Flue-cured tobacco electronic cigarette

An electronic cigarette and flue-cured tobacco technology, applied in the field of electronic cigarettes, can solve the problems of poor smoking effect and taste, inconvenient cleaning, and poor taste, and achieve the effects of good smoking effect, easy cleaning and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

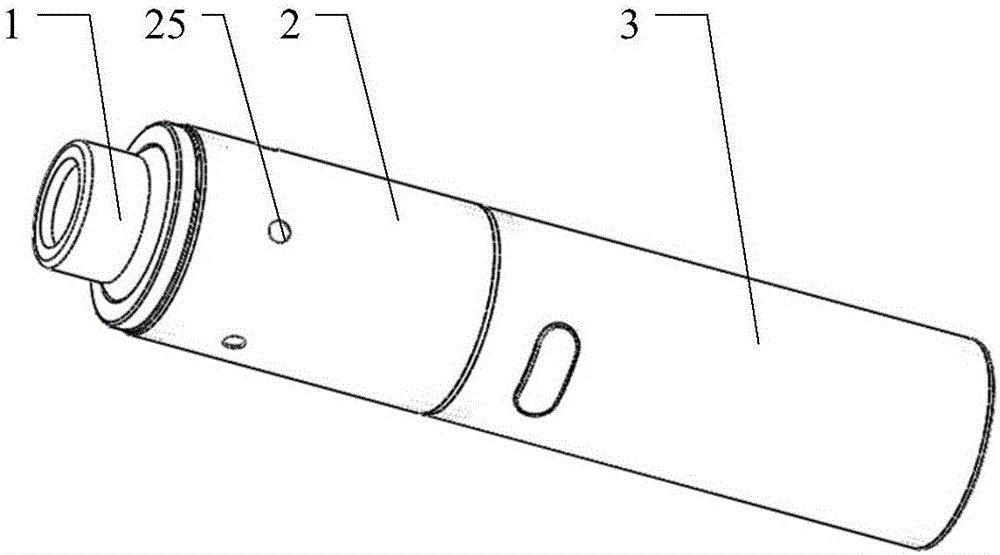

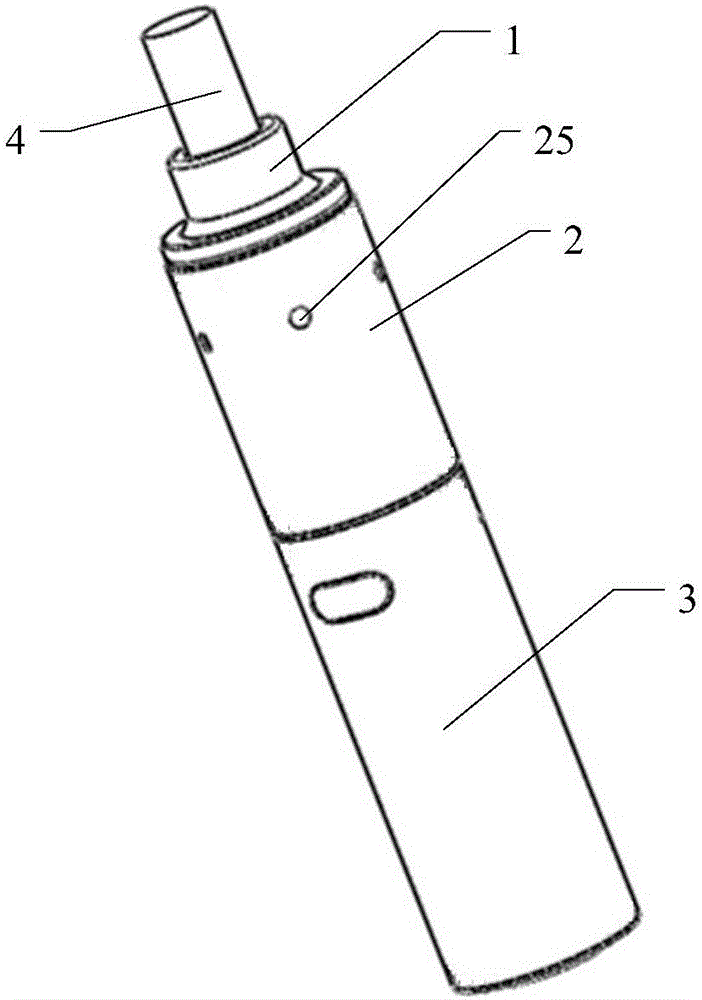

[0045] Such as Figure 1~Figure 5As shown, a flue-cured tobacco electronic cigarette includes a suction nozzle 1, an atomizing tube 2 and a battery tube 3, the atomizing tube 2 is provided with a tube 21 and a tube bracket 22, and the tube bracket 22 is located in the The bottom of the smoke liner 21, the middle part of the smoke liner 21 is provided with an upright heat conducting rod 23; the smoke liner support 22 is provided with a control circuit board 24 and a heating member electrically connected to the control circuit board 24, the The heating member is fixedly connected to the heat conducting rod 23; the battery tube 3 is located below the atomizing tube 2, and the positive and negative poles of the battery tube 3 are respectively electrically connected to the control circuit board 24; the surface of the atomizing tube 2 is provided with An air intake hole 25, an air intake gap 26 is provided between the smoke liner 21 and the liner bracket 22, and the airflow entering...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 6 As shown, the cigarette 4 is a special-purpose cigarette, and the special-purpose cigarette includes a filter tip 41, a secondary filter member 42 and a tobacco leaf roll body 43 connected in sequence, and the tobacco leaf roll body 43 is provided with tobacco leaves