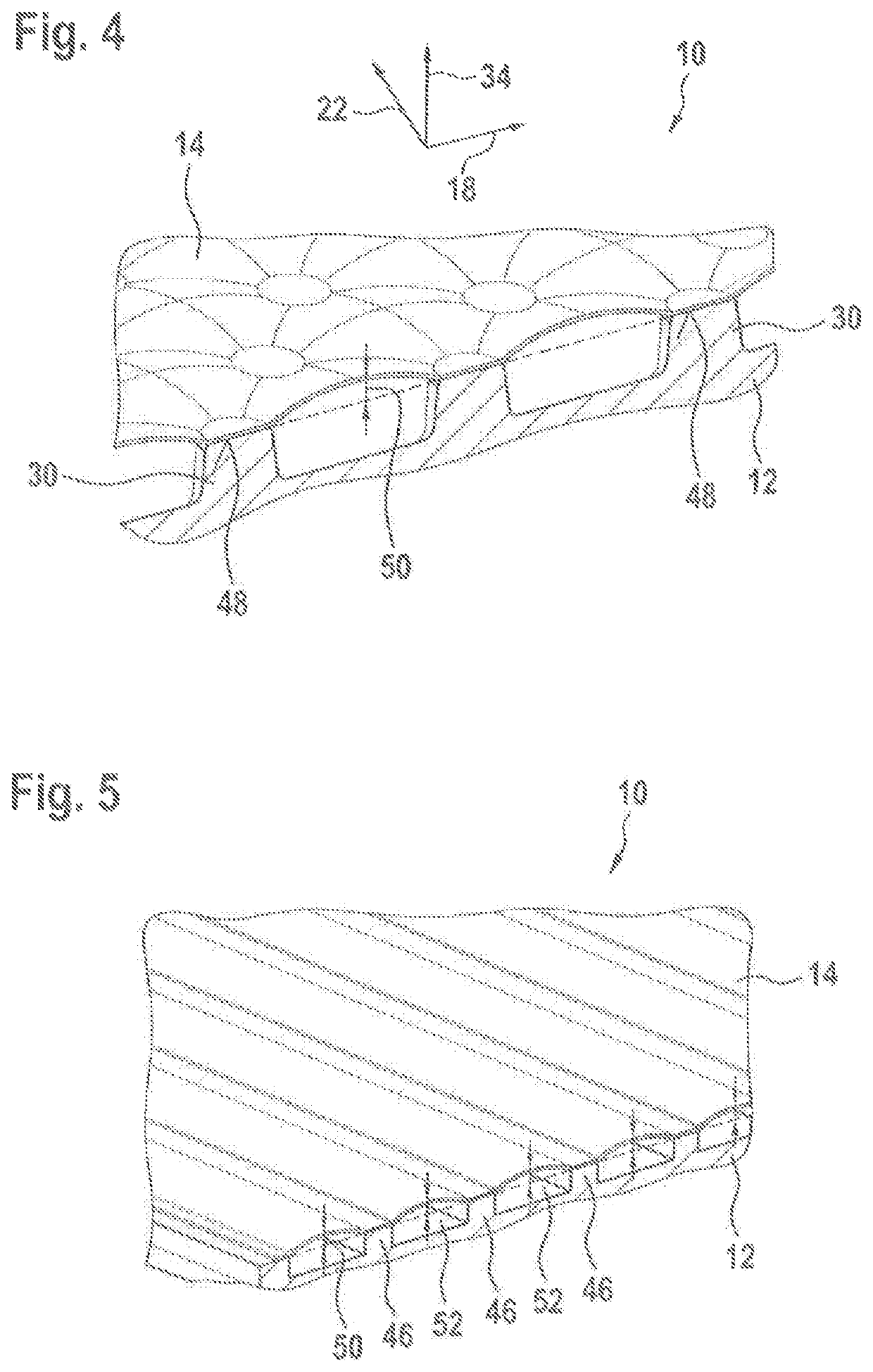

Cooling plate for the temperature control of at least one battery cell and a battery system

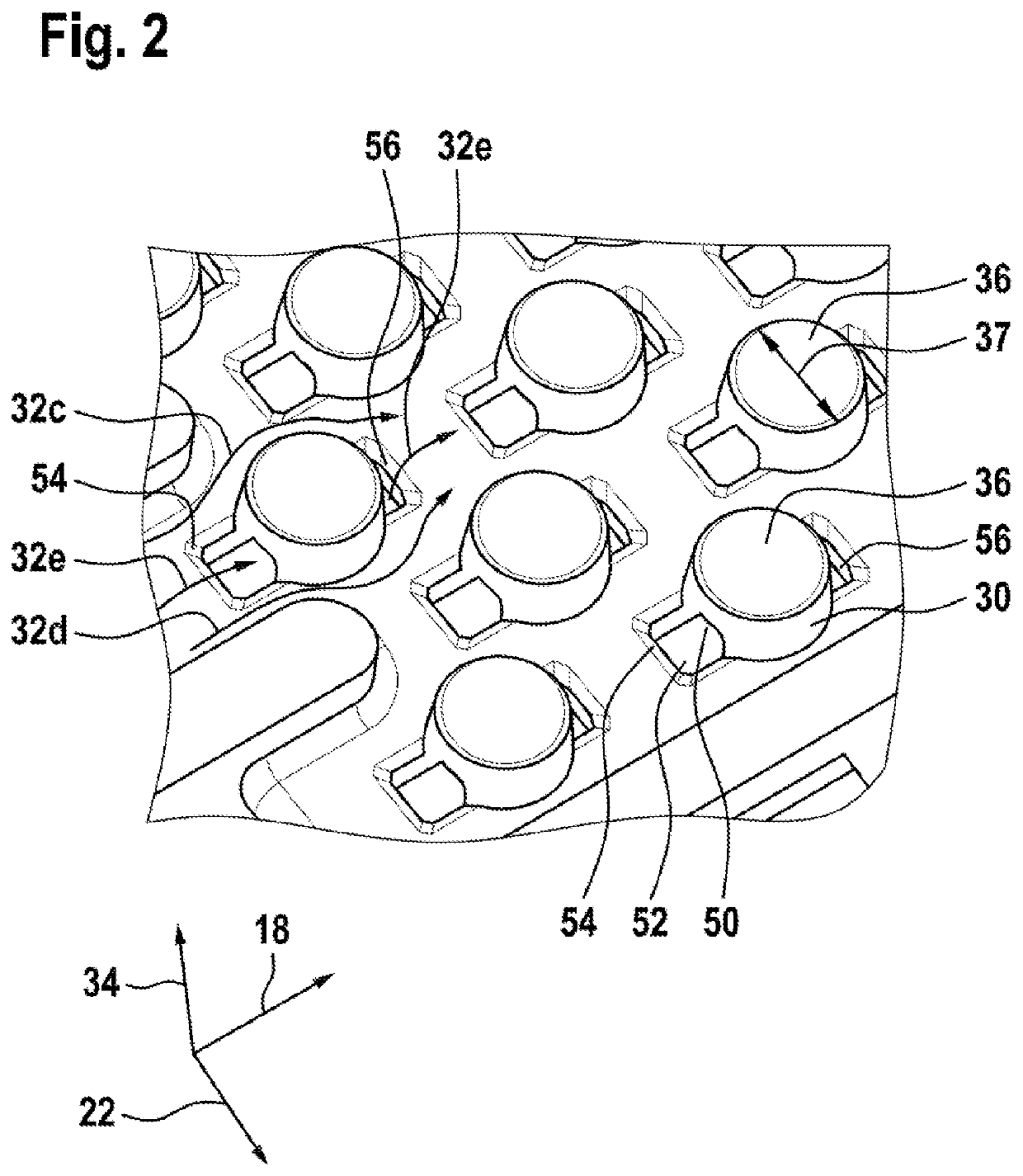

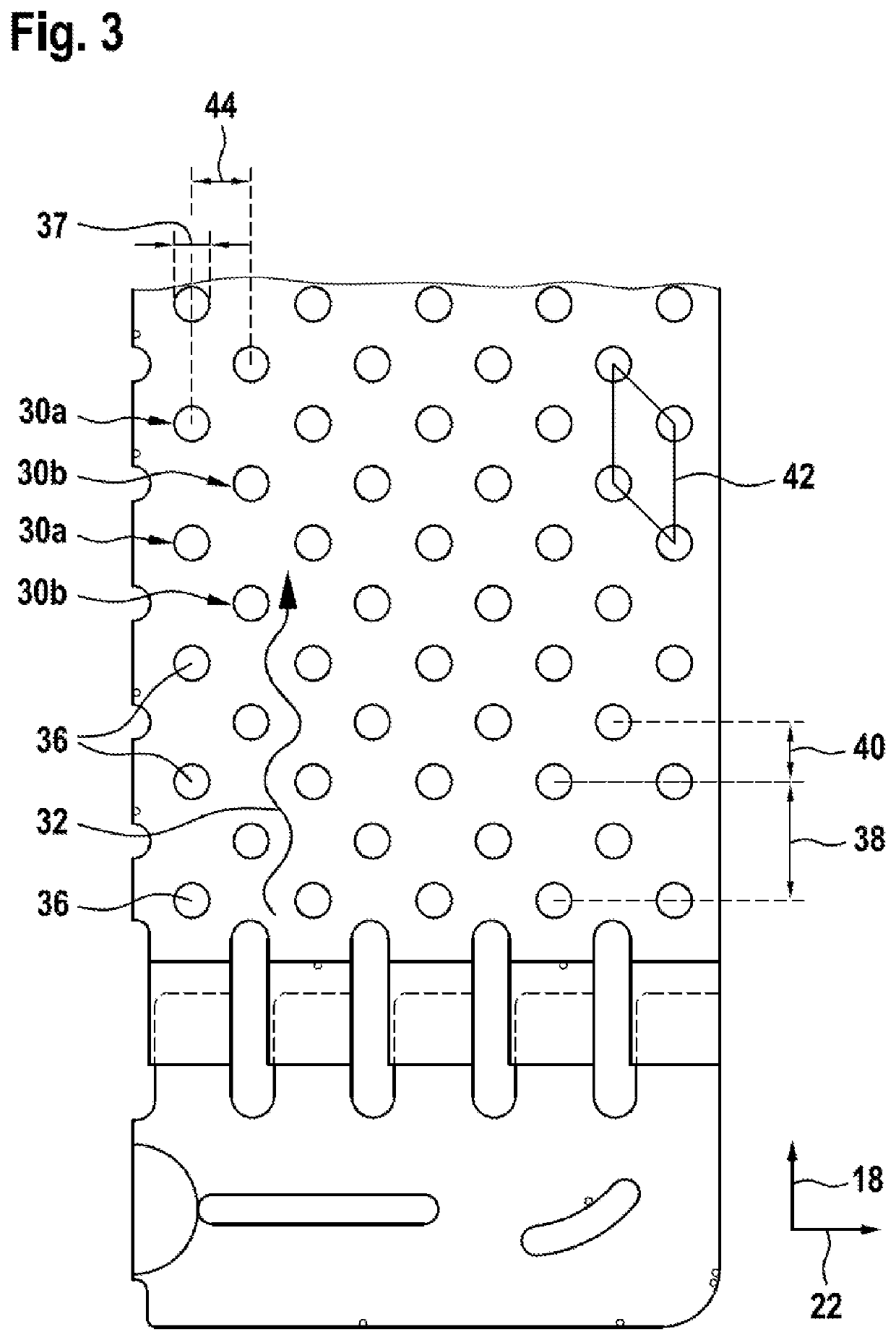

ActiveUS20200106145A1Easy to changeReliable temperature controlSecondary cellsCell component detailsTemperature controlCoolant flow

A cooling plate (10) for temperature control of a battery cell, having a frame (12) with a coolant flow space (16) and at least one perturbing contour (30) inside the flow space (16), which is provided to increase turbulence in the coolant and is designed to support the at least one battery cell or for mechanical contacting with a cover (14) of the flow space (16). The perturbing contour (30) is arranged such that the coolant can flow around the perturbing contour (30) and the perturbing contour (30) is formed in the manner of at least one opening (50) in such a way that the coolant can flow through the at least one perturbing contour (30) and / or the frame (12) forms an opening (52) beneath the perturbing contour (30) in such a way that the coolant can flow beneath the at least one perturbing contour (30).

Owner:ROBERT BOSCH GMBH

Box body interlayer water cooling high thermal power dynamic balance hypocycloidal reduction box

The invention relates to cycloidal reducers. A box body interlayer water cooling high thermal power dynamic balance hypocycloidal reduction box comprises a box body, an input shaft, a transmission mechanism and an output shaft, wherein the input shaft, the transmission mechanism and the output shaft are arranged in the box body and are in successive transmission. The box body interlayer water cooling high thermal power dynamic balance hypocycloidal reduction box is characterized in that a connecting part of an inner cylinder and a circular end cover is arranged in the box body, a flange of the inner cylinder is connected with the output end face of the box body, an outer circle of the input end of the circular end cover is in close fit with an inner hole of the input end of the box body, the input end face of the circular end cover and the input end of the box body are in seal connection through the same annular pad, the inner wall of the box body and the outer wall of the connecting part of the inner cylinder and the circular end cover form an interlayer, water inlet valves communicated with the airtight interlayer are arranged on the top of the box body, drain valves communicated with the airtight interlayer are arranged on the lateral part of the box body, the input shaft is supported in the circular end cover through a bearing, the output shaft is supported in the inner cylinder through a bearing, and the transmission mechanism comprises cycloidal gears, hypocycloidal tooth rings, eccentric bearings and pins. The box body interlayer water cooling high thermal power dynamic balance hypocycloidal reduction box has the technical advantages that heat in an airtight interlayer water sleeve is exhausted from a water outlet valve and dissipated to the outside of the box body, the structure is simple and manufacturing cost is low; the water flow rate is adjusted so that thermal power can be close to mechanical power, and dynamic balance of operation of the four gears can be achieved.

Owner:吴小杰

A kind of high hardenability gear steel and its manufacturing method

The invention discloses high-hardenability gear steel. The high-hardenability gear steel comprises the chemical elements of, by mass, 0.19-0.25% of C, 0.15-0.35% of Si, 0.70-1.05% of Mn, 0.70-0.80% ofCr, 0.40-0.65% of Ni, larger than 0 and less than or equal to 0.20% of Cu, 0.33-0.40% of Mo, 0.020-0.050% of Al, 0.003-0.010% of Ti, 0.05-0.08% of b, 0.0001-0.0003% of B, 0.0080-0.0150% of N, and thebalance Fe and other inevitable impurities. The invention further discloses a gear which is obtained through the high-hardenability gear steel. In addition, the invention further discloses a manufacturing method of the high-hardenability gear steel. The high-hardenability gear steel is high in strength and good in toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Cooling plate for the temperature control of at least one battery cell and a battery system

ActiveUS11417922B2Reliable temperature controlIntense mixingSecondary cellsCell component detailsTemperature controlCoolant flow

A cooling plate (10) for temperature control of a battery cell, having a frame (12) with a coolant flow space (16) and at least one perturbing contour (30) inside the flow space (16), which is provided to increase turbulence in the coolant and is designed to support the at least one battery cell or for mechanical contacting with a cover (14) of the flow space (16). The perturbing contour (30) is arranged such that the coolant can flow around the perturbing contour (30) and the perturbing contour (30) is formed in the manner of at least one opening (50) in such a way that the coolant can flow through the at least one perturbing contour (30) and / or the frame (12) forms an opening (52) beneath the perturbing contour (30) in such a way that the coolant can flow beneath the at least one perturbing contour (30).

