Patents

Literature

70results about How to "Accurate temperature sensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

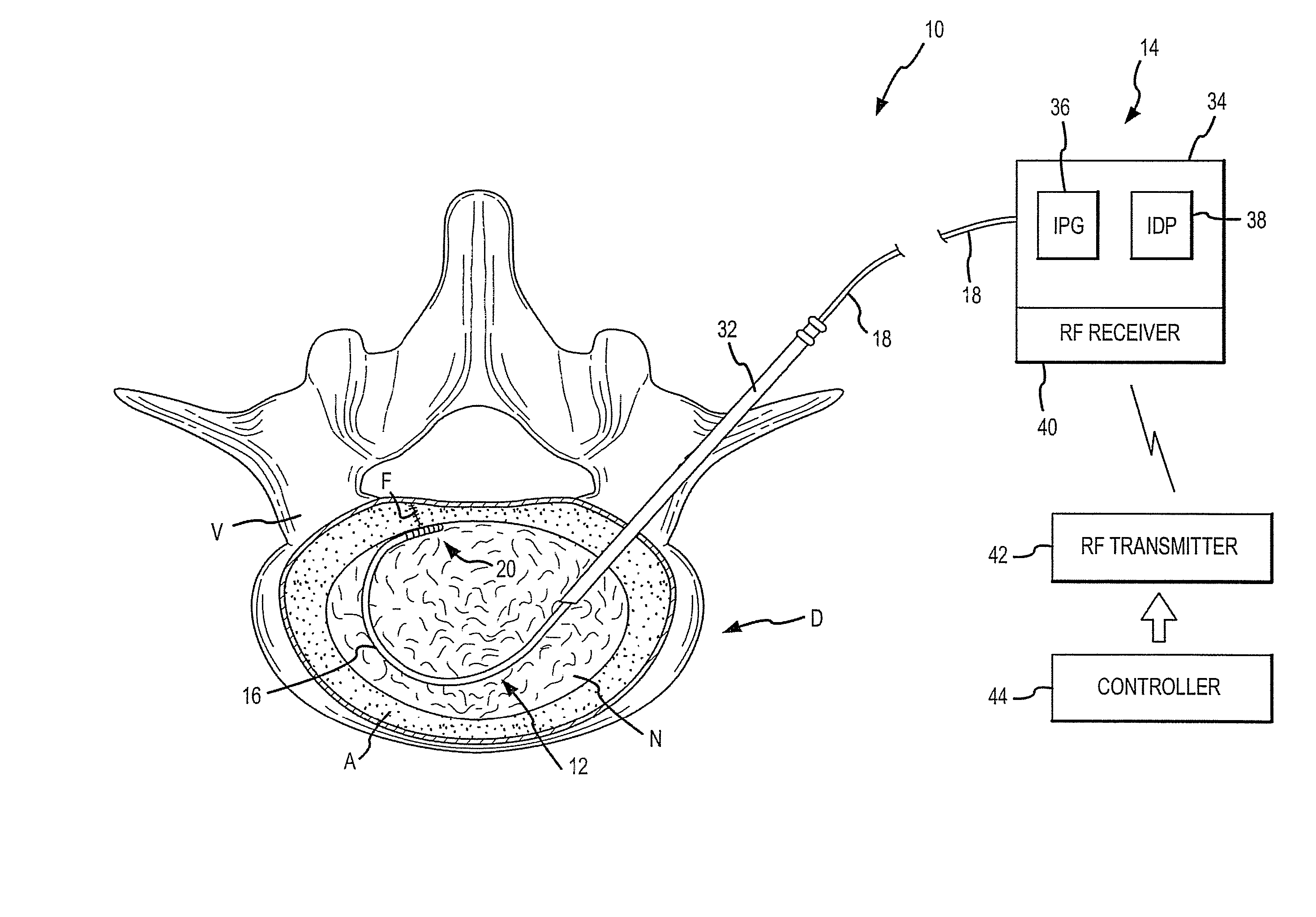

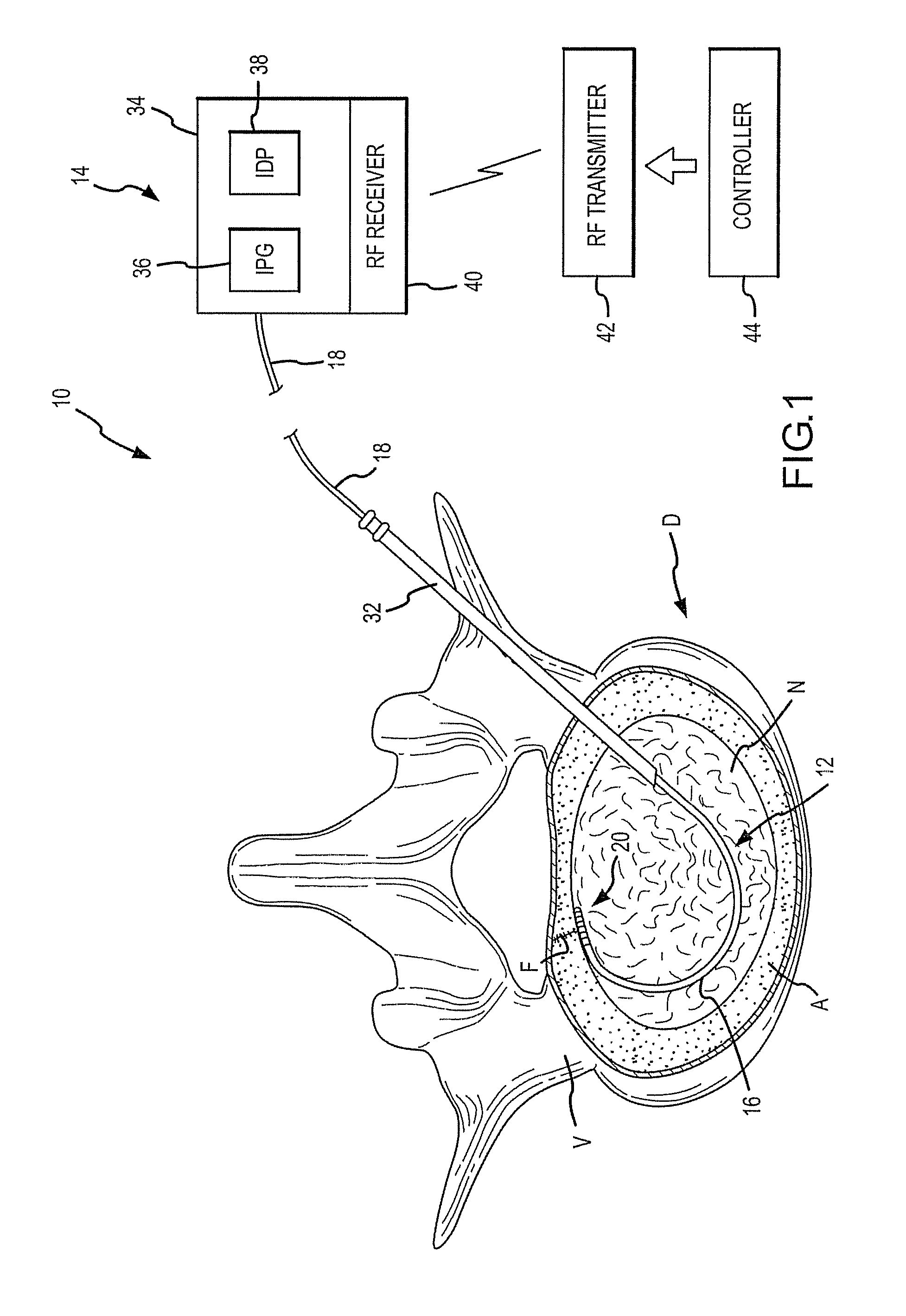

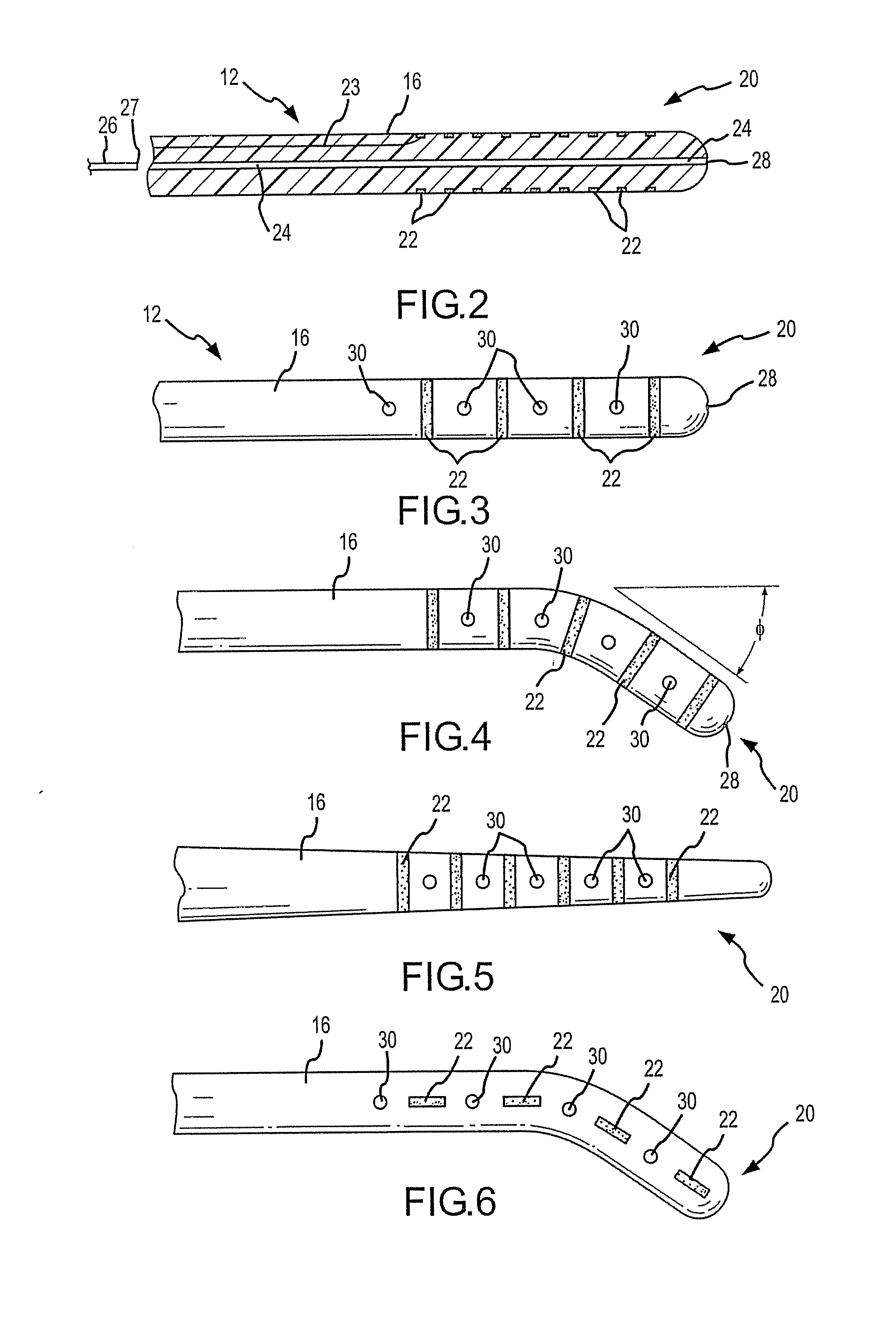

Combination Electrical Stimulating and Infusion Medical Device and Method

InactiveUS20080009927A1Prevent inadvertent bucklingAvoid displacementSpinal electrodesSurgical needlesElectricityChemical stimuli

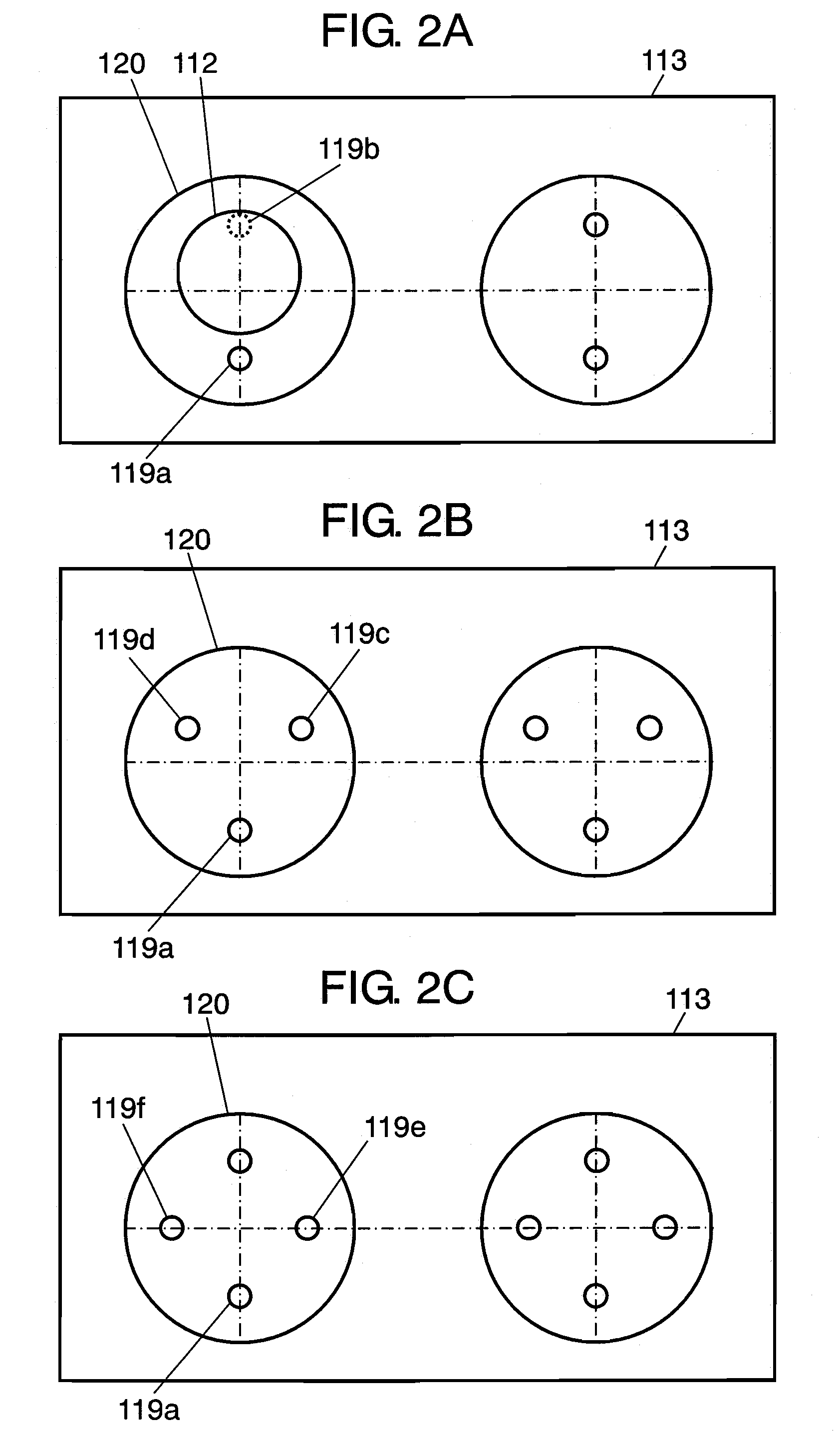

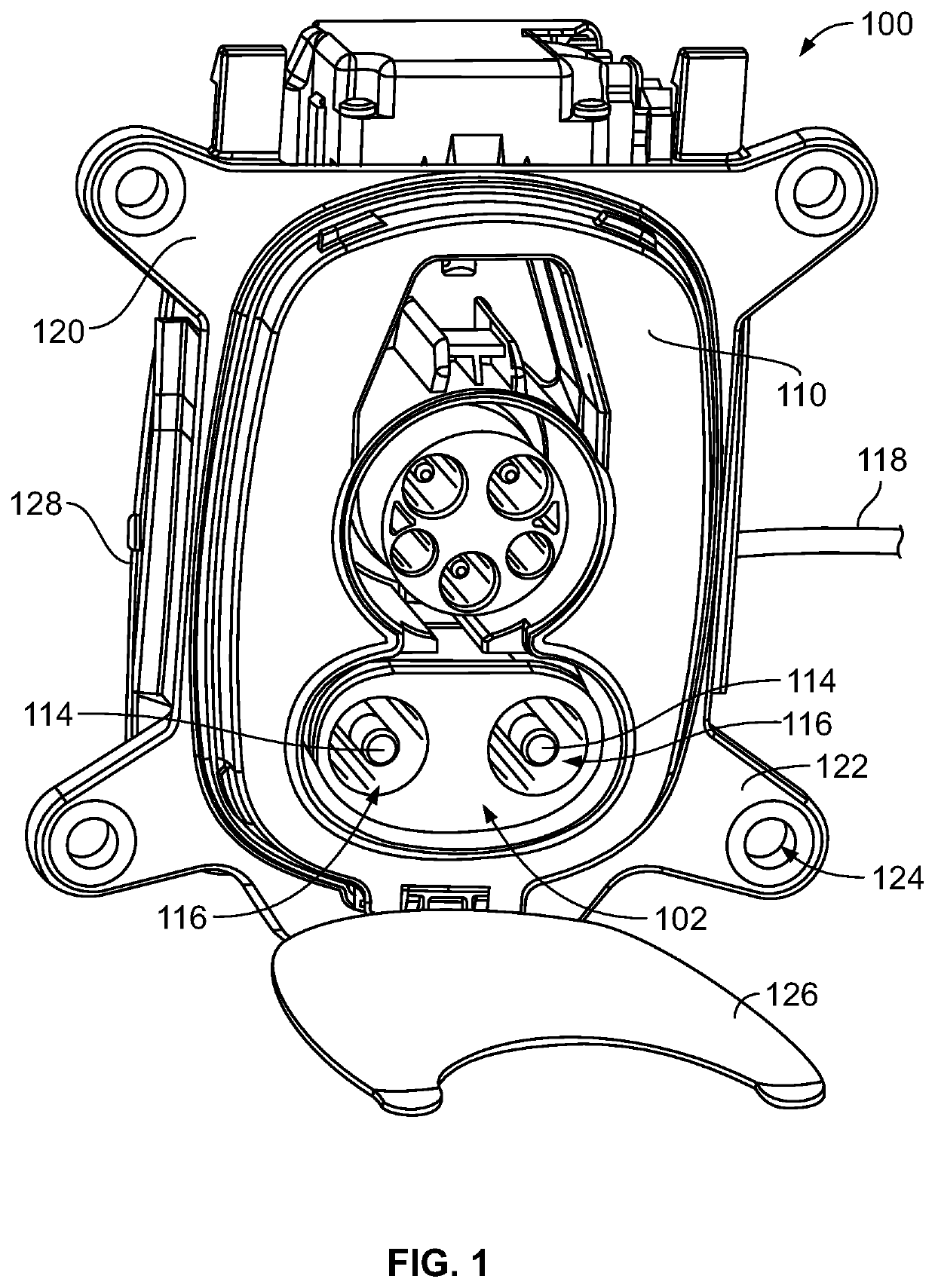

A combined electrical and chemical stimulation lead is especially adapted for providing treatment to the spine and nervous system. The stimulation lead includes electrodes that may be selectively positioned along various portions of the stimulation lead in order to precisely direct electrical energy to ablate or electrically stimulate the target tissue. Embodiments of the stimulation lead include single or multiple lead elements. The multiple lead element embodiments can be selectively deployed to cover a targeted area. The lead may also includes central infusion passageway(s) or lumen(s) that communicates with various infusion ports spaced at selected locations along the lead to thereby direct the infusion of nutrients / chemicals to the target tissue. Some embodiments utilize a disposable sheath in combination with a reusable stimulation lead.

Owner:VILIMS BRADLEY D

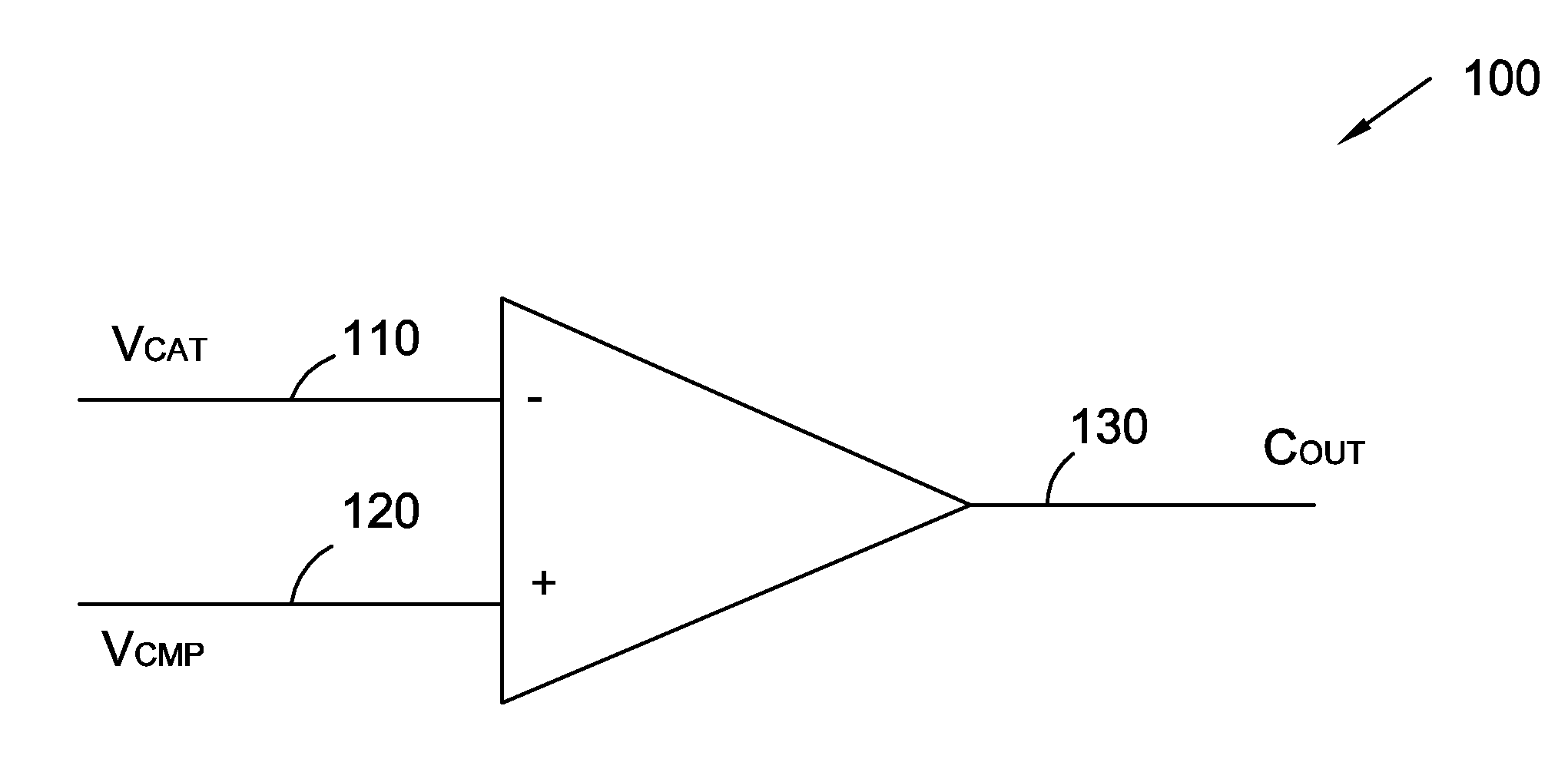

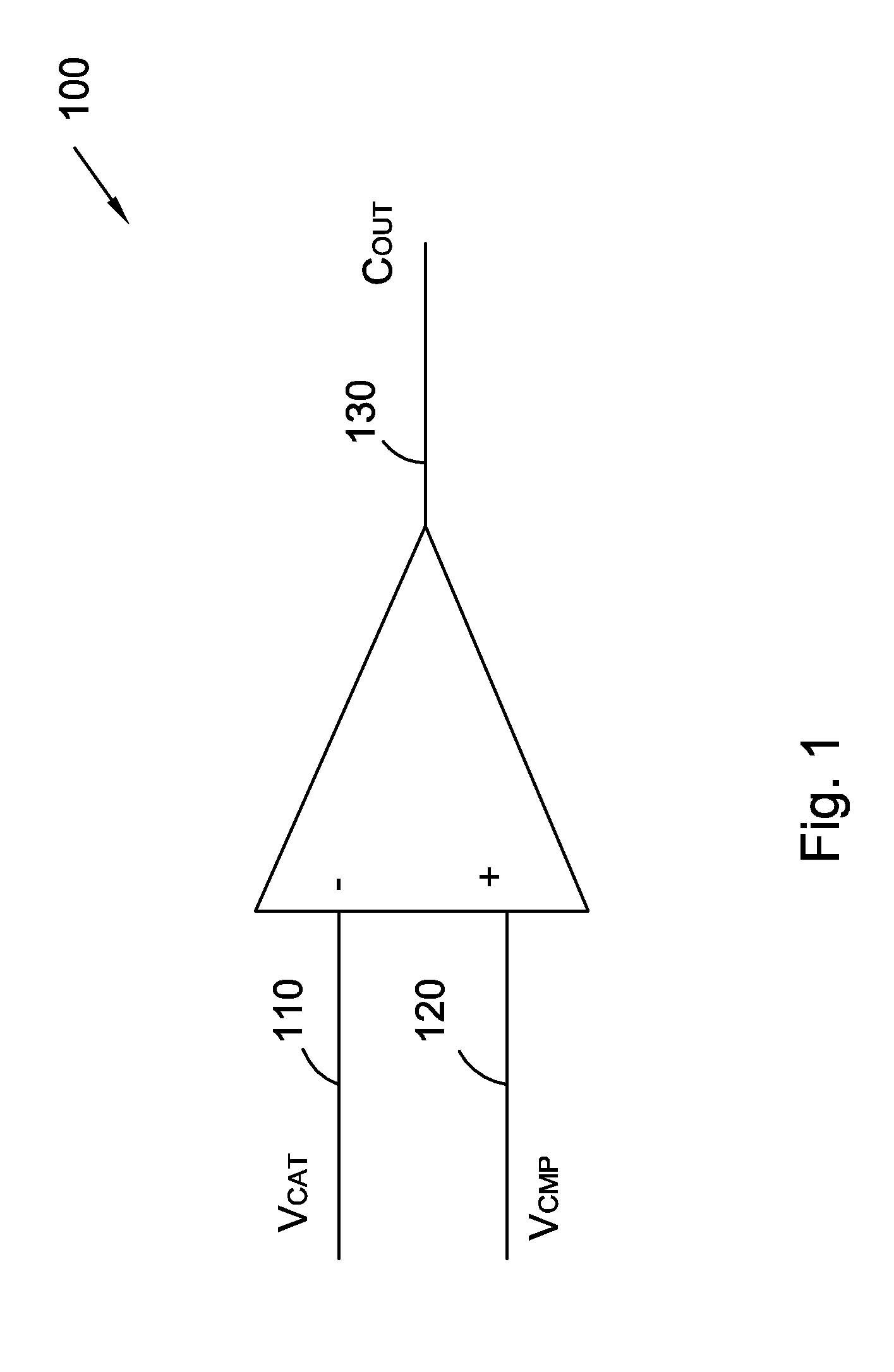

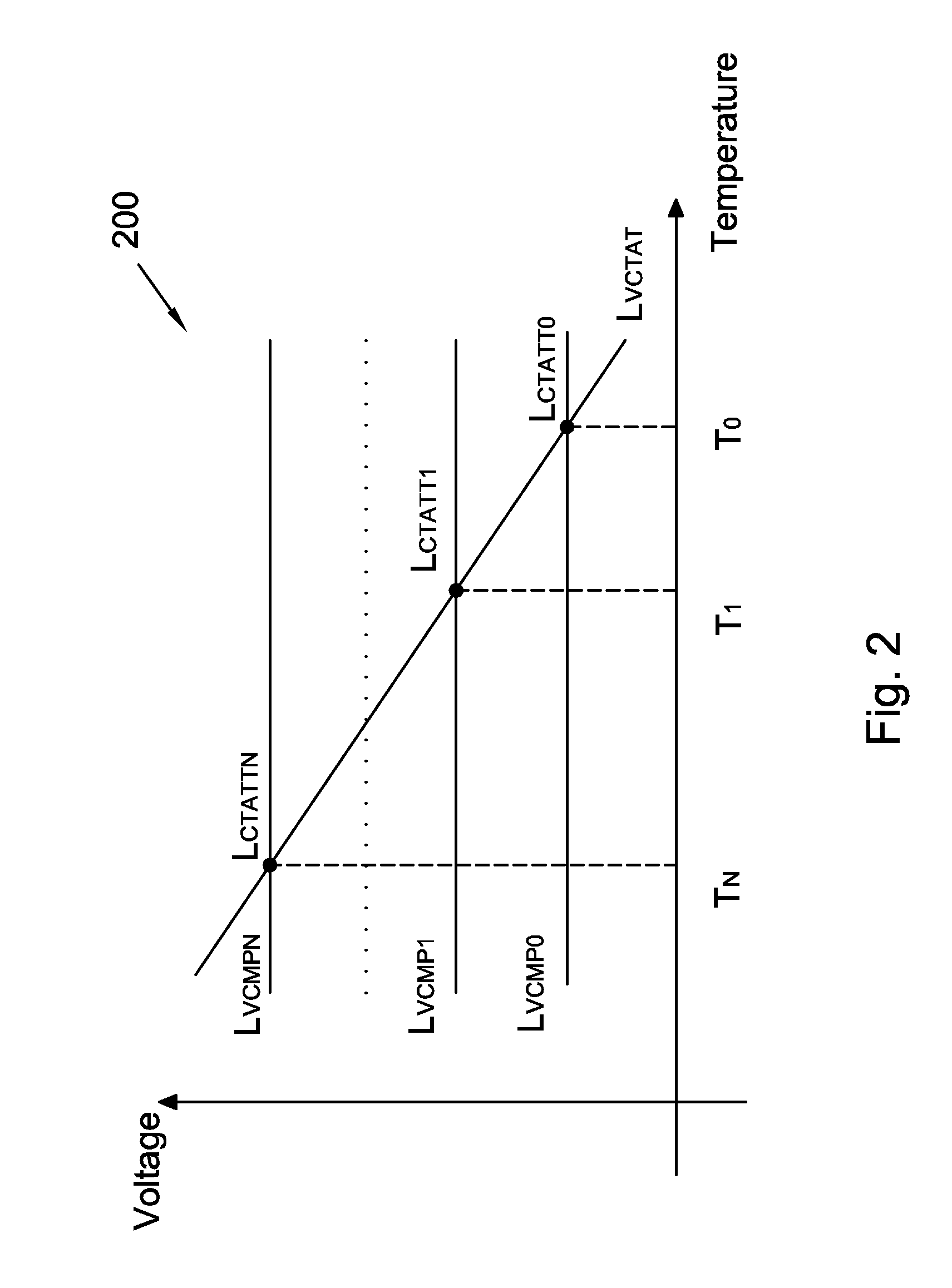

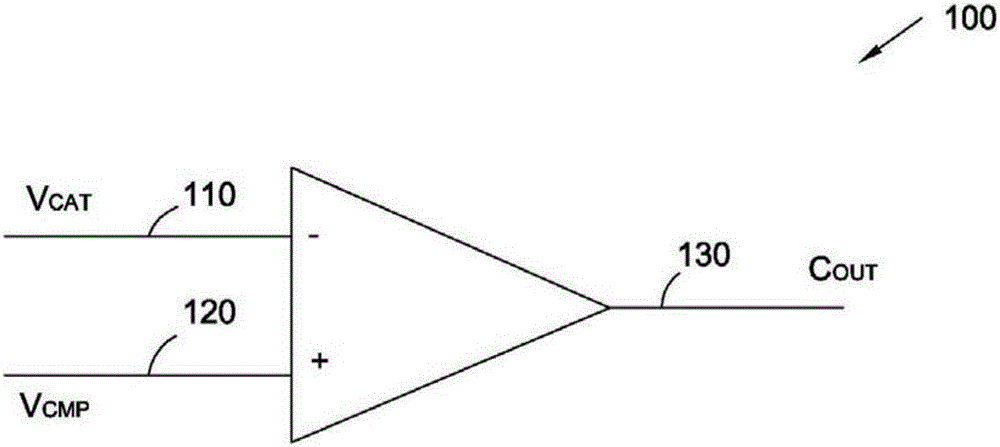

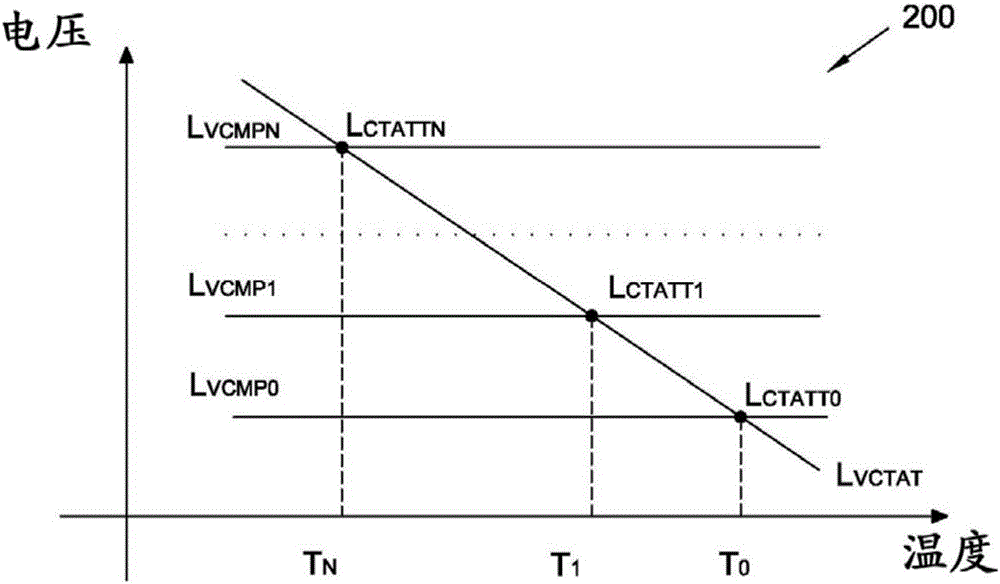

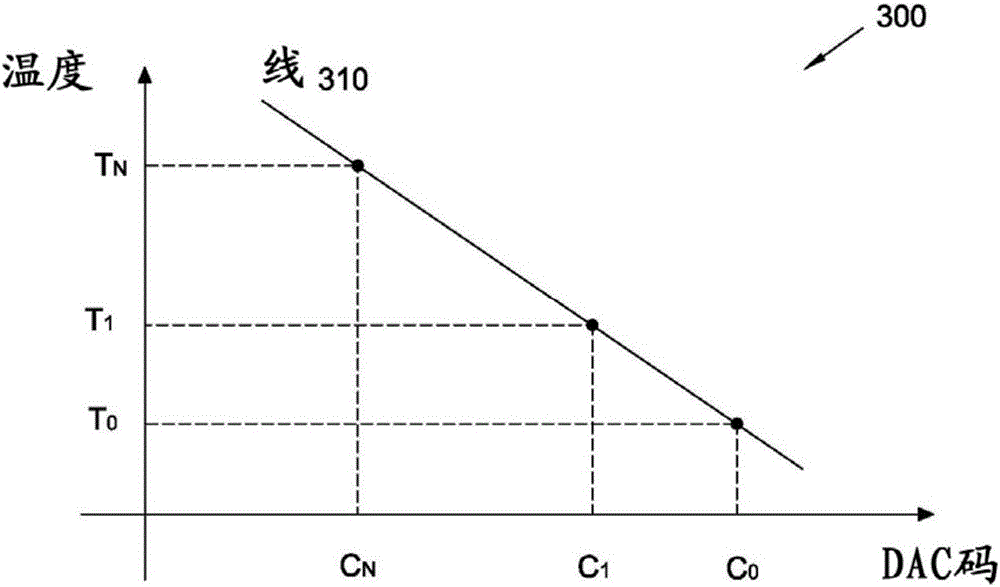

Thermal sensors and methods of operating thereof

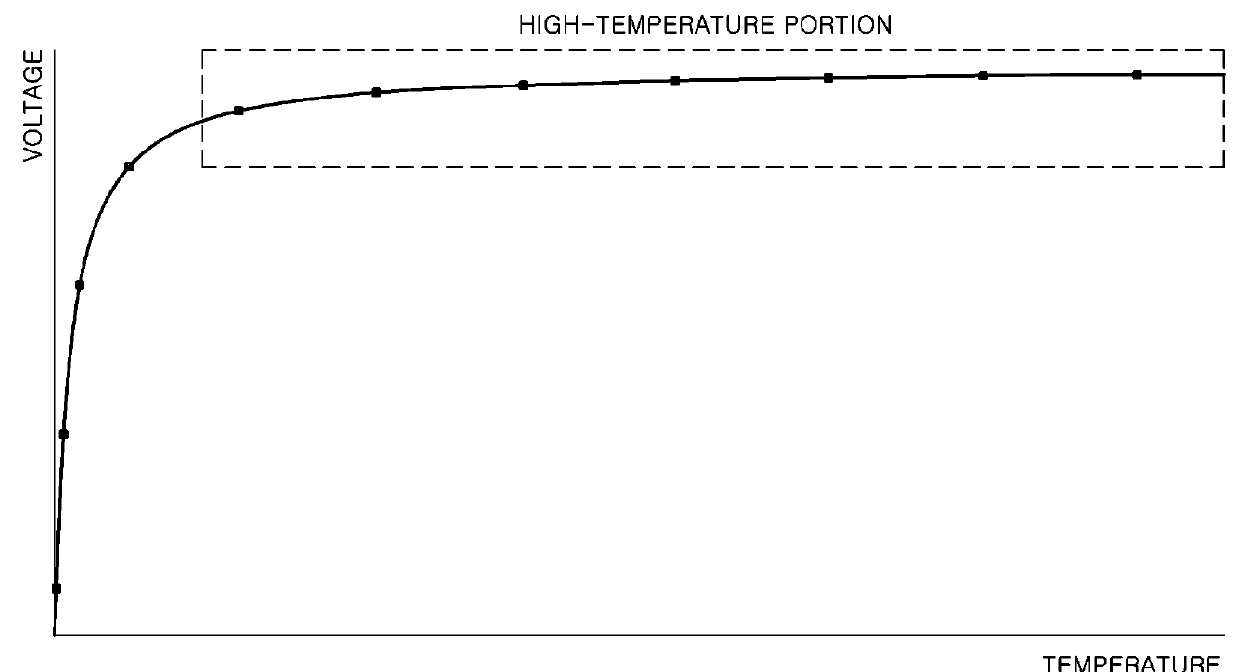

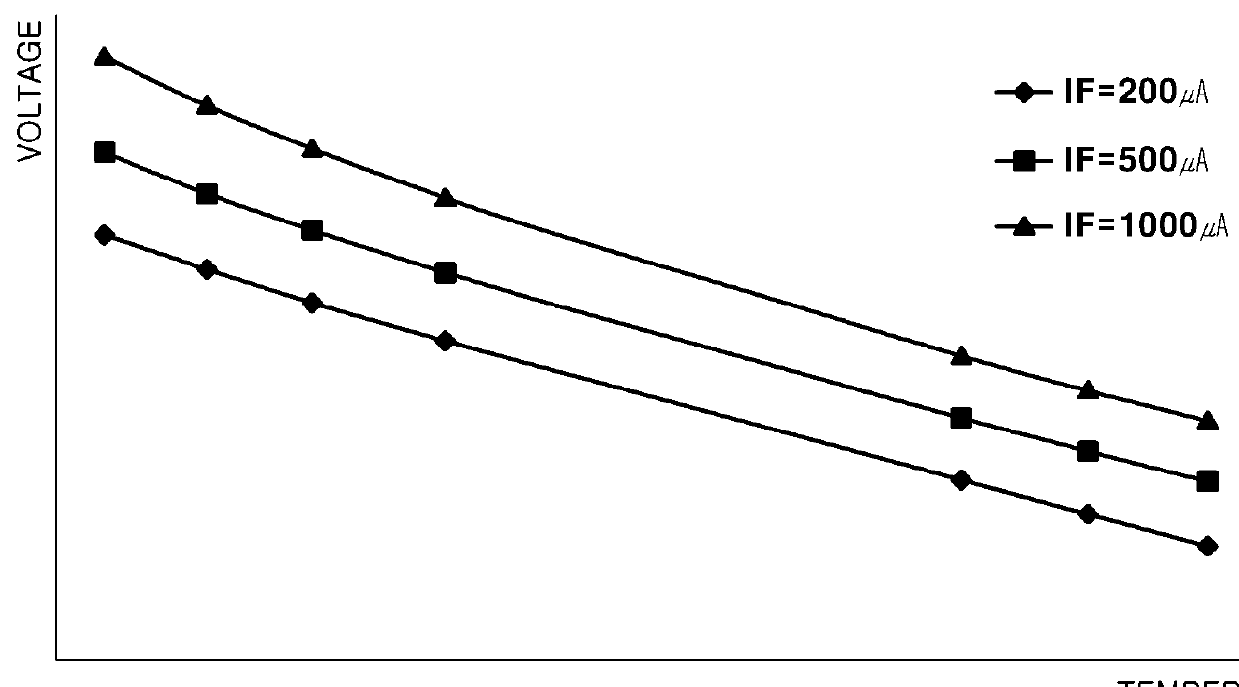

ActiveUS20110255568A1Improve accuracySimple temperature calibrationThermometer with A/D convertersThermometers using electric/magnetic elementsEngineeringVoltage reference

A thermal sensor includes a comparator having a first and second input nodes. A reference voltage generator is electrically coupled with the first input node. The reference voltage generator is configured to provide a reference voltage that is substantially temperature-independent. A temperature sensing circuit is electrically coupled with the second input node. The temperature sensing circuit is configured to provide a temperature-dependent voltage. The temperature sensing circuit includes a current mirror. A first metal-oxide-semiconductor (MOS) transistor is electrically coupled between the current mirror and ground. A first resistor is electrically coupled with the current mirror. A second MOS transistor is electrically coupled with the first resistor in series. The second MOS transistor and the first resistor are electrically coupled with the first MOS transistor in a parallel fashion.