and tobacco leaf wetting liquid. The material of the secondary filter member 42 is a polymer porous material. Wherein, the tobacco leaf rolling body is the same as a normal cigarette, and contains tobacco leaf shreds inside. The tobacco leaf wetting liquid is a liquid that increases the humidity of the tobacco leaves and evaporates after heating. Preferably, the tobacco leaf wetting liquid is VG (vegetable glycerin, vegetable glycerin).

[0051] With this technical solution, the shredded tobacco leaves in the tobacco leaf roll are mixed with the tobacco leaf wetting liquid and then heated, the active ingredients in the shredded tobacco leaves can be dissolved i...

Embodiment 3

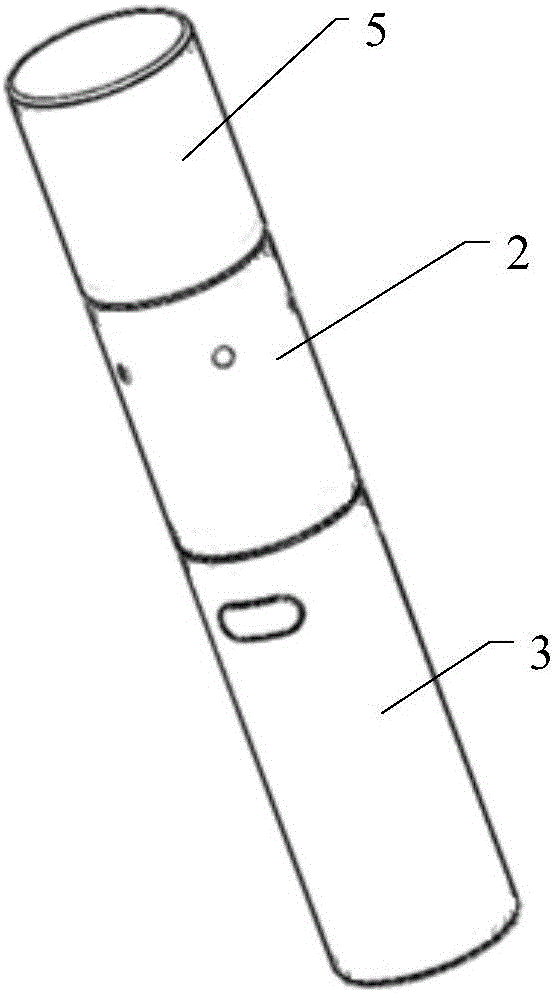

[0053] On the basis of Example 1, such as Figure 7 and Figure 8 As shown, the surface of the flue-cured tobacco electronic cigarette is provided with a switch button, a smoking button, an LED indicator light and a charging interface, and the switch button, the smoking button, an LED indicator light and a charging interface are respectively electrically connected to the control circuit board. The circuit part of the flue-cured tobacco electronic cigarette also includes an NTC thermal element, and the heating component is electrically connected to the control circuit board through the NTC thermal element. The heating member is a nickel heating sheet, and the nickel heating sheet is fixed together with the NTC thermosensitive electronics, which is convenient for better temperature control.

[0054] Such as Figure 7 and Figure 8 As shown, the circuit module of the flue-cured tobacco electronic cigarette includes a power management module, a power supply module, a battery an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com