Owner:ROBERT BOSCH GMBH

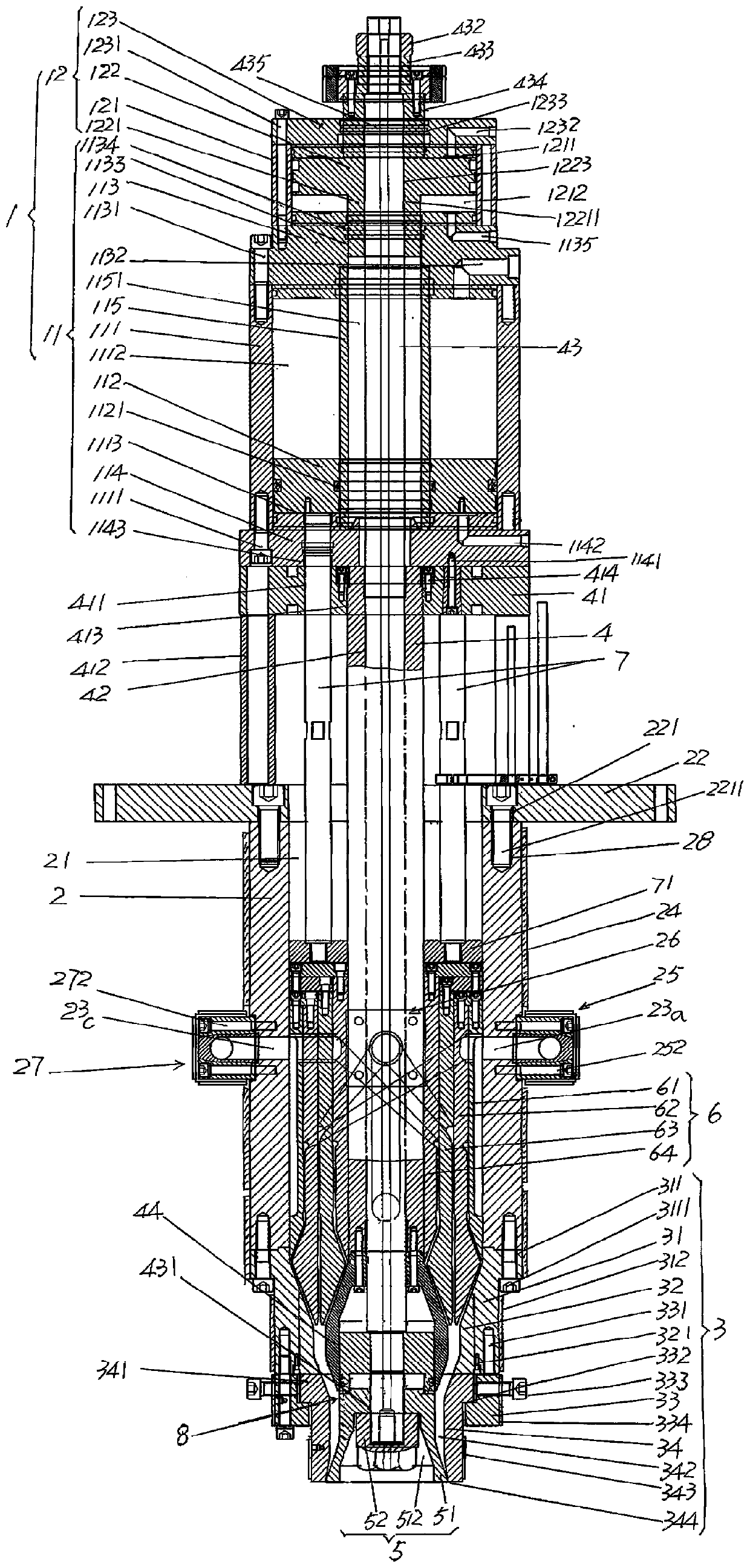

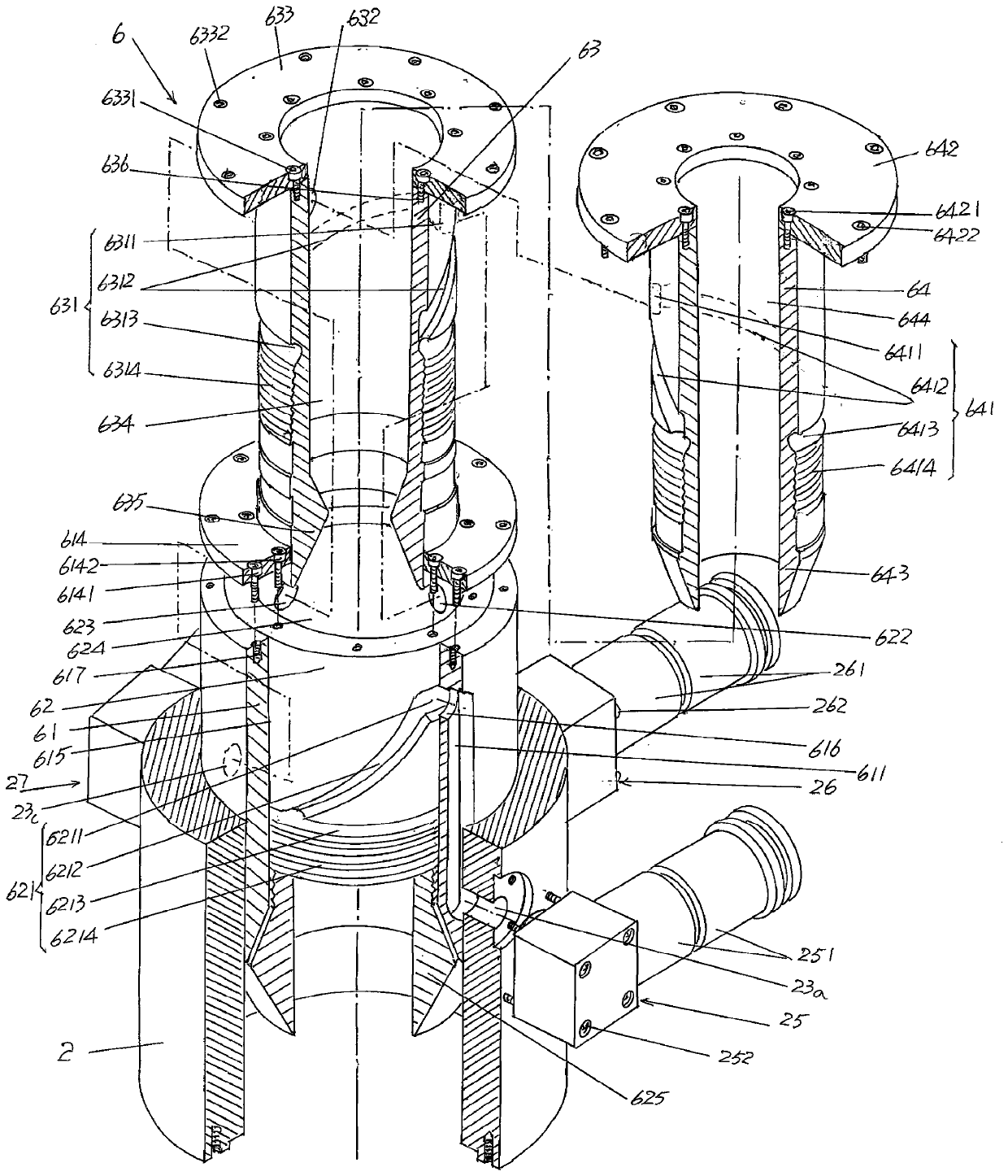

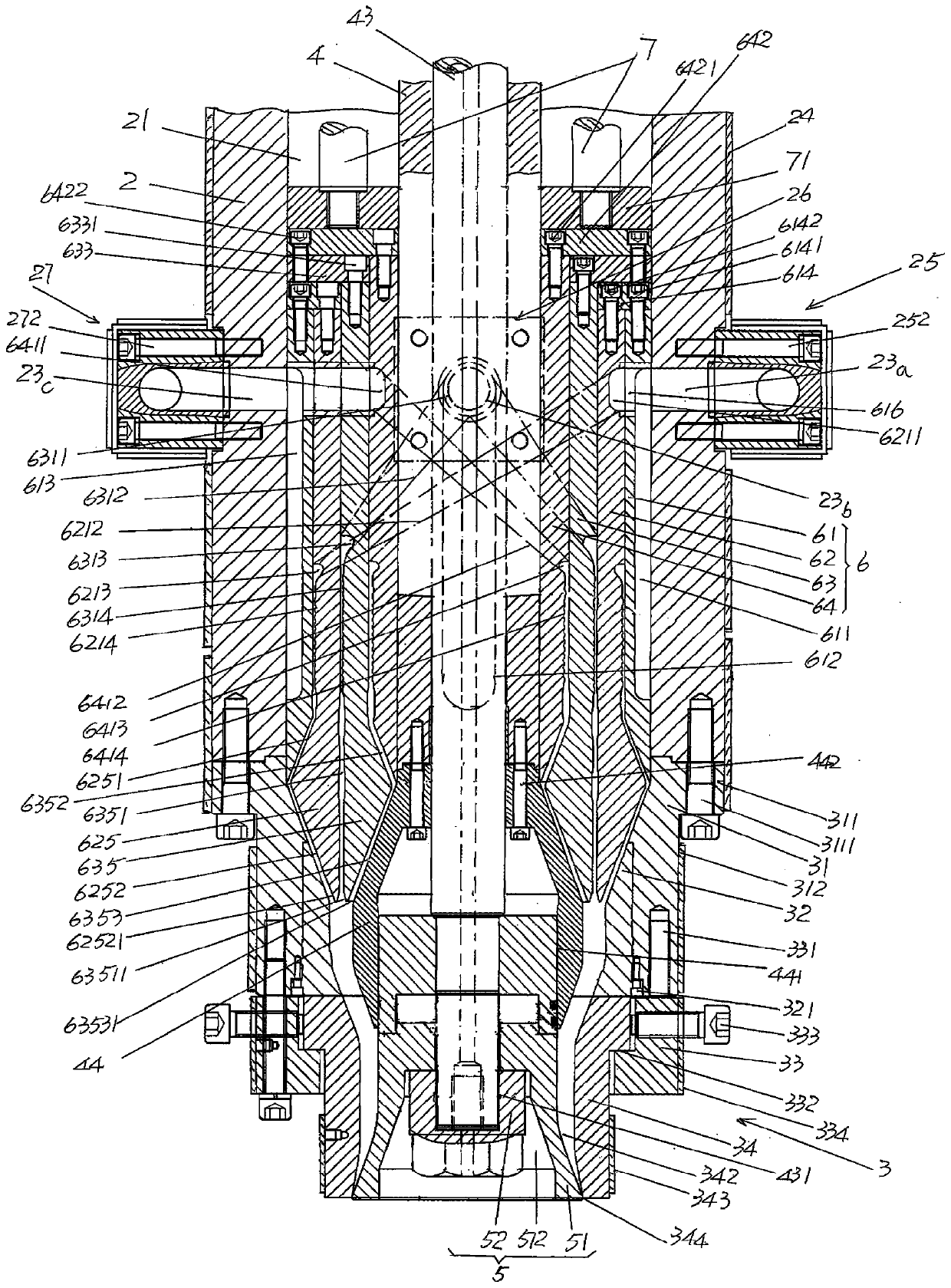

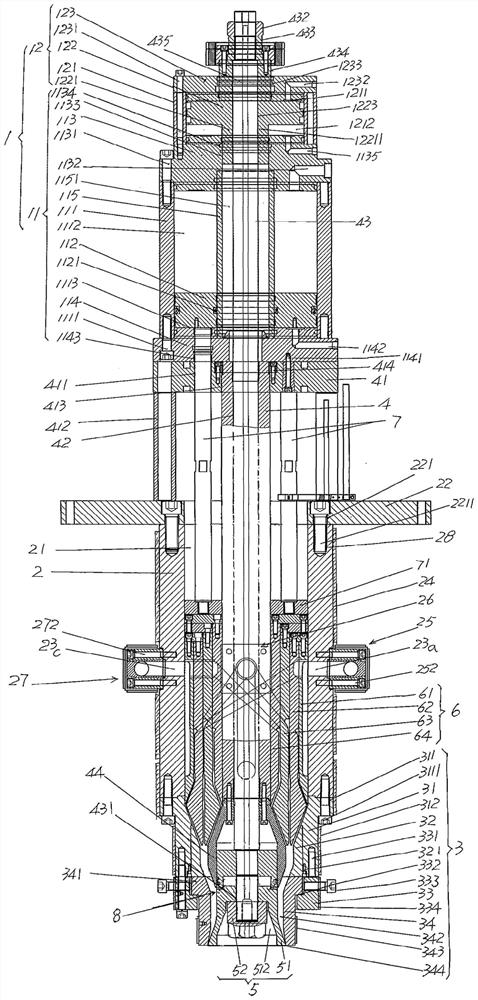

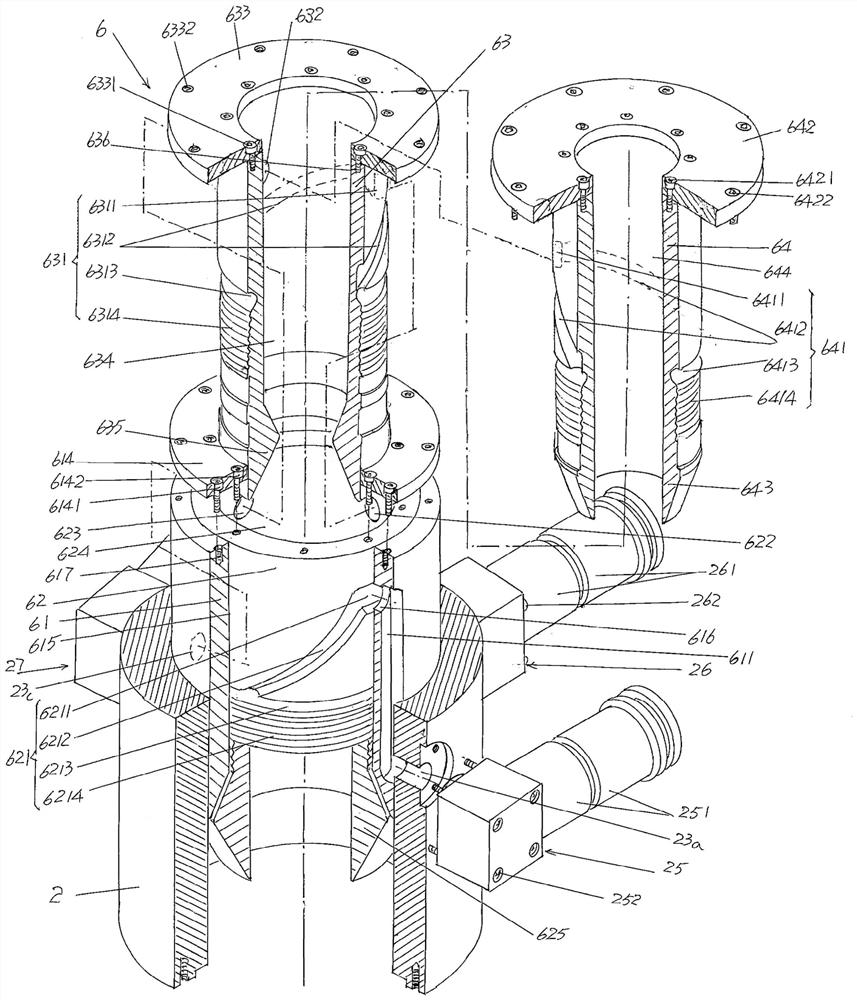

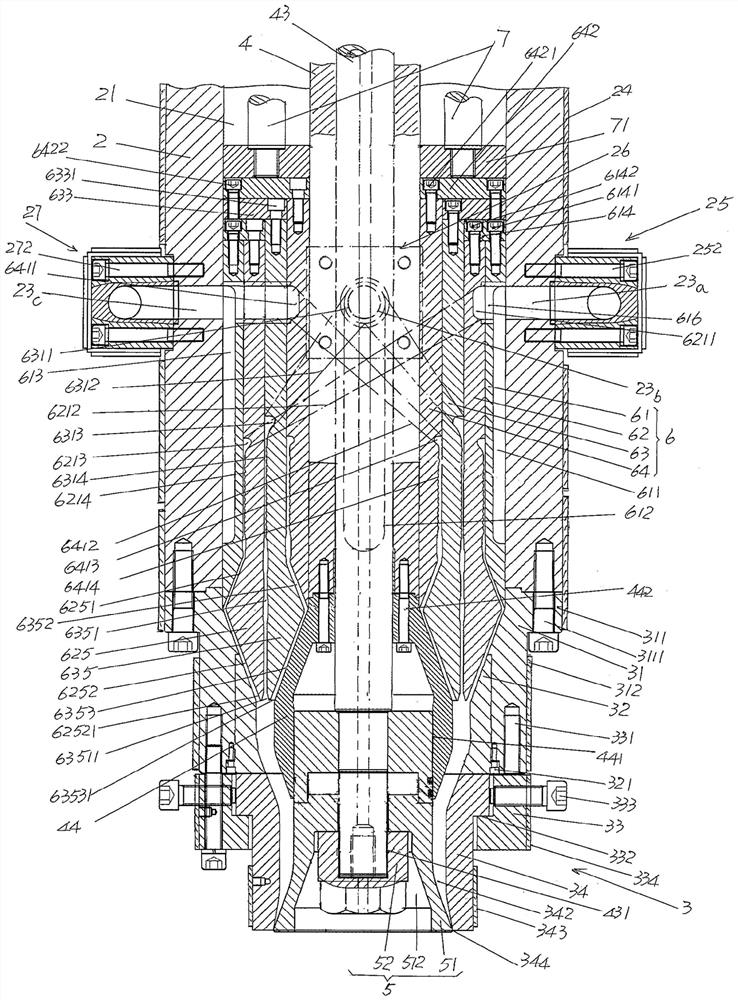

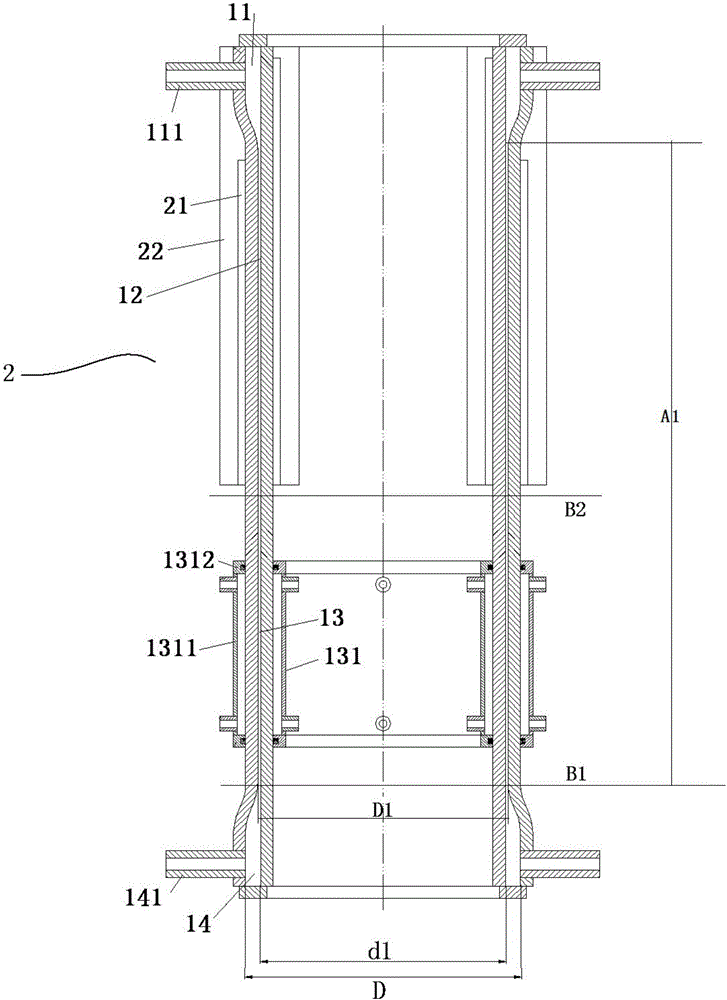

Three-layer flow-guide storage type die head device of blow molding machine

The invention discloses a three-layer flow-guide storage type die head device of a blow molding machine. The device comprises a driving mechanism, an injection cylinder sleeve, a die sleeve mechanism,a material storage core pipe; a die mechanism, a composite molten blank injection mechanism and a set of injection push rods, wherein the device has the characteristics in that the composite molten blank injection mechanism comprises a first pushing cylinder sleeve, a second pushing cylinder sleeve, a third pushing cylinder sleeve and a fourth pushing cylinder sleeve, the first pushing cylinder sleeve is arranged in an injection cylinder sleeve cavity, the outer wall of the first pushing cylinder sleeve is provided with a first pushing cylinder sleeve outer layer, middle layer and inner layermaterial guide grooves, the second pushing cylinder sleeve is arranged in a first pushing cylinder sleeve cavity, an outer layer melt guiding device is arranged on the outer wall of the second pushing cylinder sleeve, the third pushing cylinder sleeve is arranged in a second pushing cylinder sleeve cavity, a middle layer melt guiding device is arranged on the outer wall of the third pushing cylinder sleeve, the fourth pushing cylinder sleeve is arranged in a third pushing cylinder sleeve cavity, an inner layer melt guiding device is arranged on the outer wall of the fourth pushing cylinder sleeve, and an upper pressing ring is fixed on the upper end face of the fourth pushing cylinder sleeve; the lower end of the material storage core pipe extends into a fourth pushing cylinder sleeve cavity; and the lower ends of the set of injection push rods are fixed on a push rod pressing ring. The device has the advantages that the structure is simplified; the energy consumption is saved; and the material leakage is avoided, the parison degeneration is prevented, and the efficiency of color changing according requirements is ideal.

