Dry-burning-resistant glass electric kettle

An electric kettle and anti-dry technology, which is applied to water boiling appliances, beverage preparation devices, household appliances, etc., can solve the problem that the temperature controller cannot sensitively and accurately perceive the actual temperature of the glass electric kettle, which is inconvenient for mass production, and the rise of the glass kettle and other problems, to achieve the effect of easy and convenient control, convenient mass production, and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

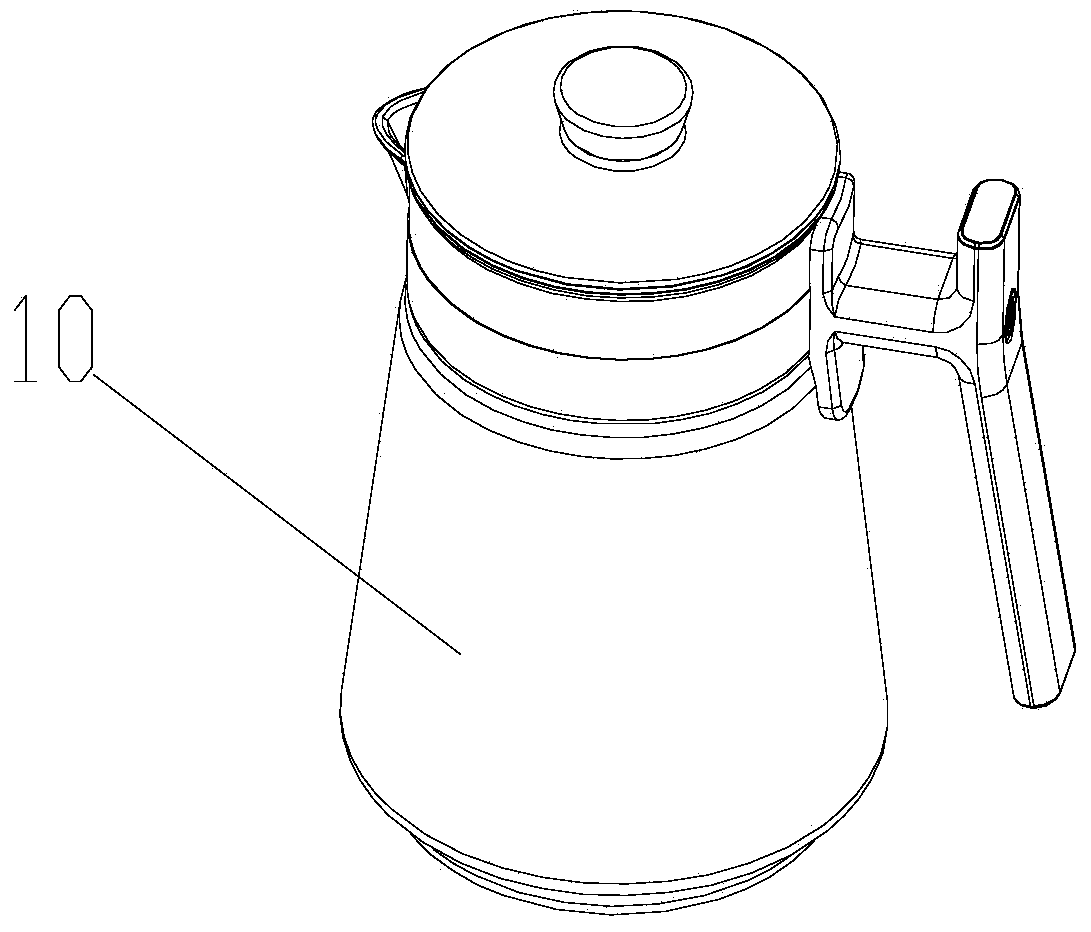

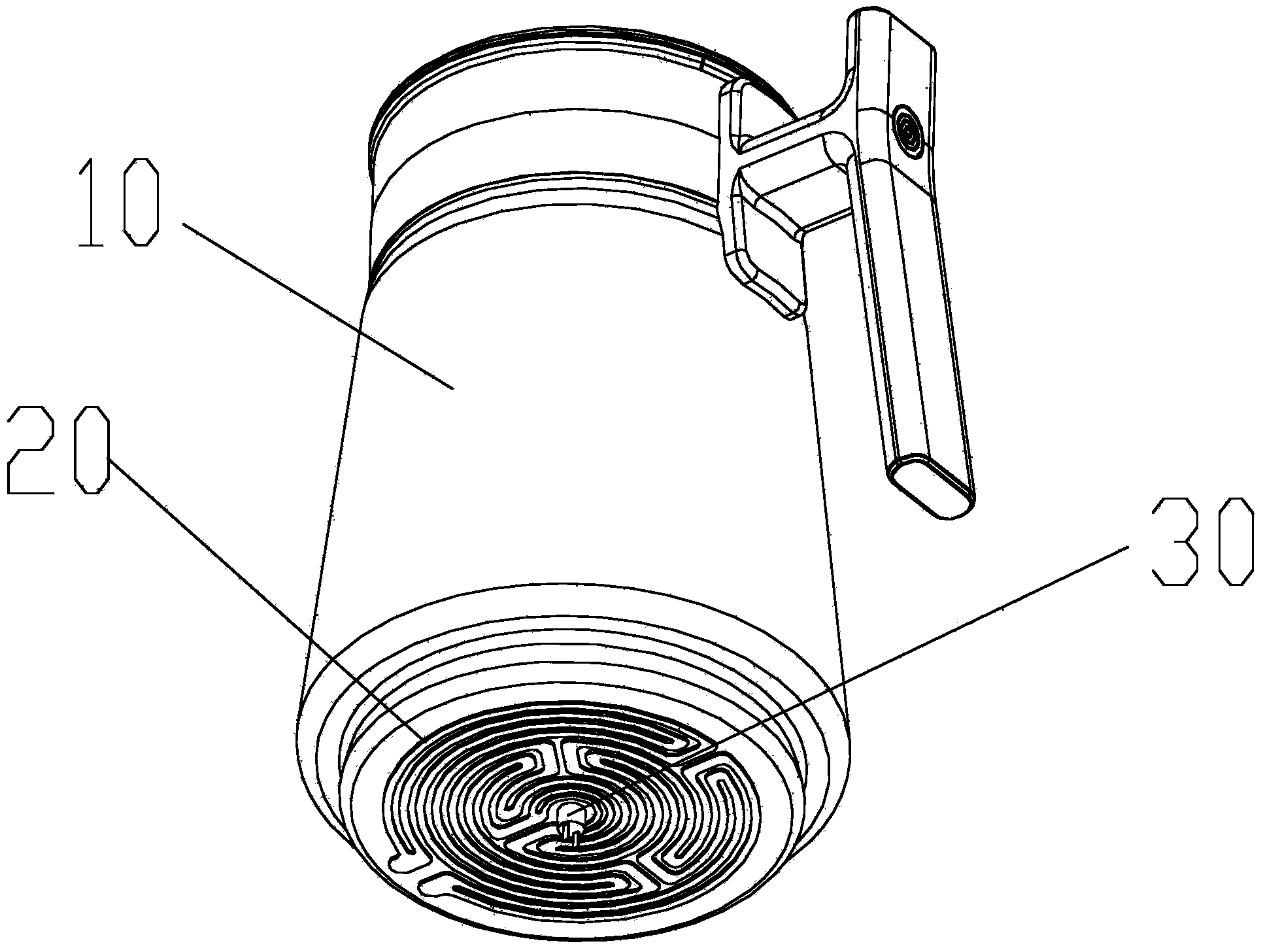

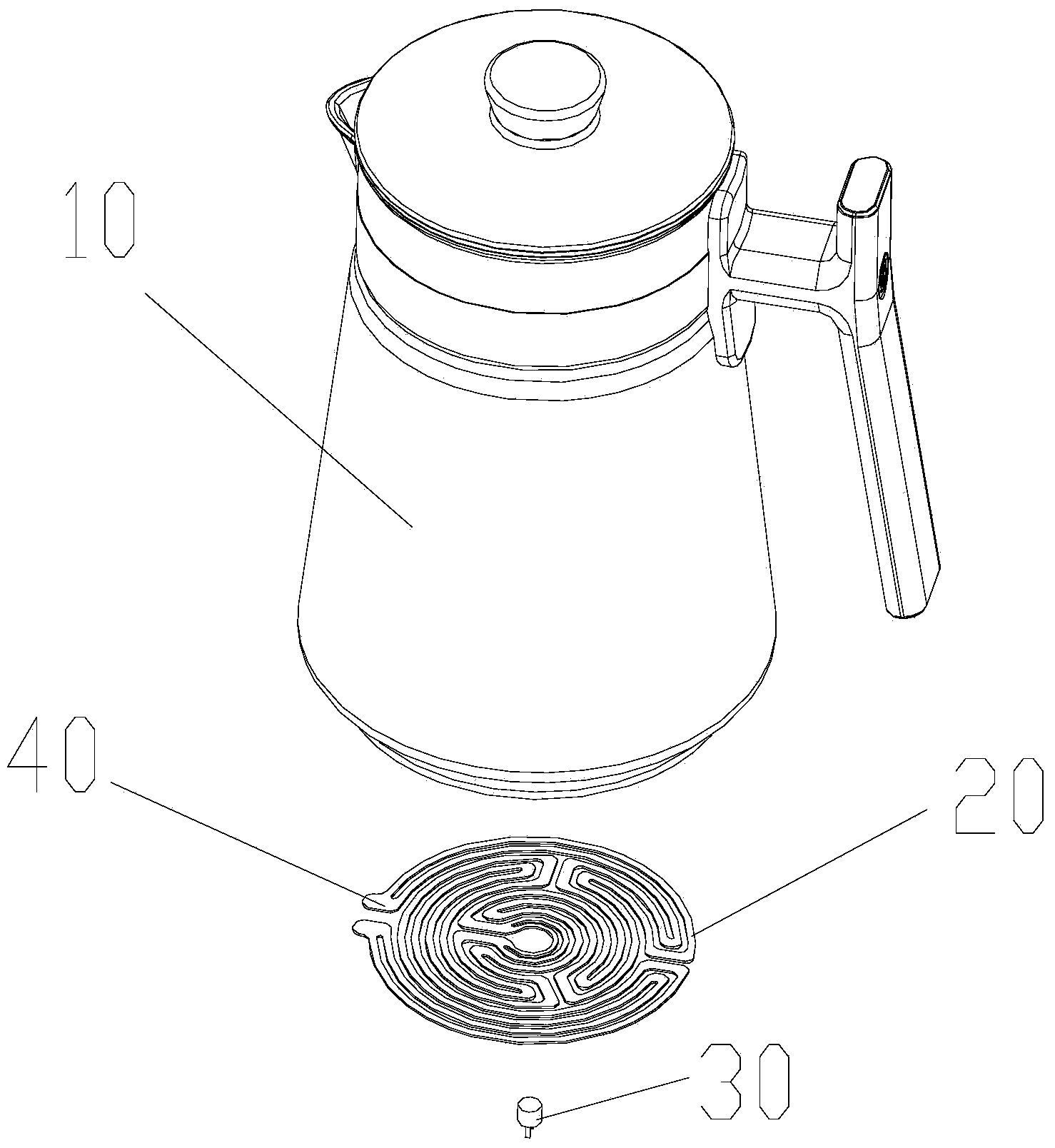

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the structure of a kind of anti-dry glass electric kettle of the present invention is as follows: comprising a glass kettle body 10 and an electric heating film 20, an electric heating film 20 is installed on the outer surface of the bottom surface of the glass kettle body 10, and a hollow space is formed inside the glass kettle body 10. Cavity 11, pot cover 12 is arranged on the top, and it also comprises thermostat 30 in addition, and thermostat 30 is attached to the outer surface of the bottom surface of glass jug body 10 and is positioned at the middle position of the bottom surface of glass jug body 10, and thermostat 30 and electric heater The film 20 is isolated and surrounded by the electrothermal film 20 on the periphery of the thermostat 30. The thermostat 30 is a bimetal snap switch, and the electrothermal film 20 is a resistive film consisting of two strip-shaped The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com