Owner:TAIWAN SEMICON MFG CO LTD

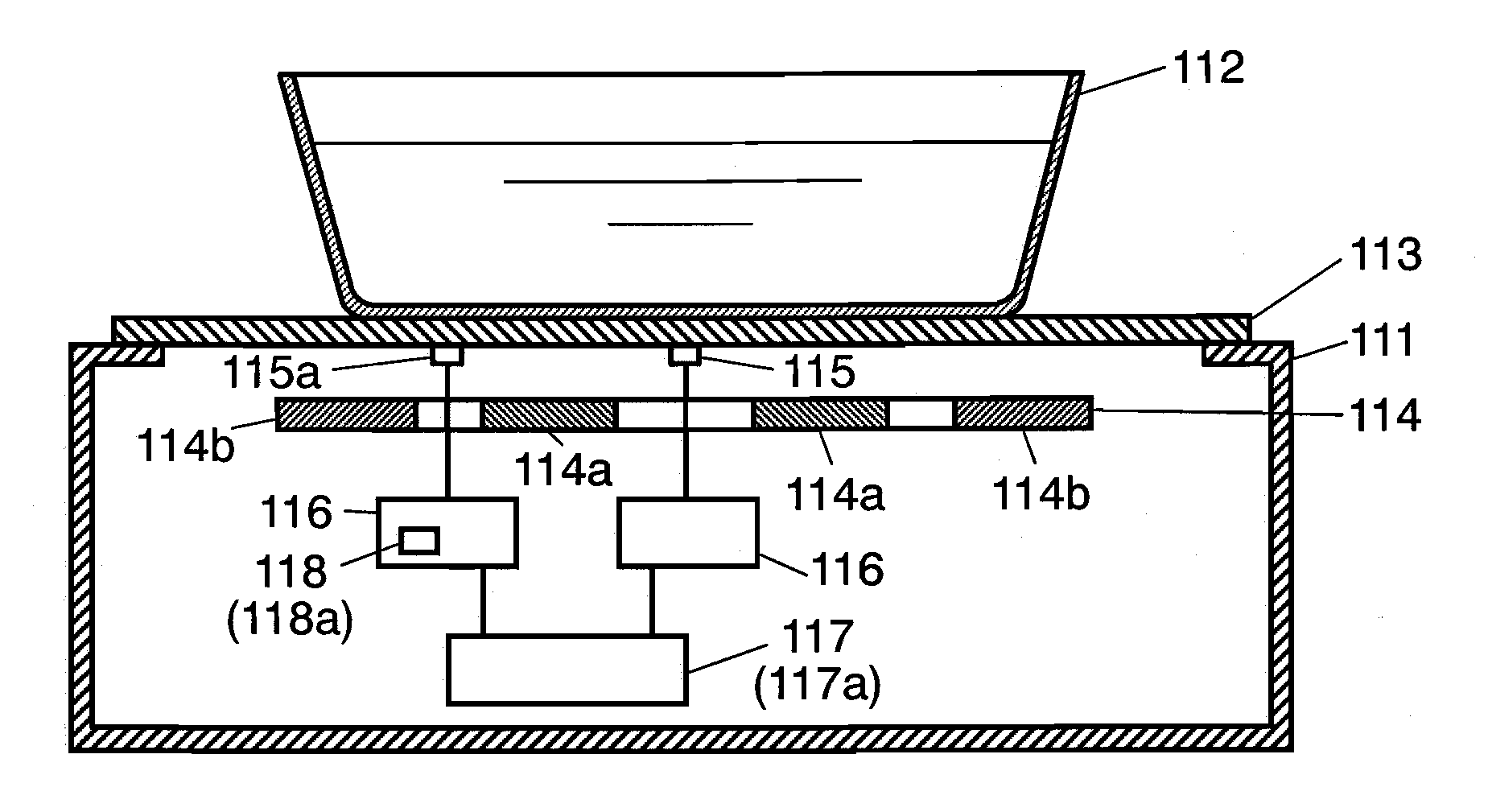

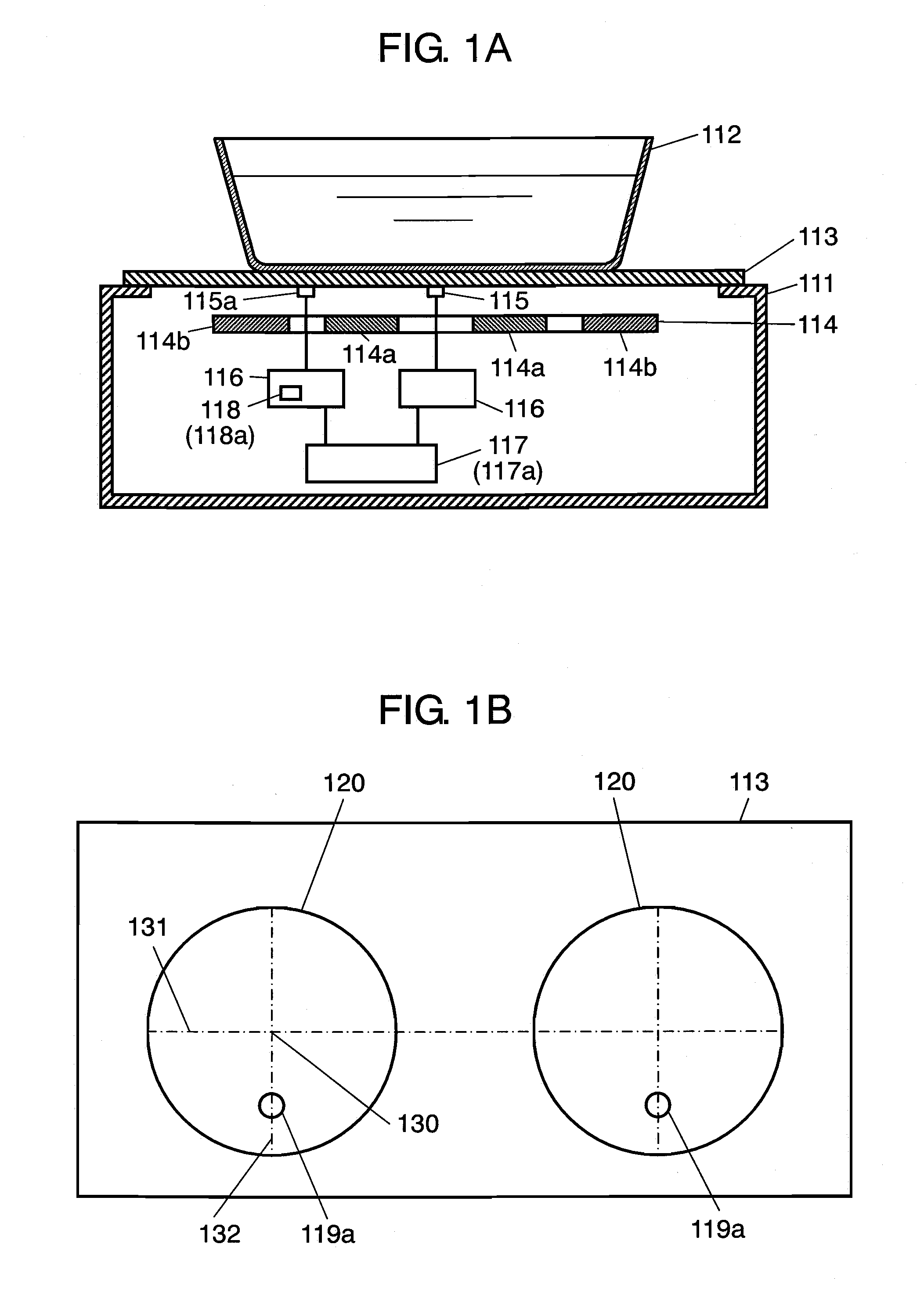

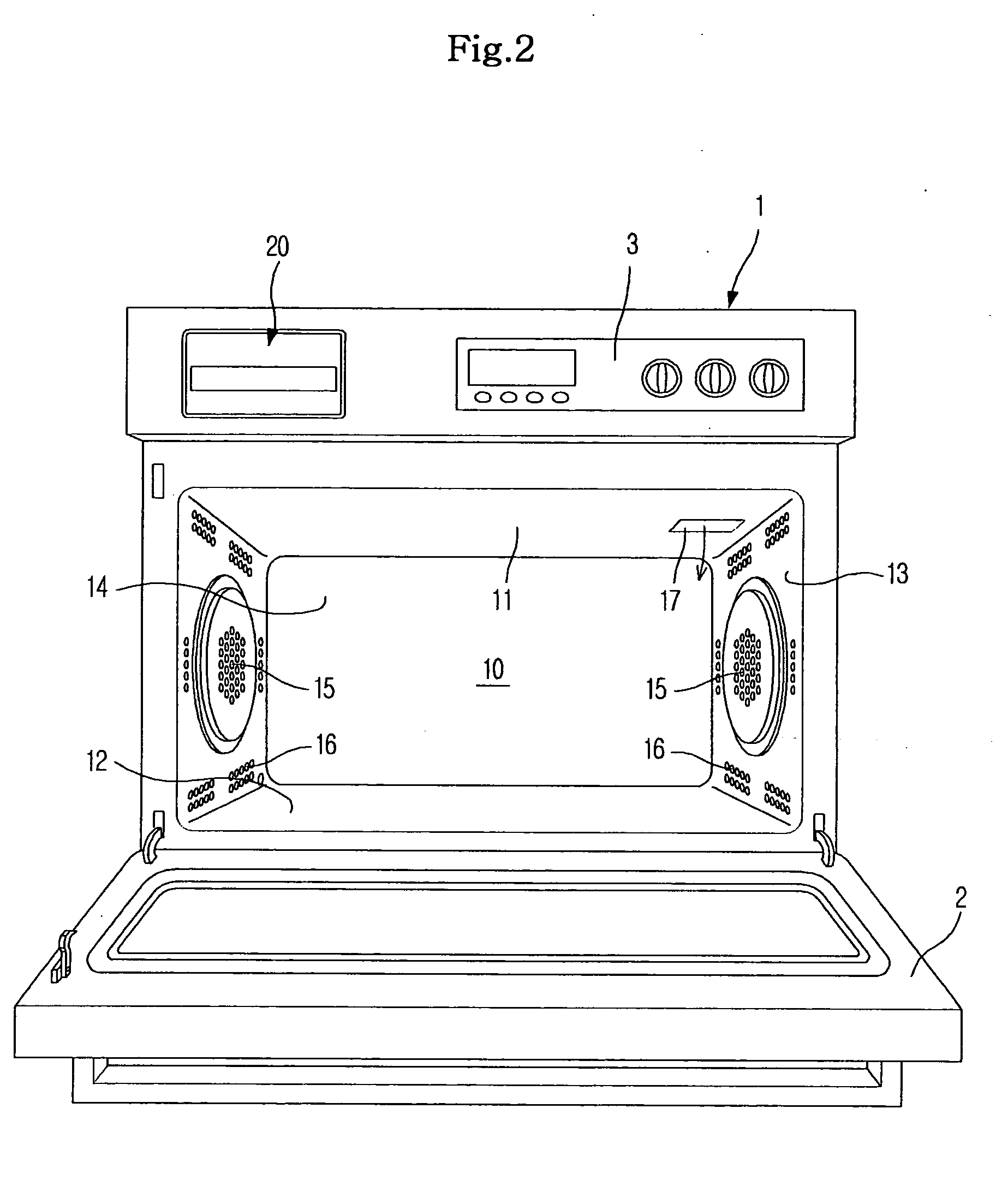

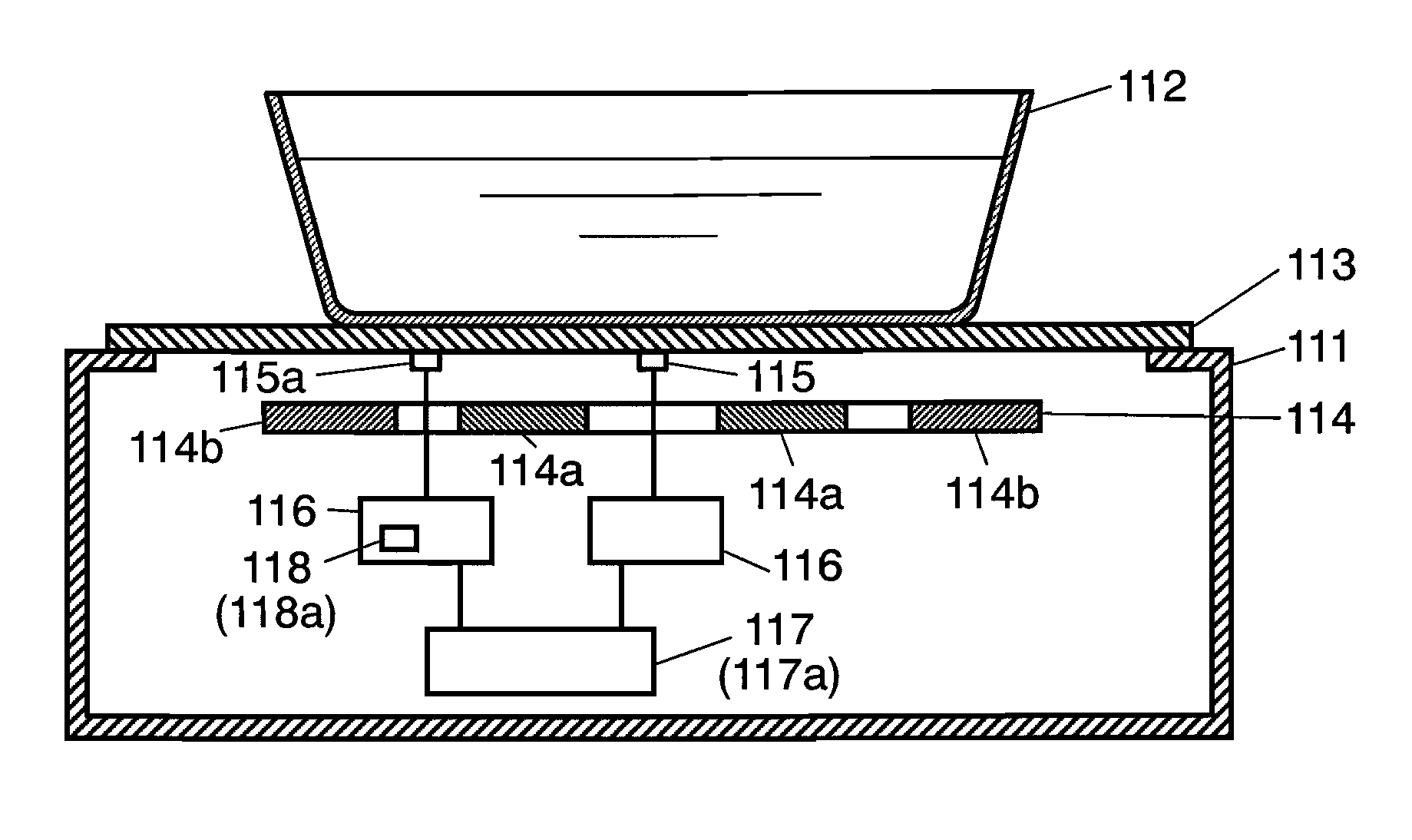

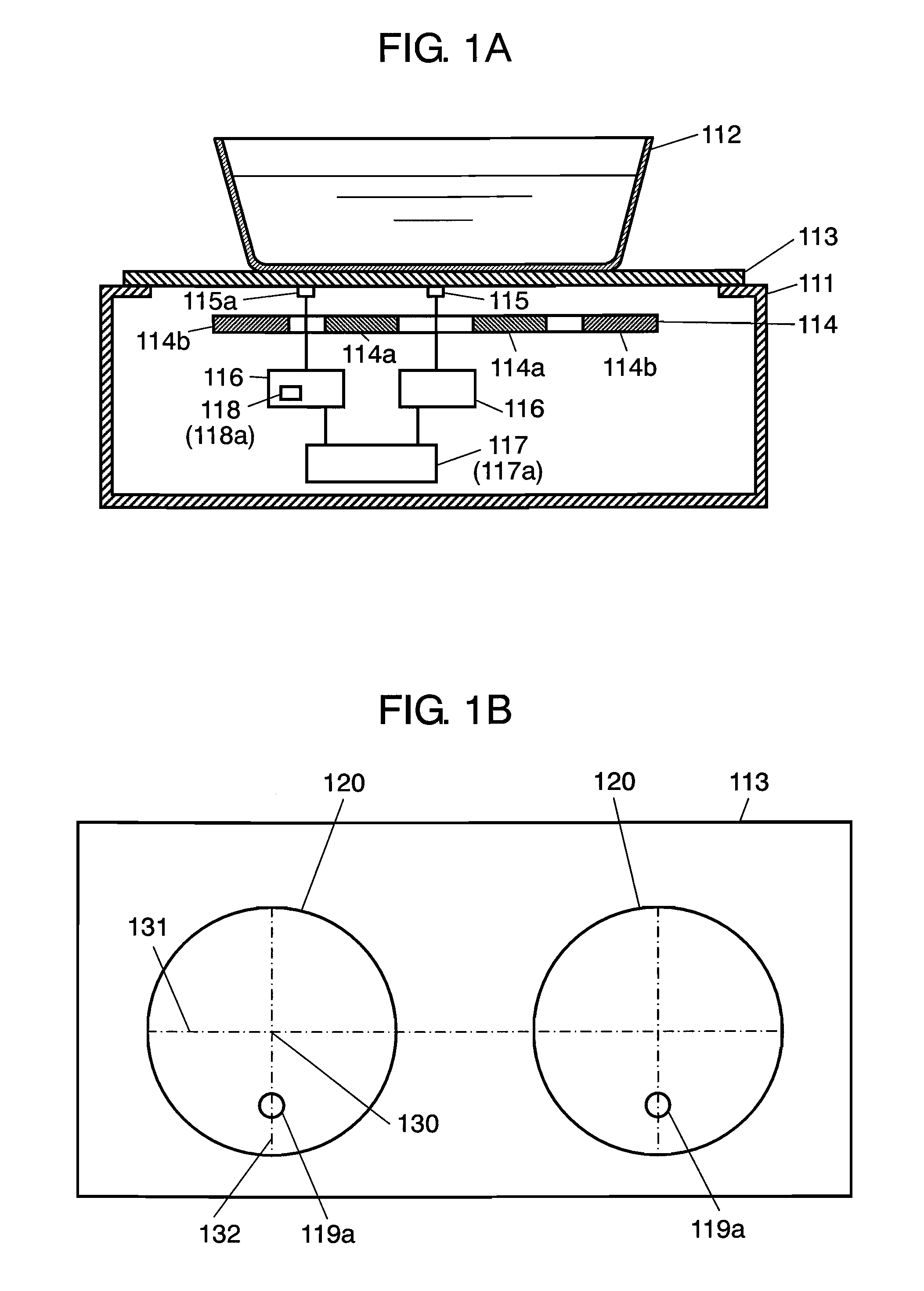

Induction heating device

ActiveUS20090134149A1High measurement accuracyAccurate temperature sensingFurnaces without endless coreInduction heating controlDisplay deviceEngineering

An induction heating device is provided that can realize an accrete sensing of the temperature of a to-be-heated object and that is user-friendly. To realize this, the induction heating device includes a sensor for sensing the temperature of the to-be-heated object and can carry out a heating operation only when it is determined that the to-be-heated object exists above the sensor. A display having a circular design and characters for example that shows the position of this sensor is provided on a top plate of the induction heating device.

