Automatic thickness measuring device for cold-type coating of roller

A cold type, coating technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor controllability, pointer reading error, large error, etc., to achieve the effect of wide application, control process quality, and solve uncontrollable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

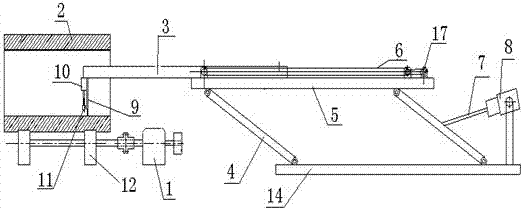

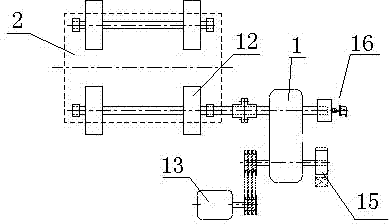

[0016] Below in conjunction with accompanying drawing, the present invention will be described in further detail: roll cold type coating automatic thickness measuring device, comprises thickness gauge (11), and the feed mechanism that drives thickness gauge to move, and described feed mechanism mainly consists of cradle mechanism , a telescopic gun rod (3), and a telescopic drive device. The cradle mechanism is composed of two parallel rocker bars (4), a parallel cradle upper rod (5) and a horizontal fixed rod (14) hinged to each other. