Wood electrothermal high-temperature processing device and heat treating device with combination drying function

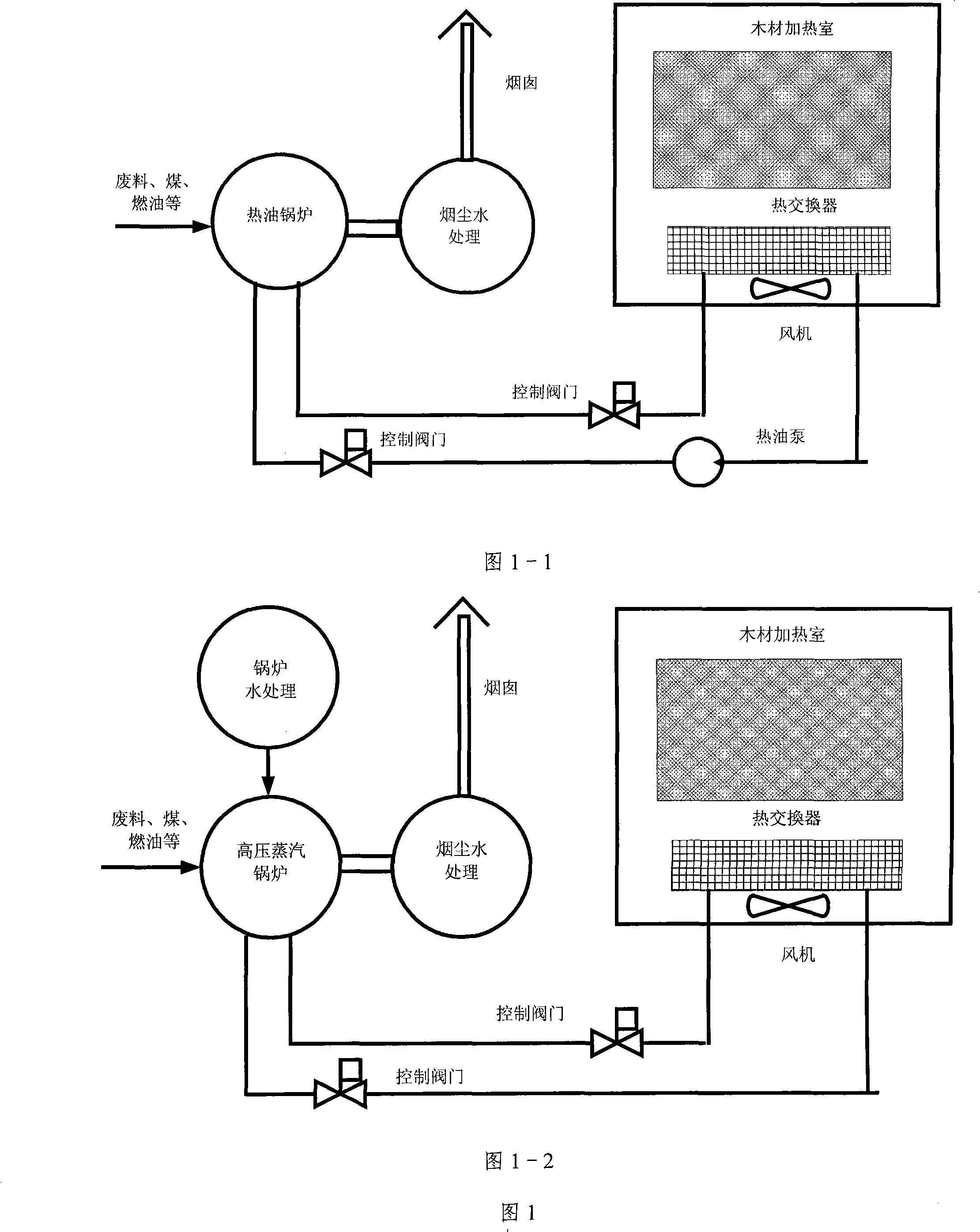

A technology of high-temperature heat treatment and combined drying, which is applied in lighting and heating equipment, partial agitation dryers, dryers for static materials, etc., can solve the problems of high safety measures, large heat loss, unfavorable paint, gluing and other processing techniques, etc. , to achieve fast and simple disassembly and installation, improved safety and reliability, fast and high-quality joint drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Further details will be given below in conjunction with various embodiments shown in the accompanying drawings.