Owner:PANASONIC CORP

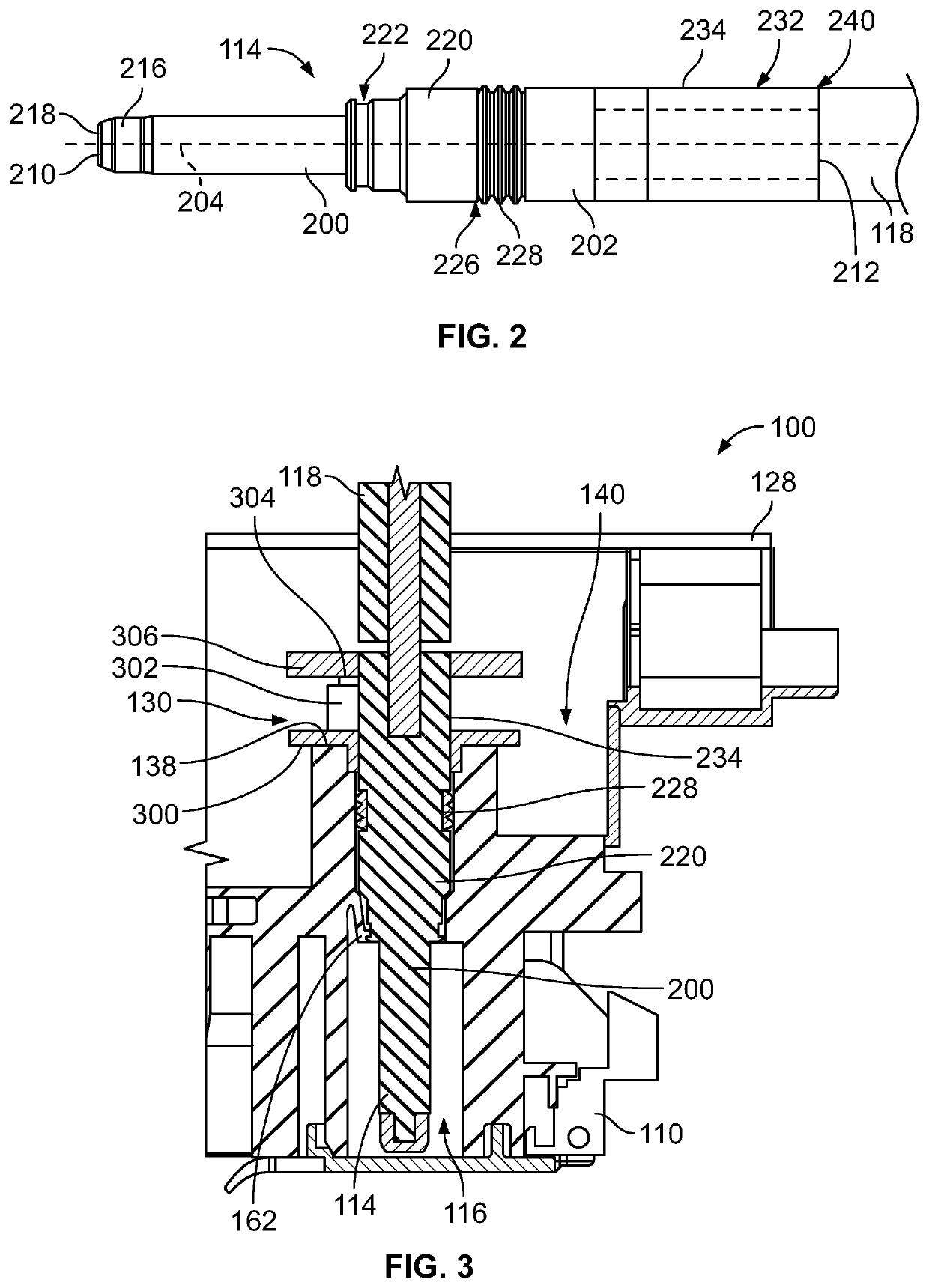

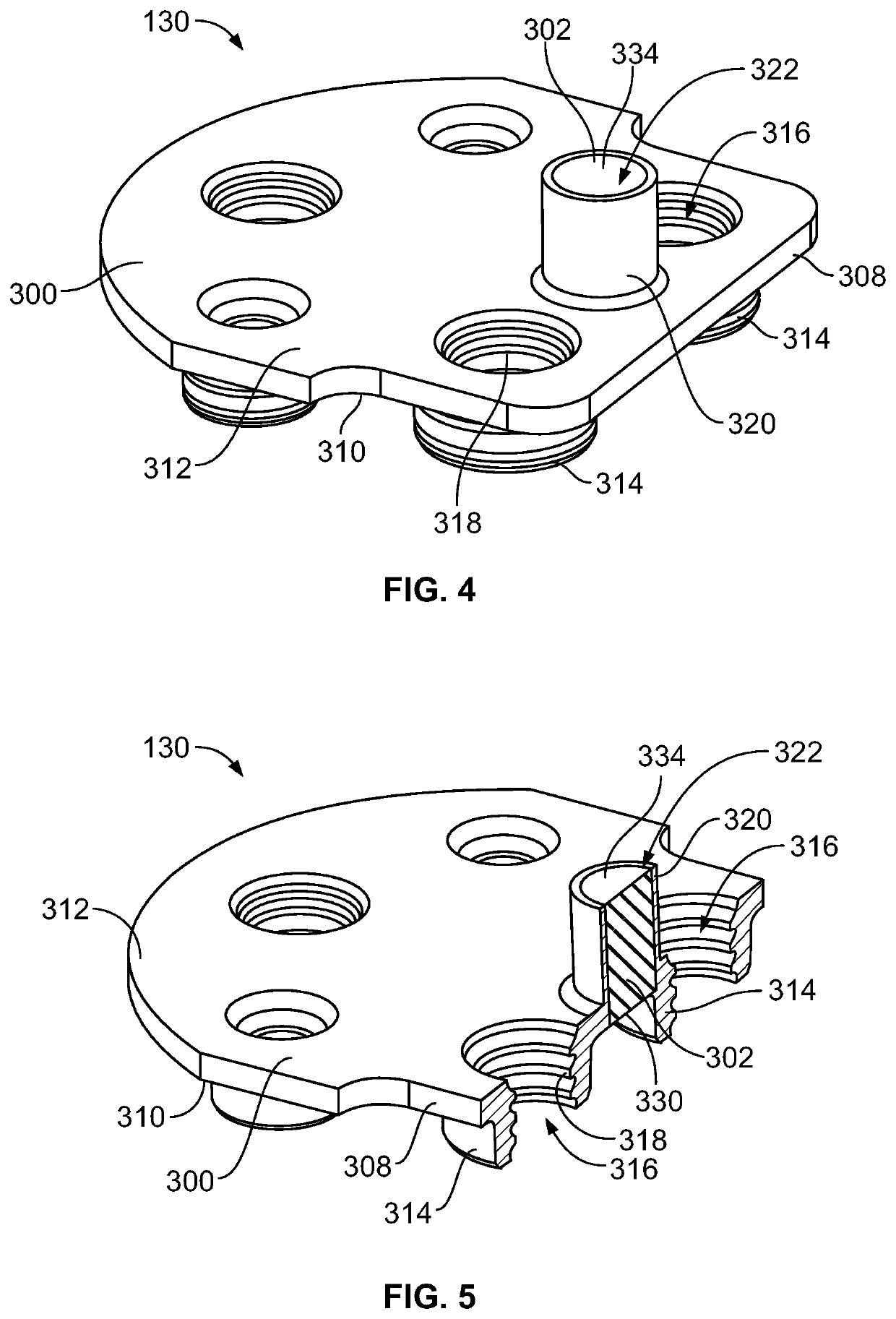

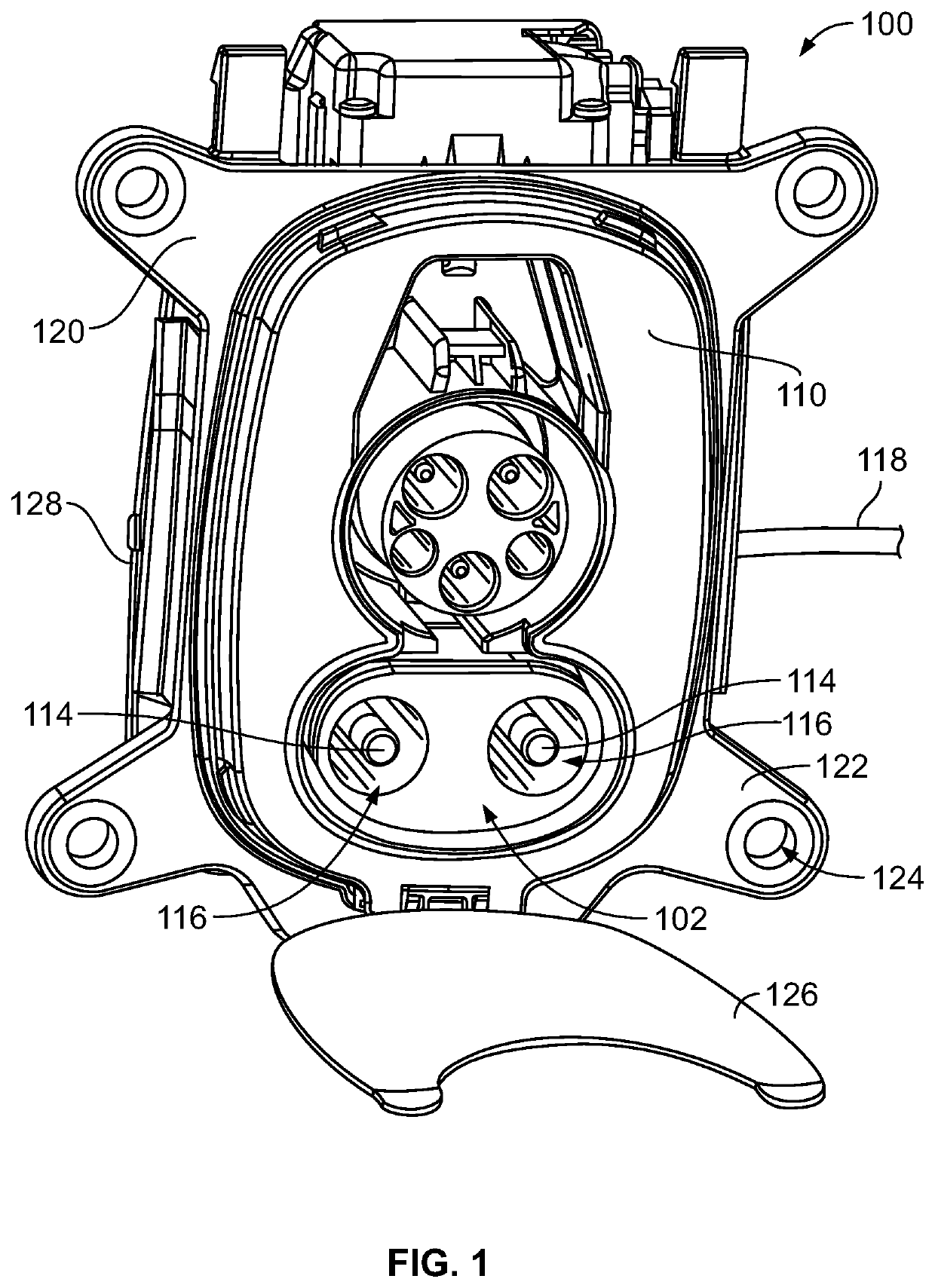

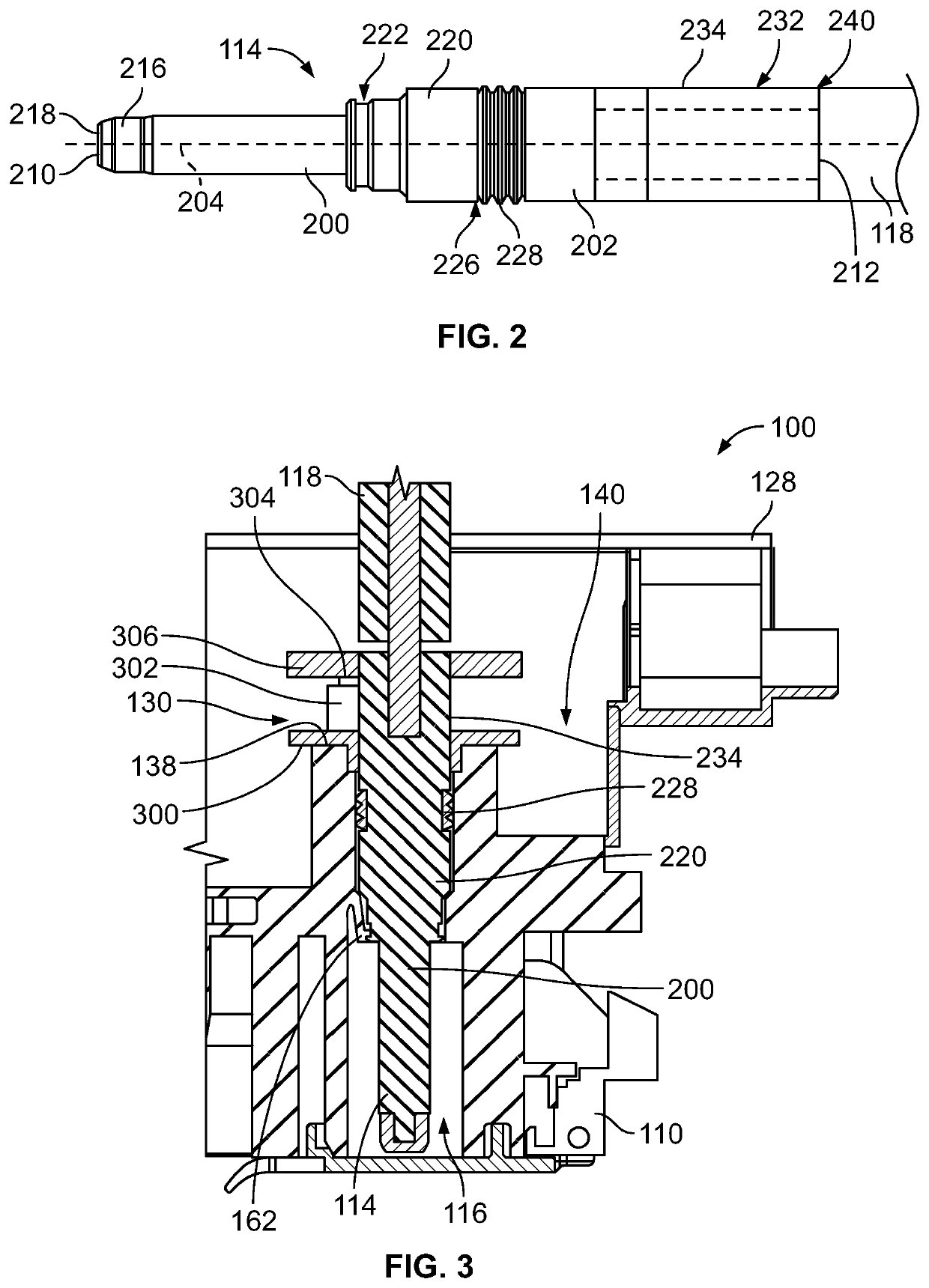

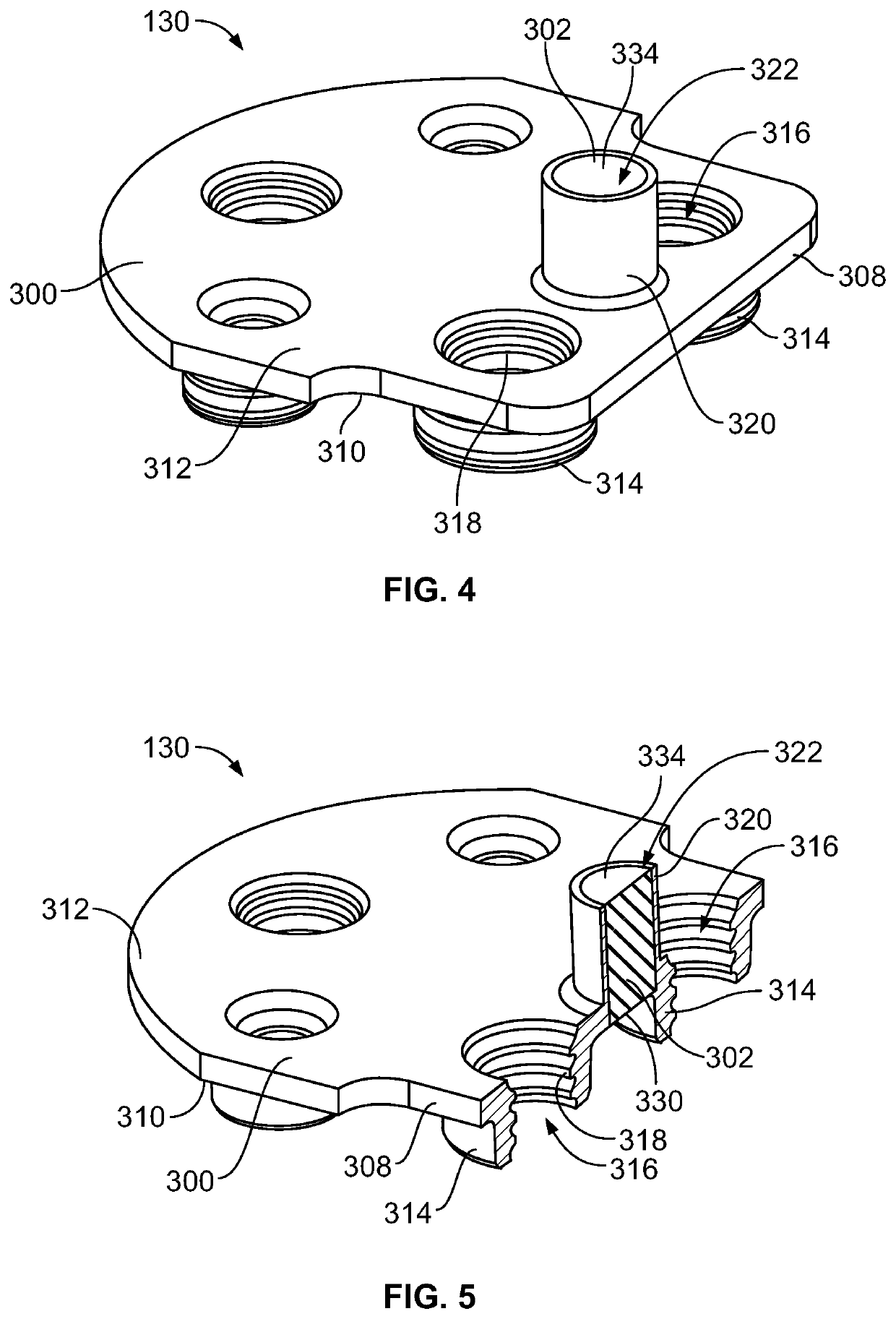

Temperature sensor assembly for an electrical connector

ActiveUS20200067237A1Fast response timeCost effectiveThermometer detailsVehicle connectorsThermal conductivityEngineering

An electrical connector including a housing having a terminal channel with a power terminal in the terminal channel. The electrical connector includes a temperature sensor assembly positioned in the chamber. The temperature sensor assembly includes a sealing pad holding the power terminal and a thermal shunt held by the sealing pad. A temperature sensor is coupled to the thermal shunt. The sealing pad is electrically insulative and has a terminal opening receiving the power terminal. The sealing pad is thermally coupled to the power terminal and thermally coupled to the thermal shunt. The thermal shunt has a thermal conductivity higher than a thermal conductivity of the sealing pad. The temperature sensor monitors the temperature of the power terminal through a thermal path defined by the sealing pad and the thermal shunt.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

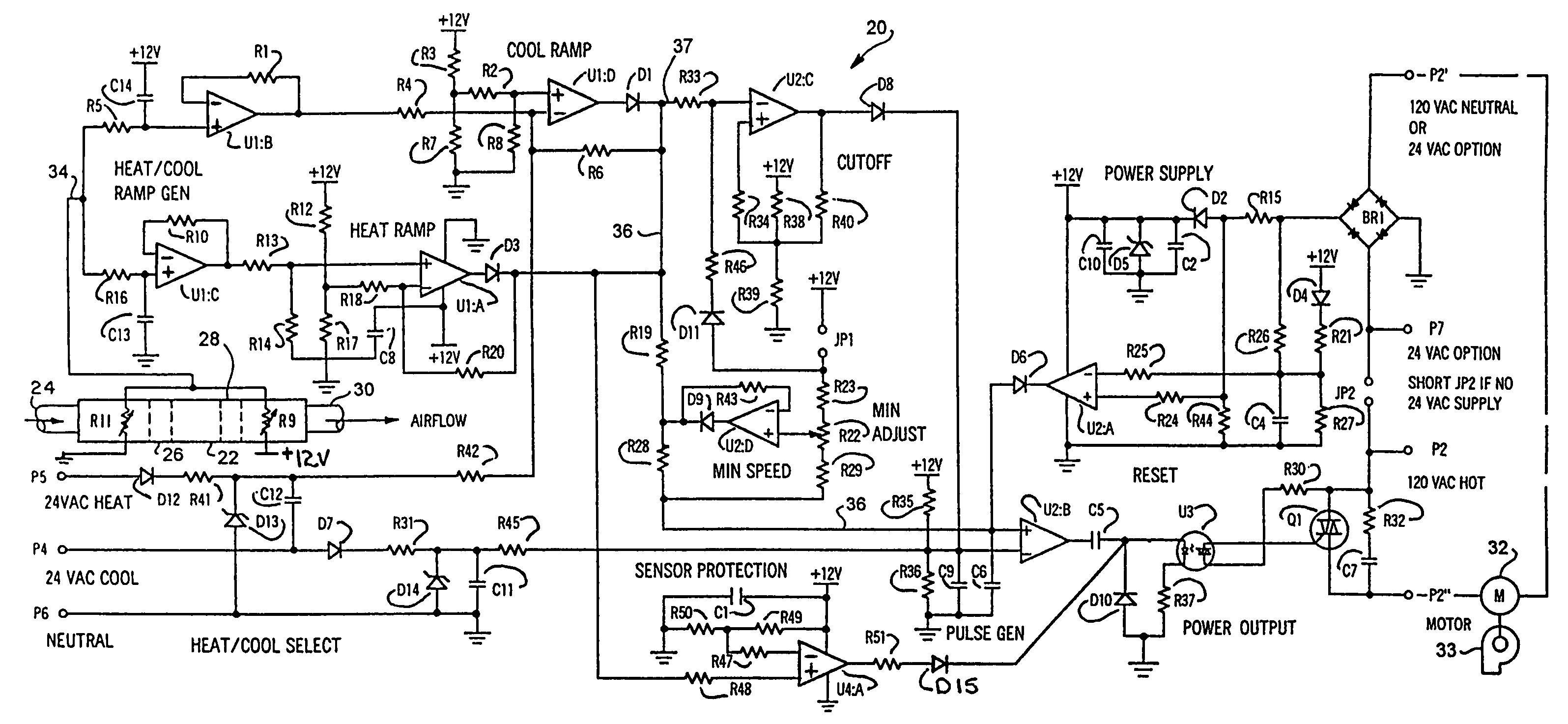

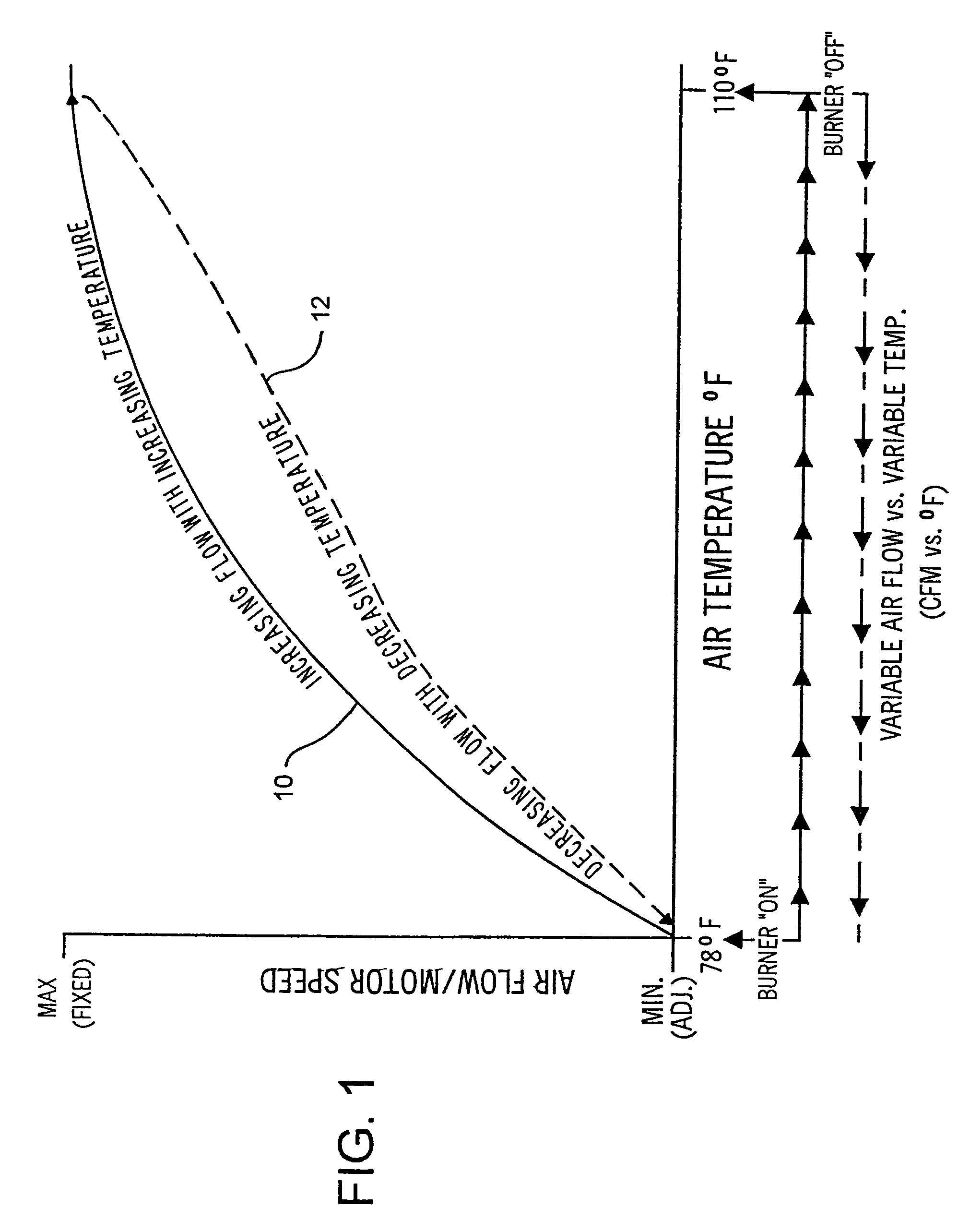

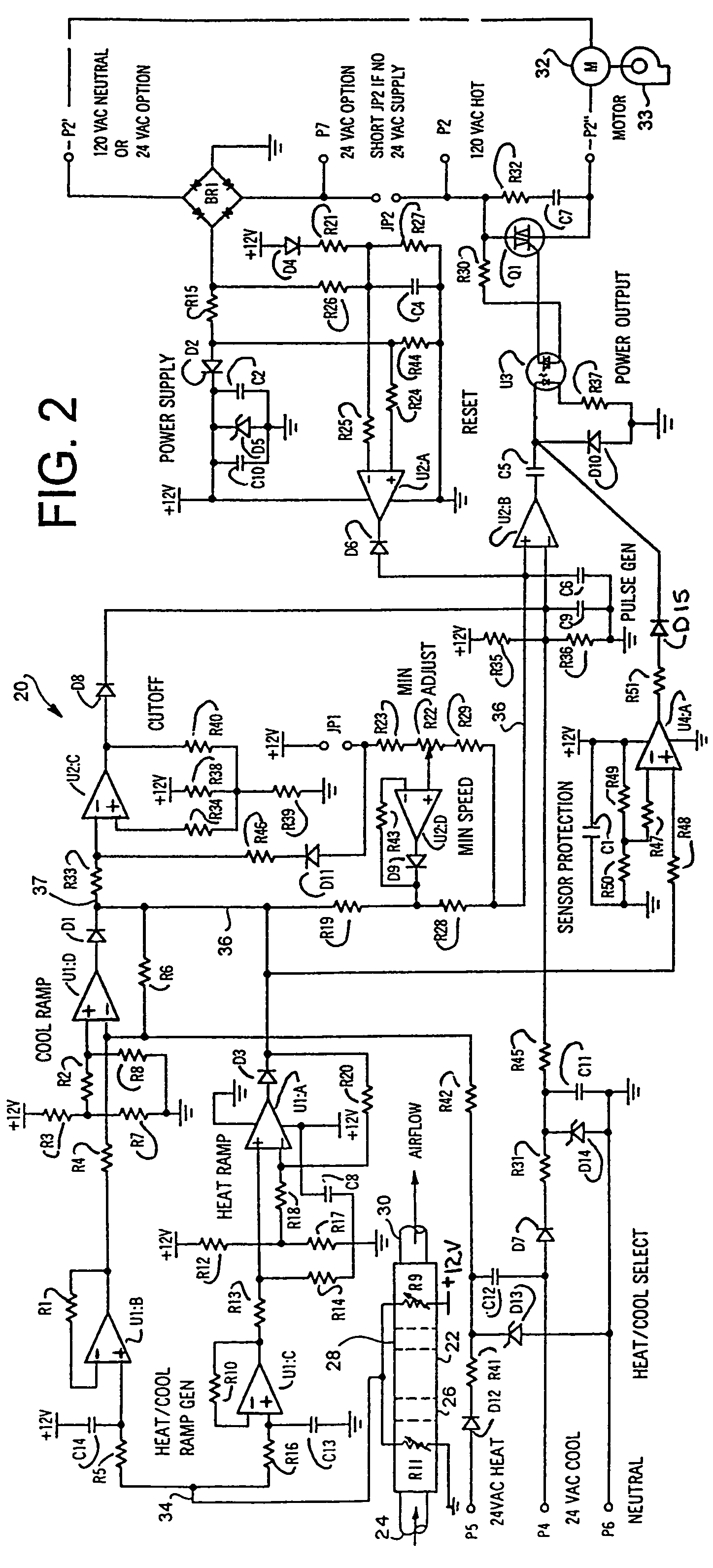

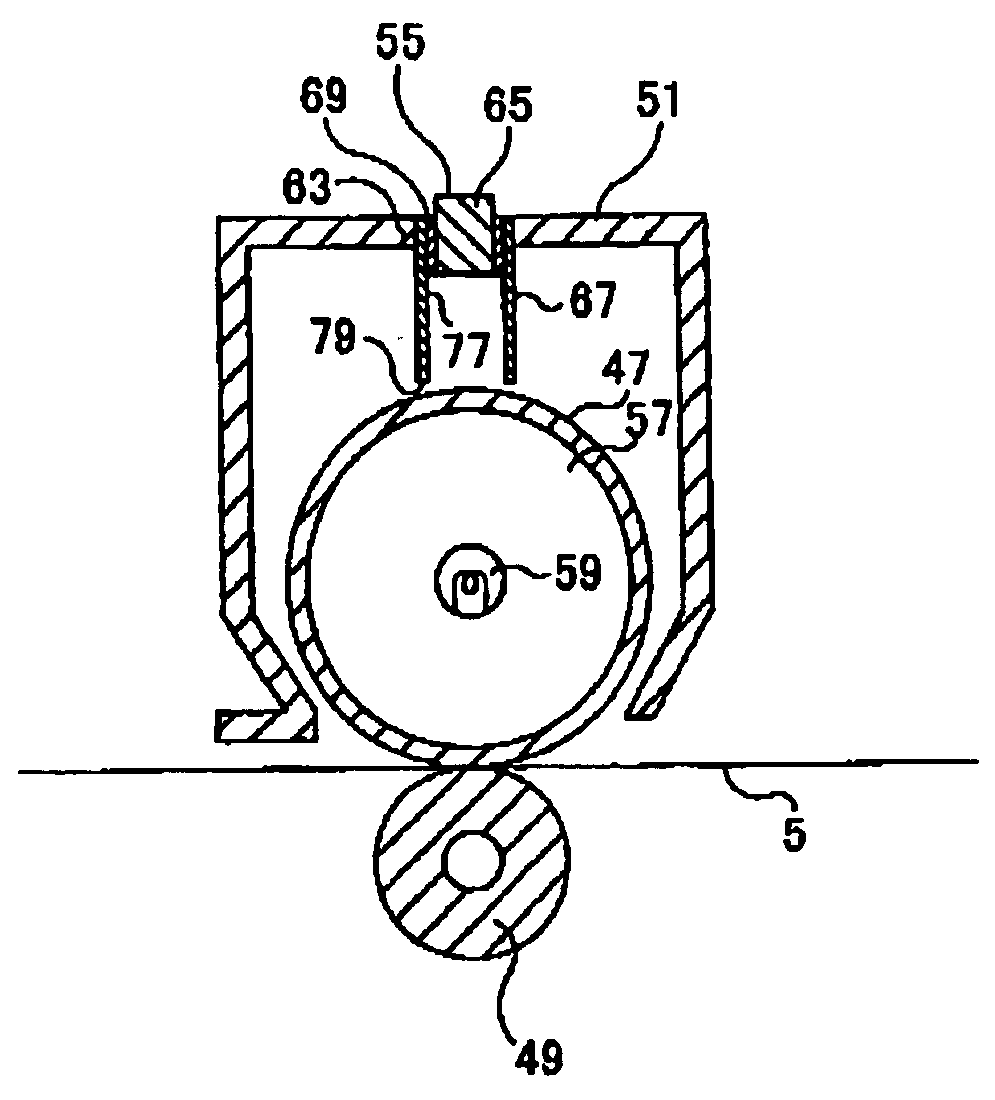

Variable speed fan motor control for forced air heating/cooling system

InactiveUS7191826B2Accurate temperature sensingVersatile control systemDC motor speed/torque controlSpace heating and ventilationDIACMotor speed

A fan motor speed control system for controlling the fan motor speed of an air conditioning system includes a power output circuit including a power triac which is turned on and off by an opto-isolator connected to a pulse generator circuit for varying an AC voltage waveform imposed on the fan motor. The pulse generator circuit is connected to heating and cooling ramp circuits and a minimum speed circuit to provide a variable voltage signal imposed on the pulse generator circuit corresponding to the temperature difference sensed by a return air sensor and a heating or cooling sensor or by separate heating and cooling sensors disposed adjacent respective heating and cooling heat exchangers of the air conditioning system. An adjustable minimum speed circuit and a cutoff circuit are provided to control motor minimum speed or motor shutoff when a predetermined minimum speed is reached to prevent motor bearing failure or overheating. Sensor protection circuits in the control system operate to drive the motor to full speed if any of the temperature sensors experience an open or short circuit condition. The control system circuit maximizes air conditioning system efficiency by capturing additional heating or cooling effect, reduces noise associated with motor startup and shutdown, and reduces rapid change in the sensed temperature in the air conditioned space during motor startup and shutdown.

Owner:HOFFMAN CONTROLS CORP

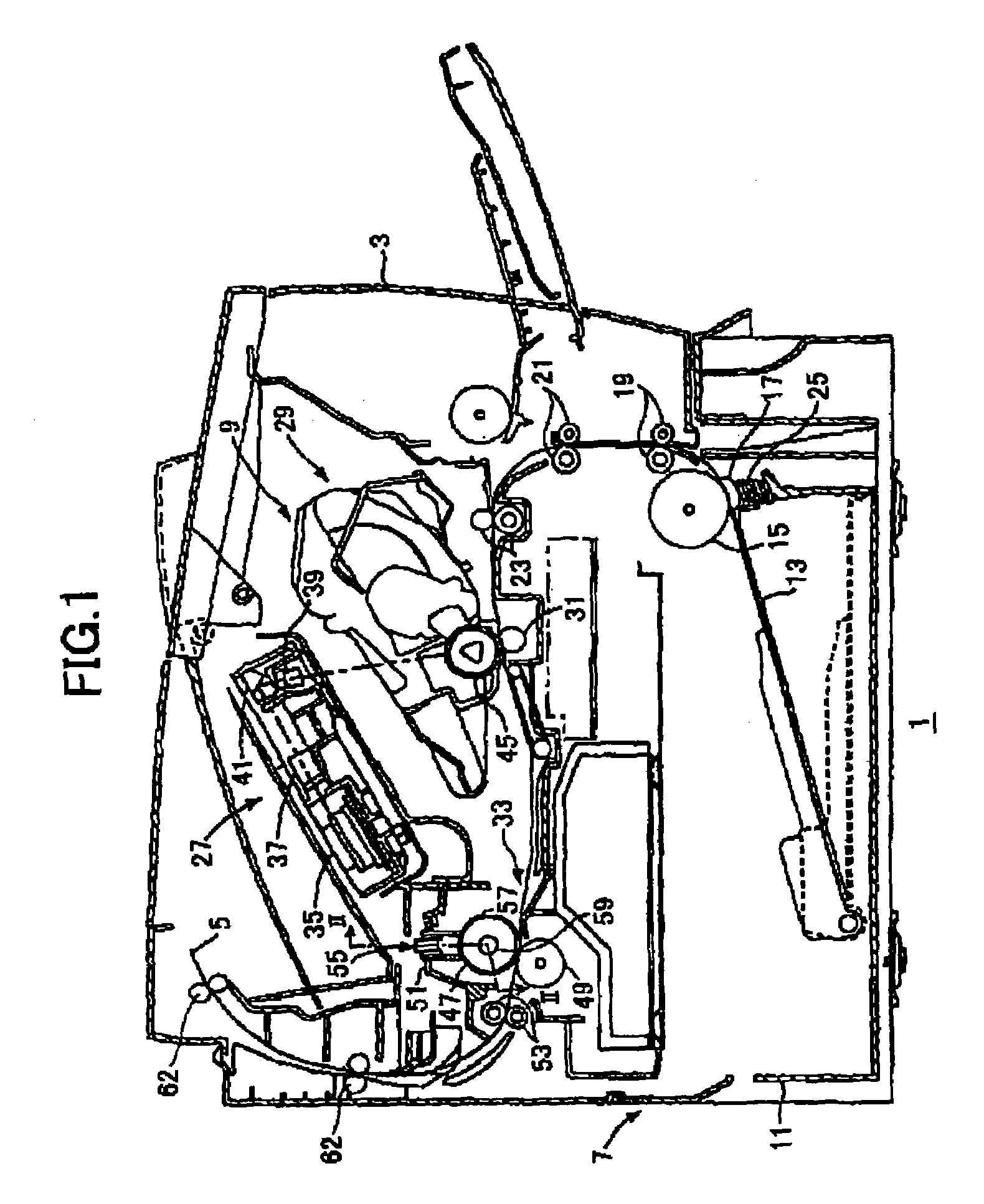

Heat fixing device and image forming apparatus

InactiveUS20050053390A1Keep distanceAvoid attenuationSensing radiation from moving bodiesElectrographic process apparatusInfraredThermal insulation

A heat fixing device capable of preventing deterioration of a temperature sensor by measuring the surface temperature of a heating roller at all times, and an image forming apparatus. The heat fixing device includes a temperature measurement unit for measuring the surface temperature of the heating roller. The temperature measurement unit further includes the temperature sensor, a conduit having a reflective surface formed inside thereof to lead infrared rays radiating from the heating roller to the temperature sensor, and a thermal insulation member installed between the conduit and the temperature sensor.