Owner:SUZHOU TONGDA MACHINERY

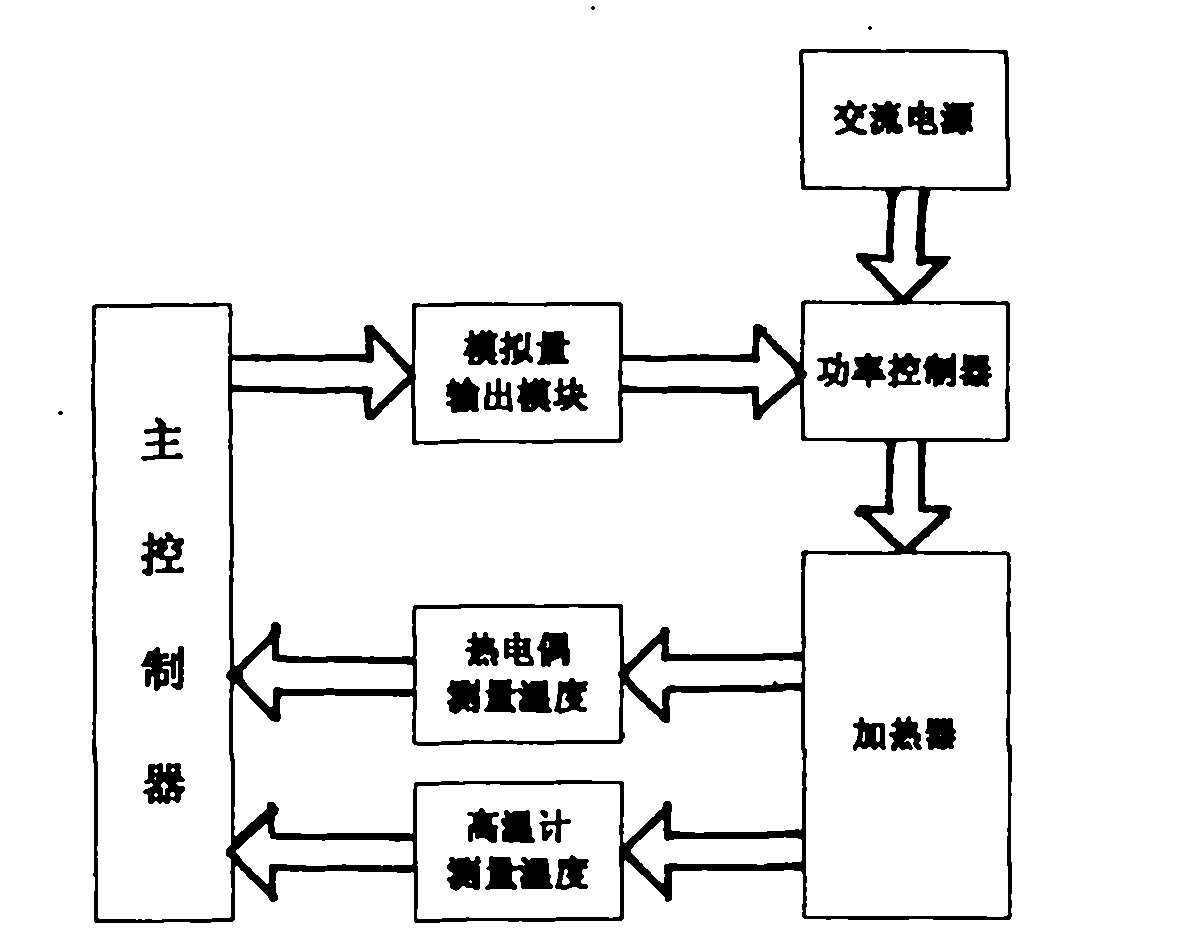

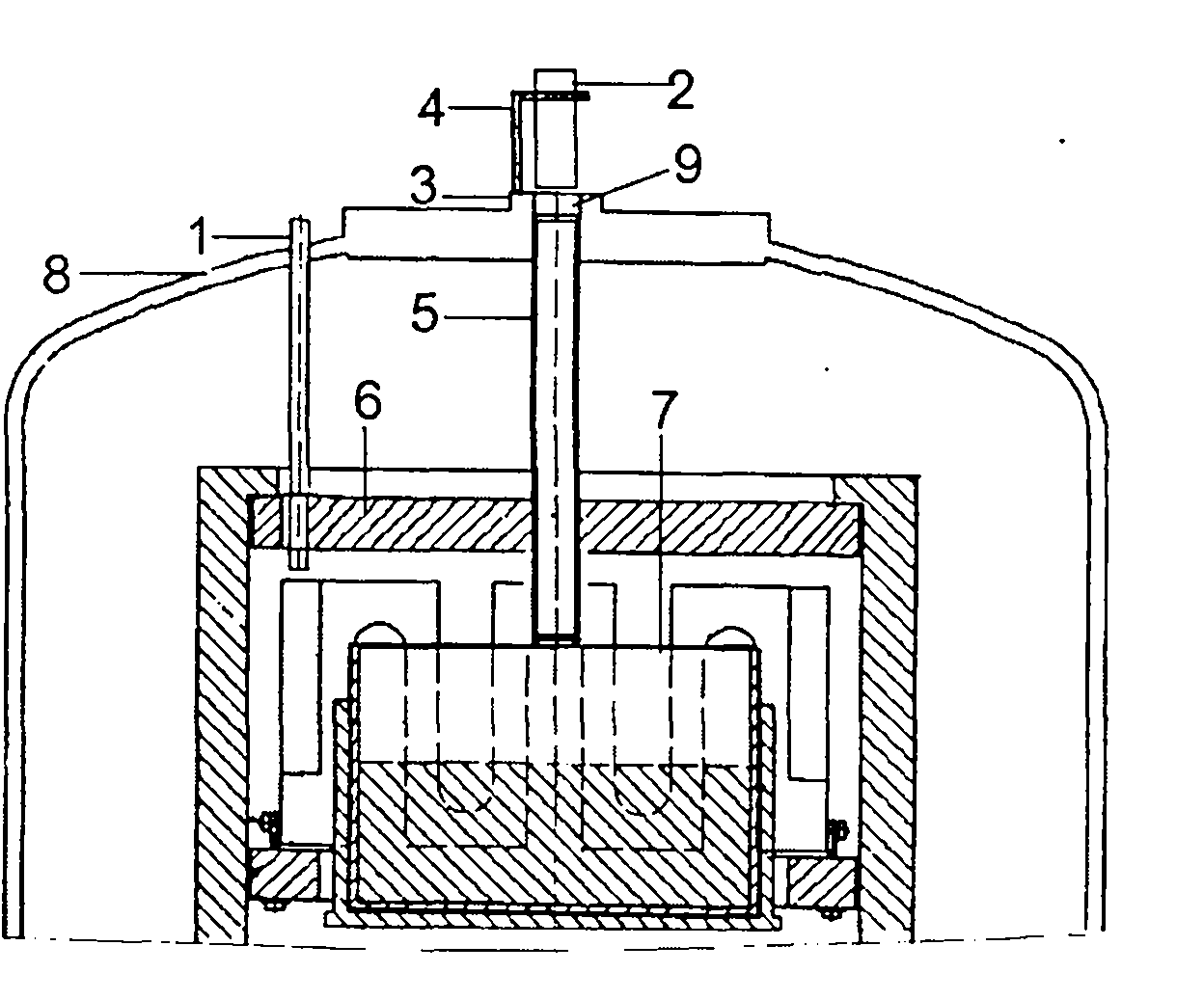

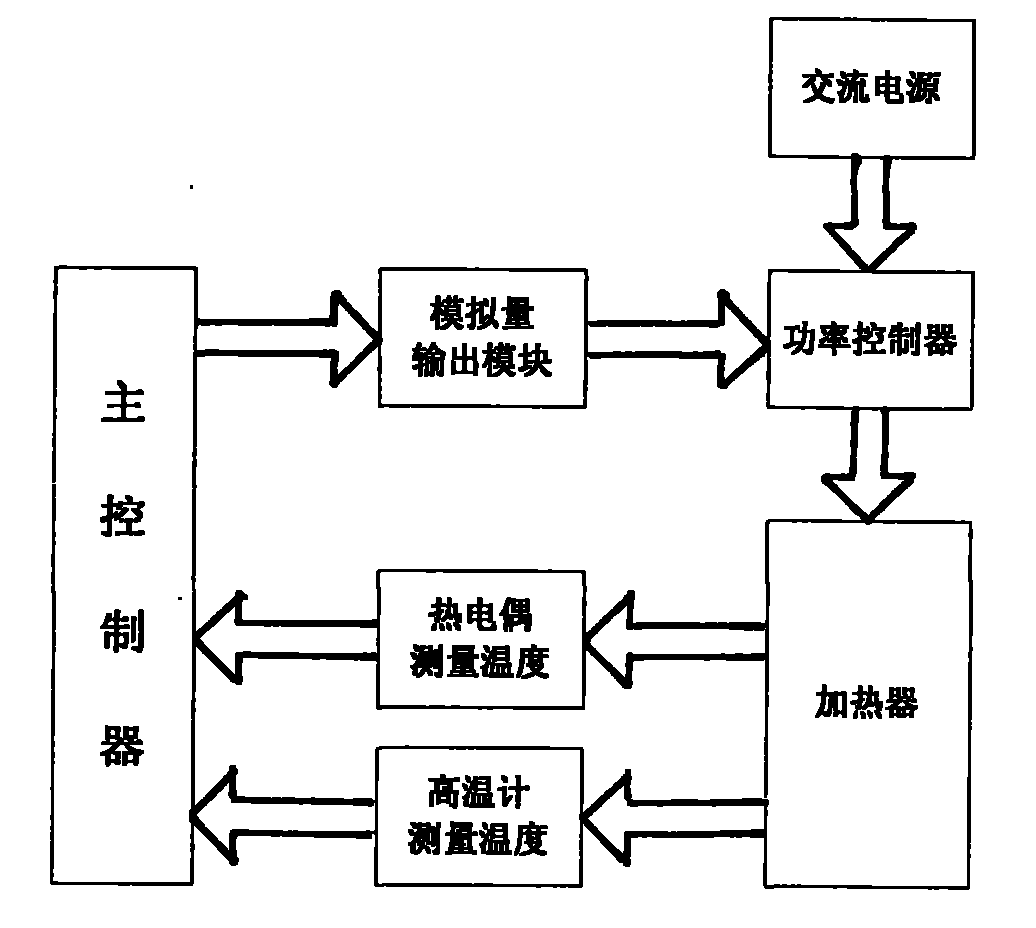

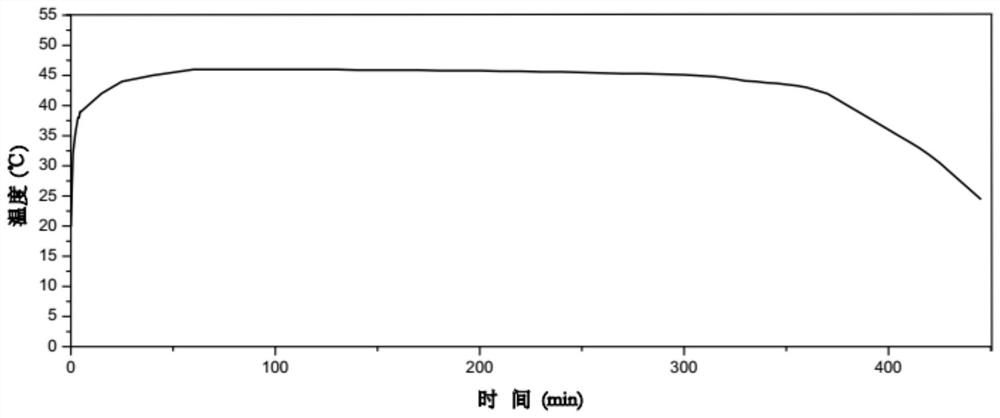

Temperature regulating device for photovoltaic polycrystalline silicon ingot casting furnace

InactiveCN101968666AQuality improvementHigh precisionPolycrystalline material growthTemperatue controlPower controllerTemperature control

The invention relates to a temperature regulating device for a photovoltaic polycrystalline silicon ingot casting furnace, belonging to the technical field of automatic temperature control of the photovoltaic polycrystalline silicon ingot casting furnace. The device comprises a temperature control thermoelectric couple mounted on the photovoltaic polycrystalline silicon ingot casting furnace, and an optical pyrometer, a main controller, an analog quantity output module, a power controller and an alternating current power source which are arranged on the photovoltaic polycrystalline silicon ingot casting furnace, wherein the temperature output ends of the temperature control thermoelectric couple and the optical pyrometer are respectively connected with the input end of the main controller; the output end of the main controller is connected with the input end of the power controller via the analog quantity output module; the output end of the power controller is connected with a heater of the photovoltaic polycrystalline silicon ingot casting furnace; and the input end of the alternating current power source is connected with another input end of the power controller. The temperature is controlled by the optical pyrometer and the thermoelectric couple at the same time. The invention has the advantages of convenient operation, reliable temperature control, high precision and the like, and greatly improves the polycrystalline silicon casting quality.