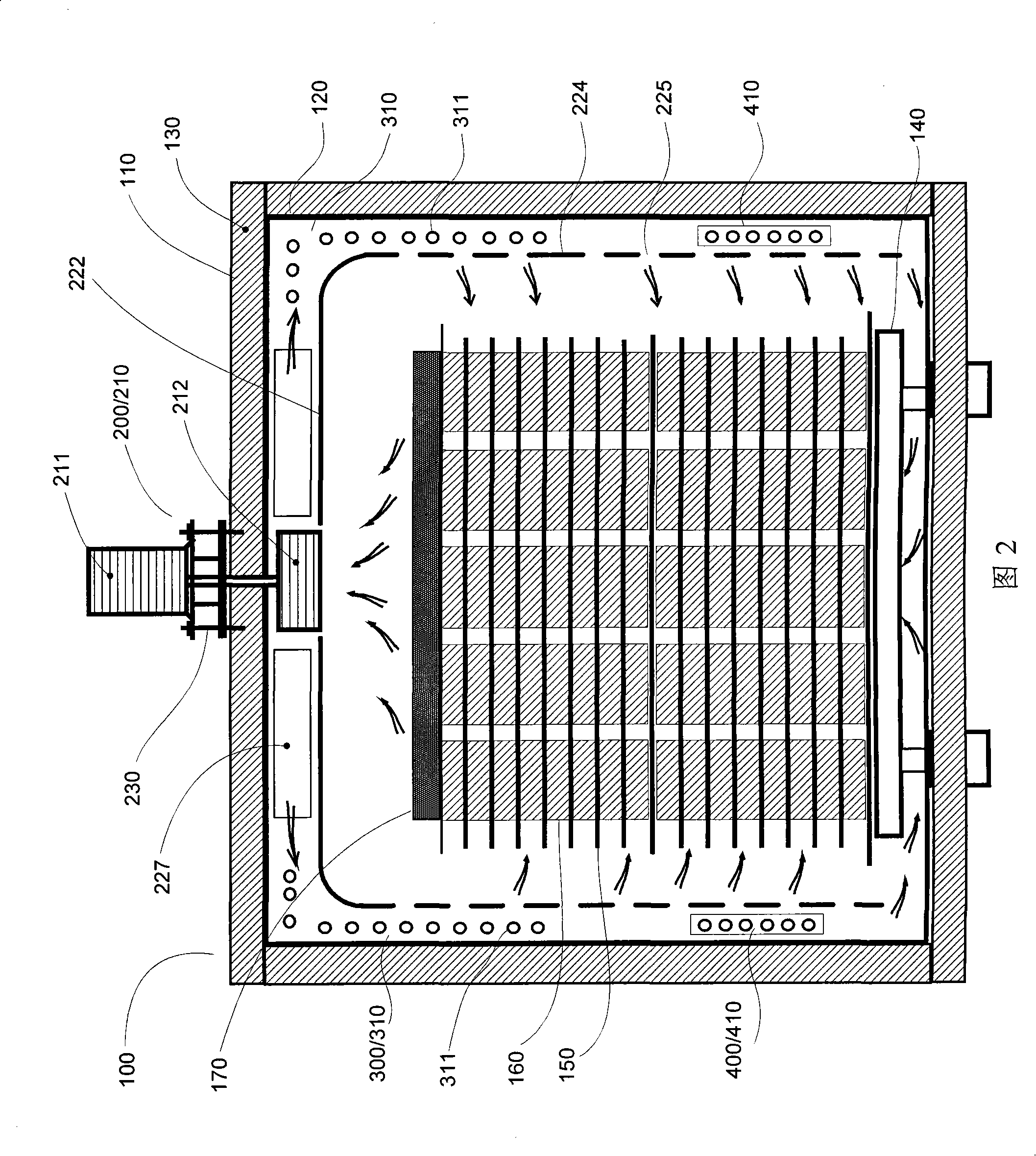

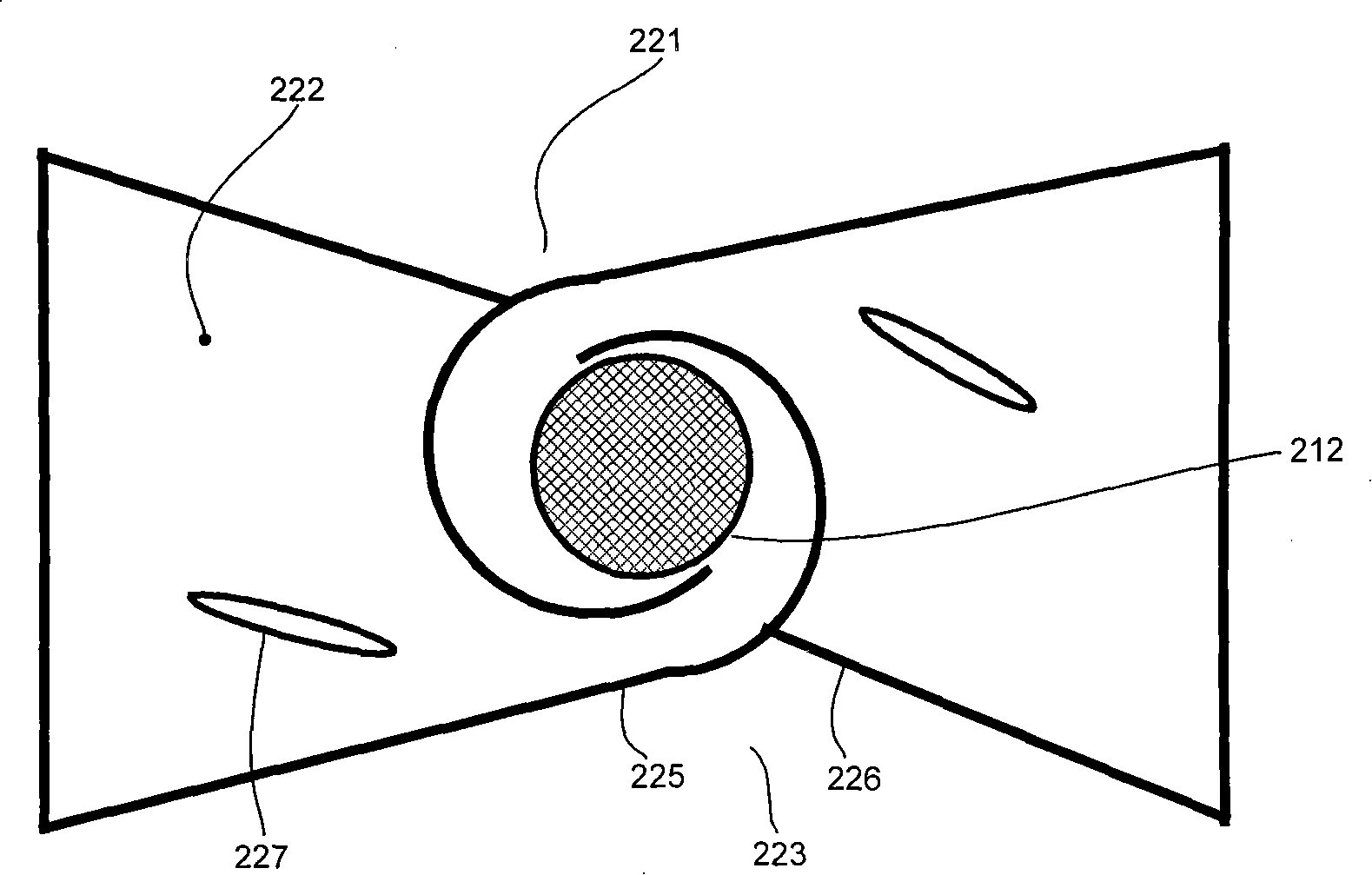

[0048] The present invention relates to a wood electric heating high-temperature heat treatment equipment, comprising a sealed cabinet 100 with a sealed door and a cooling sub-equipment 400; It is used to cool down the wood after high temperature heat treatment; especially, it also includes electric heating sub-equipment 300 and air circulation sub-equipment 200; the heat emitted by the electric heating sub-equipment 300 is evenly distributed to the sealing In the cabinet 100, the wood in the sealed cabinet 100 is subjected to high-temperature heat treatment.

[0049] In the first embodiment of the present invention, as shown in FIG. 2 , the sealed cabinet 100 further includes a sealed cabinet body 110 , a heat insulation board 120 arranged along the inner wall of the sealed door and the sealed cabinet body 110 , and an insulating material 130 ; The thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com