Owner:BROTHER KOGYO KK

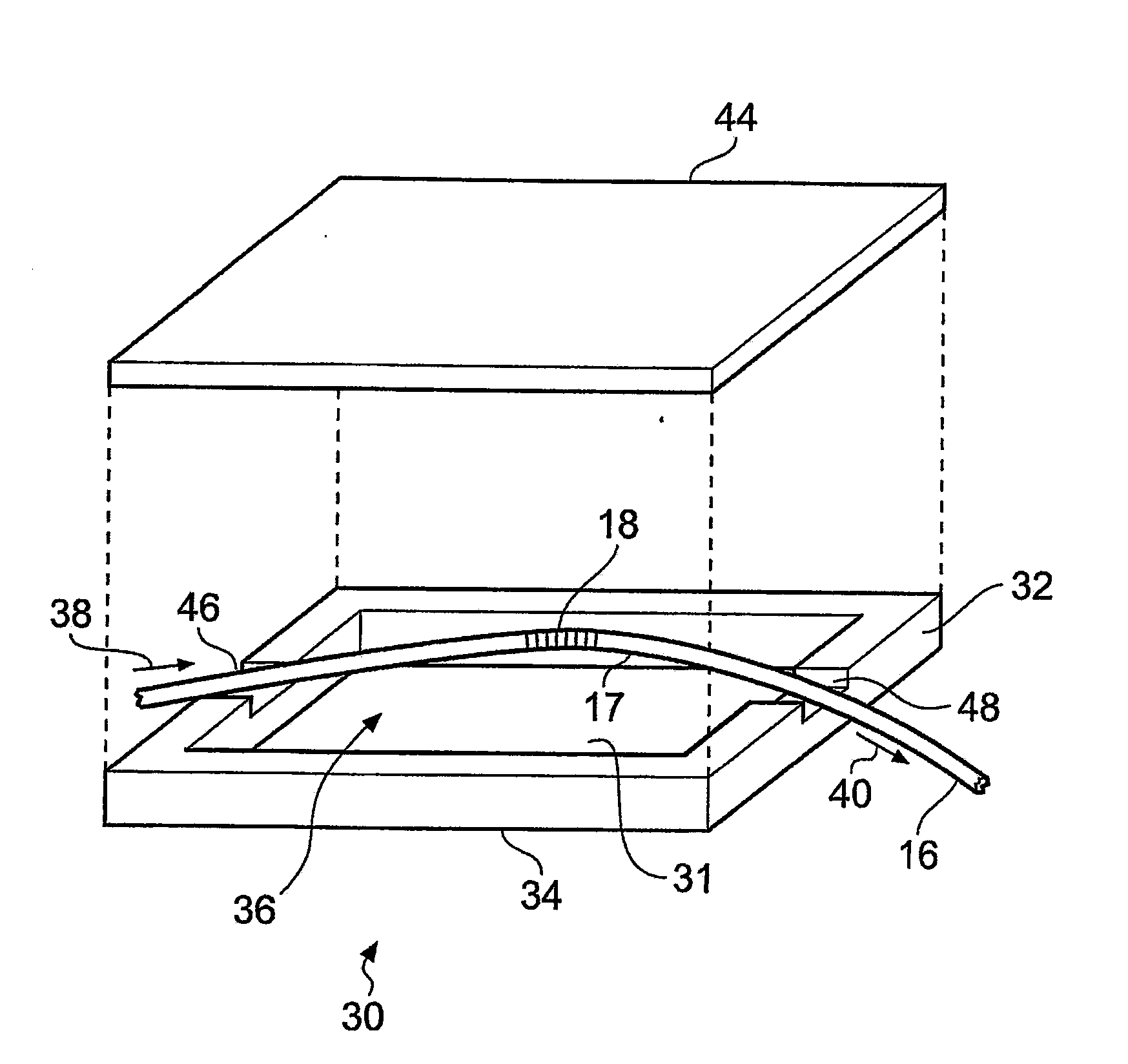

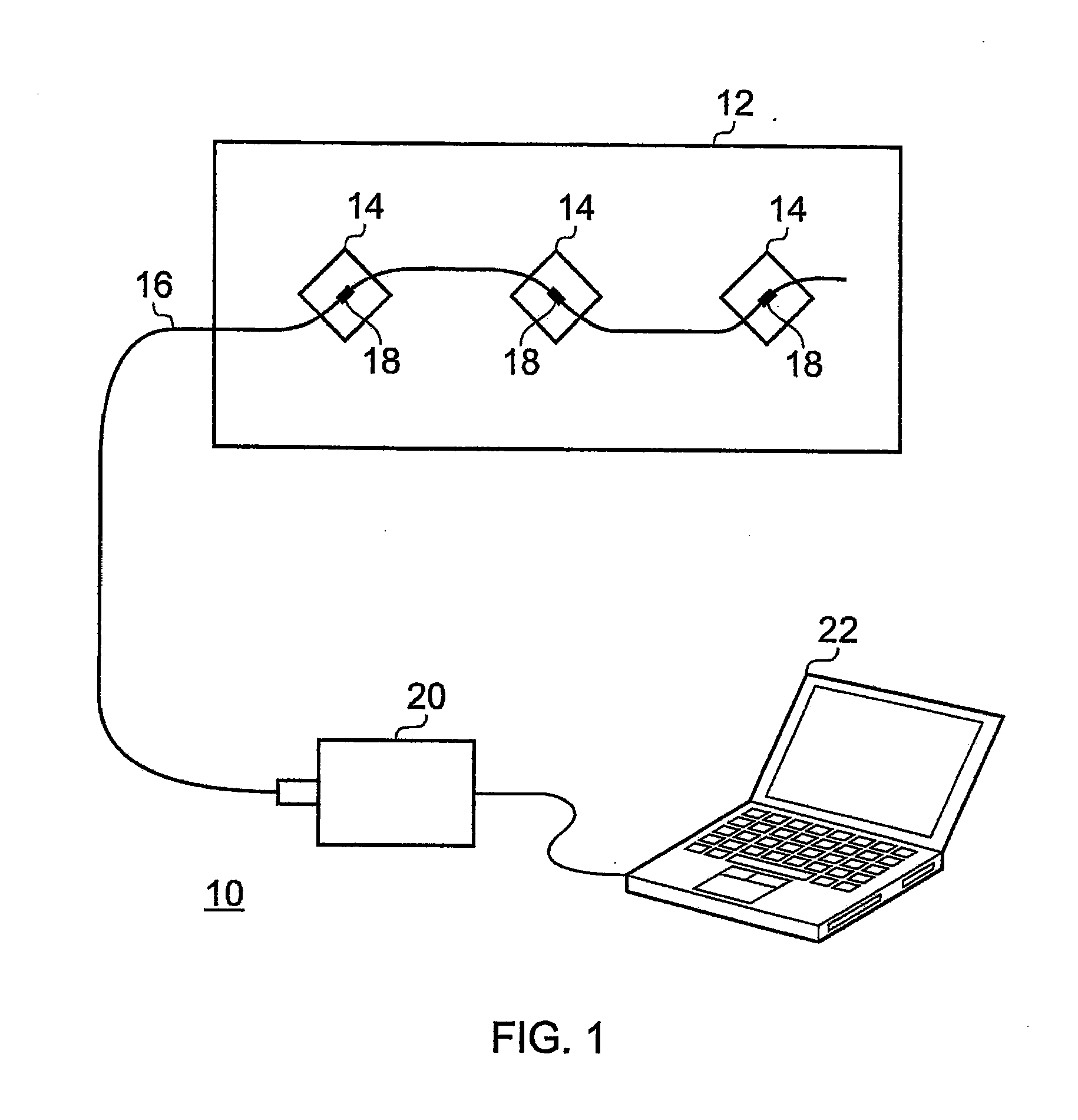

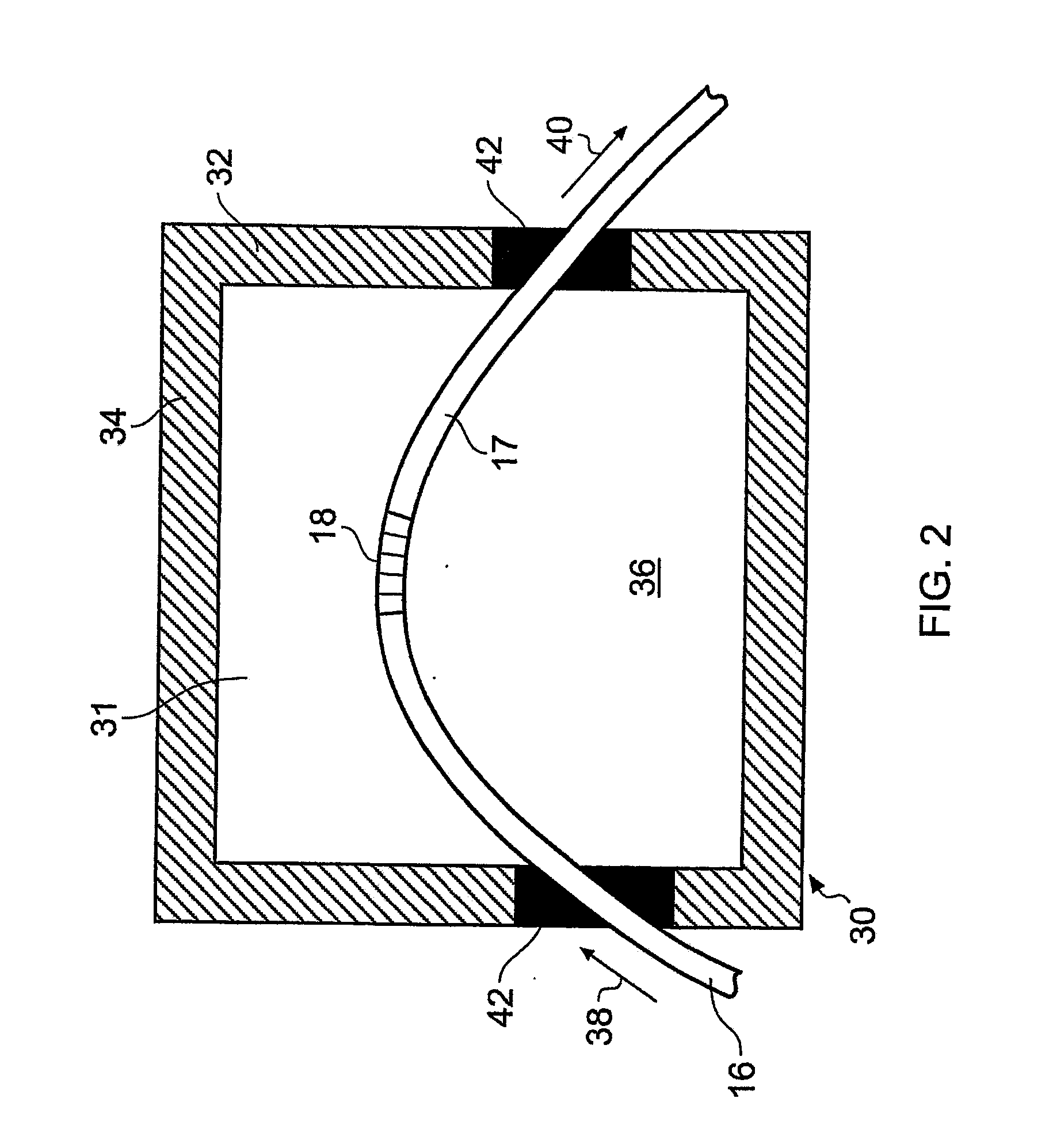

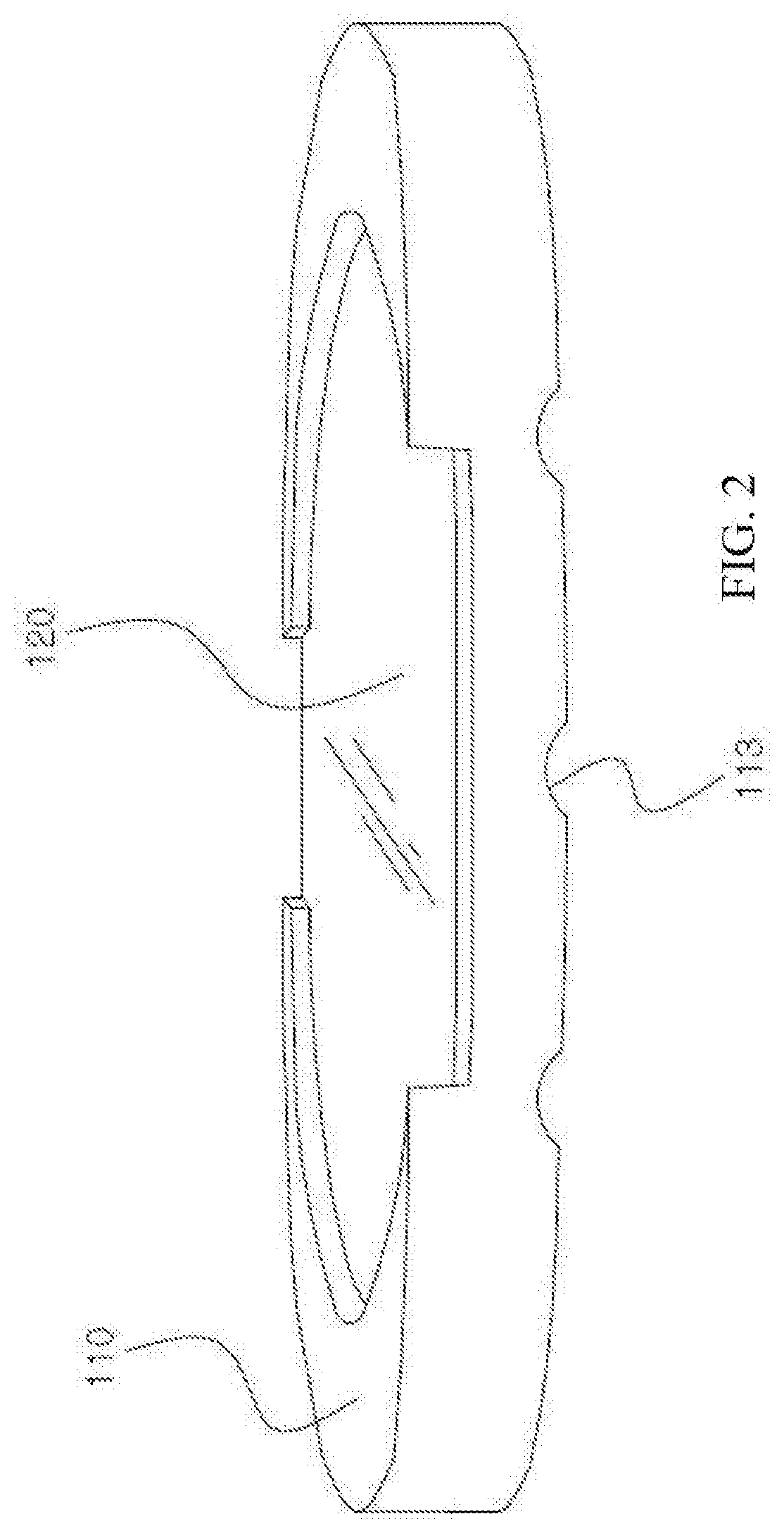

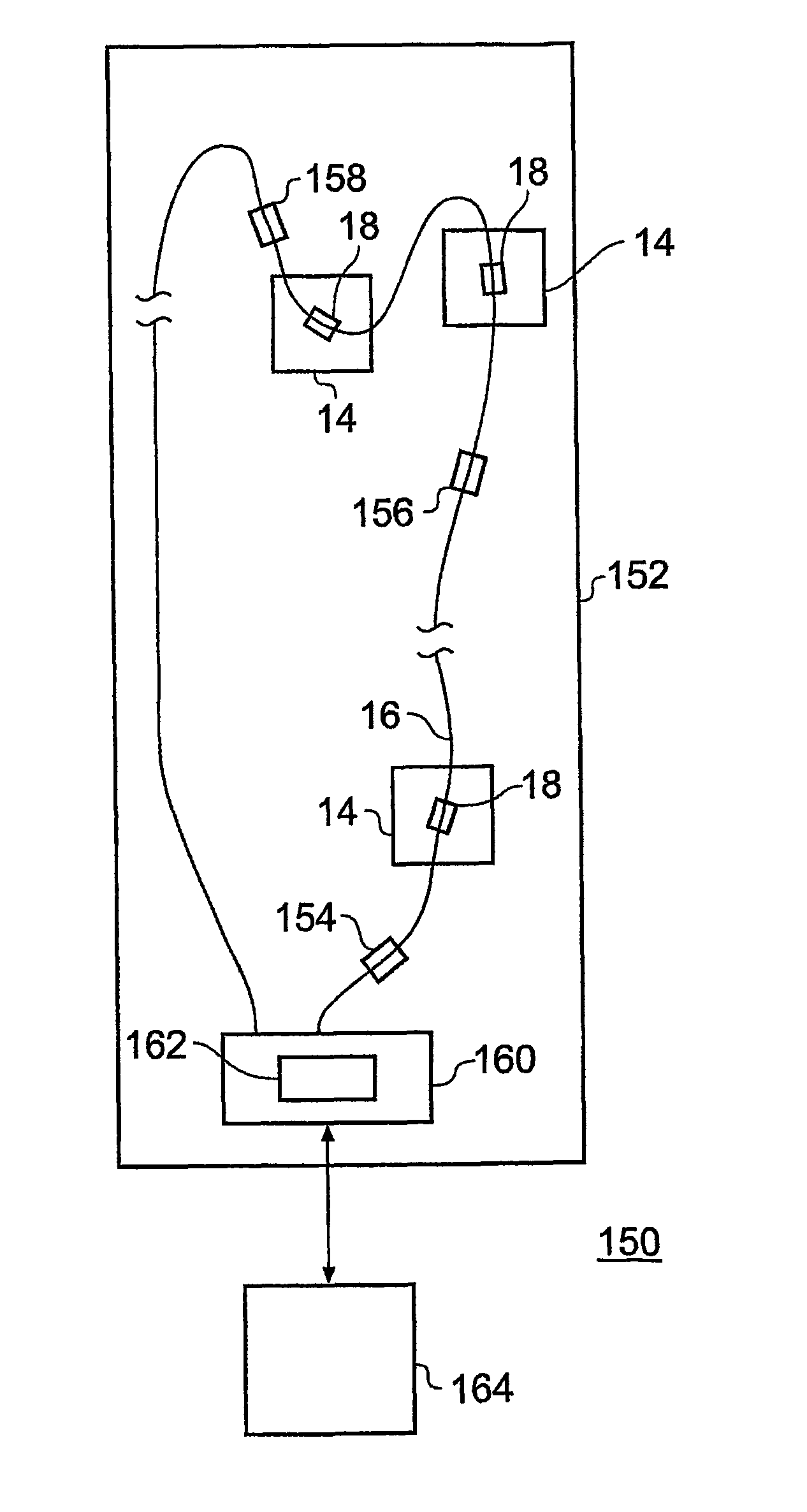

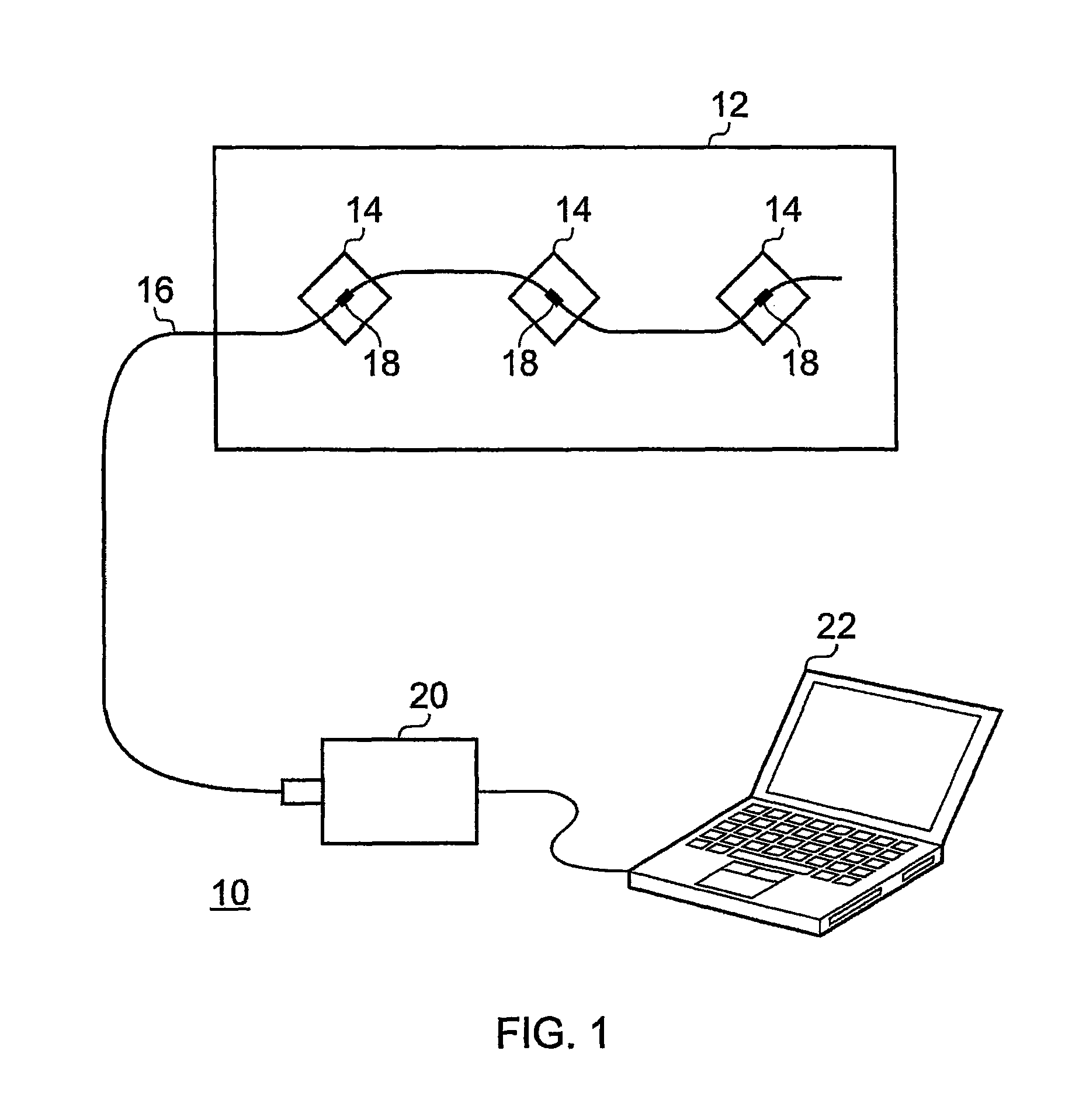

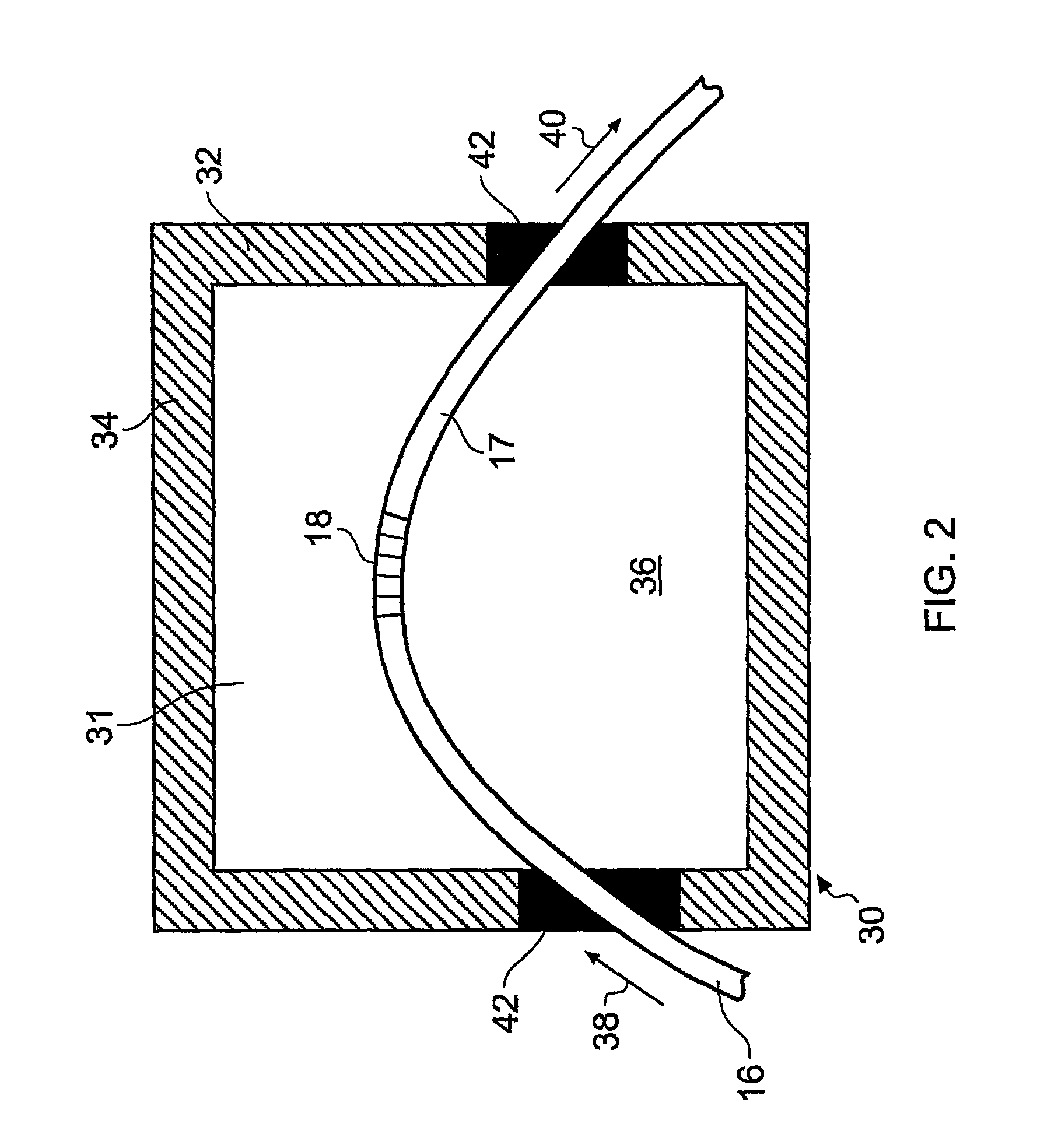

Temperature sensing

ActiveUS20100080501A1Simple processEasily be associatedThermometer detailsAutomatic control devicesSensor arrayGrating

A temperature sensor array comprises an optical fibre (16) on which are a plurality of Bragg gratings (18) on respective spaced apart portions of the fibre. Each portion is in a housing (14) which freely houses the said portion substantially without axial strain on the fibre within the housing and which also isolates the grating from strain imposed on the fibre outside the housing. Thus substantially only changes in temperature affect the Bragg grating of that portion. The array may be used to detect and control the temperature of a tool (12) for forming a composite component amongst other uses.

Owner:GKN AEROSPACE SERVICES LTD

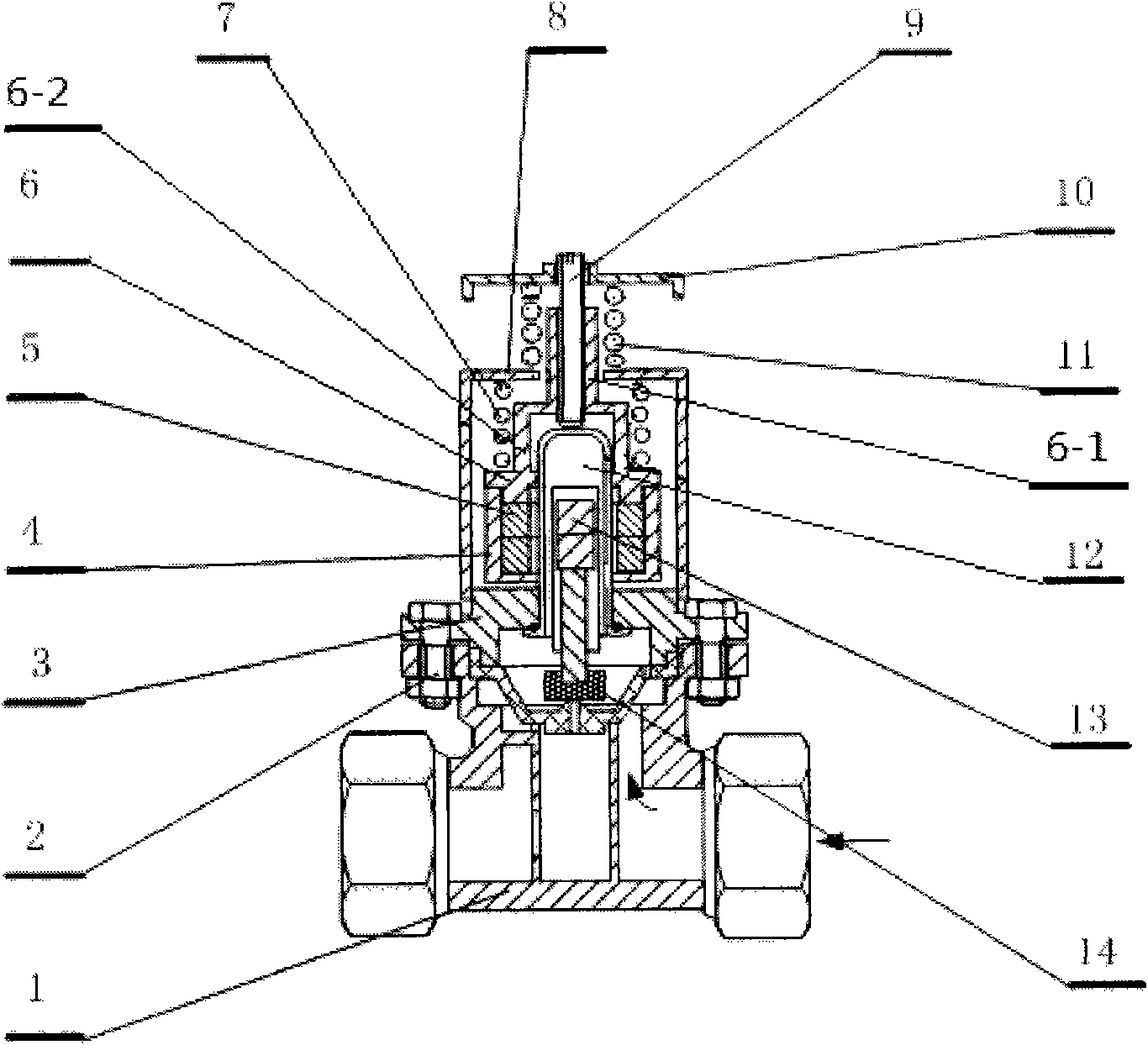

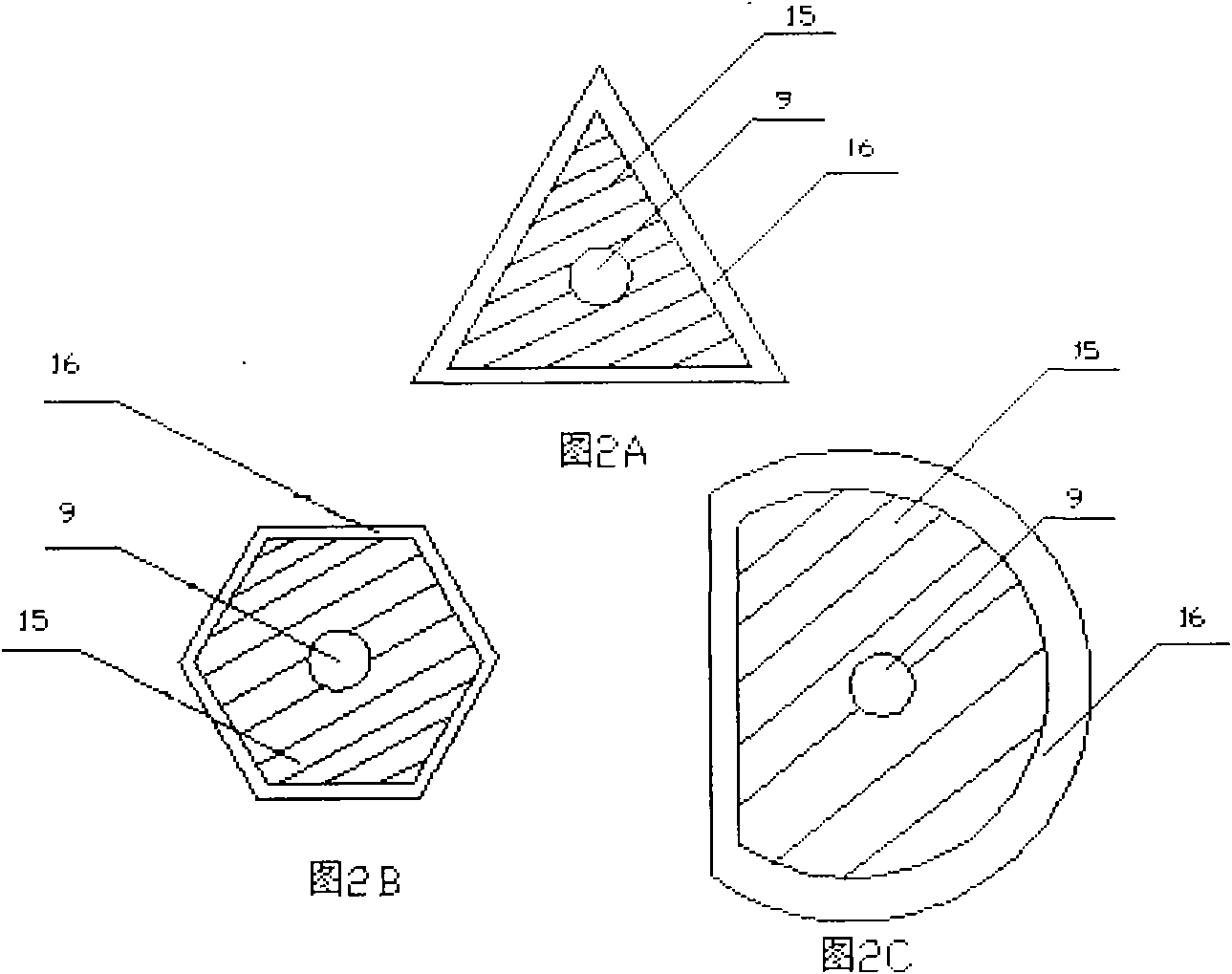

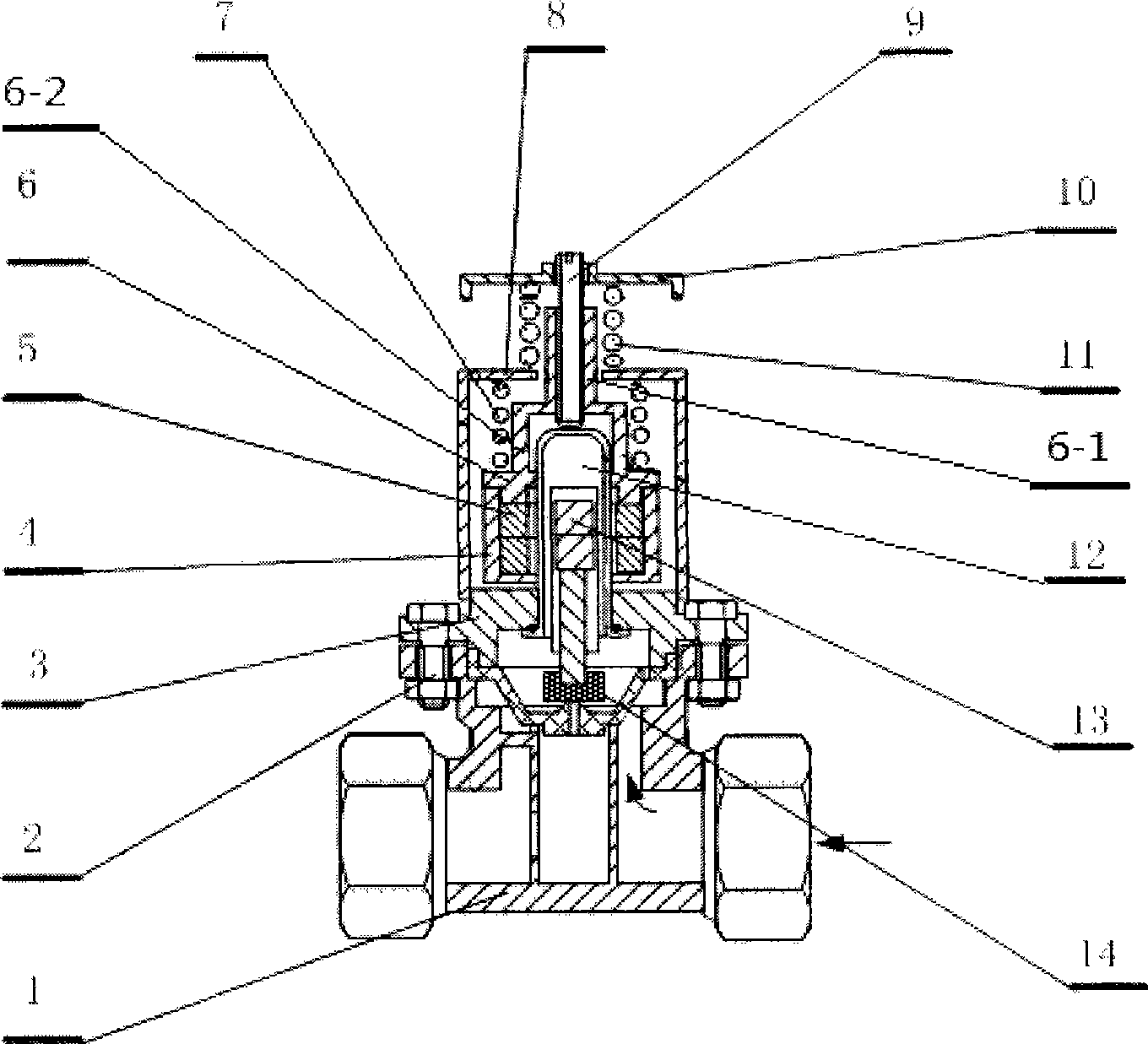

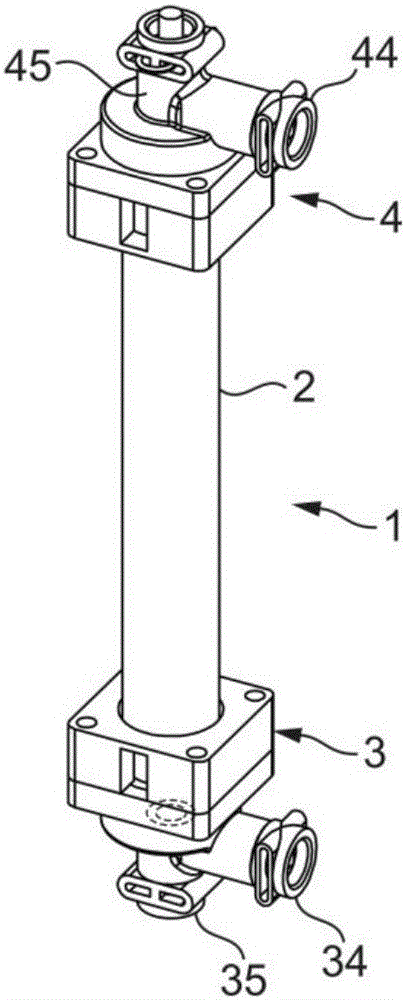

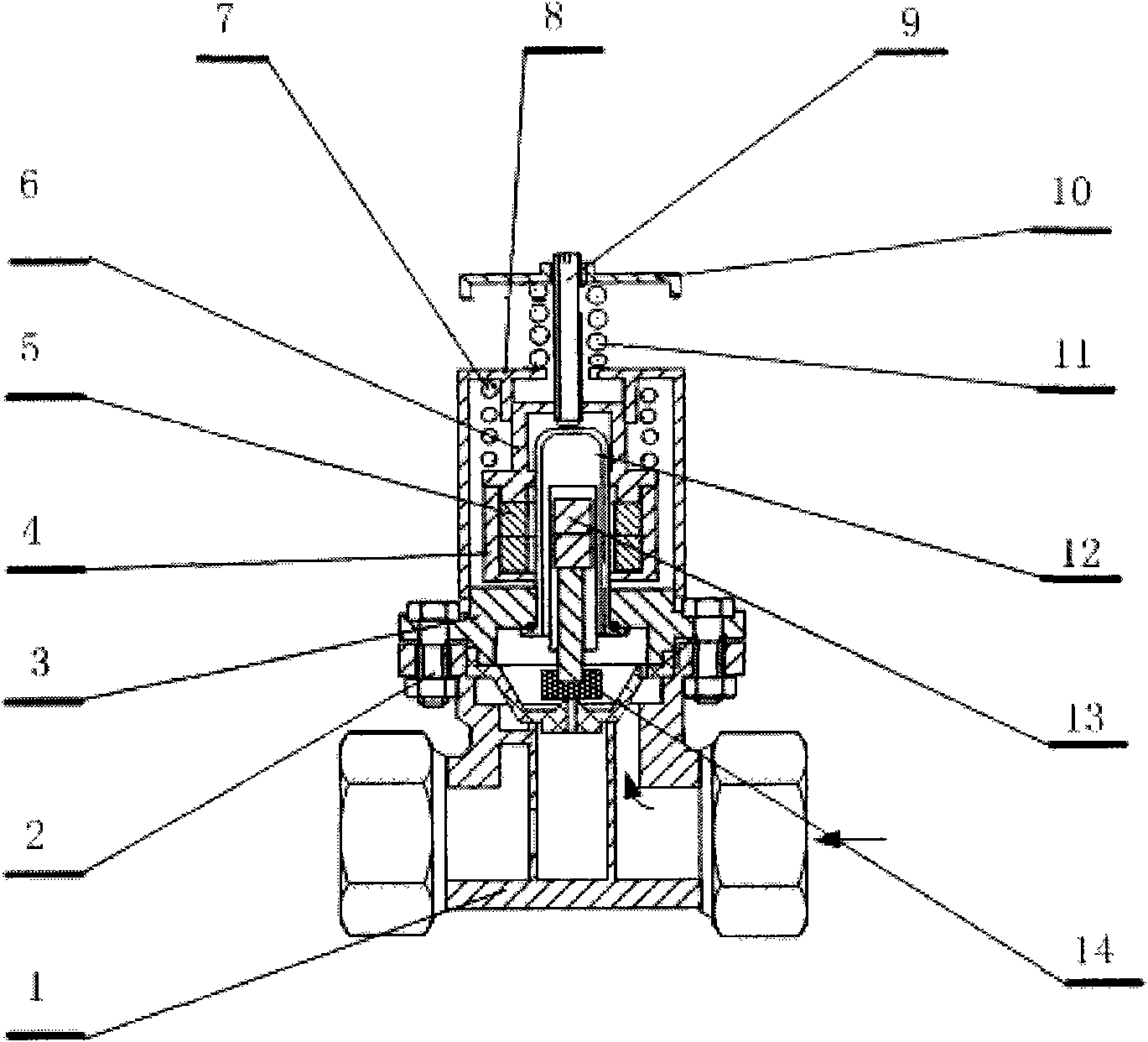

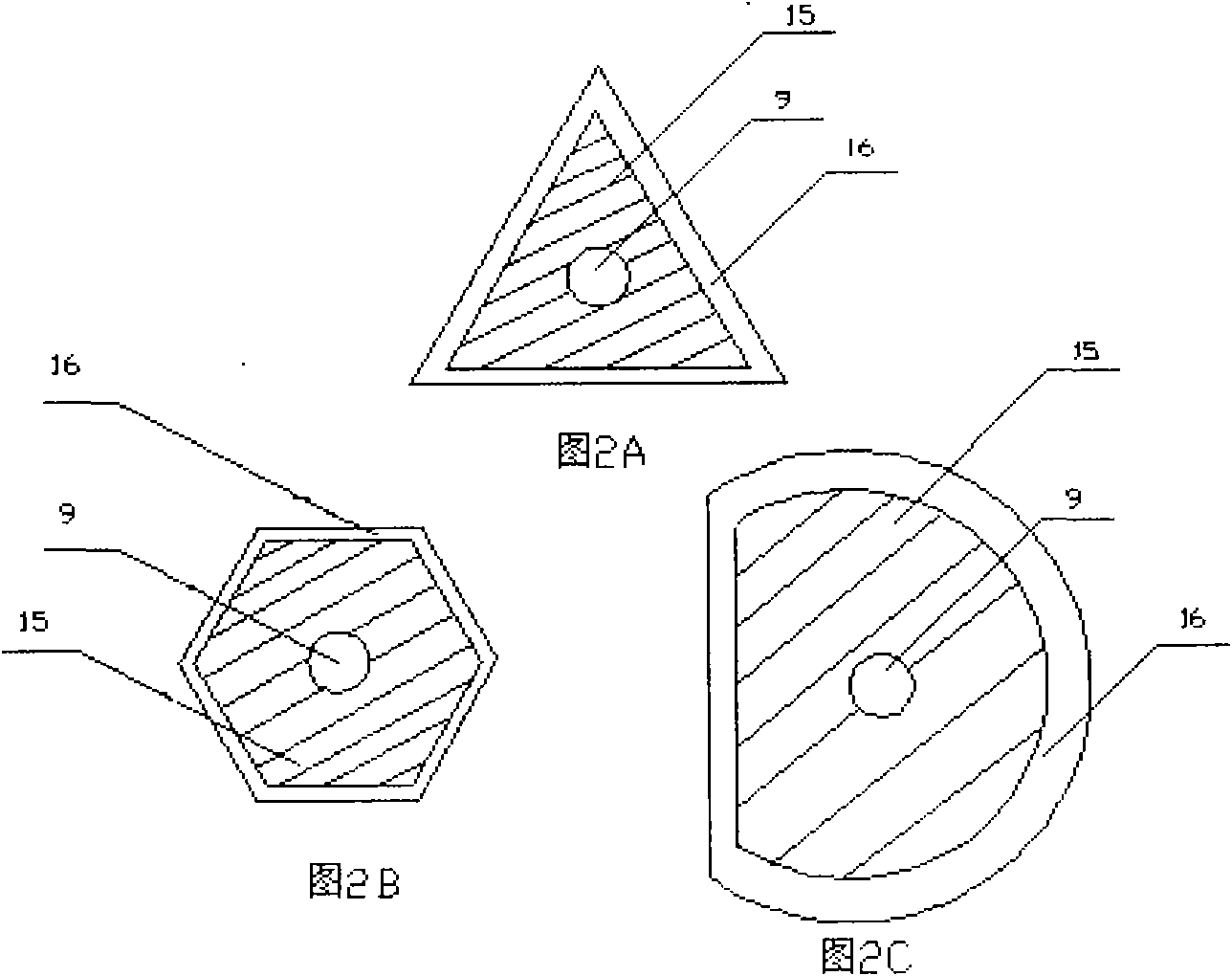

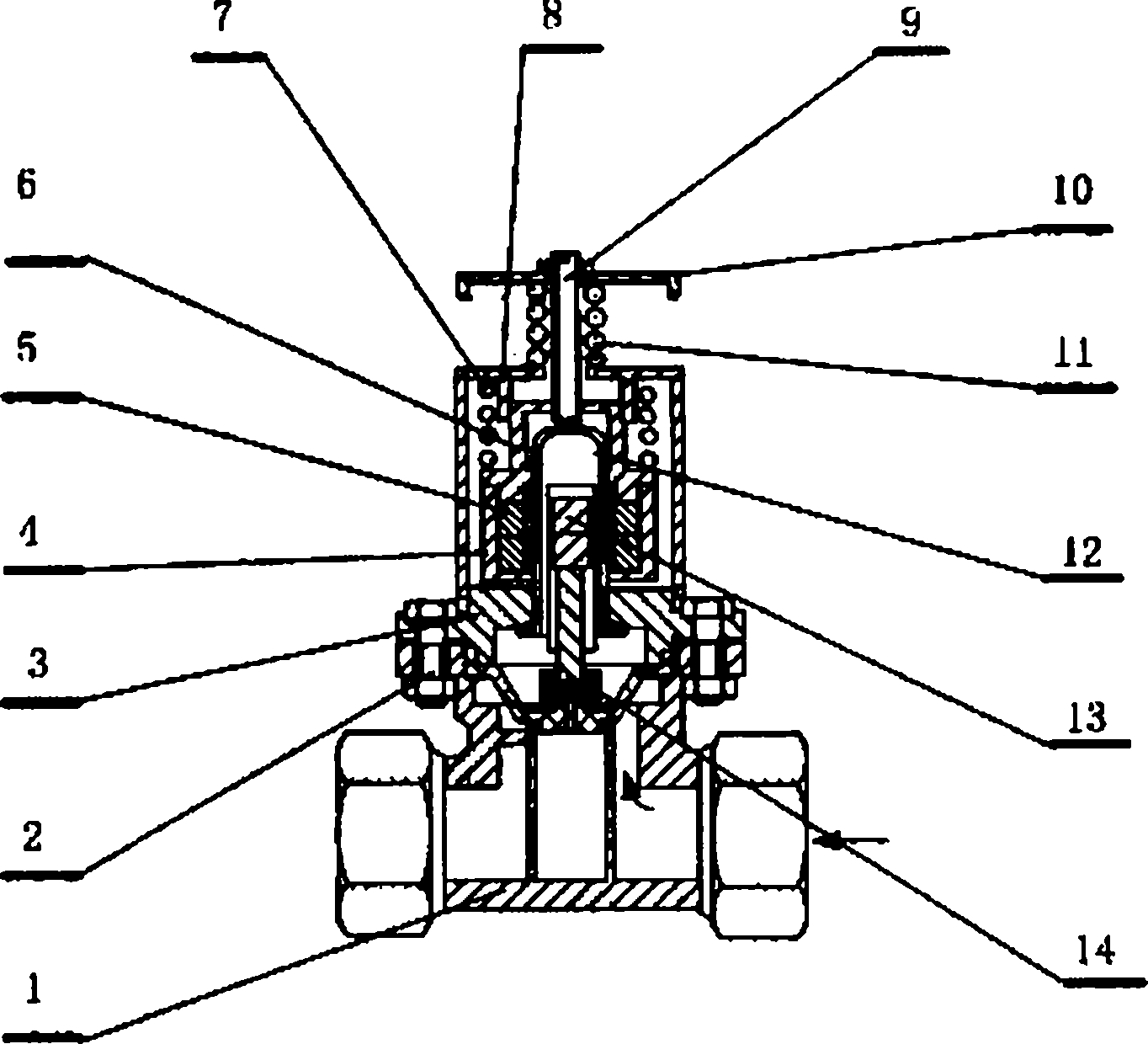

Automatic spray valve

ActiveCN102644780ALarge thrustIncrease the itineraryOperating means/releasing devices for valvesEqualizing valvesShape-memory alloyAlloy

The invention relates to an automatic spray valve which comprises a valve body, a valve cover, a magnetic ring sleeve, a magnetic ring component, a movable rod, a bias spring, a valve cover, a memory alloy, a piston cylinder, a magnetic core component and a piston, wherein the upper part of the movable rod passes through a central hole of the valve cover and protrudes out of the valve cover; the memory alloy is sleeved at the upper part of the movable rod protruding out of the valve cover, the upper end of the memory alloy contacts a spring cap, the lower end of the memory alloy contacts the valve cover, the inner diameter of a spring coil formed by winding the memory alloy is smaller than the outer diameter of the lower part of the movable rod; the spring cap contacts the top end of an adjusting rod, the outer diameter of the upper part of the adjusting rod is smaller than the outer diameter of the lower part of the adjusting rod, and the adjusting rod is connected with the upper part of the movable rod. The double-opened automatic spray valve provided by the invention has the advantages that the spring diameter of the memory alloy is reduced in design, so that the pushing force generated by the memory alloy is several times larger than that of the previous structure and thus the reliability of the opening of the valve is greatly improved; and the valve can be opened or closed through manual fine adjustment when the valve is maintained or tested; since a polygonal limit structure is arranged on the central hole of the top of the valve cover, the installation and change of the valve are convenient.

Owner:河南维科安广实业有限公司

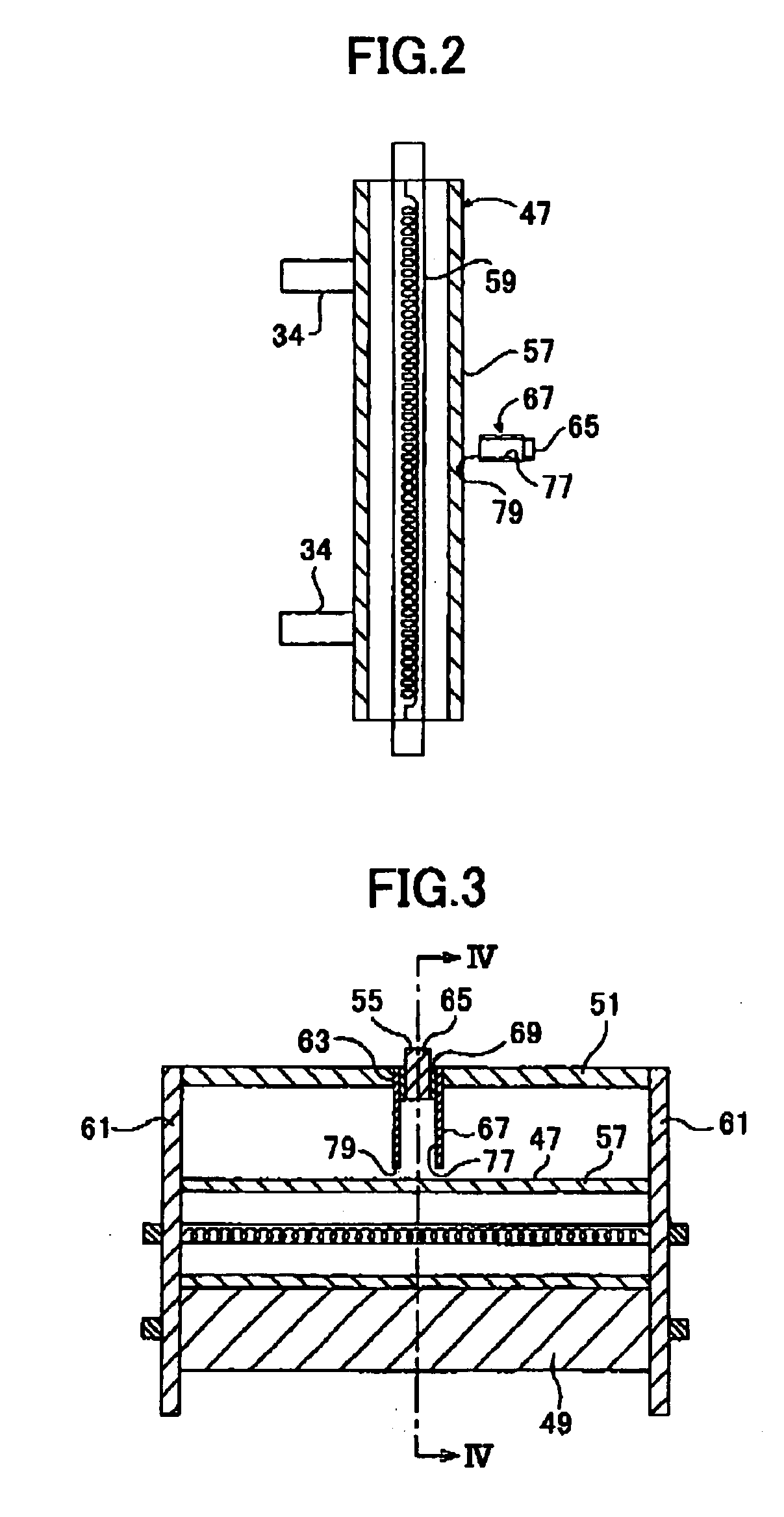

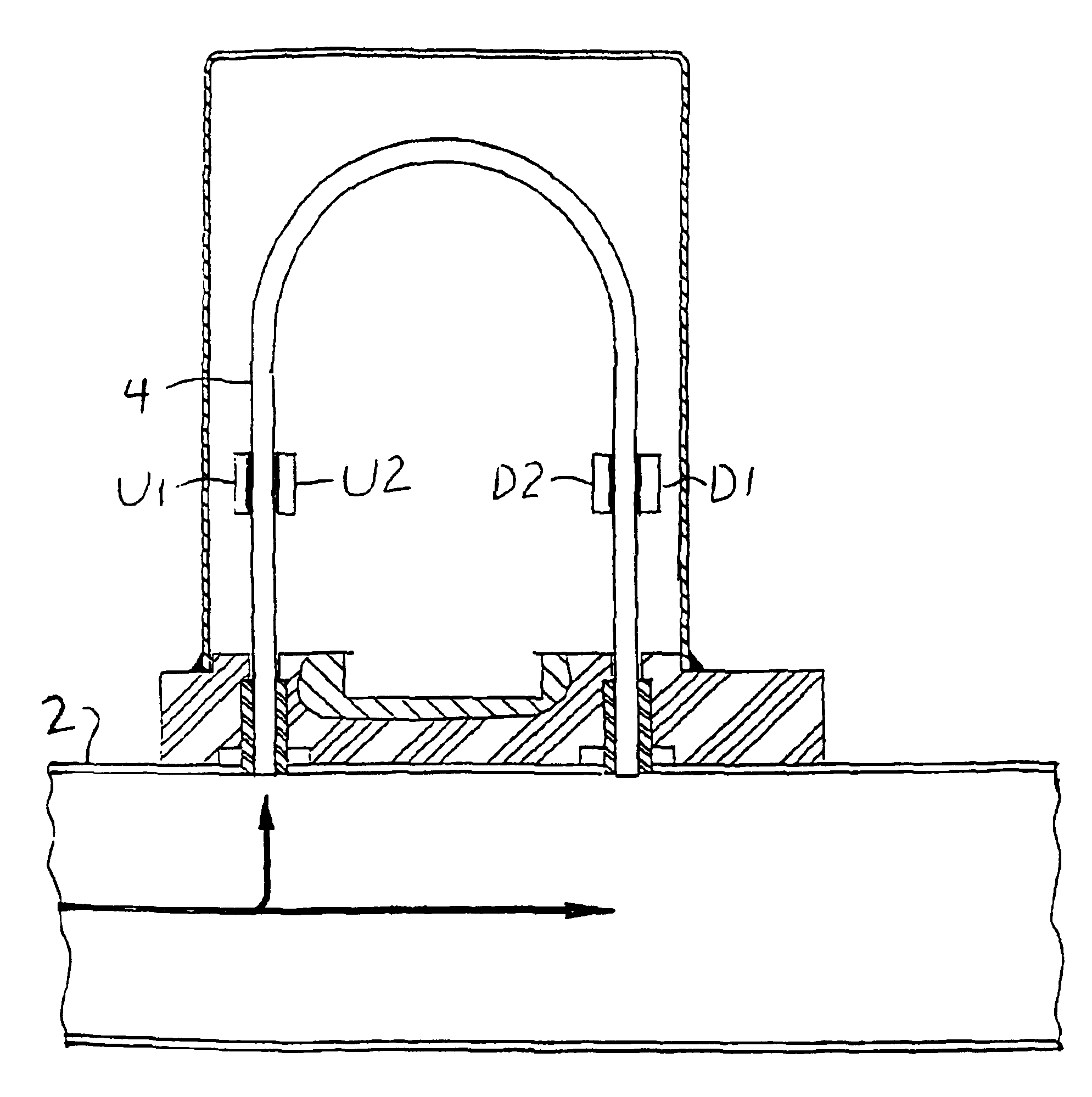

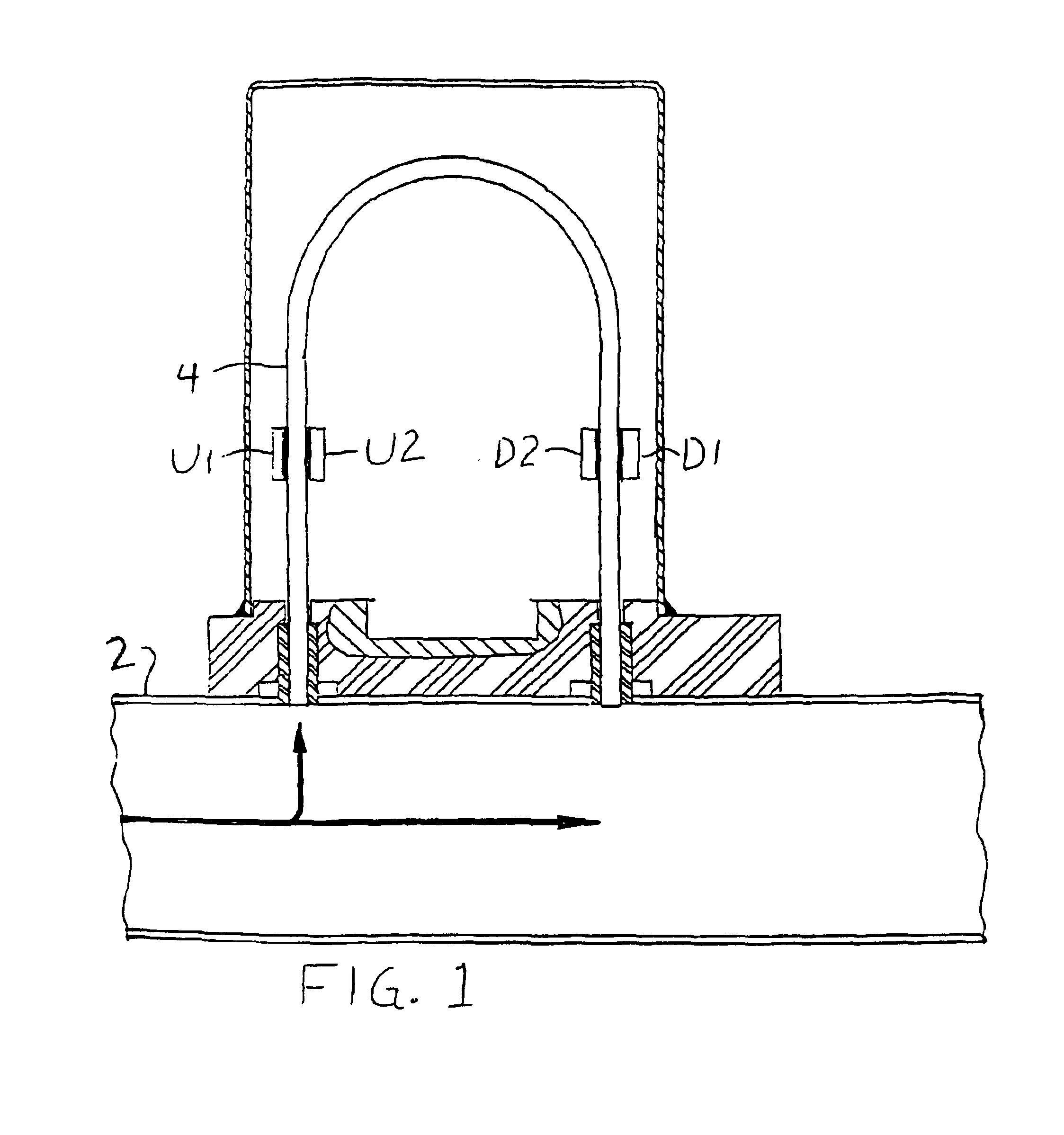

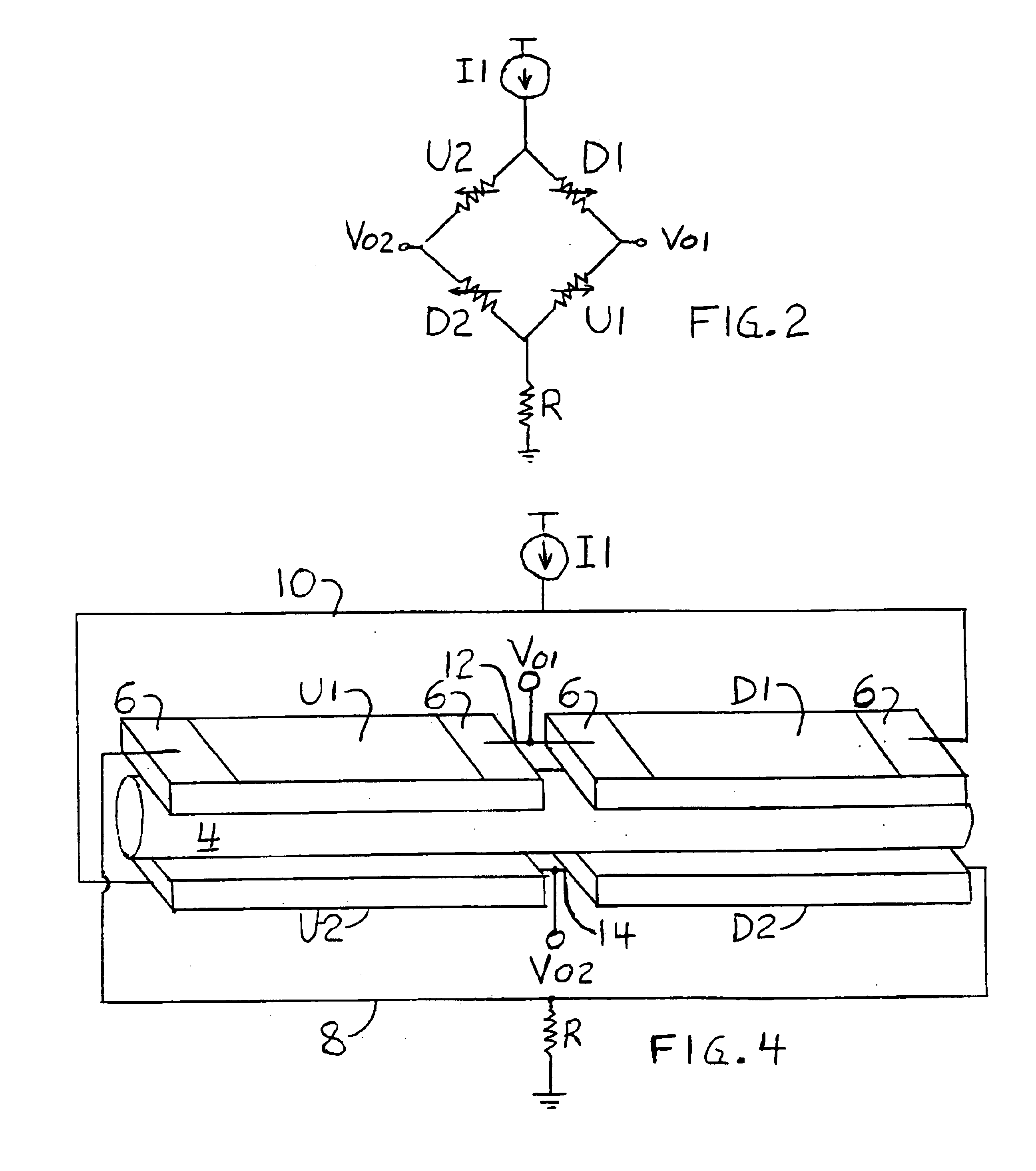

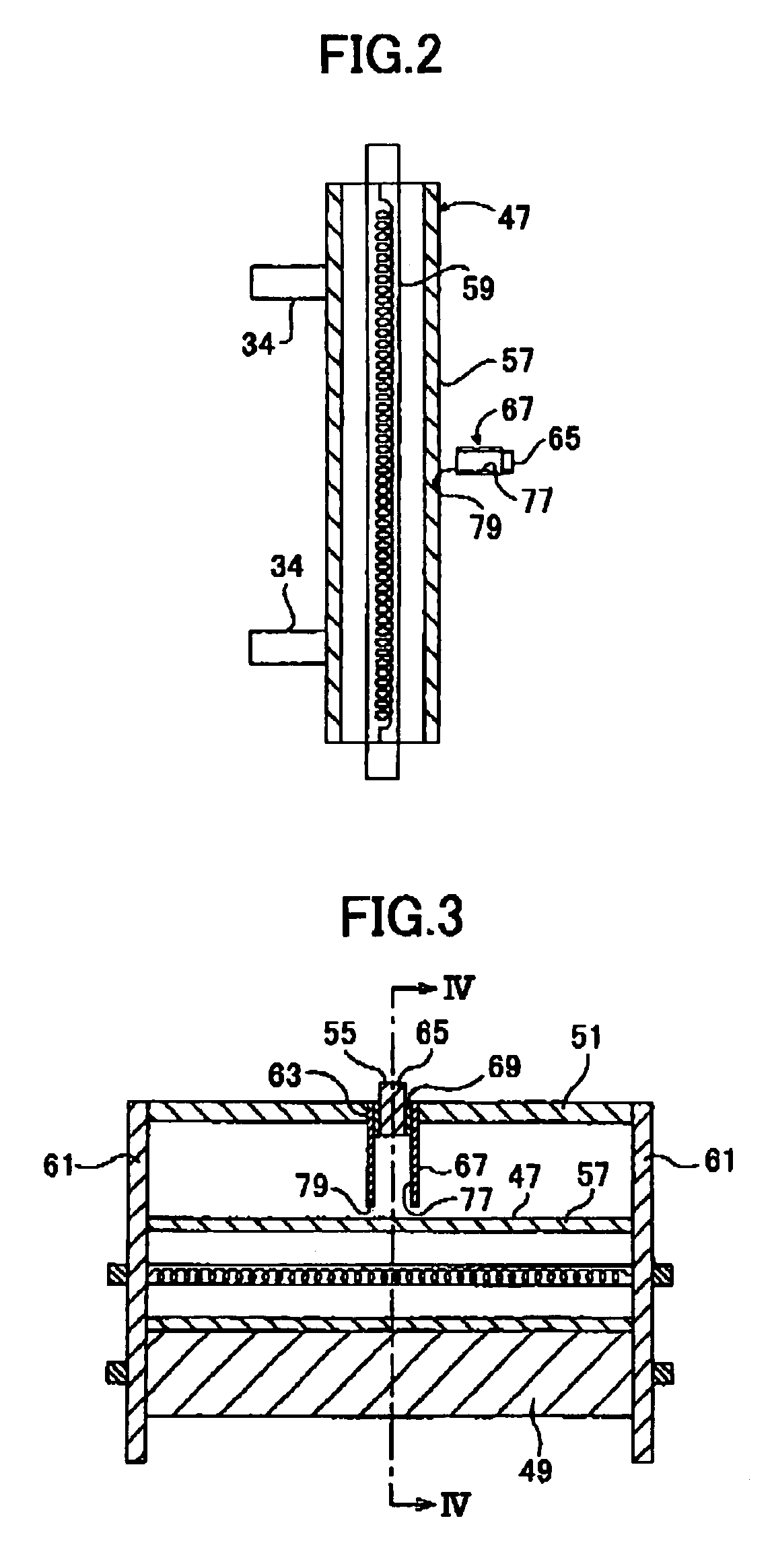

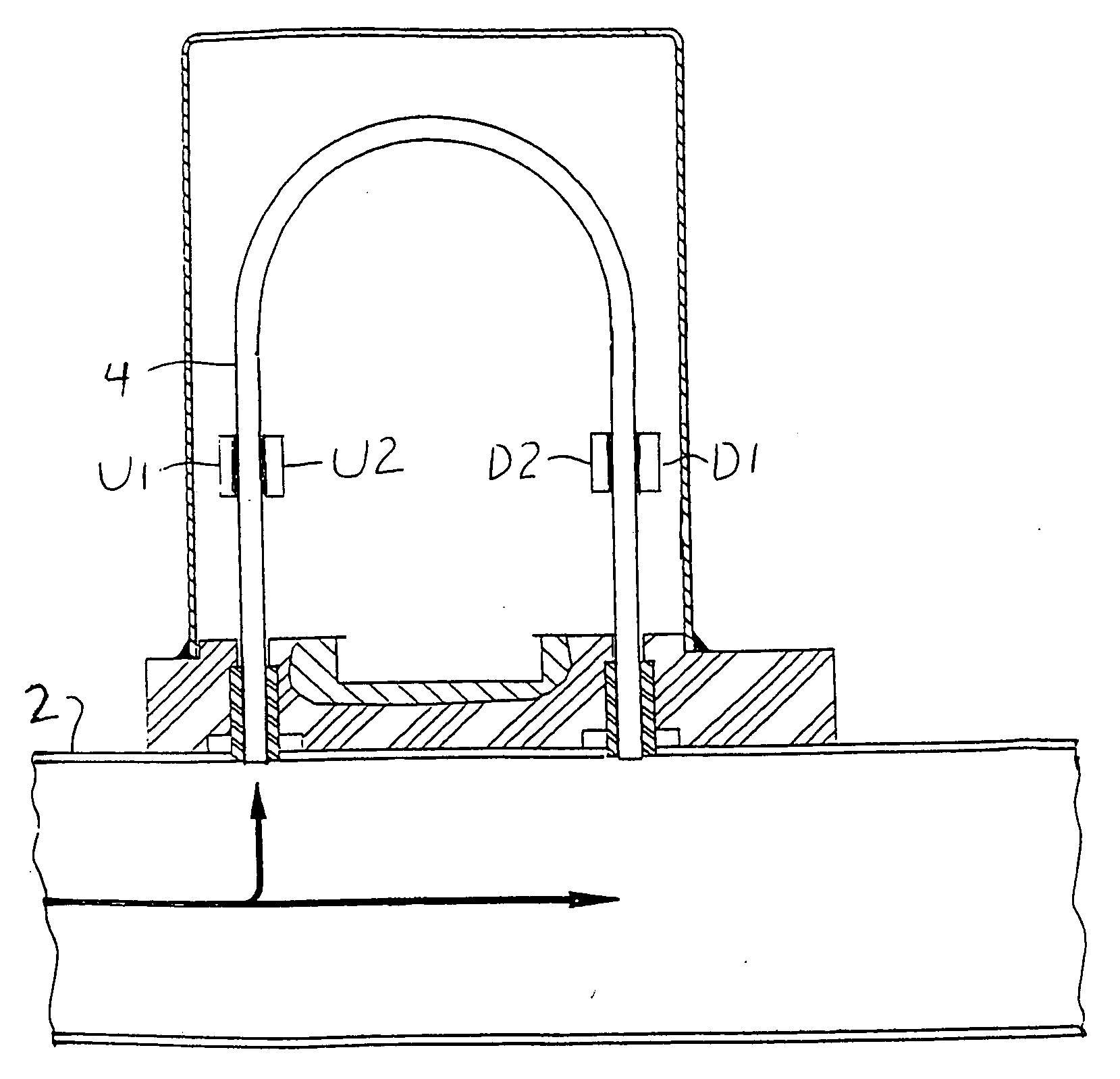

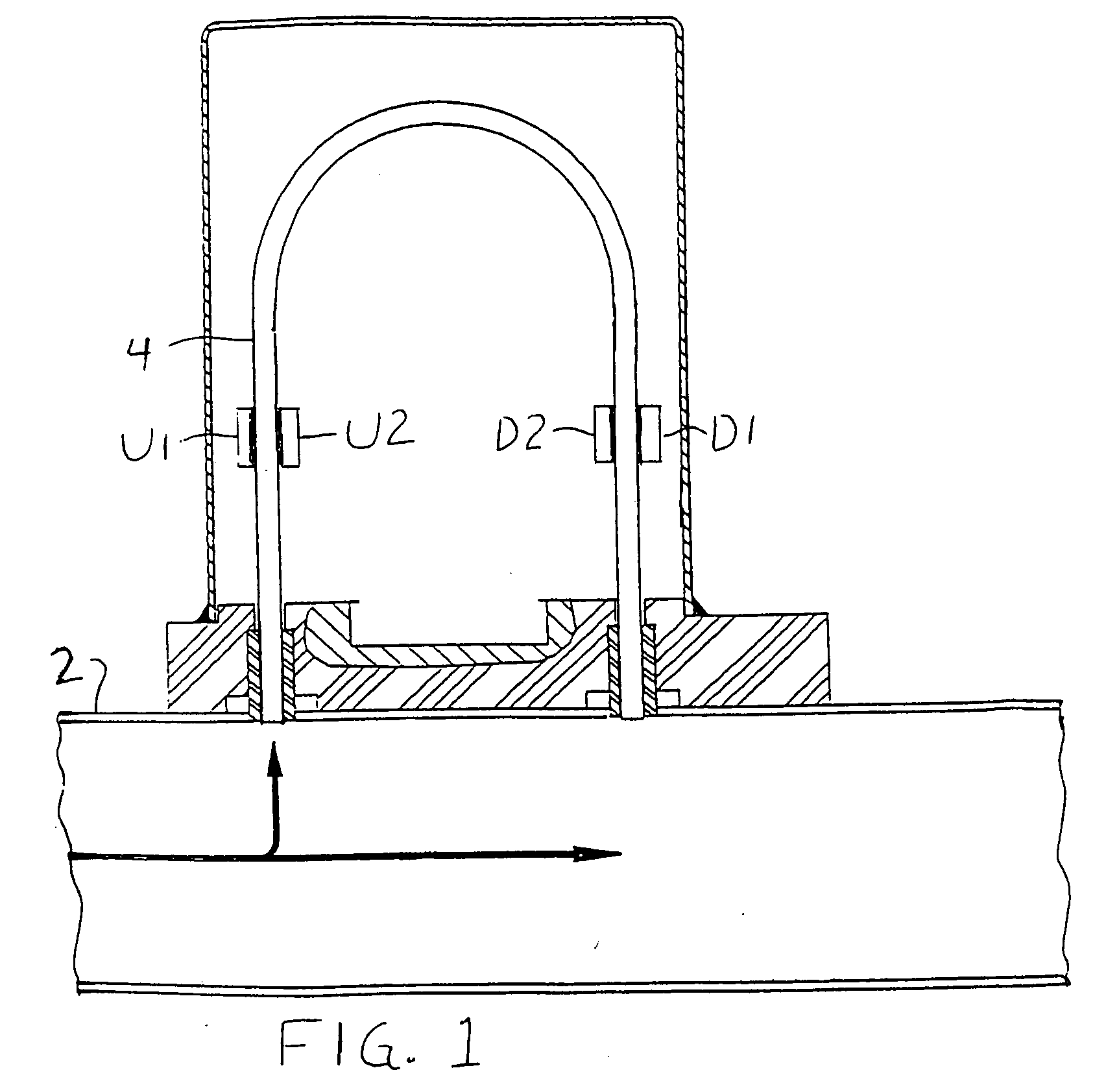

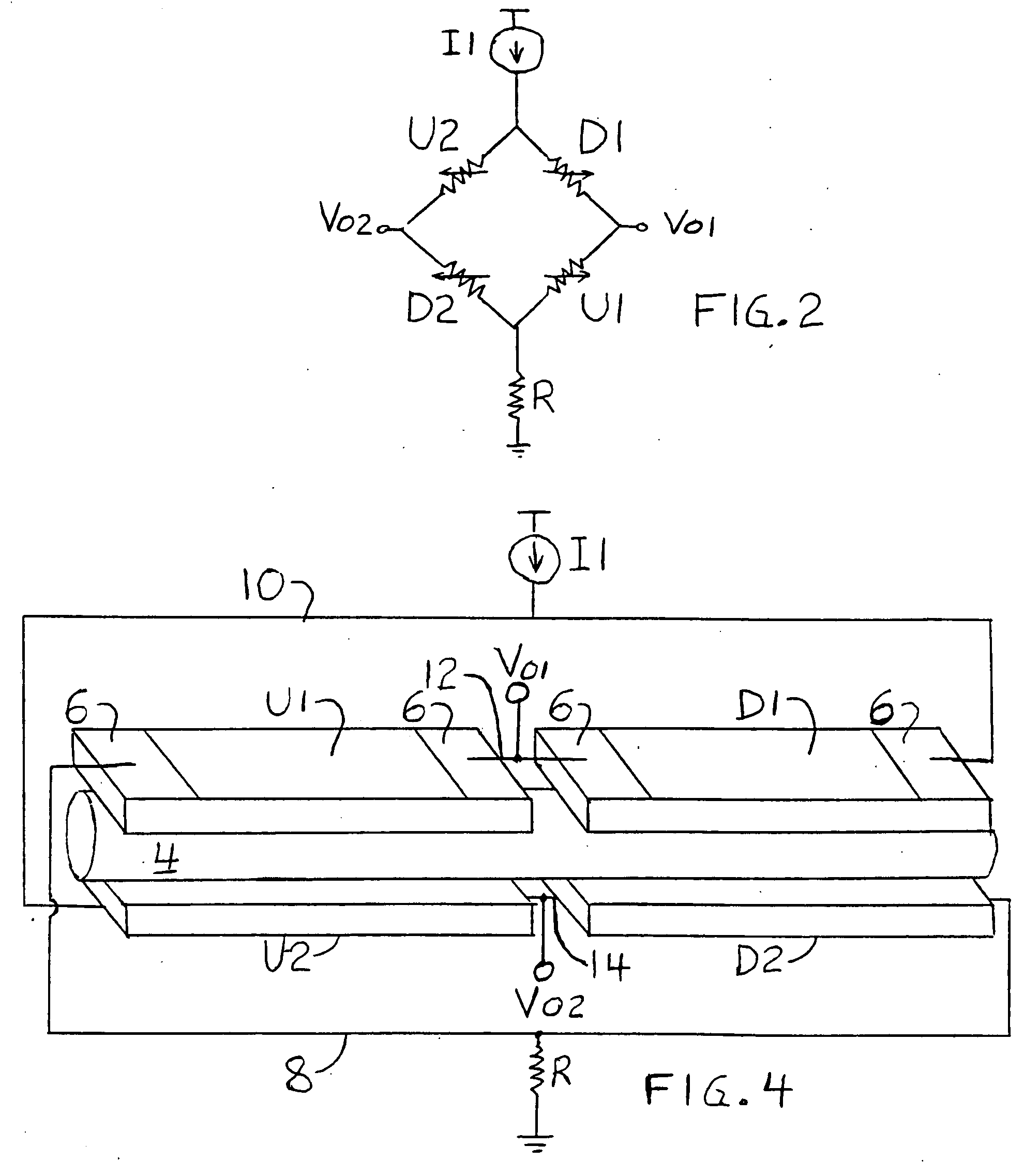

Mass flow meter with chip-type sensors

InactiveUS6883370B2Accurate temperature sensingVolume/mass flow by thermal effectsVolume flow proportion measurementSemiconductor chipEngineering

A mass flow meter employs discrete chip-type temperature sensors to sense a fluid flow rate. The sensor can be a semiconductor chip such as SiC or silicon, or thin film tungsten on an AlN substrate. The sensors can be distributed symmetrically with respect to the conduit through which the fluid flows, and can be connected in a four-sensor bridge circuit for accurate flow rate monitoring. An output from the mass flow meter can be used to control the fluid flow.

Owner:HEETRONIX

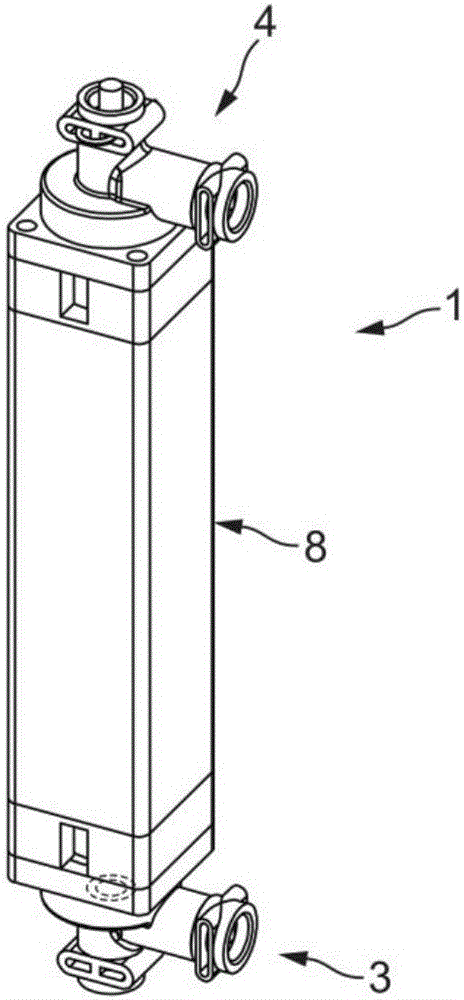

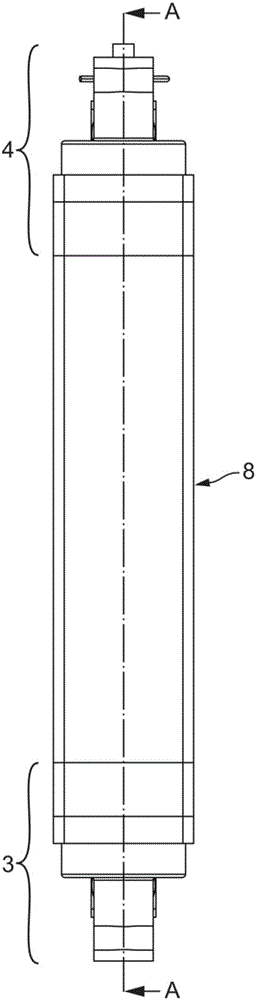

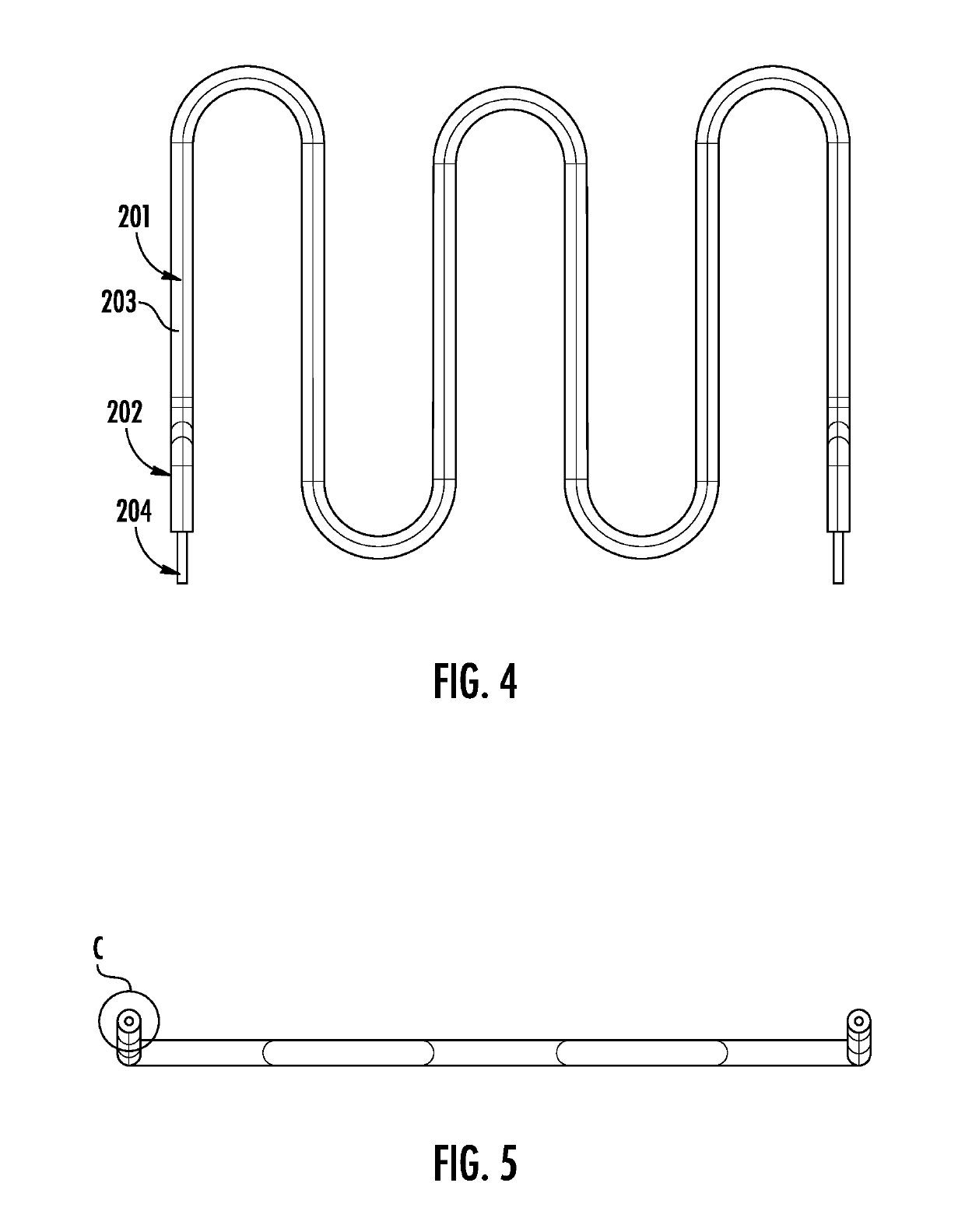

Instant tube heater with homogenous temperature control

ActiveCN106488727AAccurate temperature sensingImprove efficiencyMechanical apparatusOhmic-resistance waterproof/air-tight sealsTemperature controlHeat flow

The invention relates to an instant tube heater (1) for heating flowing liquid comprising: a hollow heating tube (2) comprising a tubular flow passage (20) extending along a central axis (I) for heating liquid as it flows through it, an inlet connector (3) sealingly connected to an inlet end (21) of the hollow heating tube, an outlet connector (4) sealingly connected to an outlet end (22) of the hollow heating tube, a temperature sensor (5) connected to the outlet connector (4) for sensing the temperature of liquid leaving the heating tube, wherein an inlet flow deviating member (6) is positioned locally at the inlet end (21) of the heating tube (2) for forcing the flow of liquid entering the tubular passage of the heating tube in at least one direction away from the direction of the central axis (I) of the tubular passage.

Owner:SOC DES PROD NESTLE SA

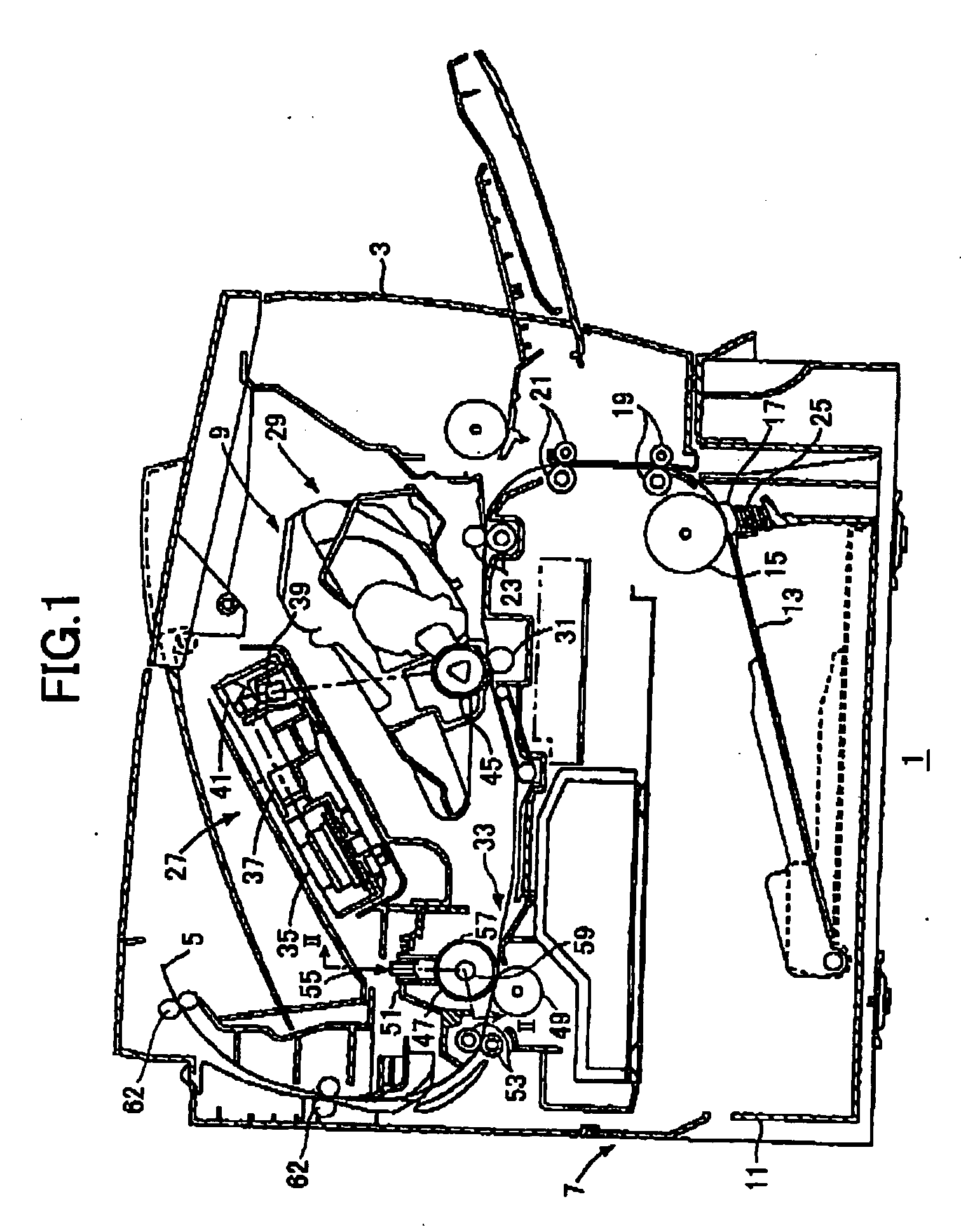

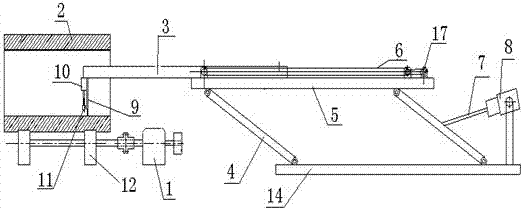

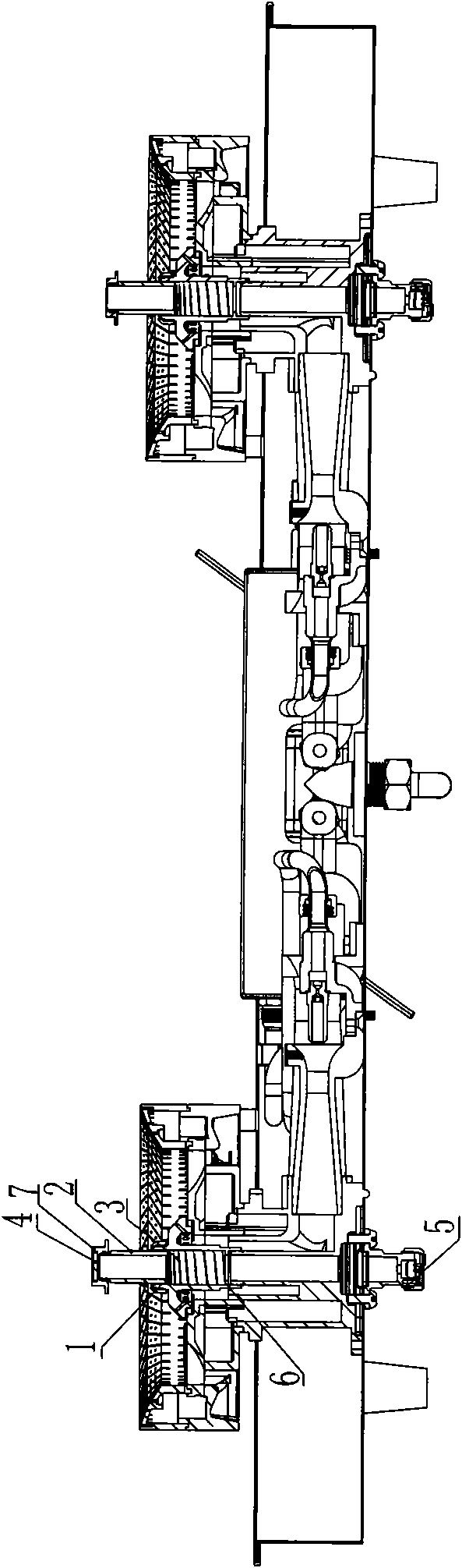

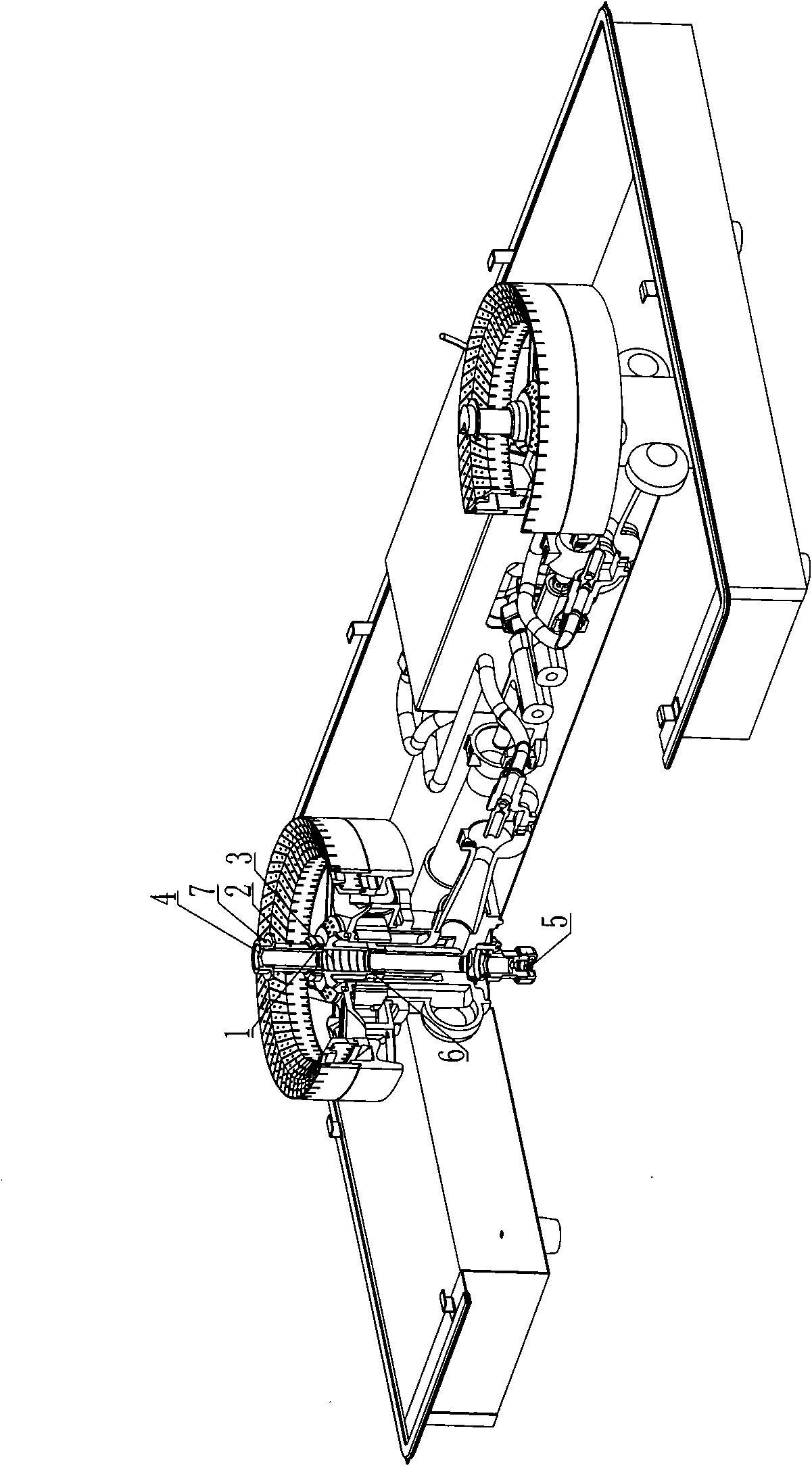

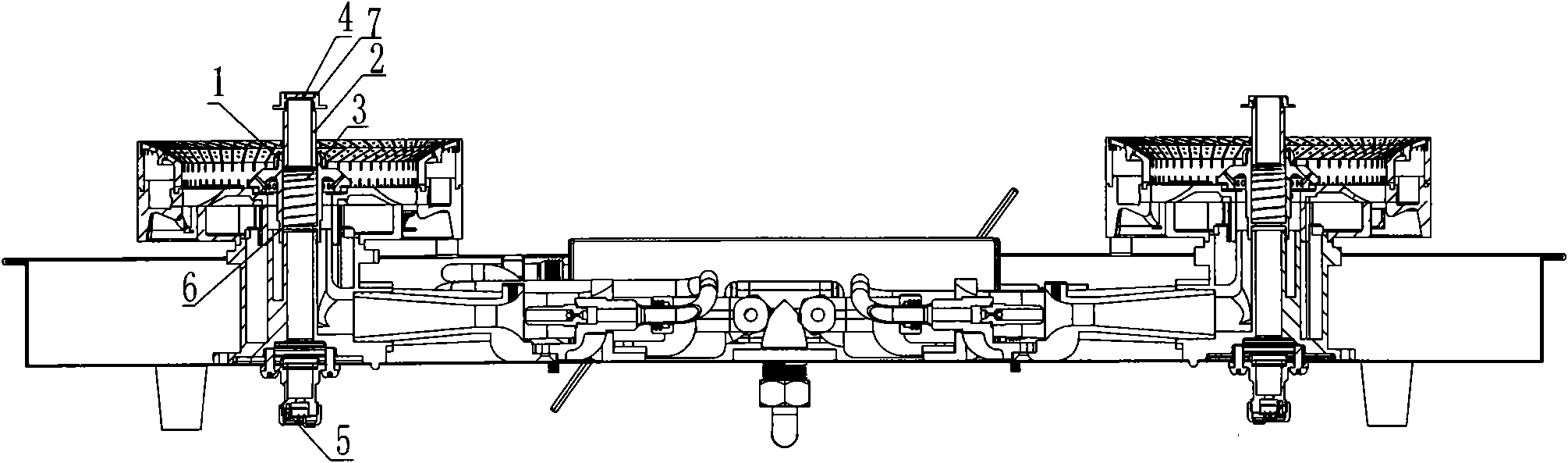

Automatic thickness measuring device for cold-type coating of roller

ActiveCN102927950ARealize automatic measurementAchieve recordMeasurement devicesEngineeringAutomation

The invention discloses an automatic thickness measuring device for a cold-type coating of a roller. The automatic thickness measuring device comprises a thickness gauge and a feeding mechanism, wherein the feeding mechanism is mainly composed of a cradle mechanism, a telescopic gun barrel and an extensible drive device. The cradle mechanism is a four-rod linkage mechanism formed by hinging a rocking rod, a cradle upper rod and a horizontal fixing rod mutually, the extensible drive device is mainly composed of a pneumatic pushing rod and an air cylinder, and the pneumatic pushing rod is hinged to the rocking rod. The telescopic gun barrel is installed on the cradle upper rod and is driven by a motor A connected with a counter, the front end of the telescopic gun barrel is provided with a small air cylinder and a thickness measuring scale, and the thickness gauge is arranged on the small air cylinder. A cold-type rotating mechanism is arranged at the position corresponding to the front end of the telescopic gun barrel of the feeding mechanism. An encoder is connected onto the cold-type rotating mechanism. The extensible drive device, the motor A, the small air cylinder, the thickness gauge, the cold-type rotating mechanism and the encoder are connected to a computer control system. The automatic thickness measuring device can finish the measurement of thickness and position of the cold-type coating and full-automation control of the coating thickness process.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

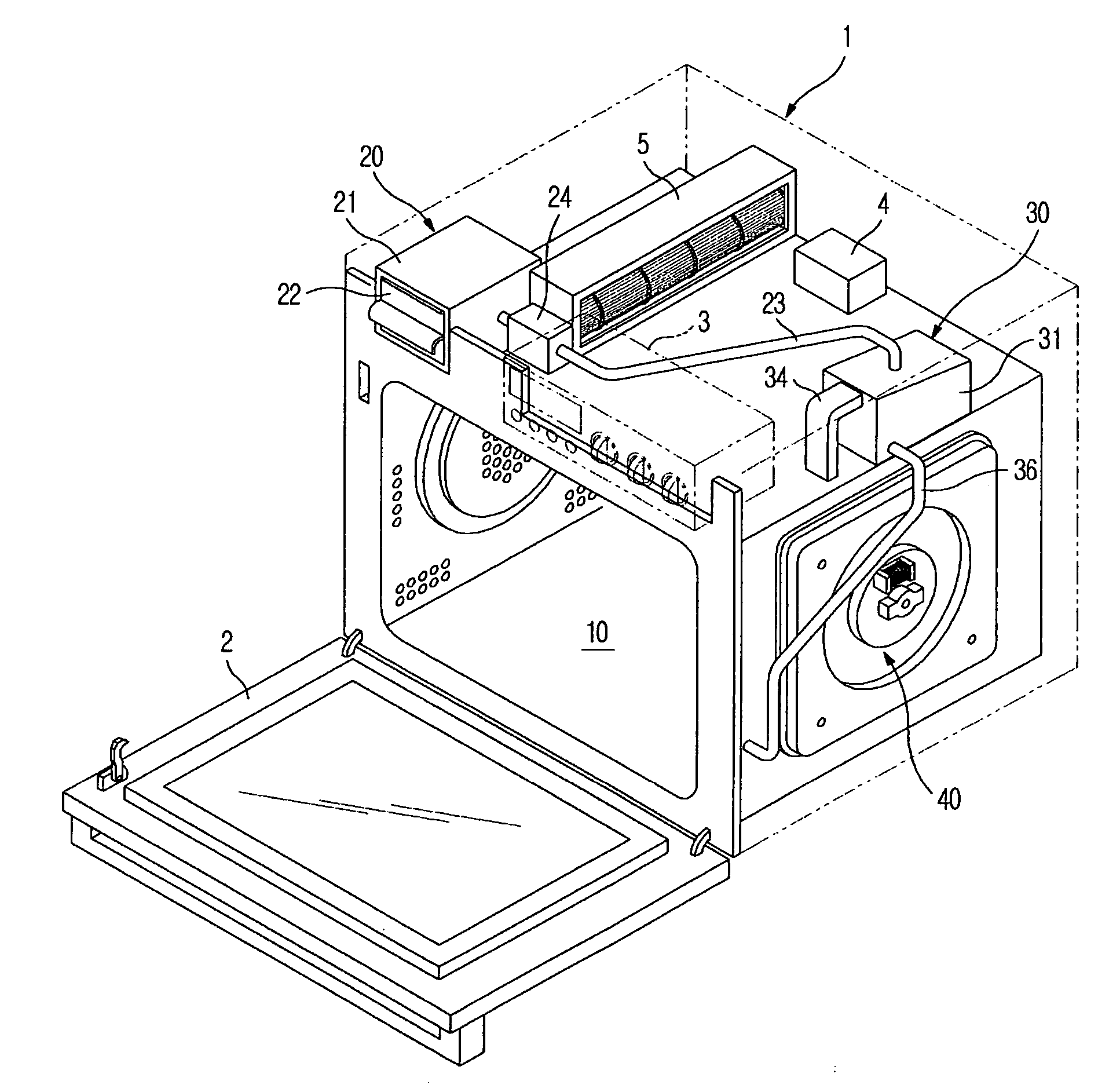

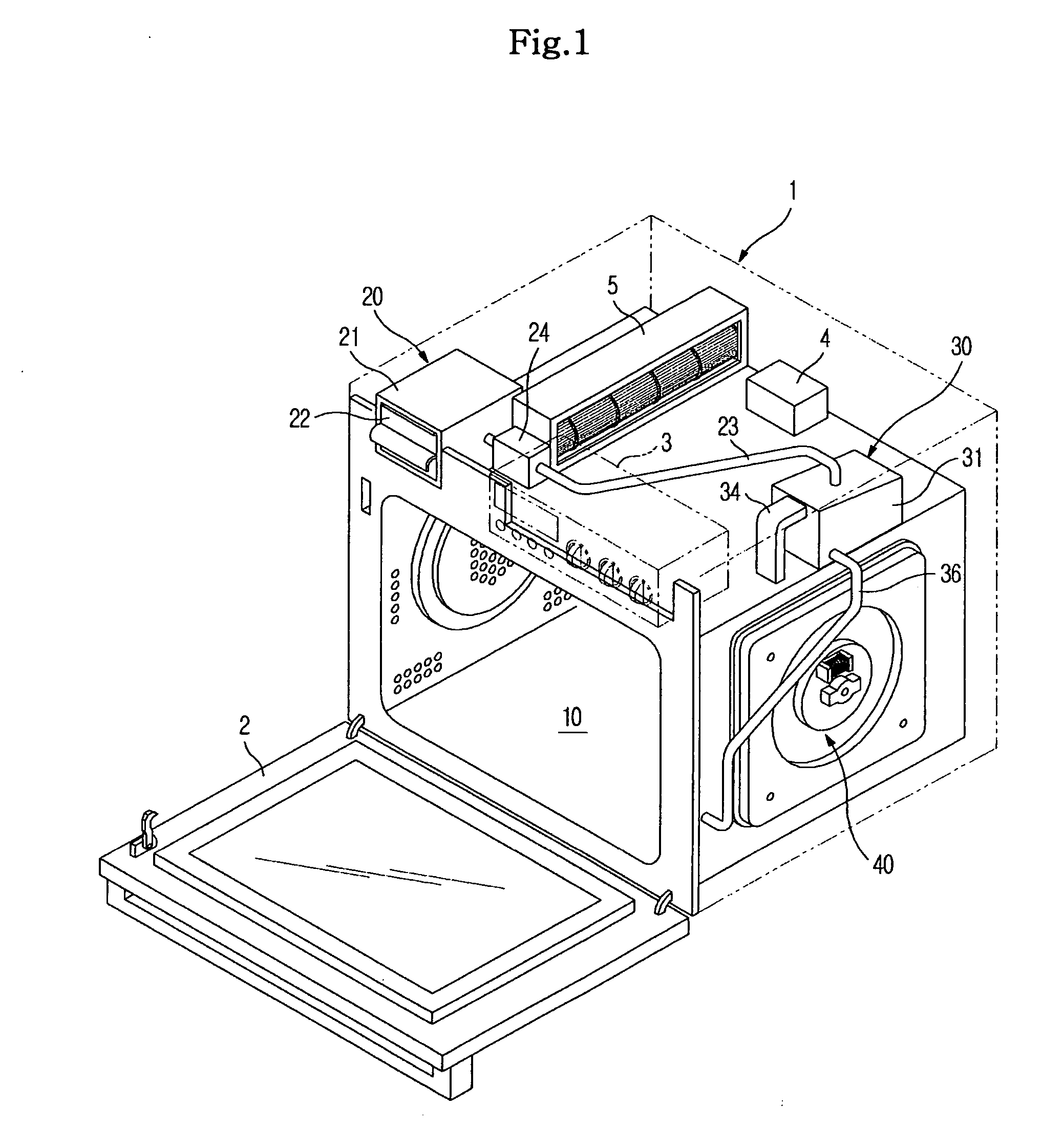

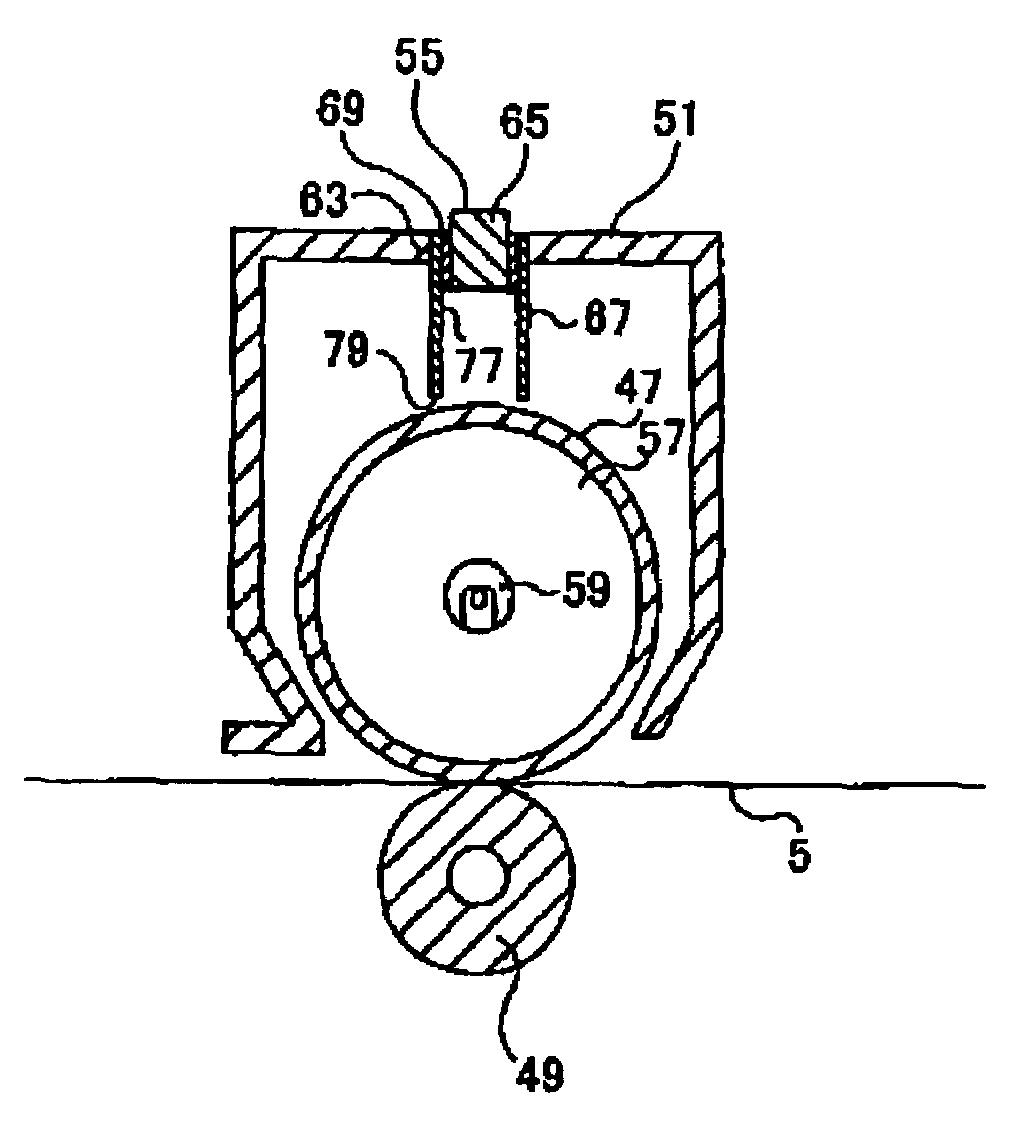

Plate-shaped heater and steam cooking apparatus including the same

InactiveUS20070114221A1Reduce manufacturing costAvoid separationDomestic stoves or rangesElectrical heating fuelManufacturing cost reductionSteam cooking

A plate-shaped heater having a PTC temperature sensor to sense a temperature of the plate-shaped heater, and a steam cooking apparatus including the same. The plate-shaped heater includes an insulating substrate, a heating element formed of a resistor pattern-printed on the insulating substrate to generate heat, and a PTC temperature sensor to sense a heating temperature of the heating element. The PTC temperature sensor is pattern-printed on the insulating substrate, and therefore, has the effect of eliminating the risk of unintentional separation thereof, and achieving a simplified manufacturing process and reduced manufacturing costs. The PTC temperature sensor is disposed on the insulating substrate in an axis of direction having a wide distance between neighboring temperature contour lines, to achieve accurate temperature sensing capability thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Heat fixing device capable of preventing deterioration of a temperature sensor and an image forming apparatus

InactiveUS7433619B2Keep distanceAvoid attenuationSensing radiation from moving bodiesElectrographic process apparatusInfraredThermal insulation

A heat fixing device capable of preventing deterioration of a temperature sensor by measuring the surface temperature of a heating roller at all times, and an image forming apparatus. The heat fixing device includes a temperature measurement unit for measuring the surface temperature of the heating roller. The temperature measurement unit further includes the temperature sensor, a conduit having a reflective surface formed inside thereof to lead infrared rays radiating from the heating roller to the temperature sensor, and a thermal insulation member installed between the conduit and the temperature sensor.

Owner:BROTHER KOGYO KK

Method of forming cooking plate with temperature sensing element

ActiveUS10368395B1Accurate temperature sensingTemperatue controlHot plates heating arrangementsEngineeringHeating element

A cooking plate includes a metal plate for cooking; a heating element, which is in contact with the metal plate and is configured to heat the metal plate; and a temperature sensing element which is integrated with the metal plate and which is configured to sense a temperature of the metal plate and outputs a sensing signal for control heating of the heating element.