Owner:TSINGHUA UNIV +2

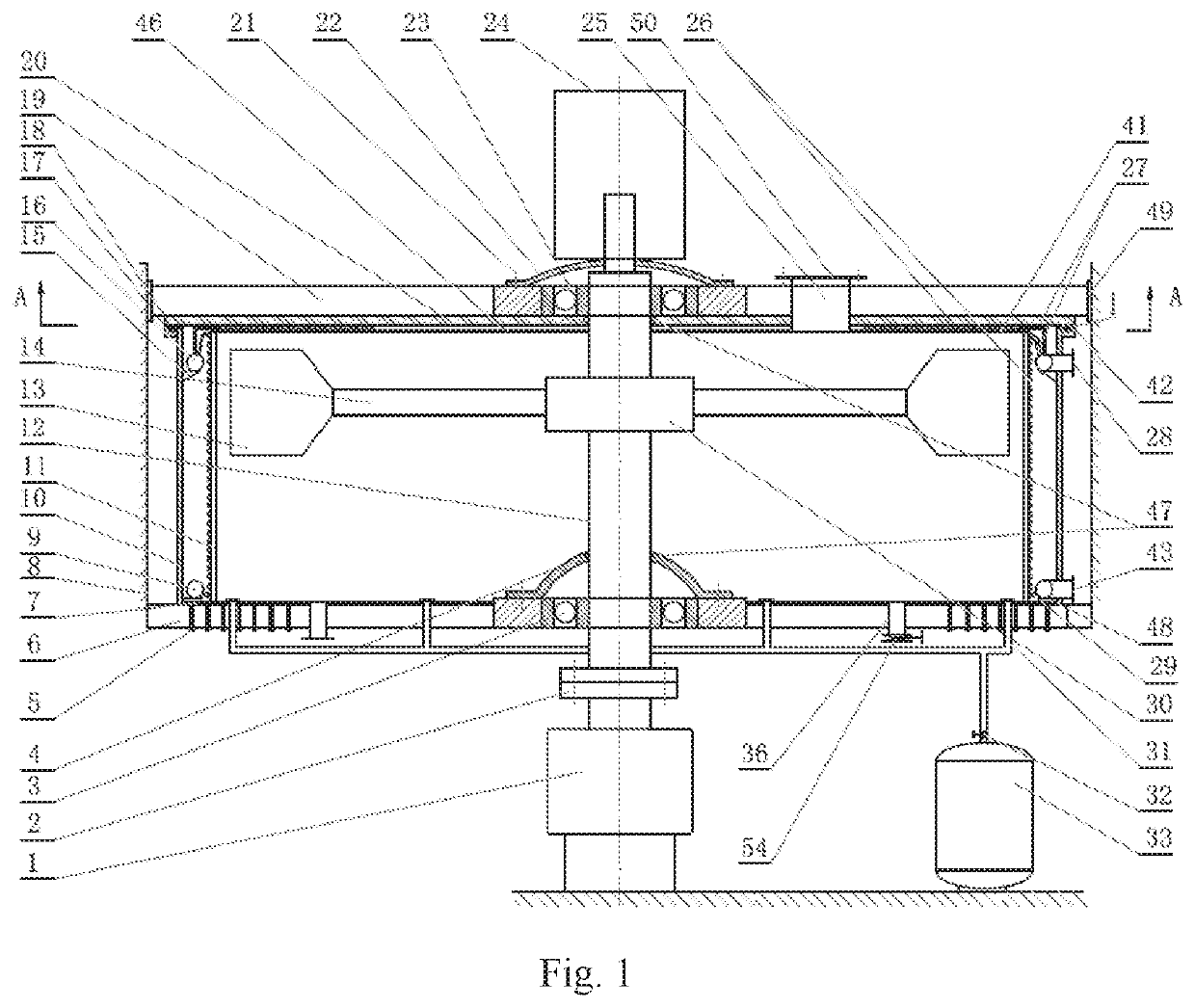

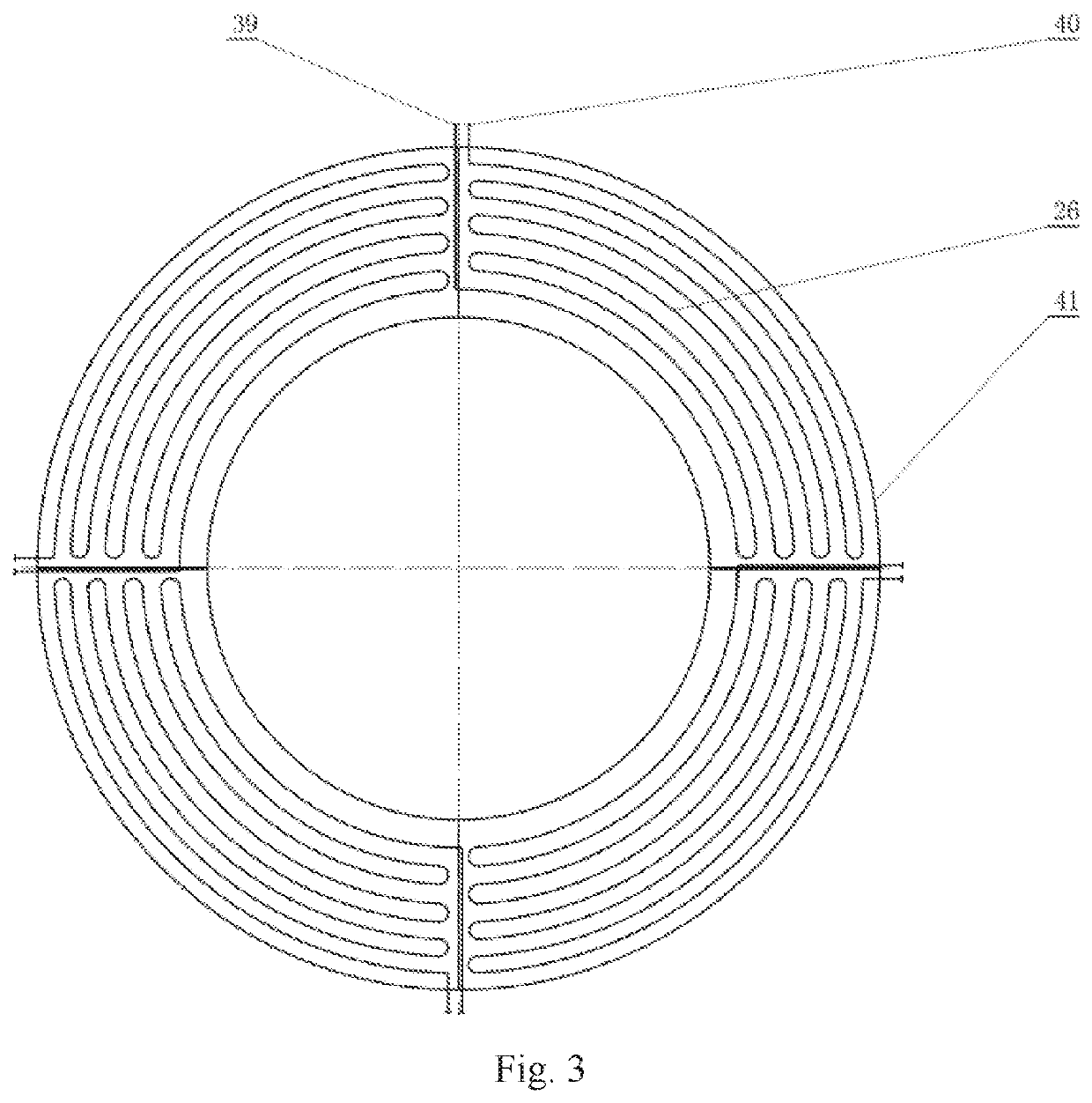

Device and method for reducing wind resistance power of large geotechnical centrifuge

PendingUS20210402418A1Reduce wind resistance powerReduced sealing requirementsRotary centrifugesStructural/machines measurementPumping vacuumVibration isolation

A device and a method for reducing wind resistance power of a large geotechnical centrifuge are provided. A semicircular tube cylindrical cooling device is installed between an internal side of a high-speed rotor system and a cylindrical shell. A serpentine top semicircular tube cooling plate is provided right above a hanging basket, and return helium gas inlet holes are opened at a center of the top semicircular tube cooling plate. A helium gas in a helium gas storage tank passes through helium gas outlets on the helium gas inlet pipes, and enters a centrifuge chamber from a bottom sealing plate. The helium gas is used to replace air in the centrifuge chamber to reduce the wind resistance power and corresponding energy consumption. No vacuuming is required, so sealing requirements are lower. Heat dissipation equipment is placed inside the centrifuge chamber, and a helium gas circulation wind duct is added to improve heat exchange coefficient and heat dissipation effect. A special vibration isolation gasket is used, in such a manner that the vibration transmitted to the top bearing system support device by the main shaft is separated from the centrifuge chamber, thereby avoiding resonance of the centrifuge chamber and the main shaft, and ensuring safety of the centrifuge chamber. The present invention is more economical when operating at an acceleration of below 1500 g, and can maintain the temperature below 45° C.

Owner:ZHEJIANG UNIV

Cooling plate for controlling the temperature of at least one battery cell, and battery system

ActiveUS11437668B2Increased turbulenceTemperature controlSecondary cellsCell component detailsCoolant flowEngineering

A cooling plate (10) for controlling the temperature of at least one battery cell, in particular for a traction battery, having a frame (12), which forms a flow chamber (16) for a coolant to flow through, and a cover (14) of flexible design which delimits the flow chamber (16) in an at least partially fluid-tight manner and is provided for making thermal contact with the at least one battery cell. It is proposed that the cooling plate (10) has at least one supporting element (30), which is arranged within the flow chamber (16) and around which coolant can flow, for increasing the turbulence in the coolant flowing through the flow chamber (16) and for supporting the at least one battery cell, which supporting element makes mechanical contact with the cover (14) of flexible design.

Owner:ROBERT BOSCH GMBH

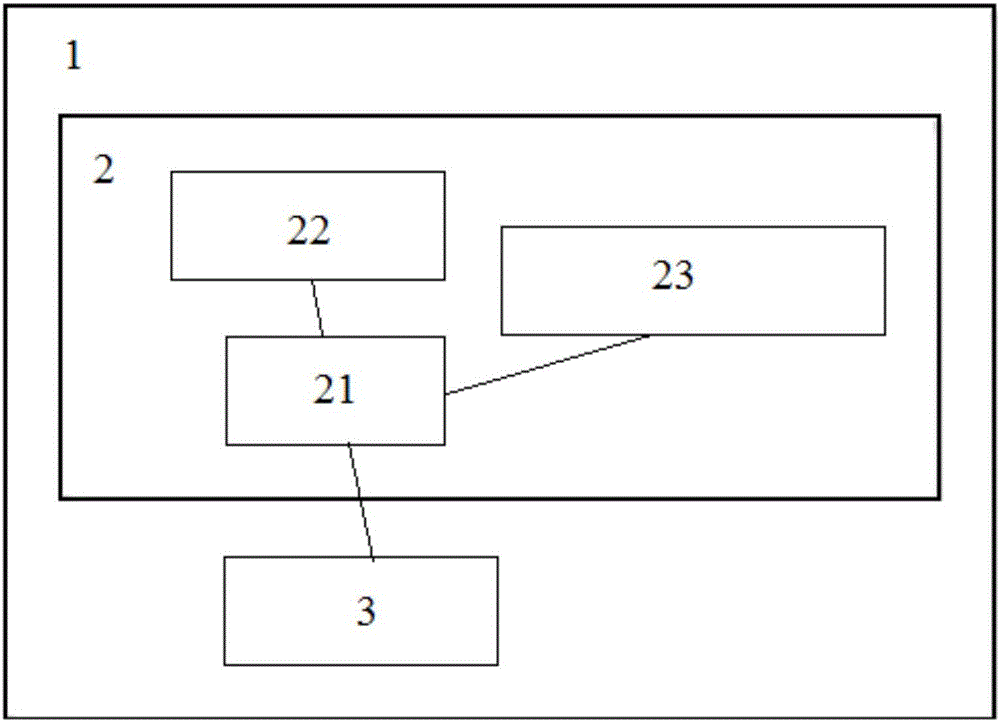

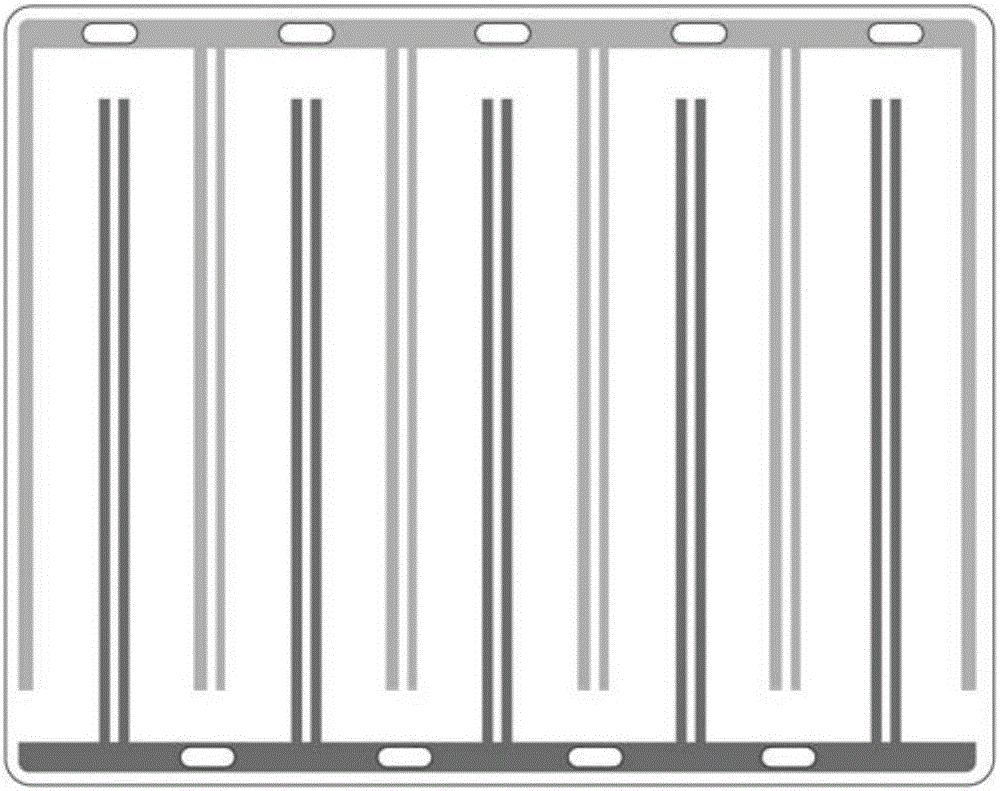

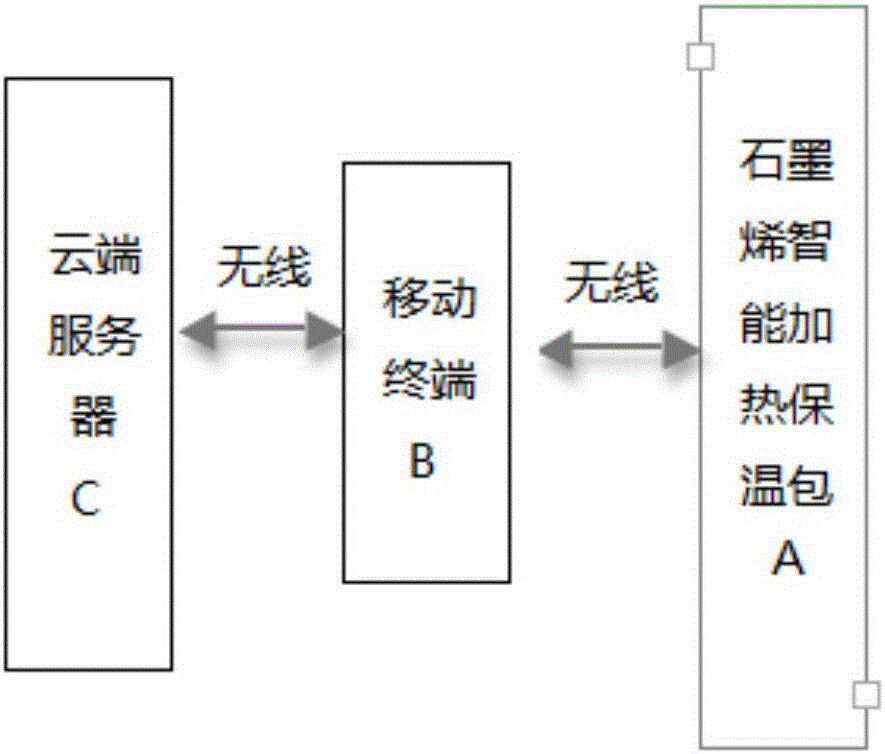

Graphene-based intelligent portable heating and heat preserving bag system

InactiveCN105929869AEasy temperature controlReliable temperature controlTemperatue controlTemperature controlComputer module

The invention relates to a graphene-based intelligent portable heating and heat preserving bag system. The graphene-based intelligent portable heating and heat preserving bag system comprises an intelligent graphene heating and heat preserving bag and a mobile terminal which are connected with each other; the intelligent graphene heating and heat preserving bag includes a heating and heat preserving bag body, an intelligent graphene temperature control module and a wireless communication module, wherein the heating and heat preserving bag body includes a bag body and a bag cover connected with the upper part of the bag body; and the intelligent graphene temperature control module is arranged at the inner wall or bottom of the bag body and is connected with the mobile terminal through the wireless communication module and is use for controlling temperature in the heating and heat preserving bag body according to the control instructions of the mobile terminal. Compared with the prior art, the graphene-based intelligent portable heating and heat preserving bag system of the invention has the advantages of easiness in temperature control, low power consumption, intelligent control and the like.

Owner:SHANGHAI XIWANG INFORMATION TECH CO LTD

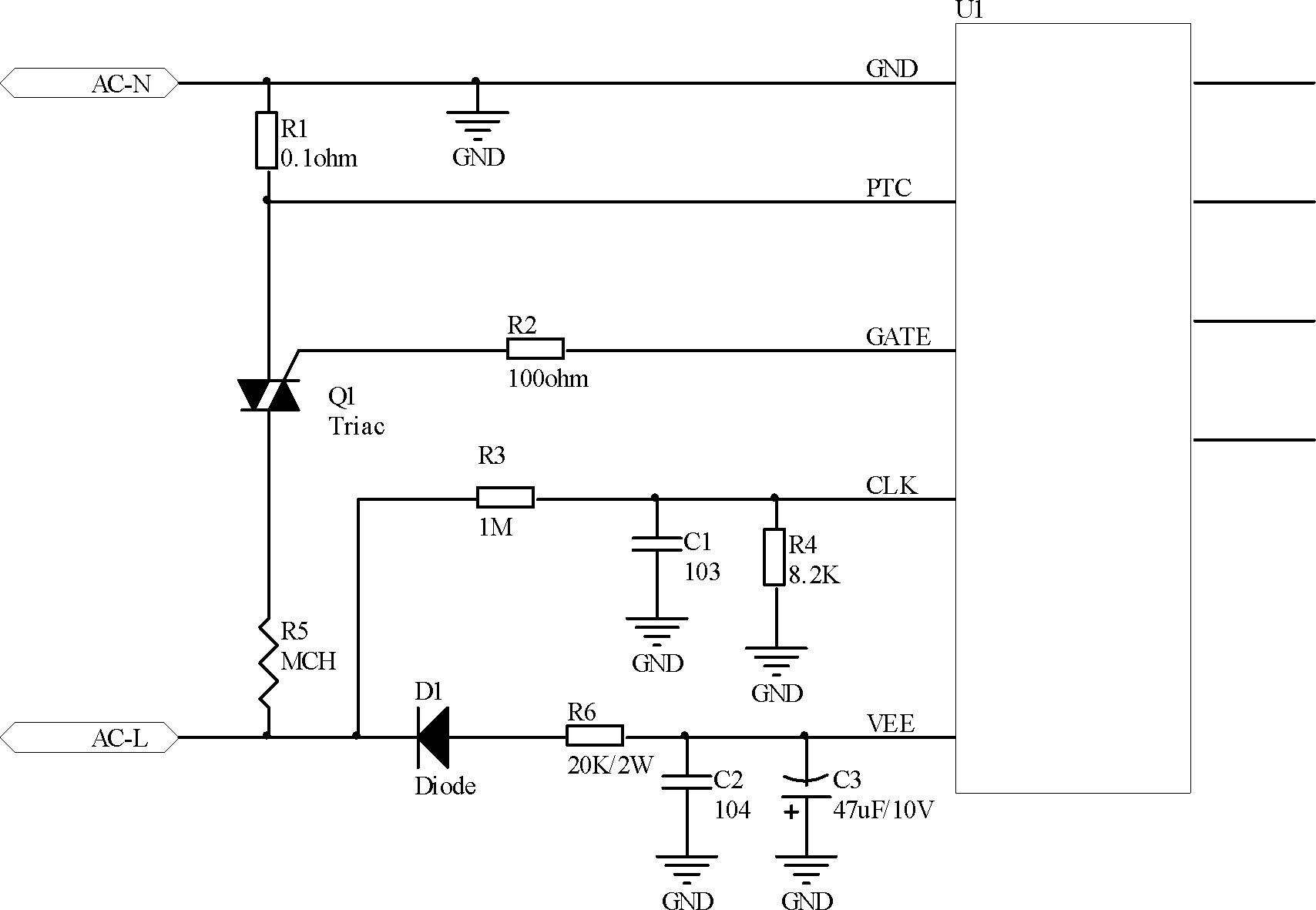

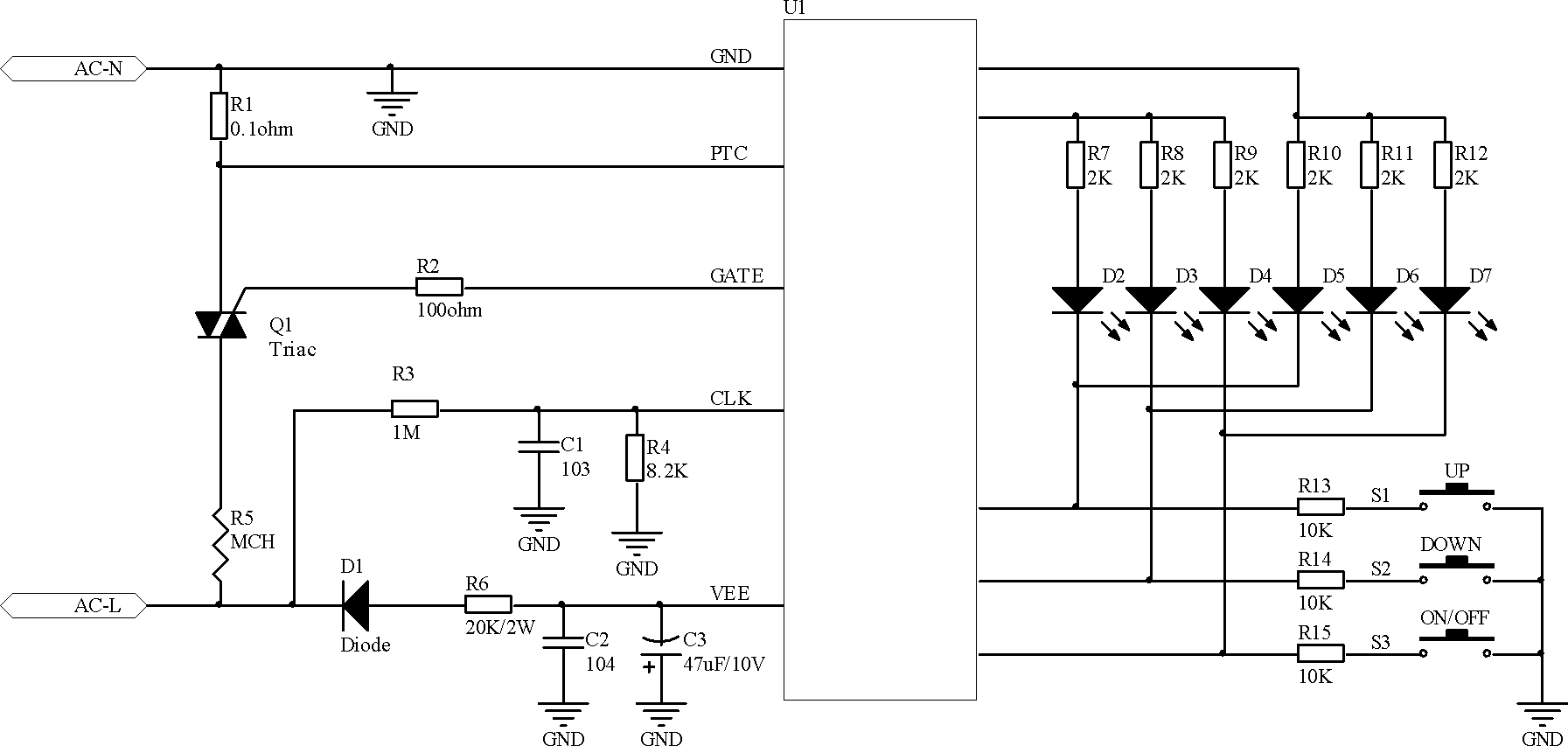

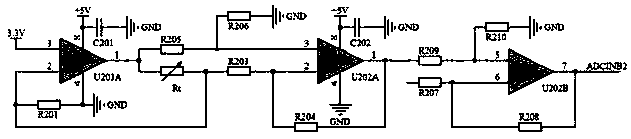

Circuit and method for controlling metal ceramic heating element through bidirectional triode thyristor

InactiveCN103987137AReliable temperature controlStable jobElectric heatingElectronic switchingIntegrated circuitCapacitance

The invention relates to the technical field of electricity and triode thyristors, in particular to a circuit and method for controlling a metal ceramic heating element through a bidirectional triode thyristor. The circuit comprises a U1 which is a dedicated temperature-controlled integrated circuit KC-0.5, 80C51, LM3911, or an integrated circuit with the functions of signal collecting, computing, output, voltage stabilizing, handles input and display output, the bidirectional triode thyristor, the metal ceramic heating element, a resistor and a capacitor. The circuit is characterized in that the circuit is formed by connecting the dedicated temperature-controlled integrated circuit U1, the bidirectional triode thyristor Q1, the metal ceramic heating element R5, a sampling resistor, a negative power source supply circuit, an alternating current clock sampling circuit and an alternating current voltage sampling circuit. Compared with the prior art, the circuit and method for controlling the metal ceramic heating element through the bidirectional triode thyristor have the advantages that an alternating current signal is input into a CLK pin of the integrated circuit U1, the alternating current clock sampling circuit is arranged inside the integrated circuit U1 to be used for computing the precise zero crossing point of the alternating current and measuring the alternating current voltage value, a GATE pin outputs the negative voltage pulse at the zero crossing point of the alternating current when the heating element is heated to make the bidirectional triode thyristor be turned on, so that stable and reliable temperature control is achieved.

Owner:SHANGHAI FOYOUNG COMM SCI

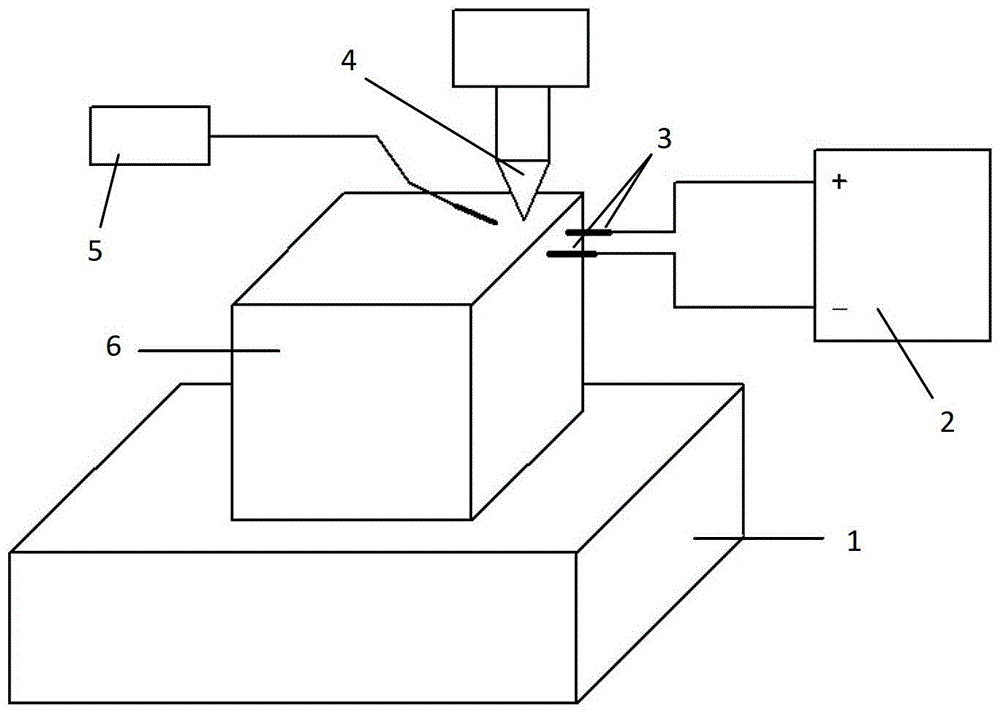

High-temperature rigidity measuring method based on electrified heating

InactiveCN102944490BFlexible temperature controlReliable temperature controlInvestigating material hardnessMetal workingDirect current

Owner:XIAMEN UNIV

Three-layer diversion material storage die head device for blow molding machine

A three-layer diversion material storage type die head device for a blow molding machine, including a driving mechanism; a shooting cylinder liner; a mold sleeve mechanism; a material storage core tube; a die mechanism; The push rod is characterized in that: the compound molten billet injection mechanism includes the first, second, third and fourth push cylinders, the first push cylinder is set in the cavity of the injection cylinder, and the first push cylinder is set on the outer wall The outer layer, the middle layer and the inner layer material guide groove of the cylinder liner, the second pushing cylinder is set in the cavity of the first pushing cylinder liner and there is an outer layer melt guiding device on the outer wall, and the third pushing cylinder liner is set at the second In the cavity of the second pushing cylinder, there is a middle melt guiding device on its outer wall, and the fourth pushing cylinder is set in the cavity of the third pushing cylinder, and there is an inner melting guiding device on its outer wall, and an upper end surface The upper pressing ring is fixed; the lower end of the material storage core tube extends into the cavity of the fourth pushing cylinder; the lower end of a group of injection push rods is fixed with the pressing ring of the pushing rod. Advantages: Simplify the structure; save energy; avoid material leakage, prevent parison cross-linking and ideal efficiency of color change on demand.

Owner:SUZHOU TONGDA MACHINERY

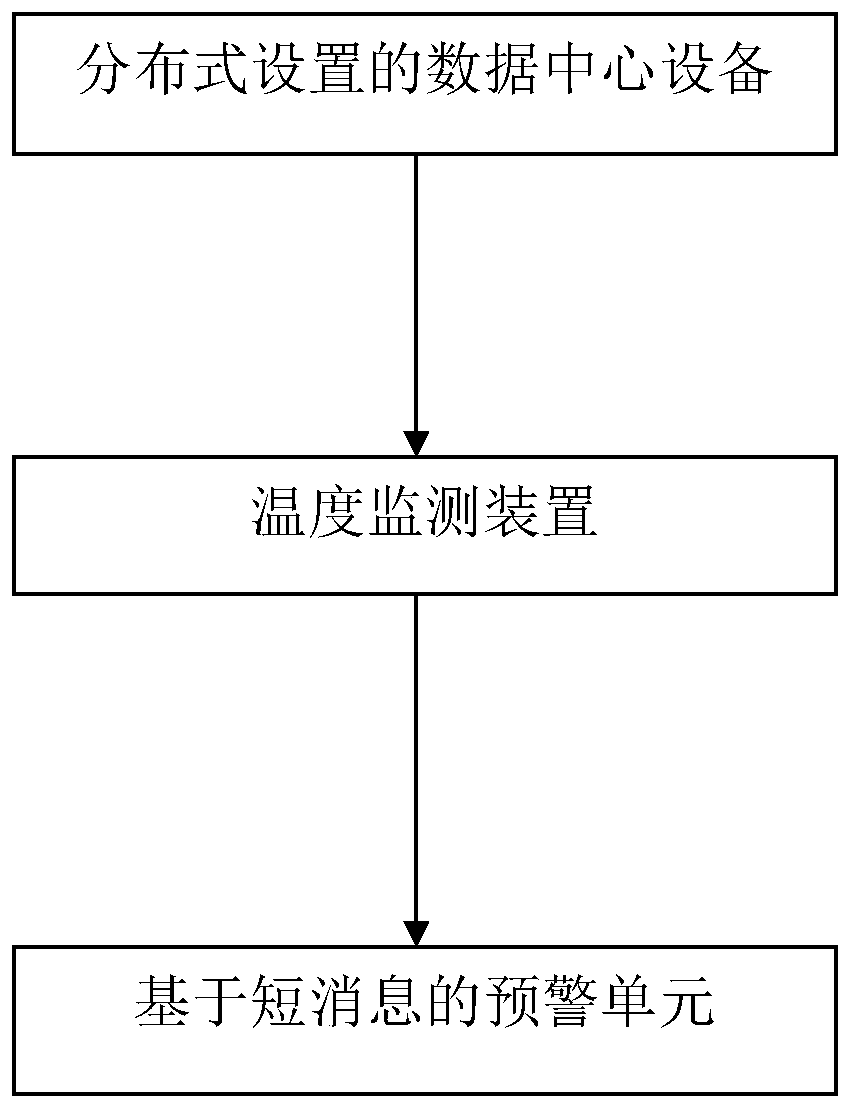

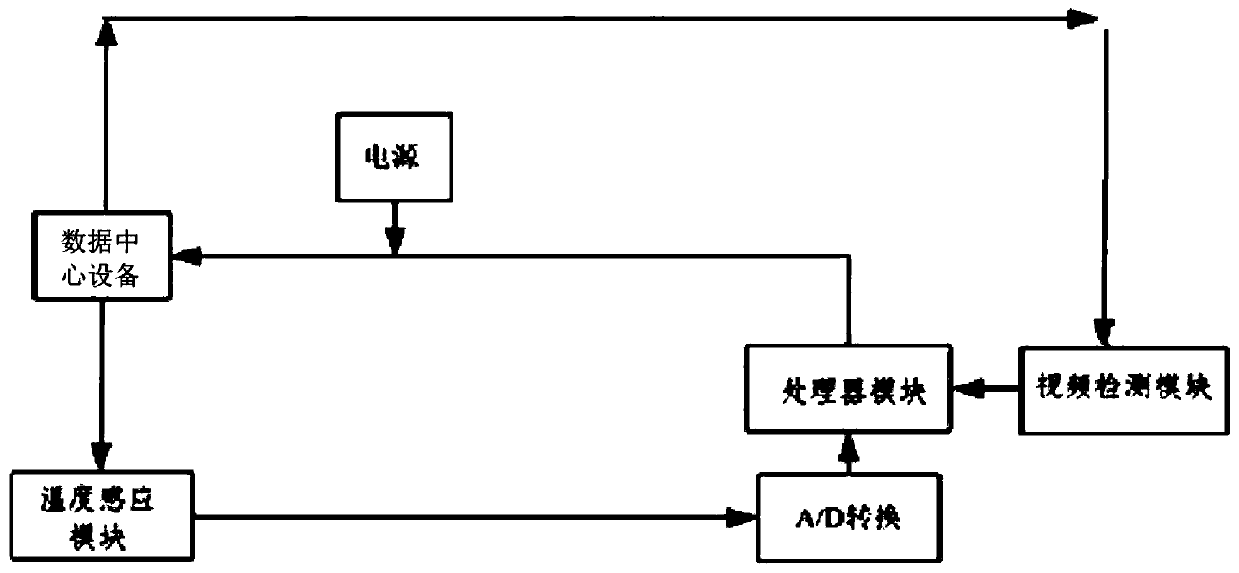

Cloud monitoring system for state of distributed data center equipment

InactiveCN109949550AReliable temperature controlGood automatic temperature control effectAlarmsThermometer applicationsData centerDevice Monitor

The invention provides a cloud monitoring system for the state of distributed data center equipment. The system comprises data center equipment arranged in a distributed manner, a temperature monitoring device and a short message based early warning unit, the temperature monitoring device monitors the temperature of the data center equipment, and sends a monitoring result including the temperatureand the number of the data center equipment corresponding to the temperature to the early warning unit, and the early warning unit sends the number of the data center equipment whose temperature exceeds a preset early warning value to a present mobile phone number. The system integrates advantages of integrated video detection and temperature induction, and fault of the data center equipment is detected intelligently.

Owner:CHENGDU PVIRTECH TECH

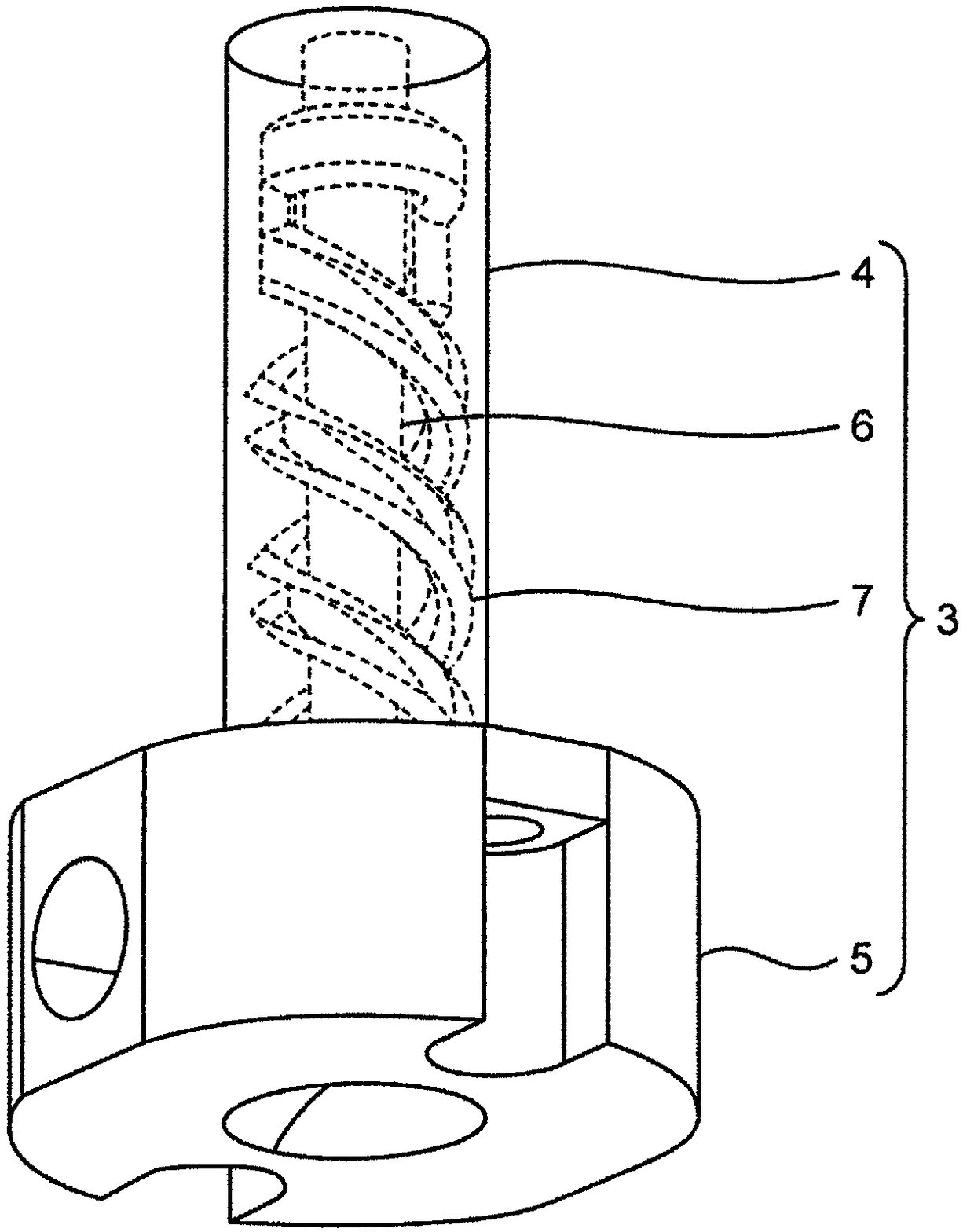

Mold and method for manufacturing mold

The present invention provides a mold comprising the following: a movable-side mold; a fixed-side mold; and a sprue bush disposed inside the fixed-side mold and provided with a cooling liquid flow path. The mold is characterized in that both the inlet portion and the outlet portion of the cooling liquid flow path are directly connected to a cooling tube disposed along a space region formed in thefixed-side mold, and in that the space region has a form in which at least one surface of the fixed-side mold has an opening.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

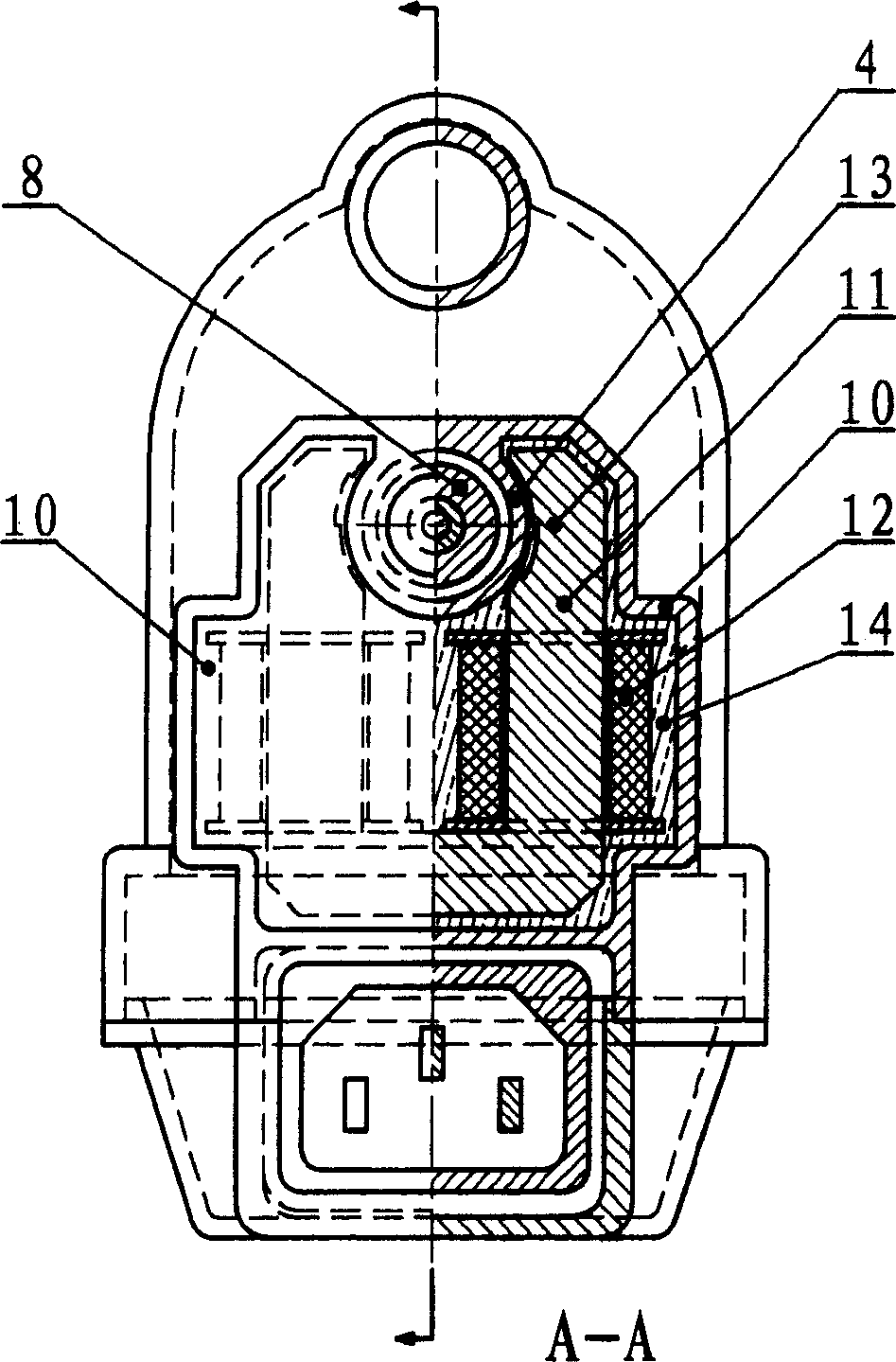

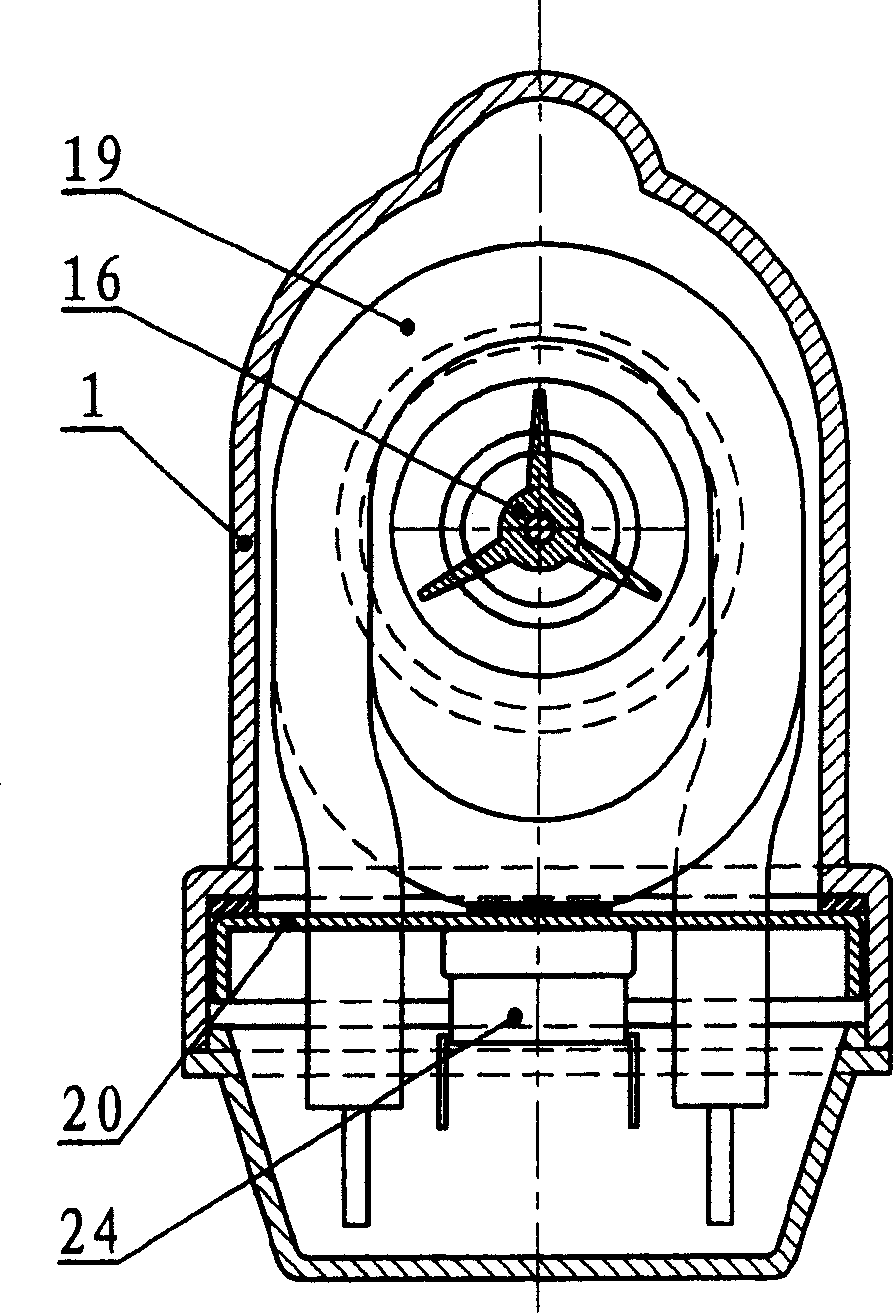

Cyclic preheater for single cavity permanent-magnet rotor pump and assembly method thereof

InactiveCN1664352AThere will be no problem of poor heat dissipationEfficient take awayMachines/enginesEngine startersPermanent magnet rotorImpeller

The invention relates to a single cavity permanent-magnet rotor pump cycle preheater and the installation method that belongs to the preheating field for the engine of automobile. The feature is that: the cavity is made up of cavity main body, front cover and electric heating pipe fixed disk; the cavity main body is manufactured by the method of plastic injecting modeling and rotor cavity, outlet, front cover mouth, electric heating pipe mouth, stator groove are set on it; the permanent-magnet rotator, front bearing and impeller are installed into the heating cavity from the front cove mouth. The spirality part of the electric heating pipe is installed in the heating cavity from heating pipe mouth. The stator is fixed in stator groove. The temperature sensors are installed on the out side of the electric heating pipe fixed disk. The junction box is installed under the fixed disk and the stator groove. The electric heating pipe component should be installed first.

Owner:于佳衣

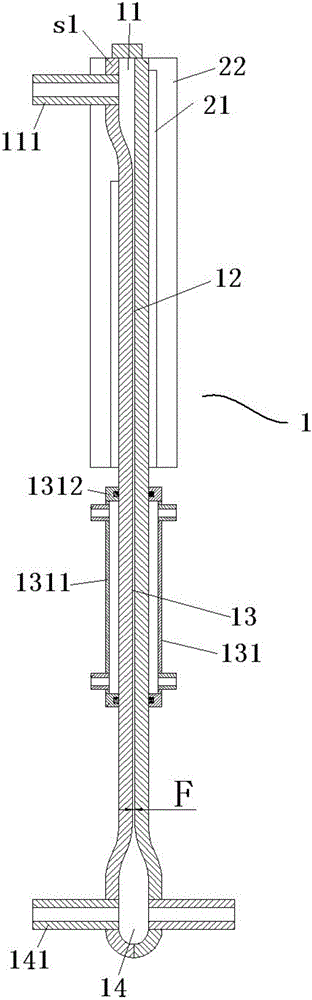

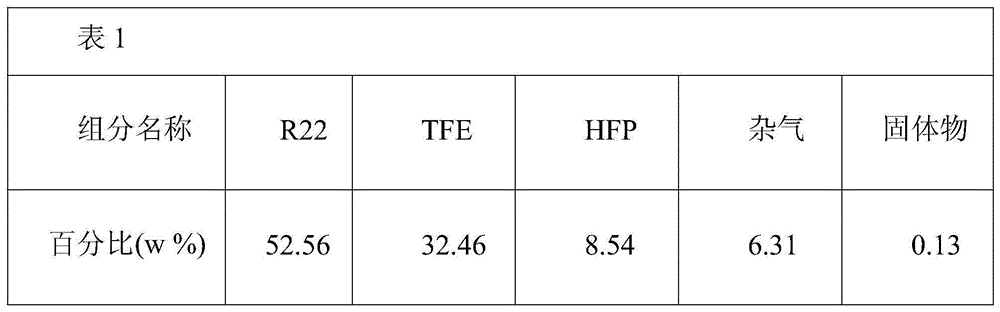

Device and method for cracking difluorochloromethane to prepare tetrafluoroethylene and hexafluoropropylene

ActiveCN103804119BLow investment costImprove securityHalogenated hydrocarbon preparationHexafluoropropyleneEngineering

The invention provides a device and method for preparing tetrafluoroethylene and hexafluoropropylene through cracking monochlorodifluoromethane. The device comprises an air inlet cavity which is arranged at the upper end of the device, a reaction cavity communicated with the lower part of the air inlet cavity, a cooling cavity communicated with the lower part of the reaction cavity, and an air outlet cavity communicated with the lower part of the cooling cavity, wherein the air inlet cavity is wider than the reaction cavity; the air outlet cavity is wider than the reaction cavity; the reaction cavity is F in width, Al in height and W1 in length; a heating body is arranged outside the reaction cavity. The method comprises the steps: cracking monochlorodifluoromethane gas to obtain tetrafluoroethylene gas, and further cracking the tetrafluoroethylene gas to obtain hexafluoropropylene; and cooling and outputting the hexafluoropropylene. According to the device and the method provided by the invention, the investment cost is greatly reduced, the safety is improved and energy is saved; gas generated from side reaction can be repeatedly used, the cost is saved and the environment is protected.

Owner:衢州市鼎盛化工科技有限公司

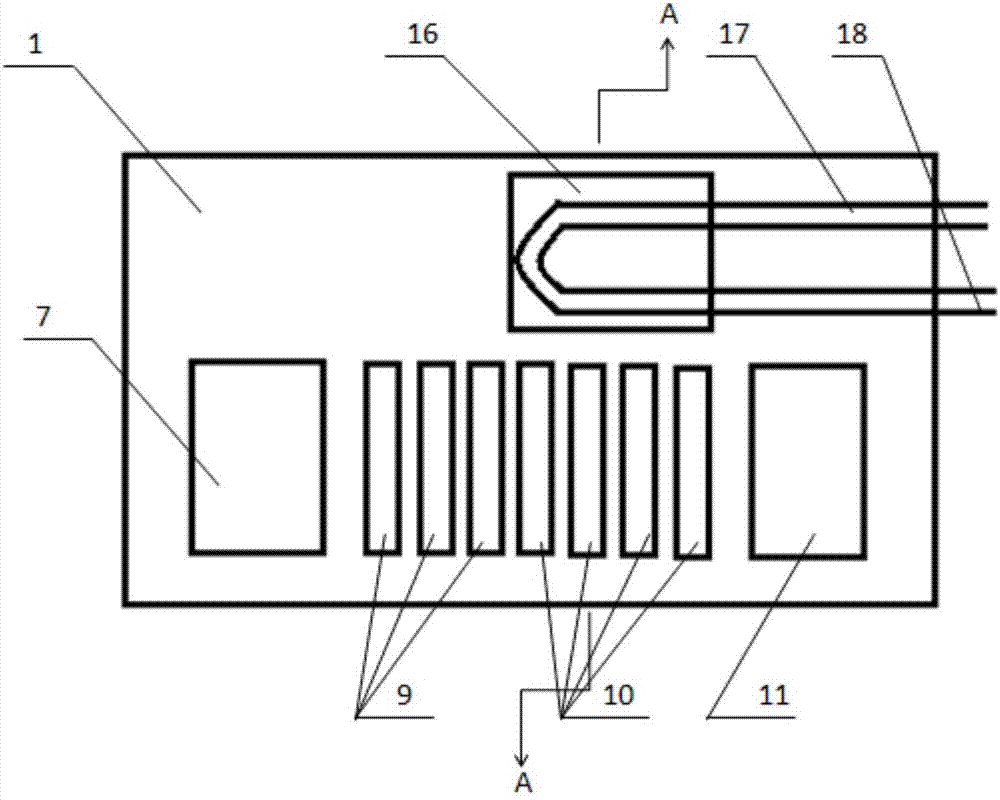

Device for temperature test

InactiveCN101893506BEvenly distributedReduce test energy consumptionOptical apparatus testingHigh temperature storageThermoelectric cooling

The invention belongs to a device for a temperature test. The device for the temperature test comprises a temperature control platform, an intelligent temperature adjuster and a constant temperature circulator, wherein the temperature control platform consists of a cold plate, a thermoelectric cooling component with an upward cold surface and a water jacket from top to bottom; a ceramic heater isadhered to the cold surface in contact with the thermoelectric cooling component; and a temperature measurer is arranged in the cold plate. The device greatly expands the working temperature range byusing a high-power thermoelectric cooler and controls the PTC ceramic heater to perform temperature compensation by using the AI-708P program type intelligent temperature adjuster to realize high-accuracy automatic temperature control; by using the HX-1050 type constant temperature circulator, the device keeps the temperature range of circulating liquid within a range of between -10 and 50 DEG C;and thus the device meets the requirement on heat dissipation, reduces the energy consumption of the test, lowers the using cost and is suitable for tests such as high temperature storage, low temperature storage, high and low temperature circulation, high temperature aging and the like of low-power photoelectric products such as passive optical fiber devices, watt-level power consumption photoelectric devices, integrated components and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

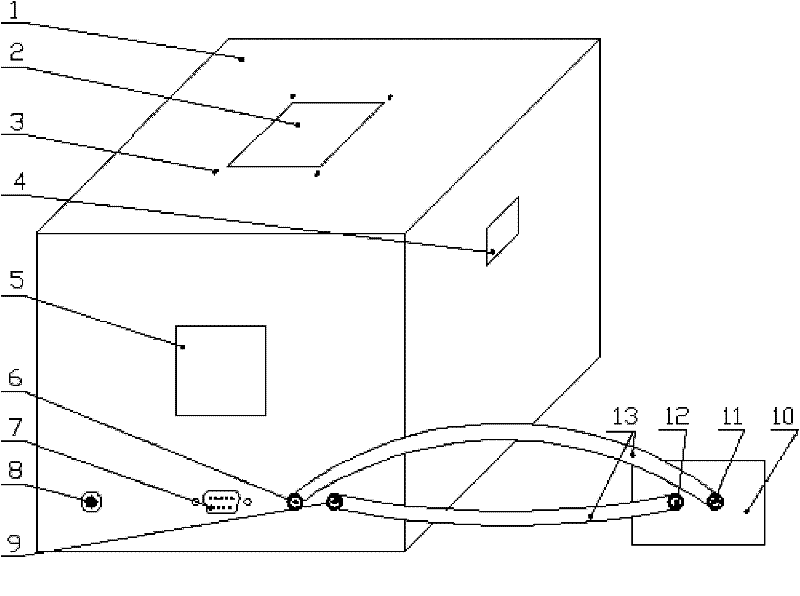

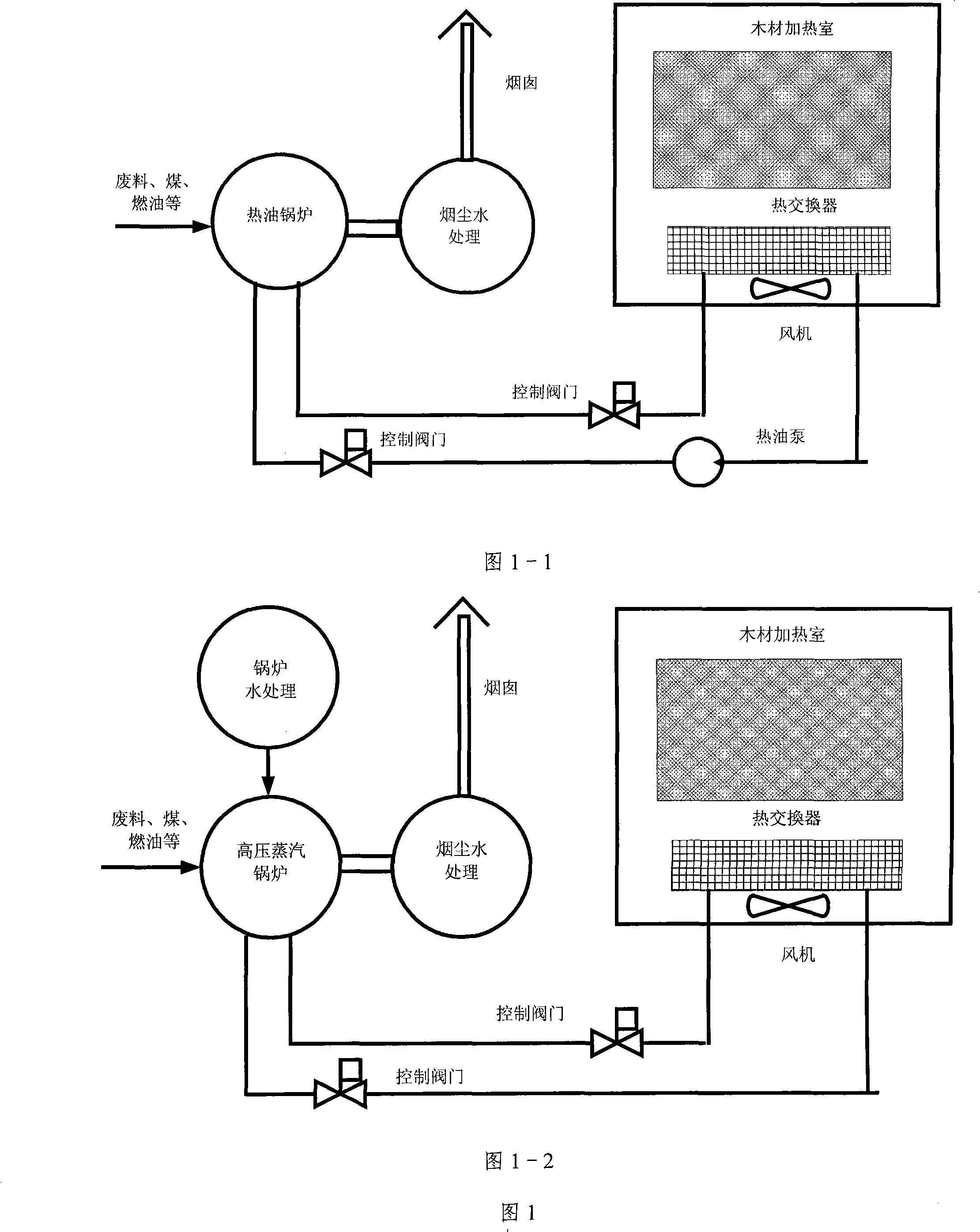

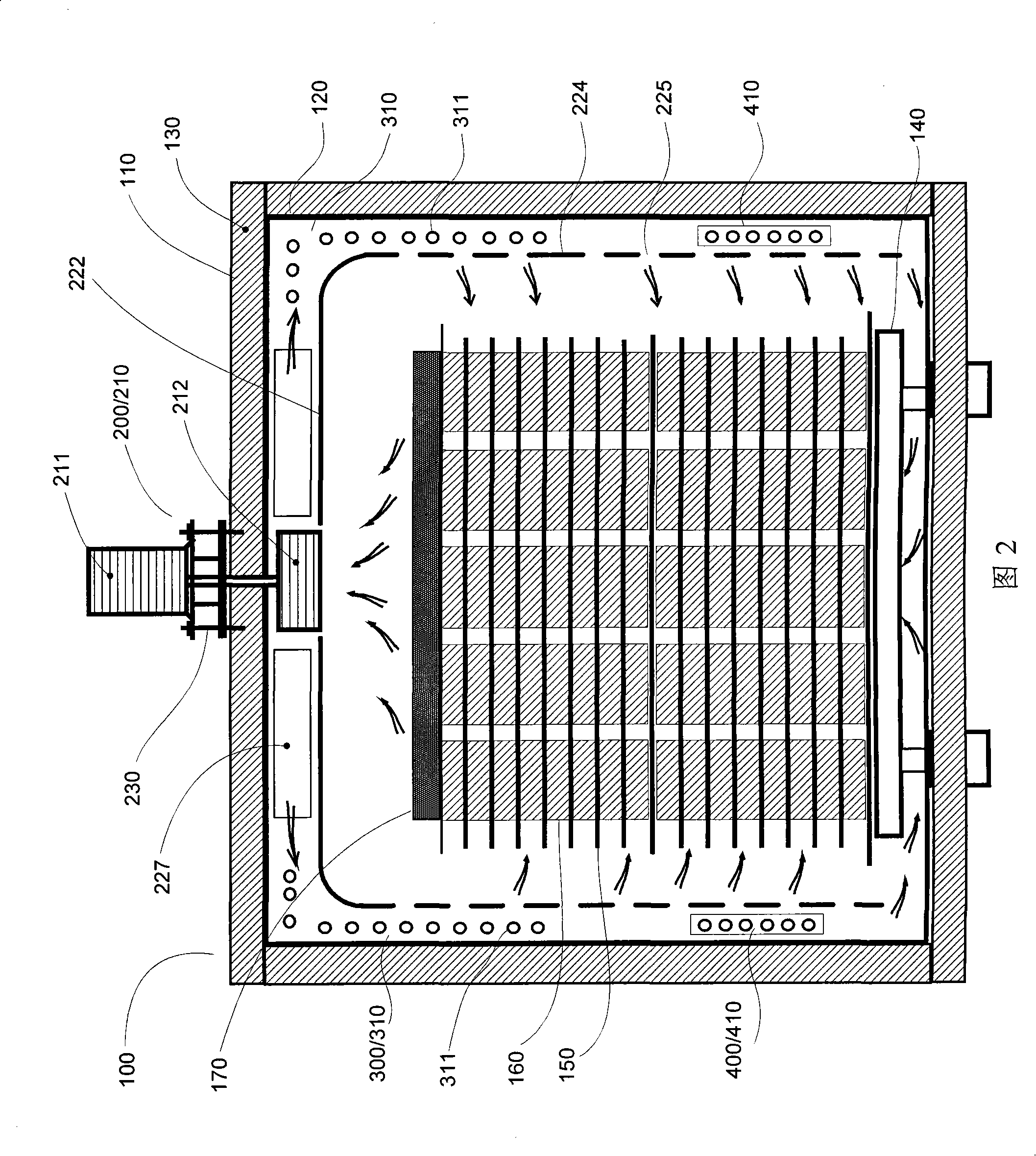

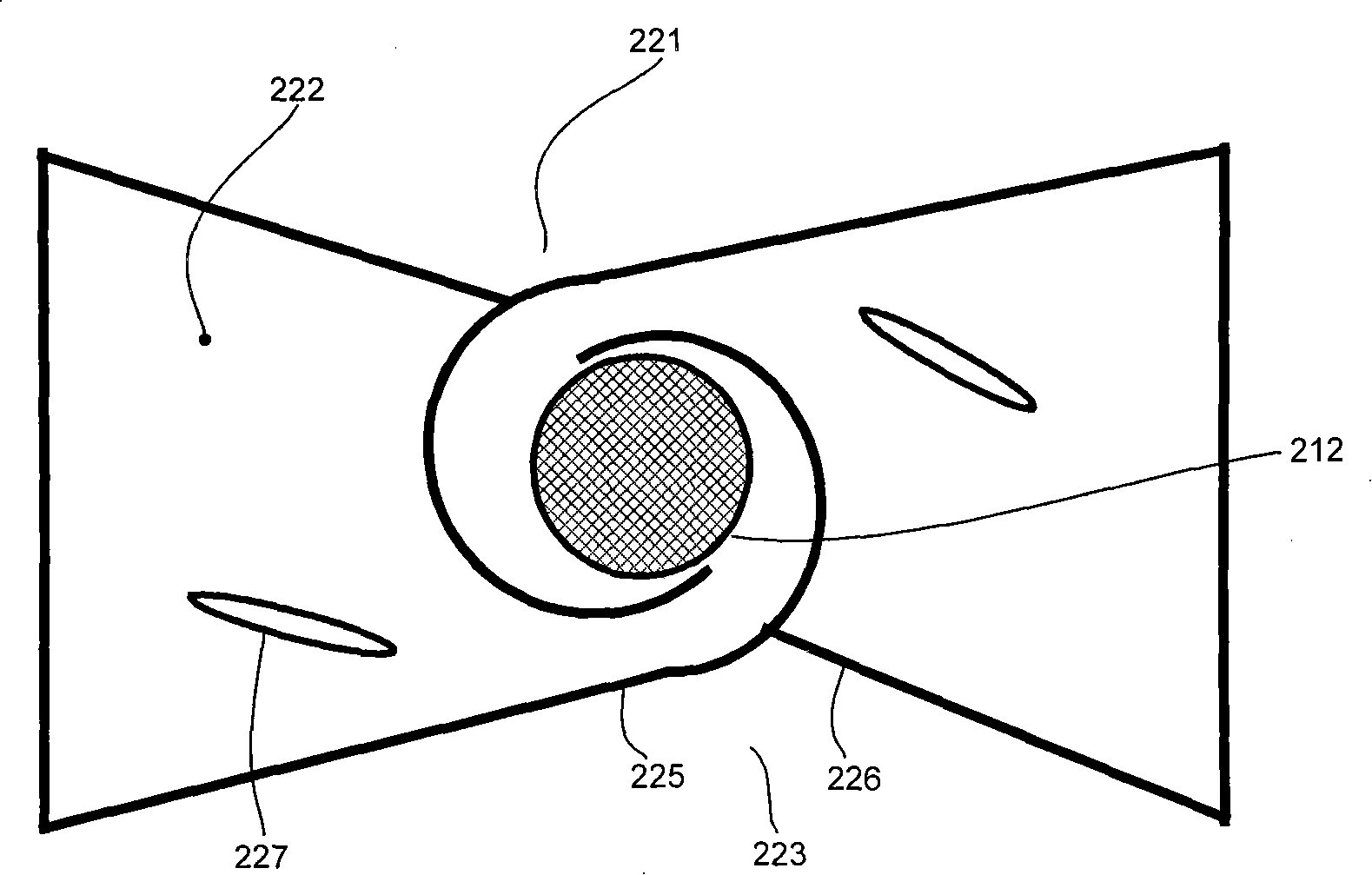

Wood electrothermal high-temperature processing device and heat treating device with combination drying function