Owner:PALATE HOME INC

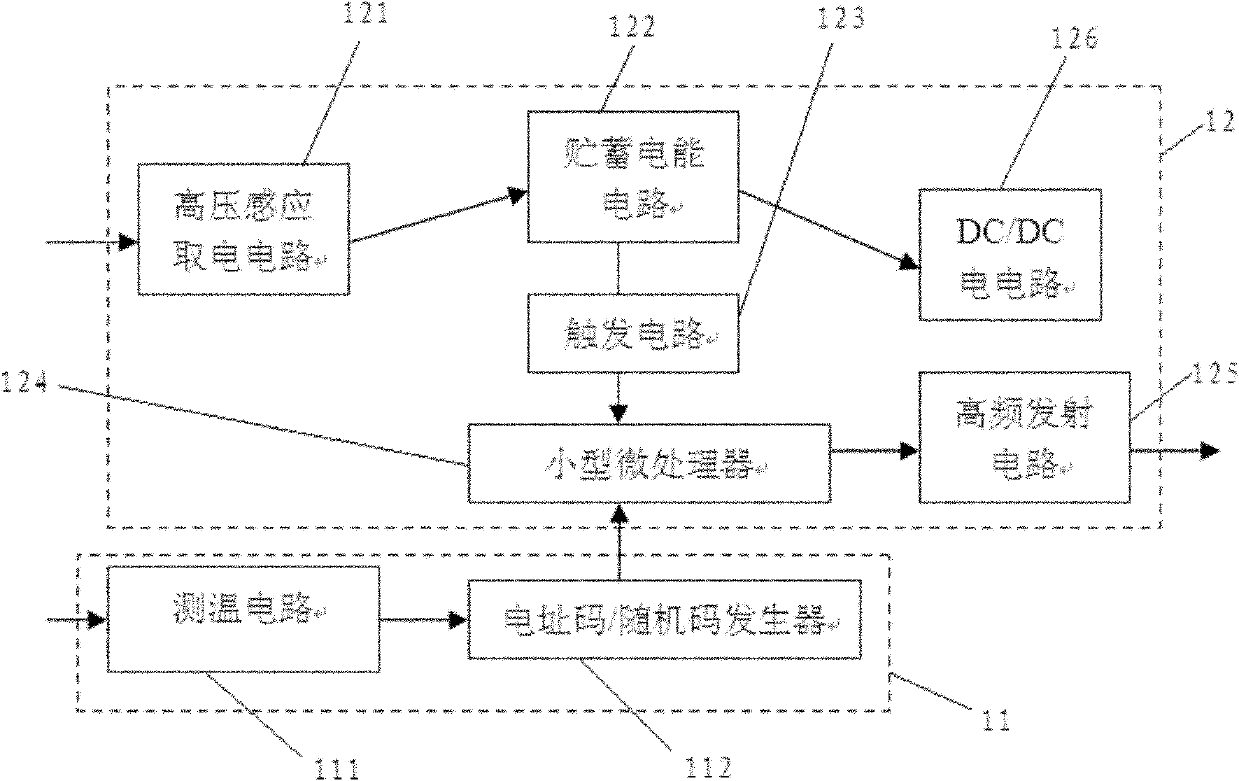

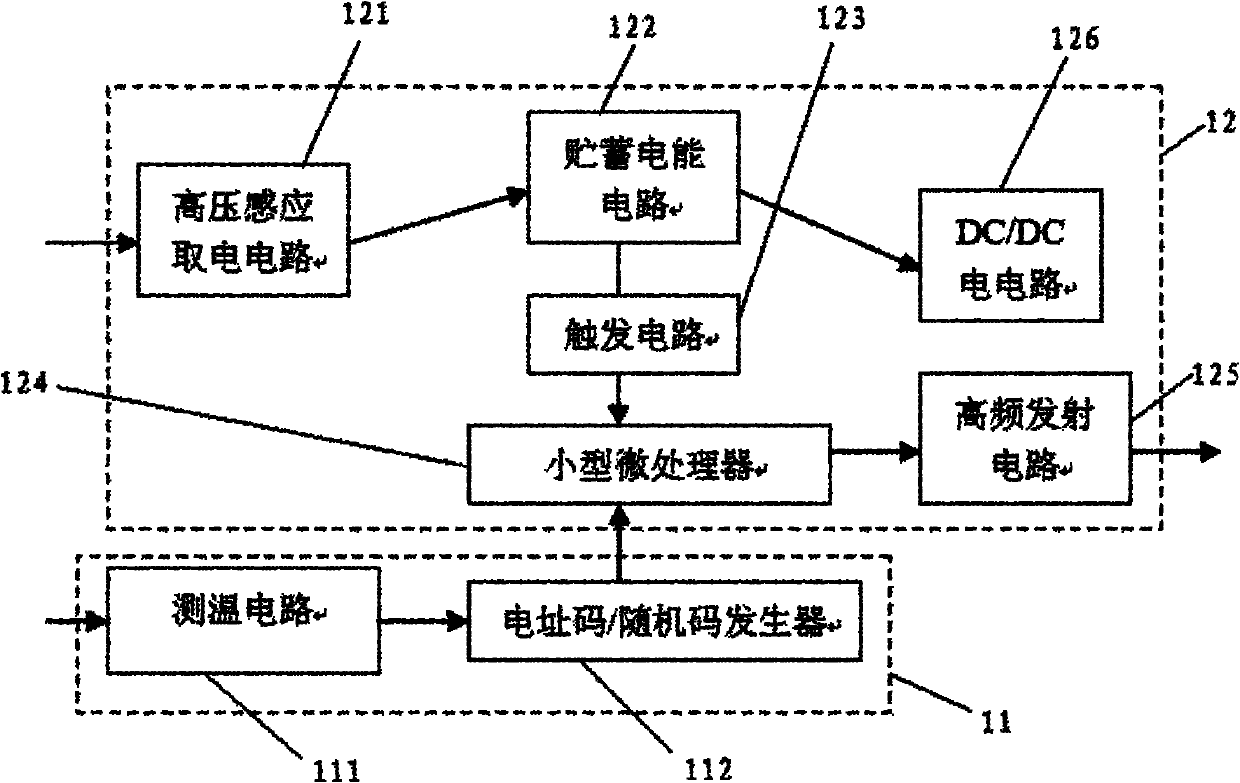

Wireless temperature sensor

InactiveCN102564625AEasy to installAccurate temperature sensingThermometer detailsTransmission systemsTest objectTemperature sense

The invention discloses a wireless temperature sensor in a shape of a bolt. The wireless temperature sensor comprises a screw portion with a thread and a nut portion which are fixed together. An electricity taking and processing module is arranged inside the nut portion, and a temperature sensing module is arranged in the screw portion. The wireless temperature sensor is easy to install and can not have any influence on power equipment. In addition, the wireless temperature sensor only needs to be installed on a tested object at one time, and is used in a long term without replacement, so that the characteristic of passiveness is achieved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +3

Infrared dry-combustion-preventing high-efficient furnace end

InactiveCN102374529AAccurate temperature sensingGuaranteed anti-dry functionGaseous fuel burnerInfraredCombustion

The invention discloses an infrared dry-combustion-preventing high-efficient furnace end, which is characterized in that: an application direction is adopted as benchmark, a conduit which runs through the furnace end in the longitudinal direction is arranged on the center of the furnace end, a telescopic sleeve and an elastic element are sequentially plugged inside the conduit from top to bottom, the lower end of the elastic element is fixed and positioned on the inner side wall of the furnace end conduit, the upper end of the elastic element is fixedly connected with the telescopic sleeve, centers of both the elastic element and the telescopic sleeve are provided with a through hole, the upper end of the telescopic sleeve stretches out of the upper end surface of the furnace end, the upper end of the telescopic sleeve is provided with high-temperature-resistant optical glass in an embedding way, the high-temperature-resistant optical glass just covers the through hole of the telescopic sleeve, and the positive lower end of the conduit on the center of the furnace end is provided with an infrared temperature measuring device. Due to the adoption of the infrared dry-combustion-preventing high-efficient furnace end, when the dry combustion on the bottom of a pot happens, the furnace quick can effectively sense the dry combustion and can disconnect the gas and distinguish the fire in time, infrared ray transmitted from the pot bottom is free from being influenced by the external environmental factors, so the infrared temperature measuring device is precise to measure the temperature, and the real dry-combustion preventing function of the furnace end can be guaranteed.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

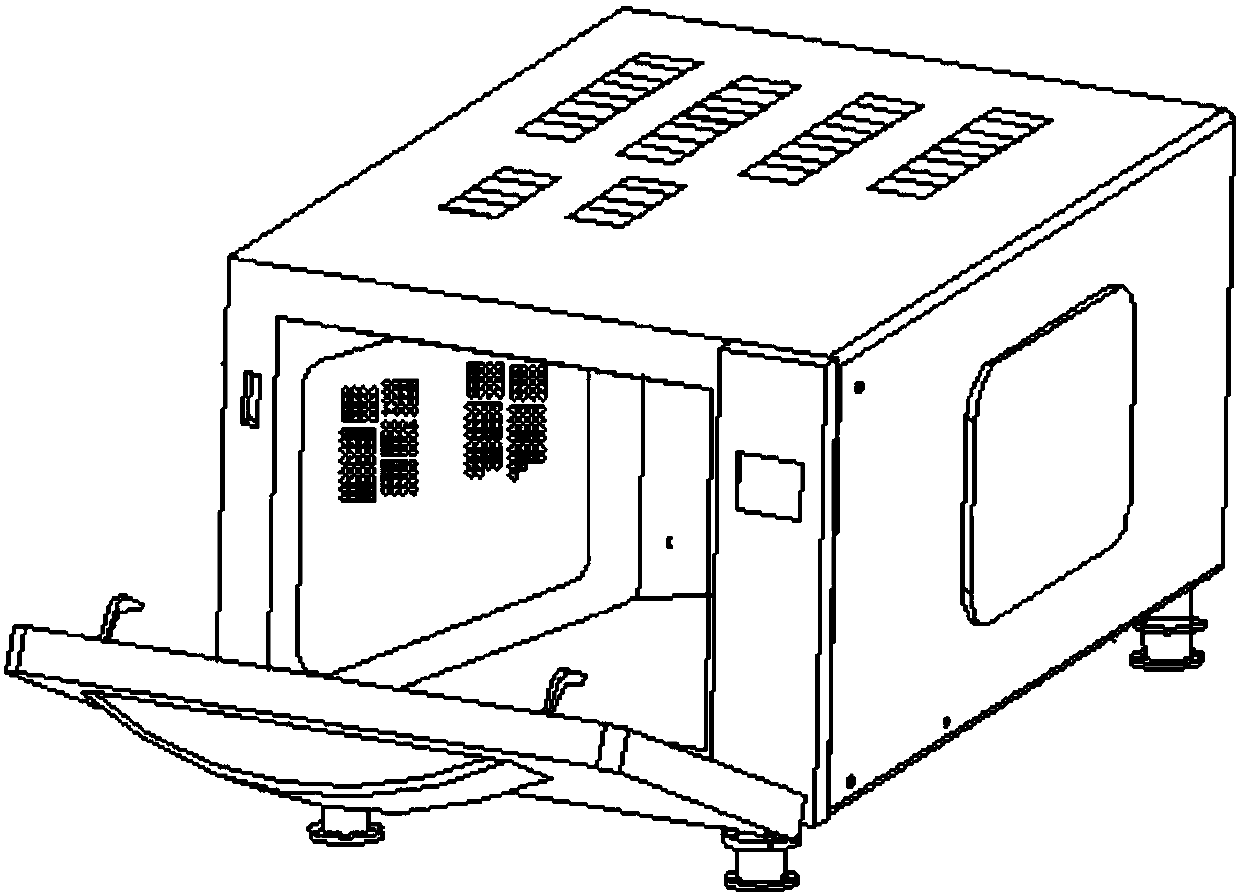

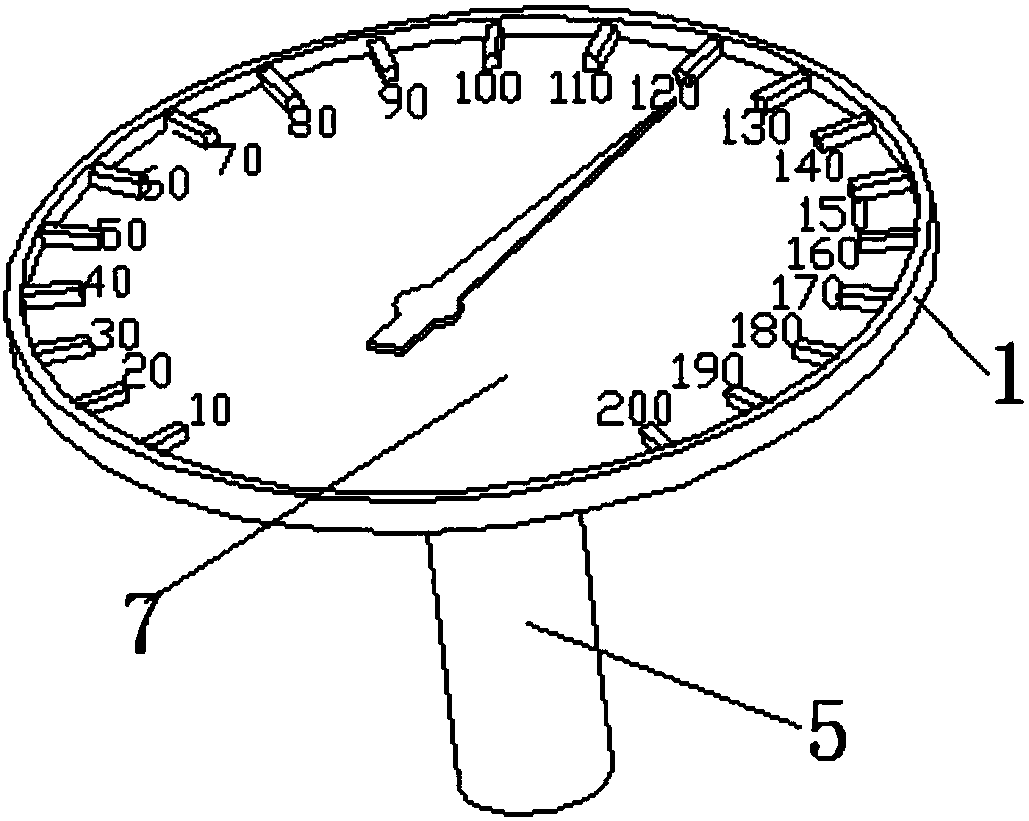

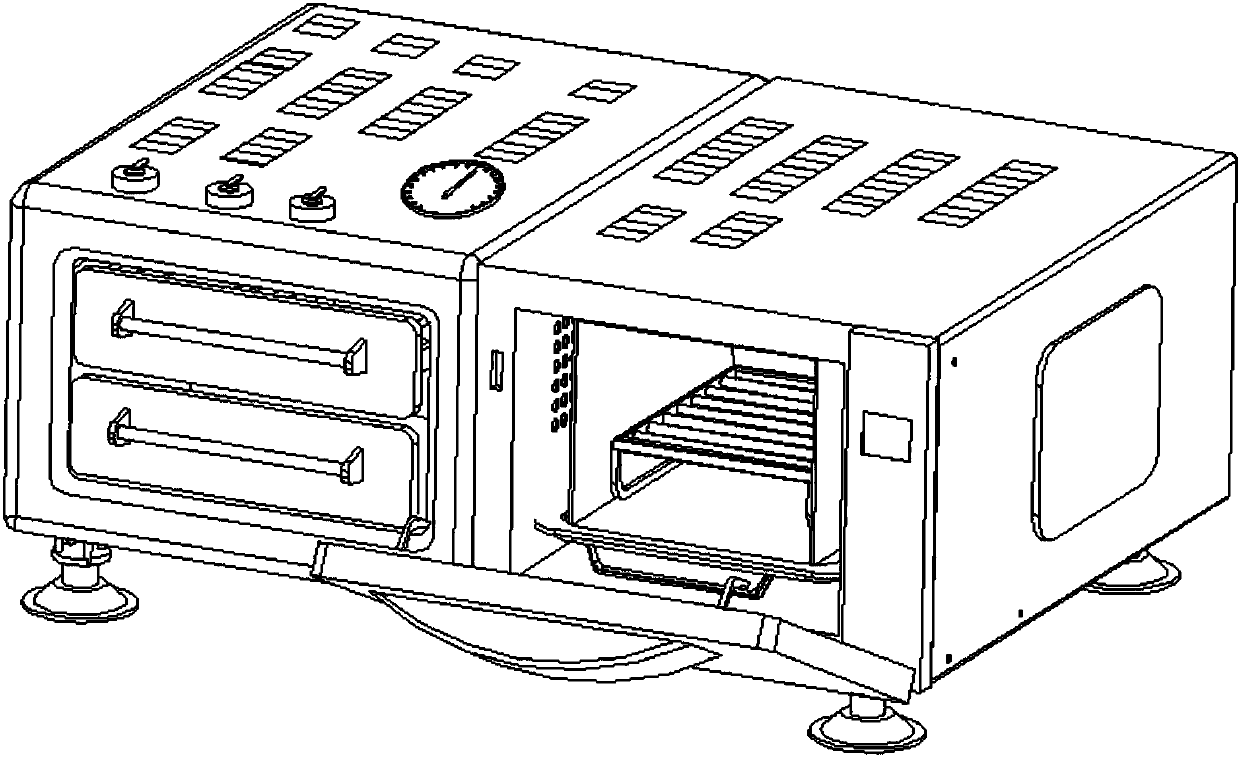

Double door kitchen electric oven with temperature display and displacement prevention functions

InactiveCN107559904ASimple structureImprove performanceDoors for stoves/rangesDomestic stoves or rangesMicrowave ovenEngineering

A double door kitchen electric oven with temperature display and displacement prevention functions comprises a displacement prevention device, a gas frying device, a duplex metal thermometer, a microwave oven body and an oven body. The microwave oven body is fixedly connected with the oven body, and the bottom of the microwave oven body and the bottom of the oven body are each provided with two first supporting feet. The gas frying device is arranged in the microwave oven body. The upper surface of the microwave oven body and the upper surface of the oven body are both provided with louvers. The displacement prevention device comprises the first supporting feet and at least one bowl-shaped suction cup. One end of the outer circle of each bowl-shaped suction cup is provided with a tongue piece used for preventing the situation that the microwave oven body is attracted too firmly so that the microwave oven body cannot be moved. The bowl-shaped suction cups are independently arranged at the bottom of the microwave oven body and the bottom of the oven body or arranged under the supporting feet. The double door kitchen electric oven adopts the overall design of double doors, and is simple and reasonable in structure, reliable in performance, convenient to use, accurate in temperature induction, safe, reliable, high in attraction force, convenient and fast in machining production, low in cost and flexible to operate.

Owner:刘永昌

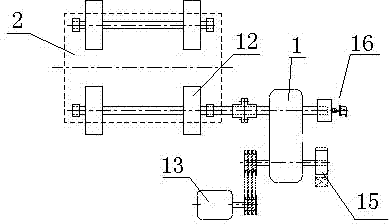

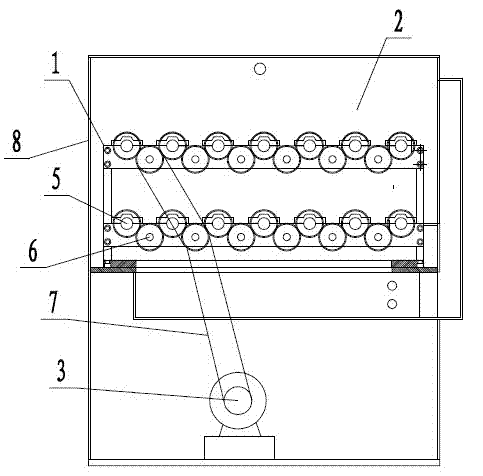

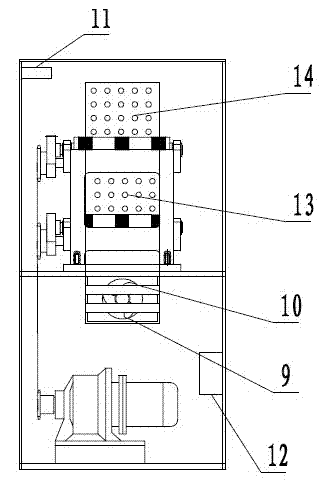

Gear transmission optical fiber coloring printing ink blender

InactiveCN102755851AIncrease the amount of stirringLarge amount of stirringMixer accessoriesTemperature controlColor printing

The invention discloses a gear transmission optical fiber coloring printing ink blender which comprises a support, a rotary drum device, a motor, a speed changer and a temperature control module. The motor is connected with the speed changer, two layers / a plurality of layers of rotary drum device are arranged on the support, the rotary drum device is connected with the speed changer to drive, the temperature control module comprises a transparent box, a fan, a heating module, a temperature thermocouple and a temperature control device, and the rotary drum device is located in the transparent box. The gear transmission optical fiber coloring printing ink blender increases mixing amount through the plurality of layers of rotary drum device, achieves speed adjustment through a speed changing box, achieves temperature regulation in a stirring process through the temperature control module, improves adaptability of a blender on ambient temperature, promotes stirring quality, and is suitable to stirring of printing ink in various types.

Owner:ZHEJIANG FUCHUNJIANG PHOTOELECTRIC SCI & TECH

Thermal sensors and methods of operating thereof

InactiveCN105784158AHigh precisionSimple Temperature CalibrationThermometer with A/D convertersThermometers using electric/magnetic elementsVoltage referenceResistor

A thermal sensor includes a comparator having first and second input nodes. A reference voltage generator is electrically coupled with the first input node. The reference voltage generator is configured to provide a reference voltage that is substantially temperature-independent. A temperature sensing circuit is electrically coupled with the second input node. The temperature sensing circuit is configured to provide a temperature-dependent voltage. The temperature sensing circuit includes a current mirror. A first metal-oxide-semiconductor (MOS) transistor is electrically coupled between the current mirror and ground. A first resistor is electrically coupled with the current mirror. A second MOS transistor is electrically coupled with the first resistor in series. The second MOS transistor and the first resistor are electrically coupled with the first MOS transistor in a parallel fashion.

Owner:TAIWAN SEMICON MFG CO LTD

Mass flow meter with chip-type sensors

InactiveUS20050087011A1Accurate temperature sensingVolume/mass flow by thermal effectsVolume flow proportion measurementSemiconductor chipEngineering

A mass flow meter employs discrete chip-type temperature sensors to sense a fluid flow rate. The sensor can be a semiconductor chip such as SiC or silicon, or thin film tungsten on an AlN substrate. The sensors can be distributed symmetrically with respect to the conduit through which the fluid flows, and can be connected in a four-sensor bridge circuit for accurate flow rate monitoring. An output from the mass flow meter can be used to control the fluid flow.

Owner:HEETRONIX

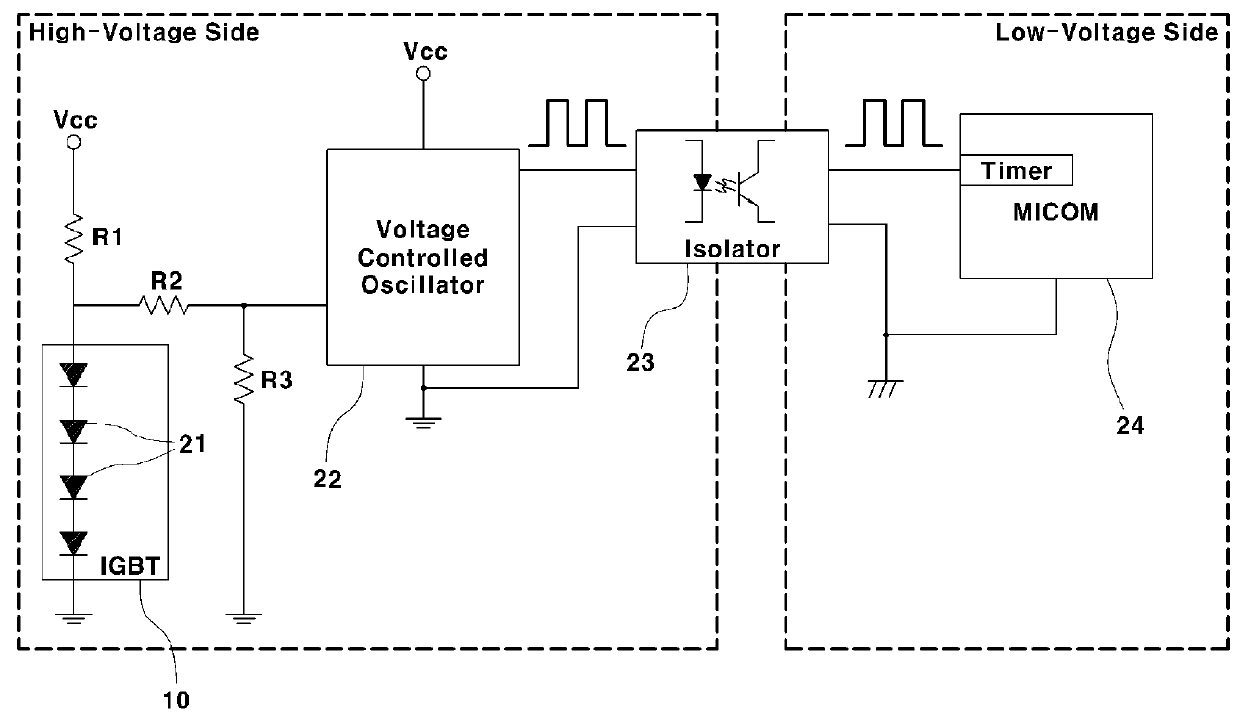

Temperature sensing system for switching device

InactiveUS9995636B2Accurate temperature sensingAvoid damageThermometers using electric/magnetic elementsElectronic switchingAnalog signalSignal transition

A temperature sensing system for a switching device is provided The temperature sensing system includes a sensing device that is configured to sense a temperature of the switching device and a signal converter that is configured to output a digital signal having a frequency based on a voltage across the sensing device by a frequency variable method which receives the voltage across the sensing device which is a temperature sensing value when a current flows in the sensing device to convert a level of an analog signal into a frequency of the digital signal. An isolator is configured to be connected to an output terminal of the signal converter to isolate and transmit the digital signal output from the signal converter. The system also includes a controller configured to recognize the temperature from the frequency of the digital signal transmitted through the isolator.

Owner:HYUNDAI MOTOR CO LTD

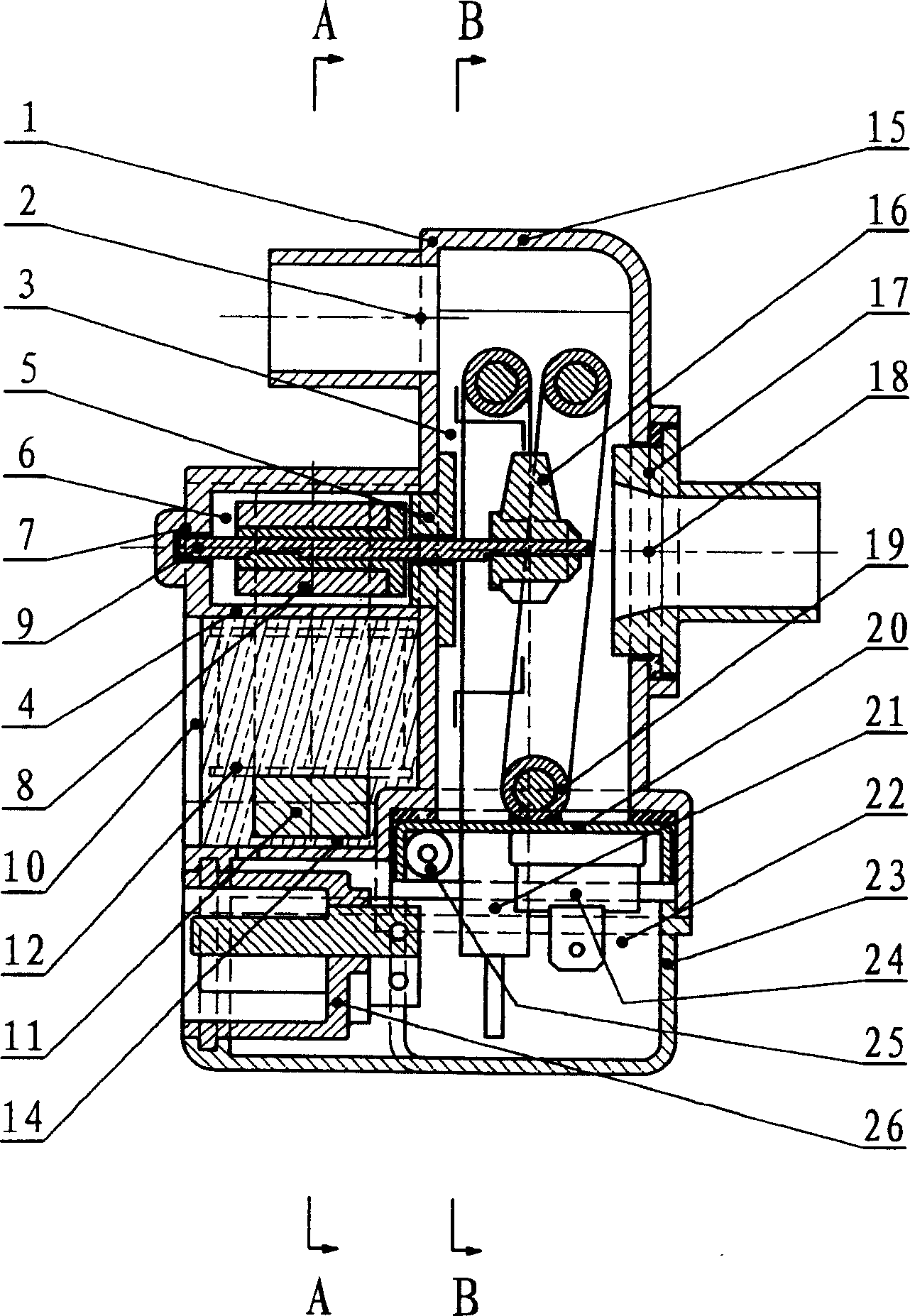

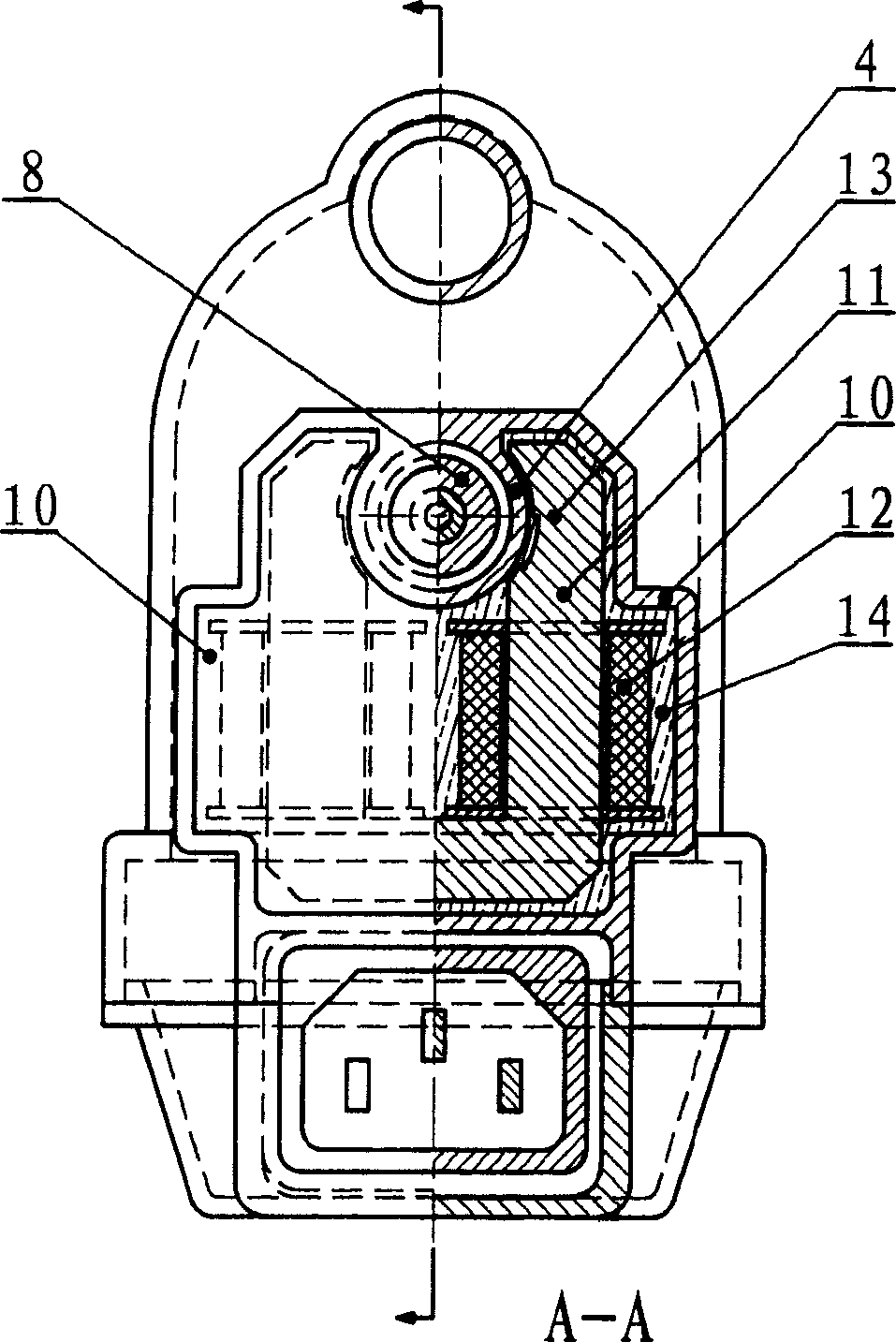

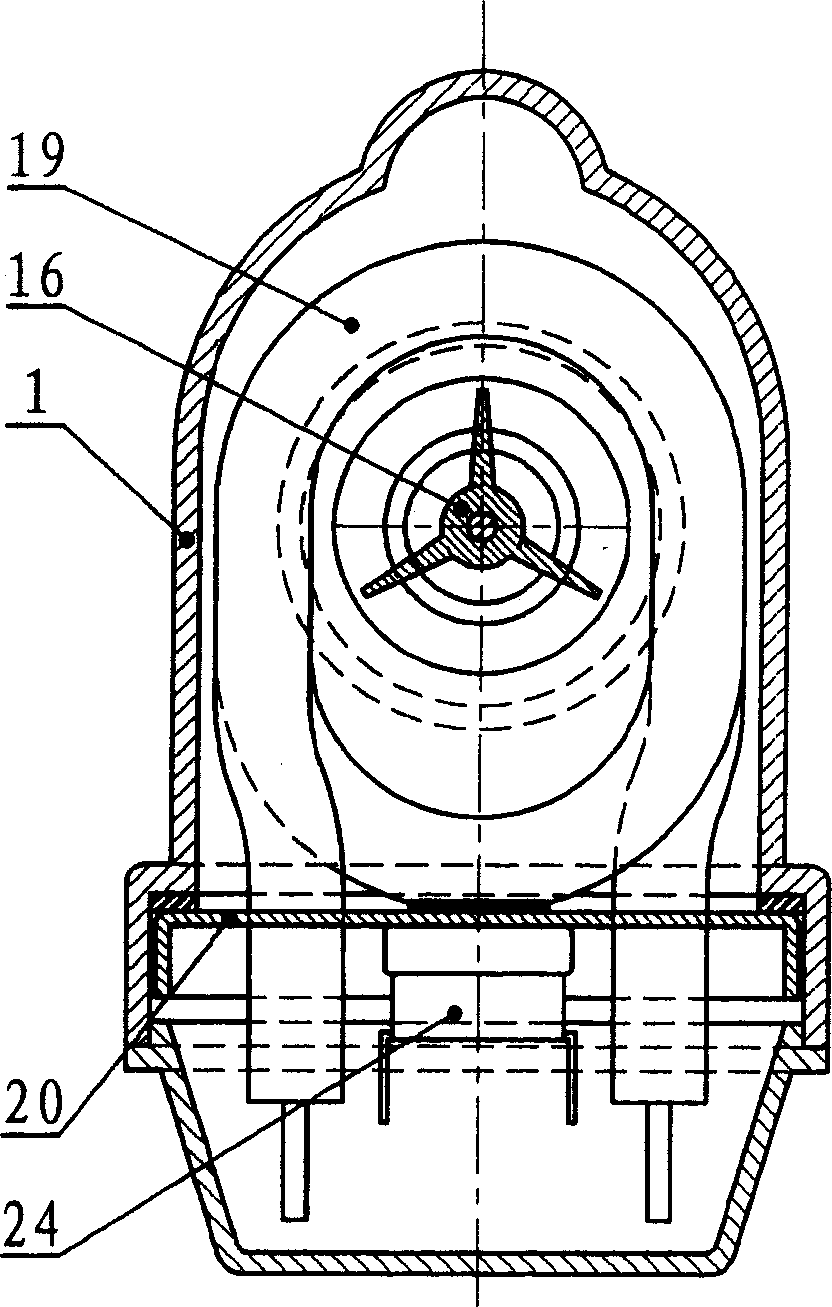

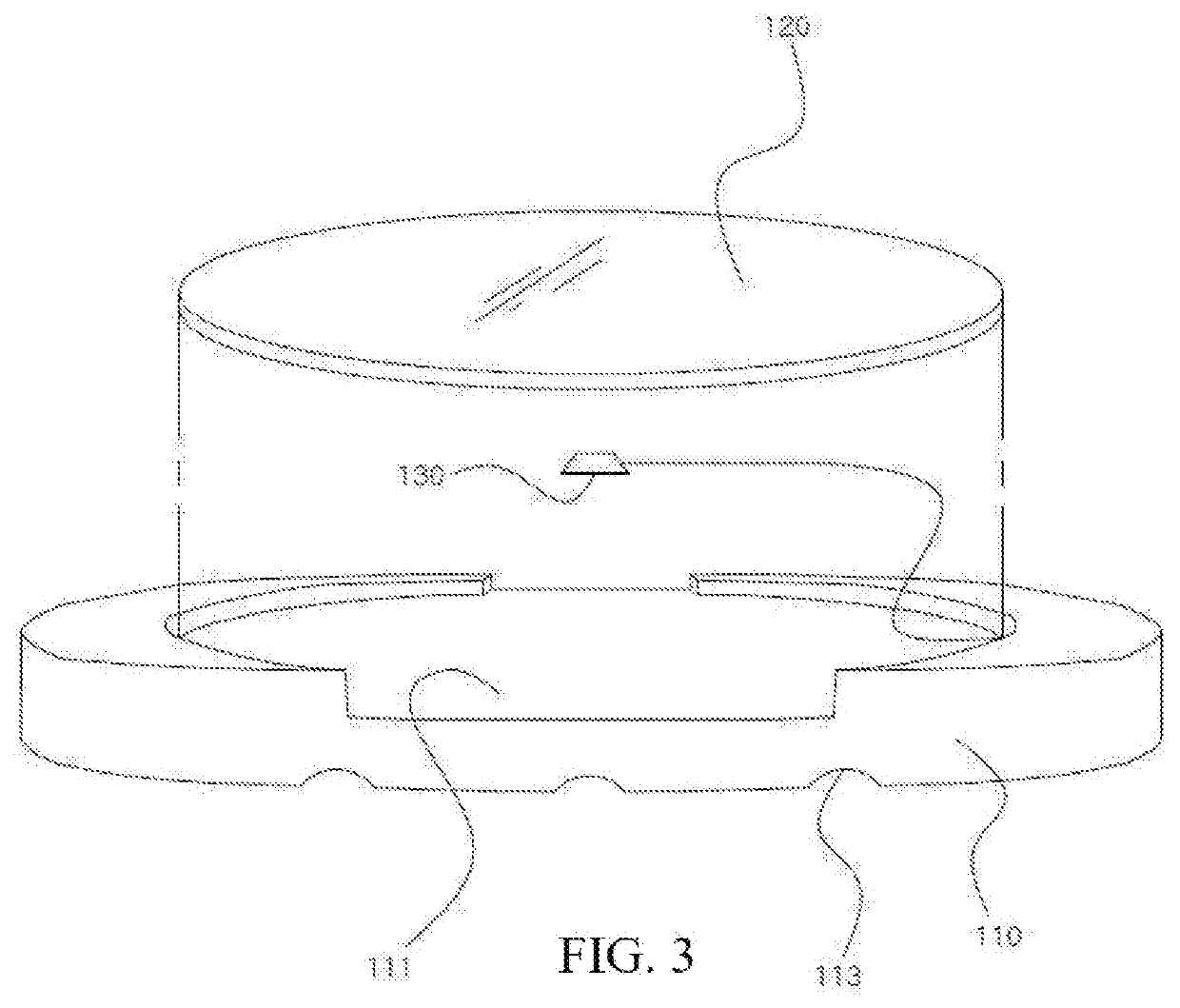

Circular preheater of permanent magnet rotary pump in single cavity, and assembly method

ActiveCN1760535ASmall footprintSmall sizeMachines/enginesEngine startersPermanent magnet rotorImpeller

A circulating preheater with single cavity permanent magnet rotor ( PMR ) pump is featured as preparing cavity body rotor and cavity shell by plastic injection molding for setting then in one body or one body connected structure ; setting outlet , front head opening , electro thermal tube ( ET ) opening at bottom and separated stator slot on cavity body ; installing PMR , front hearing and impeller in rotor or heating cavity from front head opening ; installing ET spiral portion in heating cavity from its own opening ; filling and sealing stator in stator slot ; setting temperature sensing component on external side surface of ET fixture disc and setting junction box below ET fixture disc and stator slot . The ET should be installed first when assembling operation is carried out.

Owner:青岛快乐电气有限公司

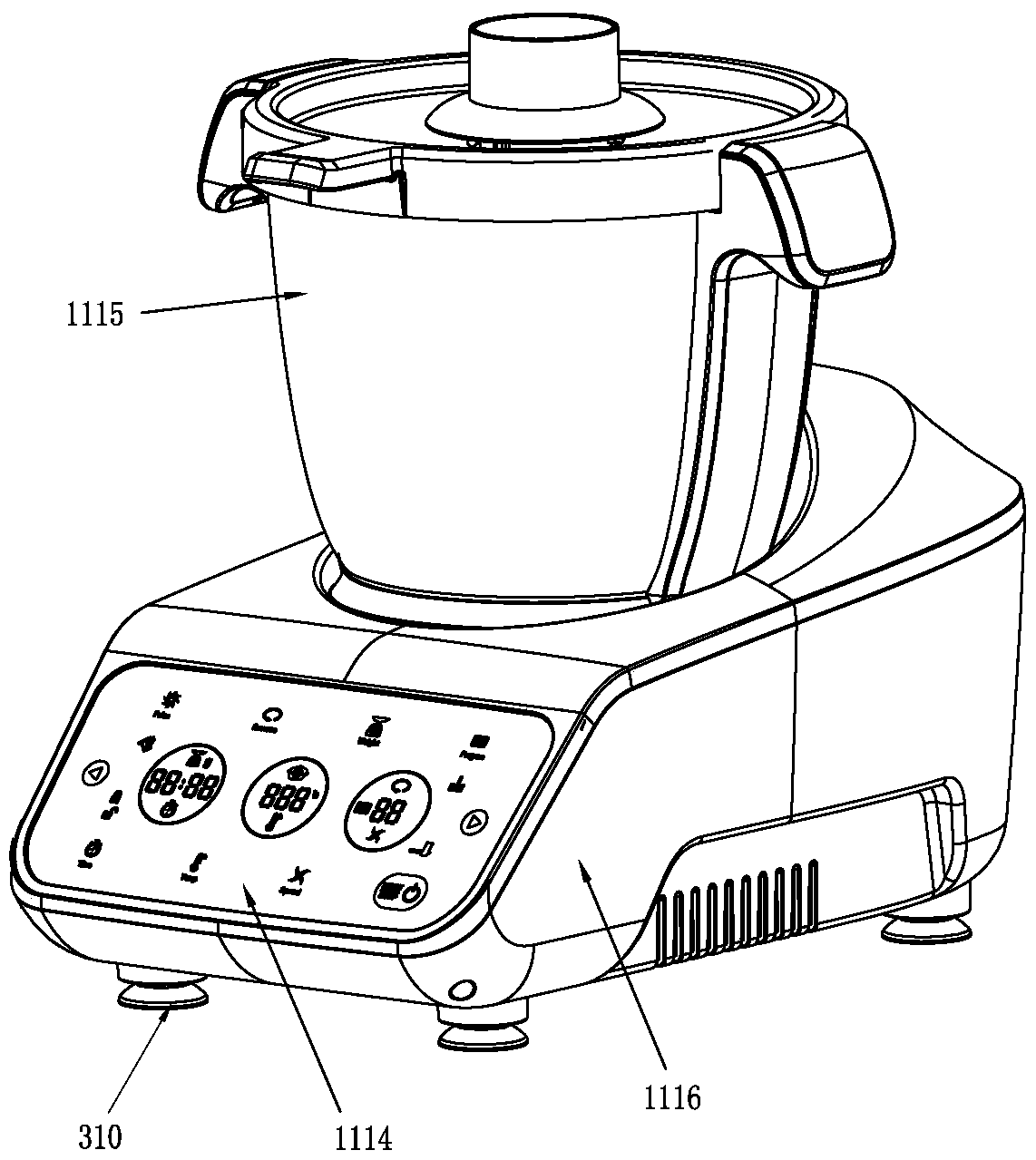

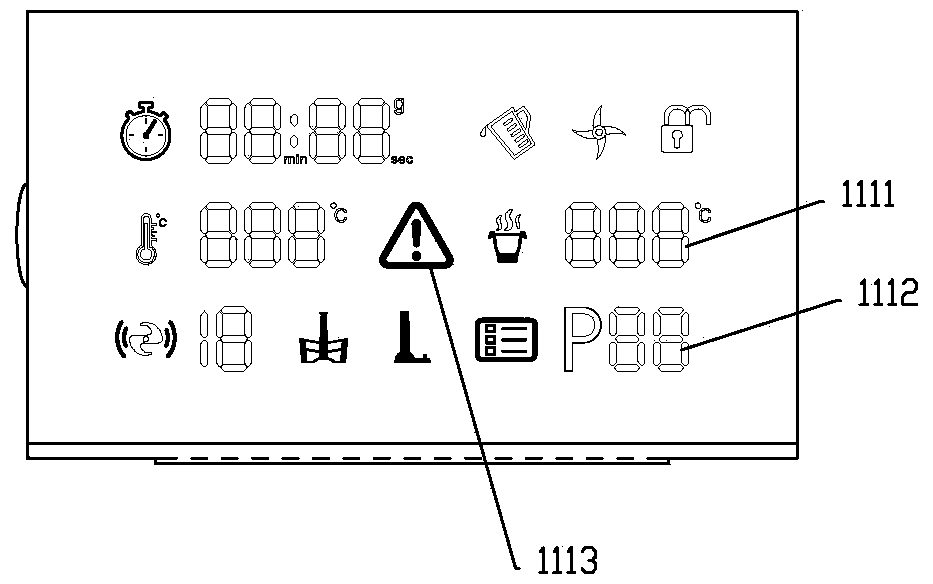

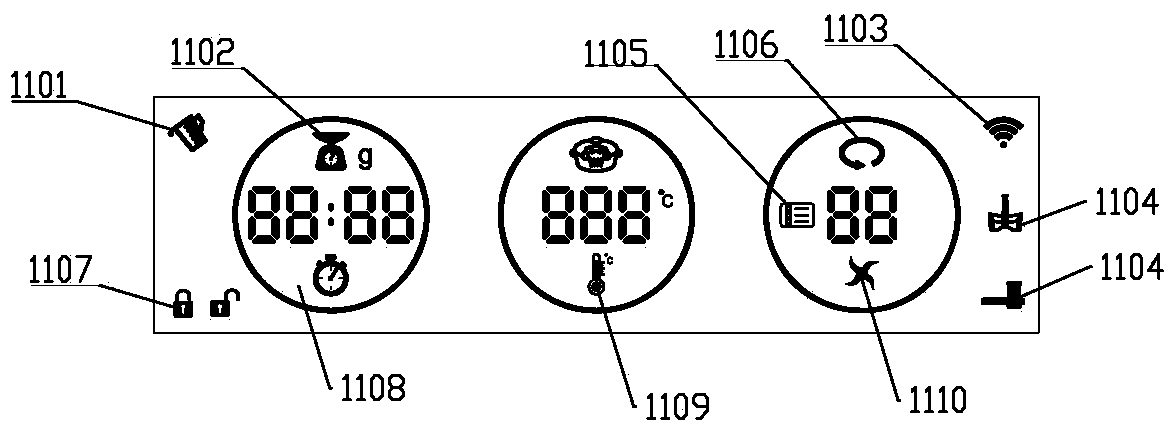

Intelligent control method and system of multifunctional cooking machine

The invention discloses an intelligent control method and system of a multifunctional cooking machine. The system comprises a cooking pot with stirring and heating functions and a triggering microcomputer. The method includes that a user starts a touch screen and triggers the microcomputer in a machine according to a menu corresponding to food to be made, and a corresponding program in the microcomputer is selected according to a program specified in the menu; the food is made according to guidance of the corresponding menu, the microcomputer can automatically set corresponding operation procedures in the process of making, needed time, temperature and rotating speed can be set automatically at each stage, the program can automatically prompt knives needing to be replaced at the next stageafter one program stage or the making step is finished and can automatically prompt whether food materials need to be added or not, and prompting can be made when each stage is finished through voiceor prompting sound; corresponding parameters can be set by oneself to complete food making. The intelligent control method and system is high in intelligence level and good in user using experience.

Owner:DONGGUAN COFAR ELECTRICAL APPLIANCES TECH CO LTD

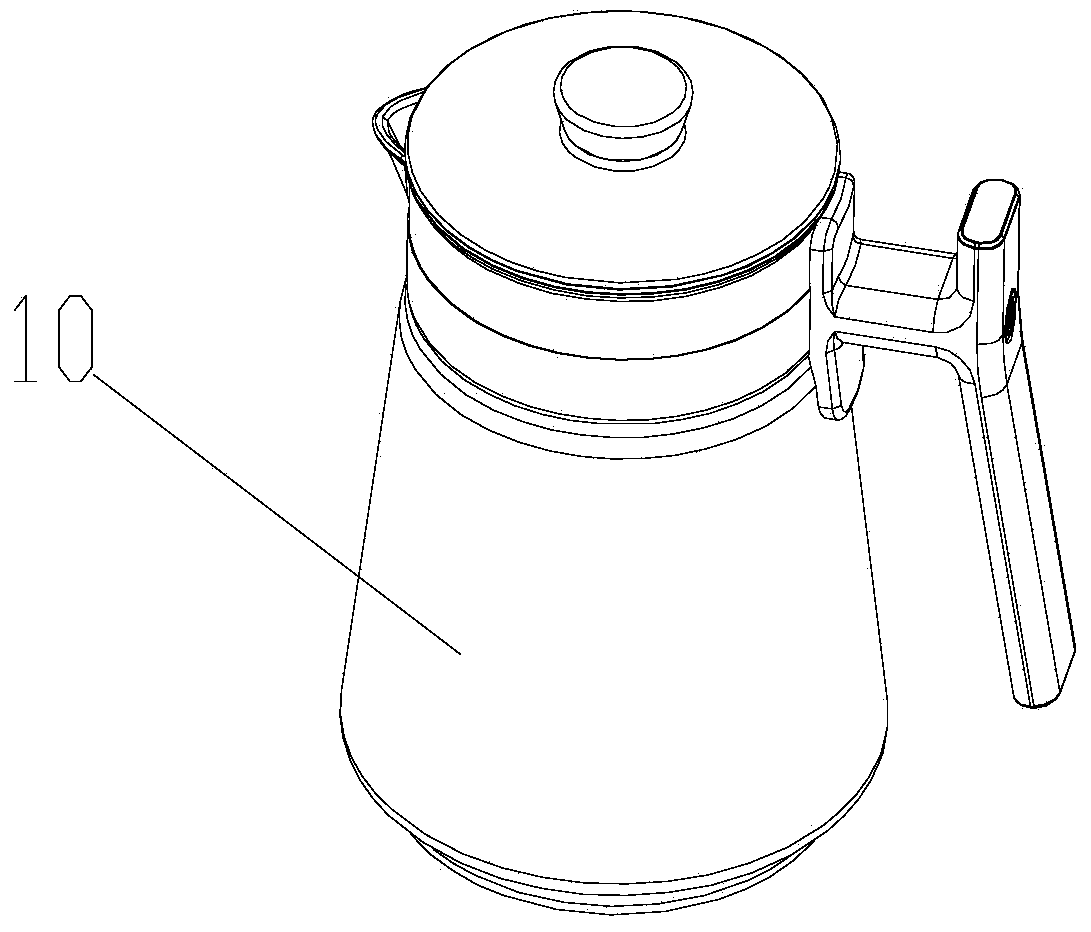

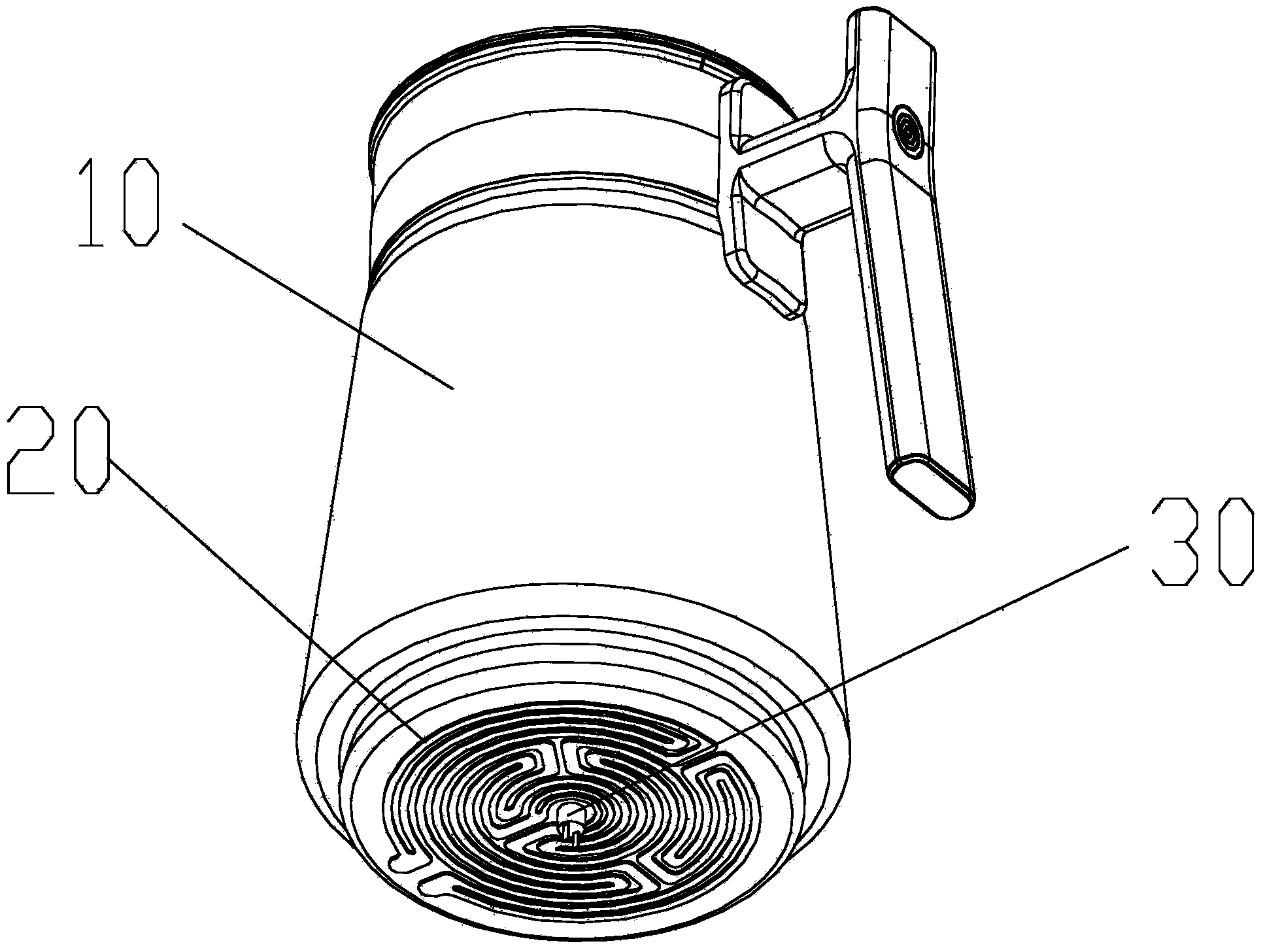

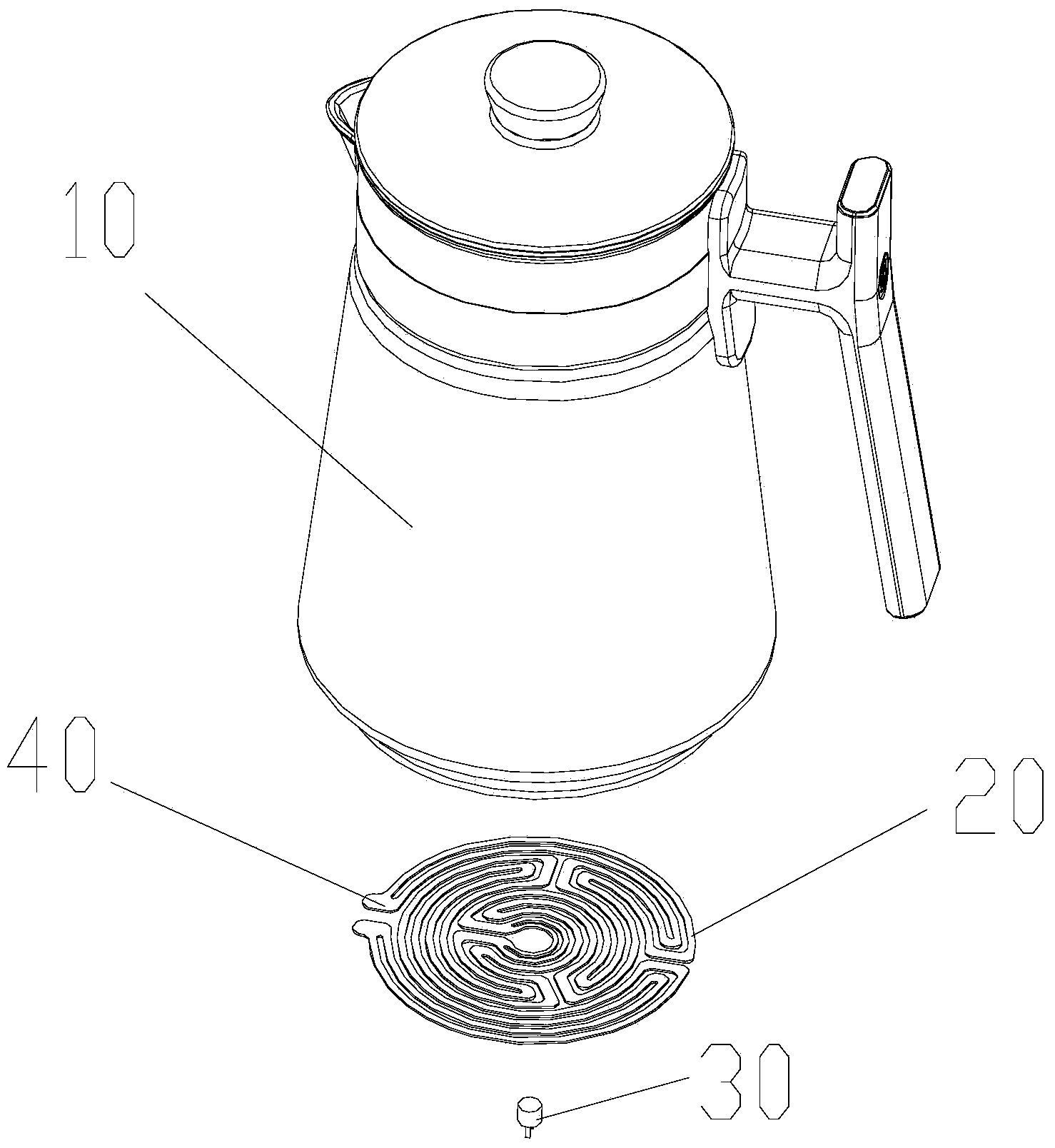

Dry-burning-resistant glass electric kettle

InactiveCN104172914AAccurately monitor temperatureQuick responseWater-boiling vesselsBeverage vesselsEngineeringWater bottle

Owner:李高升 +2

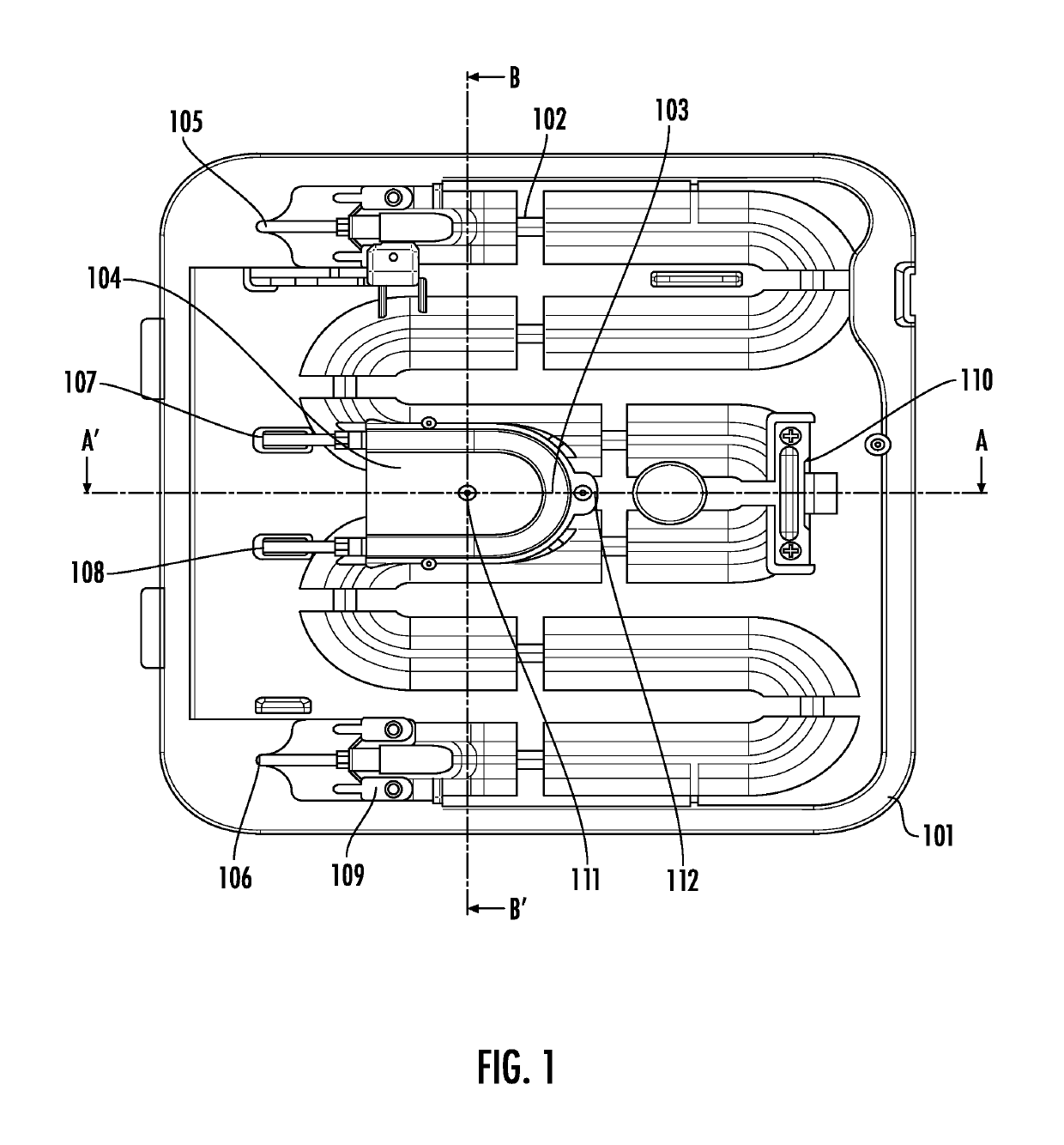

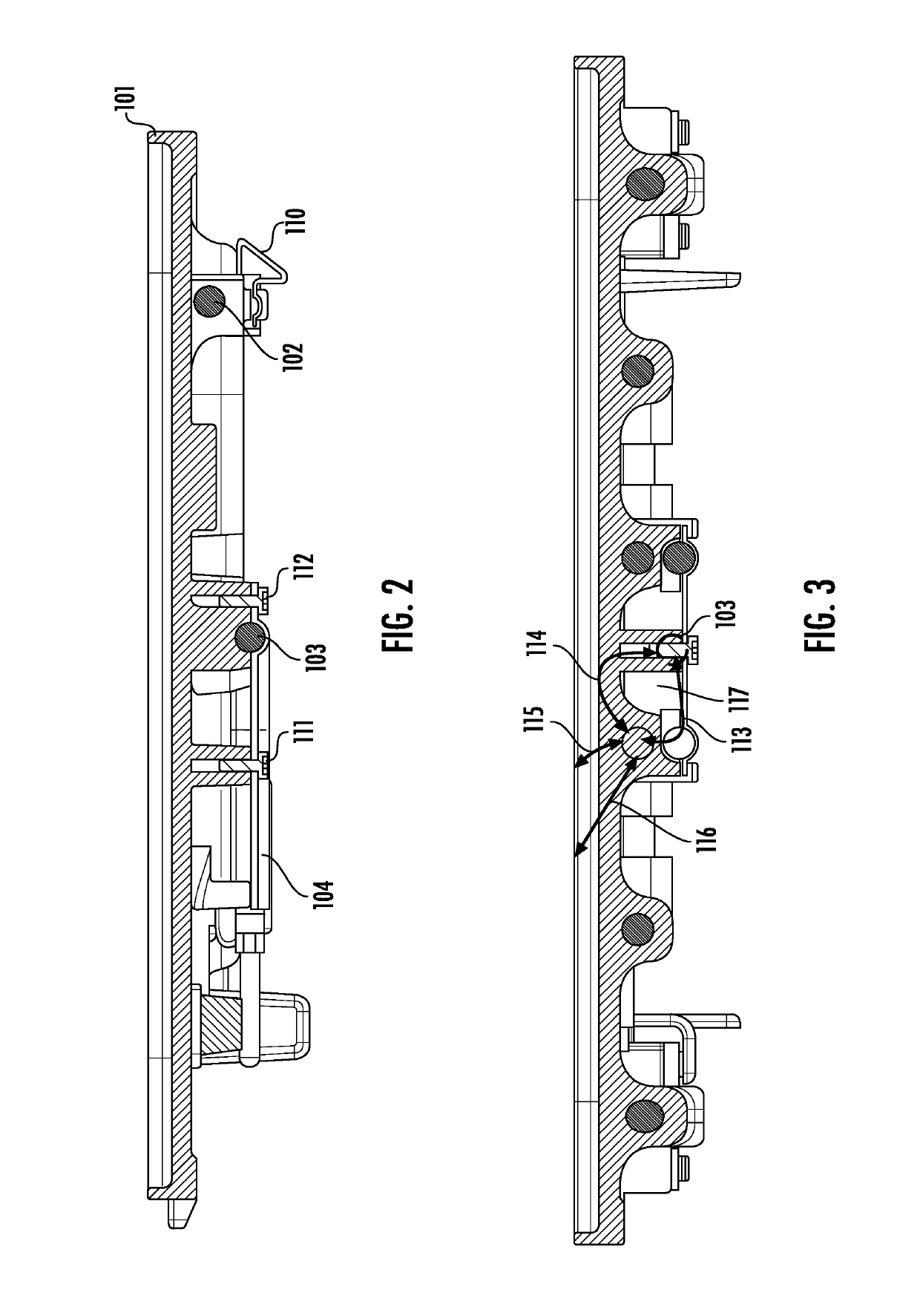

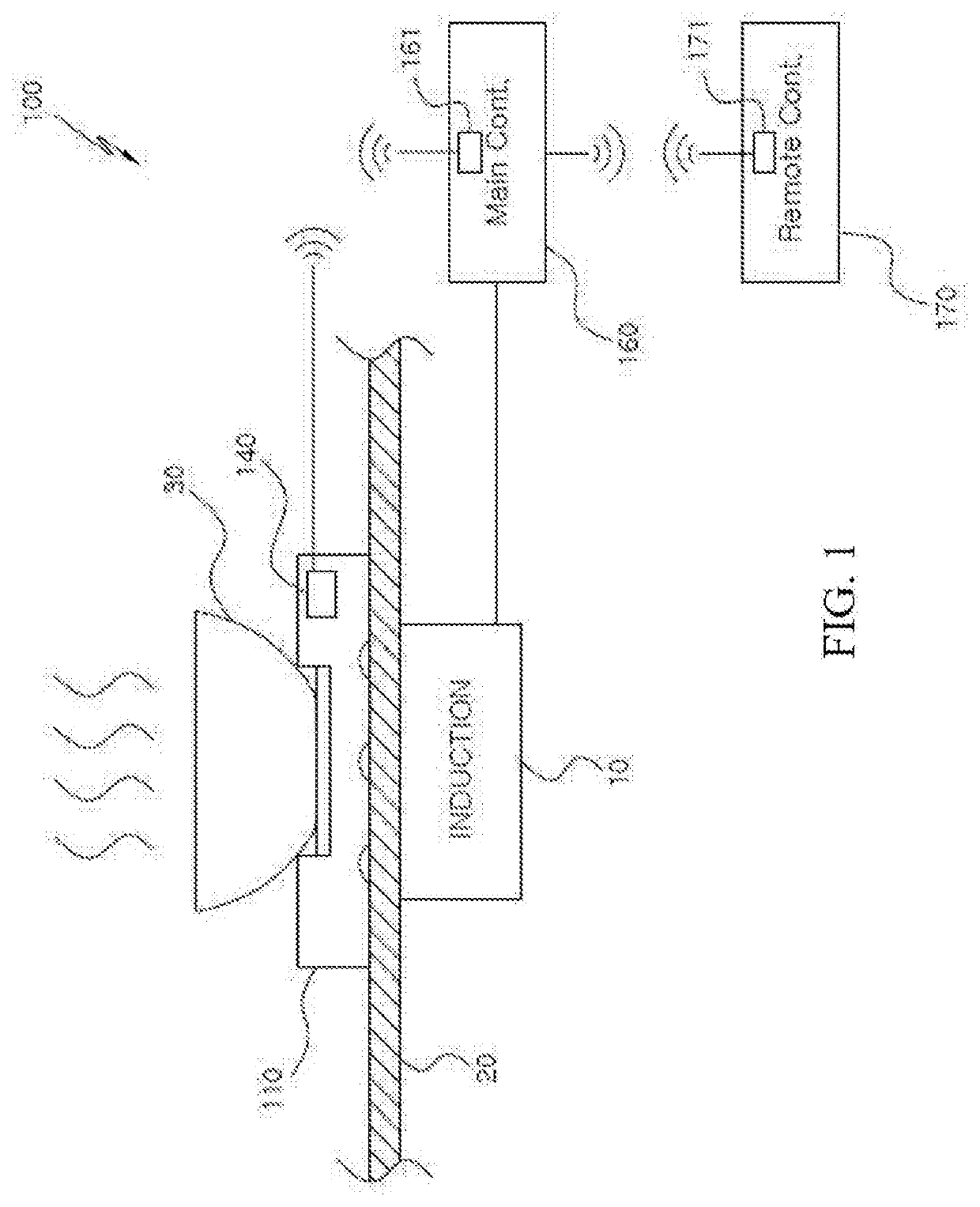

Device to support cooking container for smart under range

ActiveUS20200205240A1Easy to operate and controlEasy to installMagnetic/electric field screeningInduction heating controlProcess engineeringMechanical engineering

Owner:PEACEWORLD CO LTD +1

Biswitch automatic spraying valve

InactiveCN102661435ALarge thrustIncrease the itineraryOperating means/releasing devices for valvesPistonMagnetic core

The invention relates to a biswitch automatic spraying valve, which comprises a valve body, a valve cover, a magnetic ring sleeve, a magnetic ring component, a movable rod, a bias spring, a valve cover, a memory alloy, a piston cylinder, a magnetic core component and a piston, wherein the memory alloy is sleeved on an adjustment rod; the upper end of the memory alloy is contacted with a spring cap, and the lower end of the memory alloy is contacted with the valve cover; the inner diameter of a spring ring encircled by the memory alloy is smaller than the outer diameter of the upper part of the movable rod; the spring cap is connected with the top of the adjustment rod; the movable rod is positioned in the valve cover; a screw thread is formed on the adjustment rod; a screw thread hole is formed at the upper end of the movable rod; the adjustment rod passes through a middle hole on the top of the valve cover and is matched with the movable rod through the screw thread and the screw thread hole; and the outer diameter of the adjustment rod is smaller than that of the movable rod. According to the biswitch automatic spraying valve, the spring diameter of the memory alloy is reduced, so that the thrust produced by the memory alloy is several times greater than that of the conventional structure, and the reliability of opening the valve is greatly improved; and the valve can be opened or closed through manual fine adjustment during maintenance or test, so that the using effect is enhanced, and the use range is expanded.

Owner:全龙浩

Temperature sensing

ActiveUS8290315B2Simple processEasily be associatedThermometer detailsAutomatic control devicesSensor arrayFiber

A temperature sensor array comprises an optical fiber (16) on which are a plurality of Bragg gratings (18) on respective spaced apart portions of the fiber. Each portion is in a housing (14) which freely houses the said portion substantially without axial strain on the fiber within the housing and which also isolates the grating from strain imposed on the fiber outside the housing. Thus substantially only changes in temperature affect the Bragg grating of that portion. The array may be used to detect and control the temperature of a tool (12) for forming a composite component amongst other uses.

Owner:GKN AEROSPACE SERVICES LTD

Temperature sensor assembly for an electrical connector

ActiveUS10833458B2Fast response timeCost effectiveThermometer detailsVehicle connectorsShunt DeviceElectrical connection

An electrical connector including a housing having a terminal channel with a power terminal in the terminal channel. The electrical connector includes a temperature sensor assembly positioned in the chamber. The temperature sensor assembly includes a sealing pad holding the power terminal and a thermal shunt held by the sealing pad. A temperature sensor is coupled to the thermal shunt. The sealing pad is electrically insulative and has a terminal opening receiving the power terminal. The sealing pad is thermally coupled to the power terminal and thermally coupled to the thermal shunt. The thermal shunt has a thermal conductivity higher than a thermal conductivity of the sealing pad. The temperature sensor monitors the temperature of the power terminal through a thermal path defined by the sealing pad and the thermal shunt.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

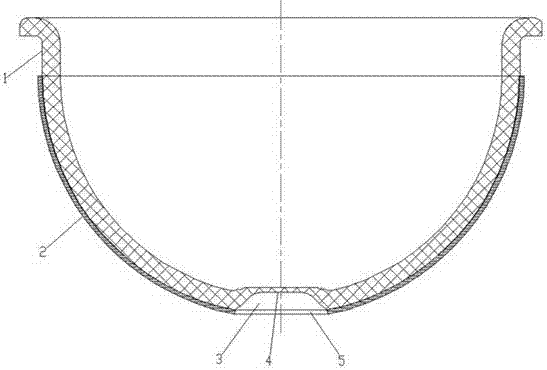

Ceramic inner container with metal case of IH (induction heating) electric rice cooker

PendingCN107019432AAccurate temperature sensingHeating fastCooking-vessel materialsVessels with intergral heatingRice dishesWhole body

The invention provides a ceramic inner container with a metal case of an IH (induction heating) electric rice cooker, wherein the ceramic inner container of the electric rice cooker comprises a ceramic container body, the periphery of the ceramic container body is wrapped by the metal case, and the ceramic container body is tightly fitted with the metal case. When the IH electric rice cooker works, the metal case is heated due to induction heating, the ceramic container body is heated, and the whole body of the ceramic container body is heated in a balanced manner, and is rapidly heated. The respective advantages of the ceramic inner container and a metal inner container of the IH electric rice cooker are combined, the ceramic inner container has the functions of heating rapidly, heating in a balanced manner and storing heat, and can cook delicious rice. The ceramic inner container is not only suitable for the IH electric rice cooker, but also suitable for an electric rice cooker or electric soup cooker adopting a heating disc, and also suitable for an induction cooker.

Owner:范进秋

Induction heating device

ActiveUS8426782B2High sensitivityHigh measurement accuracyFurnaces without endless coreInduction heating controlDisplay deviceEngineering

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com