InactiveCN101288963BReliable temperature controlEasy to operateDrying machines with local agitationDrying machines with materials at restAir cycleTemperature control

The invention relates to a wood electric heating high temperature processing device and a wood heat processing device which has the function of double-heat sources combined drying. The invention comprises a seal tank provided with a seal door, more particularly, the invention also comprises an electric heating sub-device, an air circulating sub-device and a heat exchanging sub-device. The heat sent out by the electric heating sub-device is uniformly distributed in the seal tank by the air circulating sub-device, thereby carrying out processing on the wood in the seal tank; the heat exchangingsub-device can be used for carrying out heating or temperature reducing on the wood. As the electricity is easy to be operated and controlled and the temperature control in the seal tank is accurate and reliable, the device of the invention has the advantages that the operation is simple and the using cost is low. The heat sent out by the electric heating sub-device is directly used for heating the wood by the air circulating sub-device in the seal tank, which has less heat loss and greatly improves the efficiency of the device greatly; furthermore, the device has less supporting facilities and is faster and simpler to be dismounted and mounted; the wood heat processing device which has the function of double-heat sources combined drying can carry out fast combined drying with high quality on the wood.

Owner:车炳雷

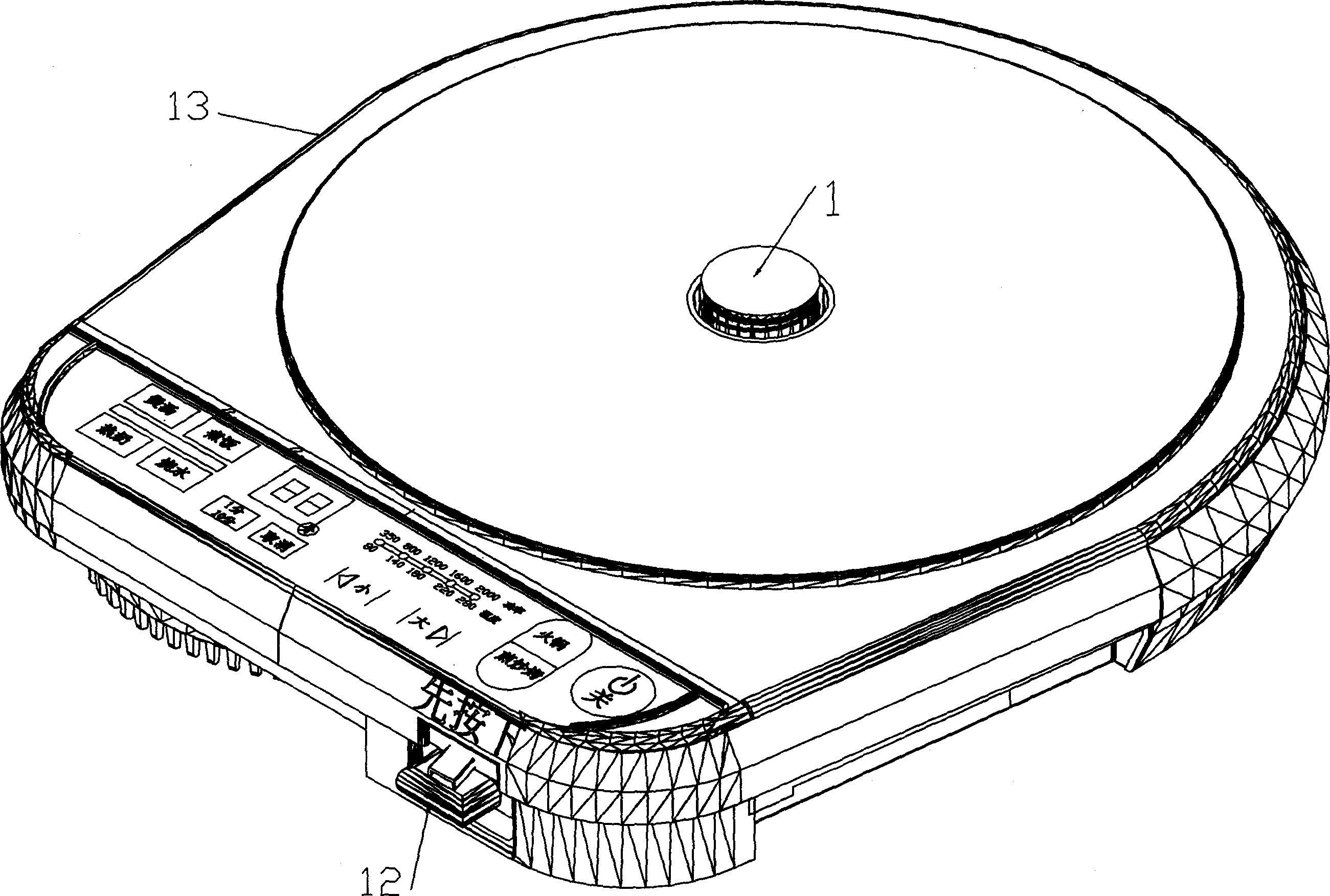

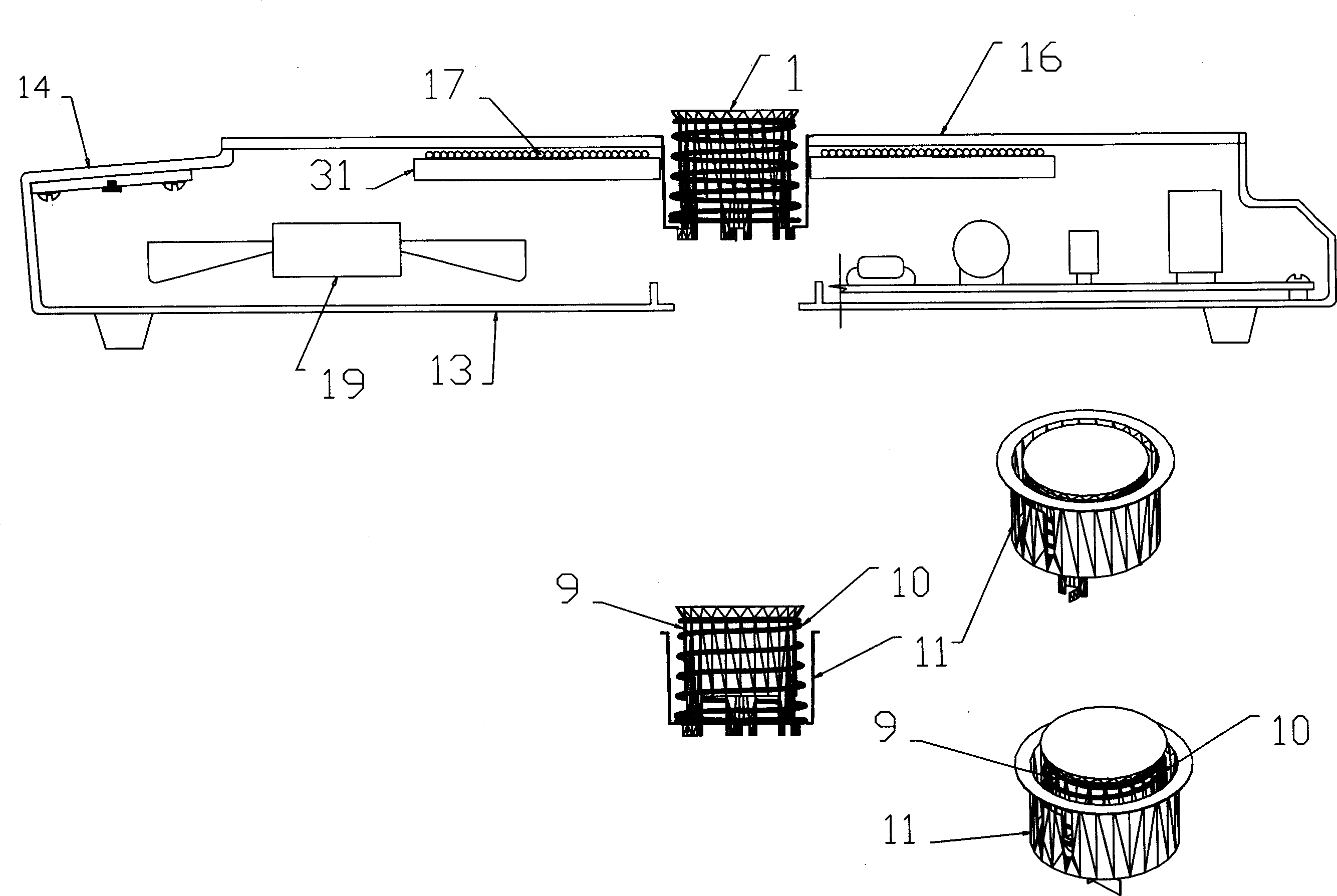

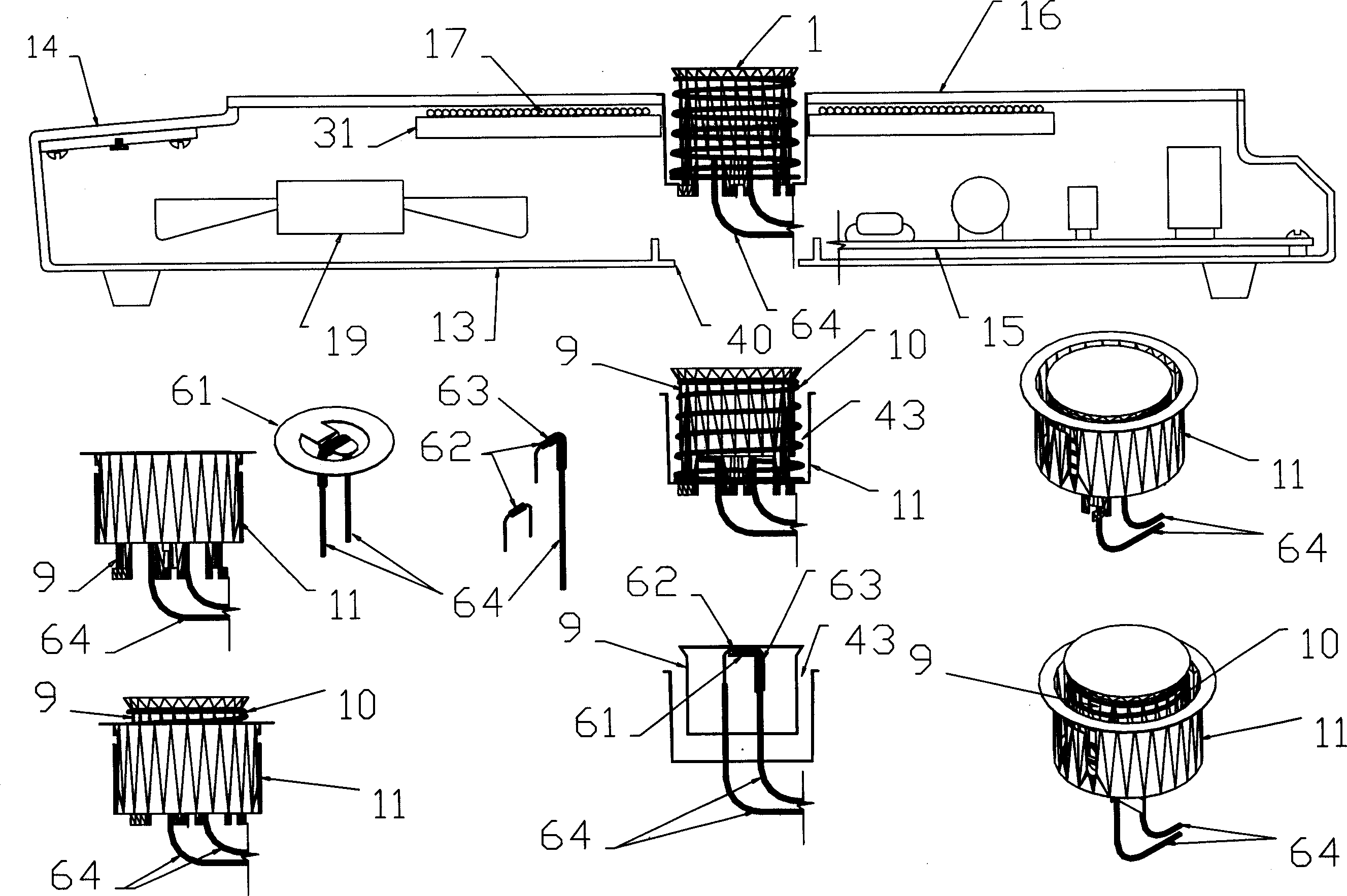

Induction cooker capable of installing sleeve

InactiveCN1916503AReliable temperature controlAccurate temperature sensingDomestic stoves or rangesLighting and heating apparatusTemperature controlElectrical resistance and conductance

An electromagnetic stove enabling to erect sleeve on it is featured as opening hole on magnetic force coil and face plate of said stove for erecting sleeve, contacting sleeve with heating component on face plate and setting temperature control element in sleeve, detecting temperature of heating component by temperature control element through sleeve.

Owner:甘柏海

A kind of rapid heating and constant temperature hot compress spirit and preparation method thereof

ActiveCN109907878BStable heating temperatureUniform heating surfaceTherapeutic coolingTherapeutic heatingTemperature controlEngineering

The invention discloses a rapid-heating constant-temperature hot compress patch and a preparation method thereof. The rapid-heating constant-temperature hot compress patch comprises a nonwoven fabriccoating layer, an adhesive layer, an automatic-temperature-control heating layer, a power-on circuit and a power source. The automatic-temperature-control heating layer is peripherally coated with thenonwoven fabric coating layer, one surface of the nonwoven fabric coating layer is provided with the adhesive layer, and the outer face of the adhesive layer is provided with a release layer. The automatic-temperature-control heating layer is connected with the power source through the power-on circuit to form electrical connection. The automatic-temperature-control heating layer is prepared from, by mass, 10-30 parts of a base material, 30-60 parts of organic crystals, 30-40 parts of conductive particles and 2-10 parts of a synthesis auxiliary agent. Compared with existing hot compress patches on the market, the rapid-heating constant-temperature hot compress patch has advantages of light weight, softness, portability, high accuracy in temperature control, elimination of scalding causedby overheating and suitableness for the demand of human body hot compress.

Owner:SOUTH CHINA UNIV OF TECH +1

Integrated sample gas suction-assisted dilution module and working method thereof

PendingCN113776917AReduce the likelihood of generatingReduce volumeWithdrawing sample devicesPreparing sample for investigationTemperature controlJet flow

The invention discloses an integrated sample gas suction-assisted dilution module and a working method thereof. The dilution module comprises a filter, a jet pump and a dilution unit which are integrated in a shell, the shell is provided with a sample gas inlet, a standard gas and reverse blowing connector, a zero gas inlet and a mixed sample gas outlet, the sample gas inlet is communicated with the dilution unit through the filter, the zero gas inlet and the mixed sample gas outlet are both communicated with the dilution unit, the sample gas inlet is communicated with the jet pump through a plurality of pumping assisting pipelines, and the sample gas inlet and the standard gas are communicated with the back flushing interface. Based on the integrated module design, the whole dilution module can realize the heat tracing function of all parts only by using one heat tracing system, so that the heat tracing structure of the system is greatly simplified, the probability that the temperature control link of the system goes wrong is reduced, the reliability of the whole system is improved, and meanwhile, the volume of the dilution module is greatly reduced.

Owner:江苏优尔孚机电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com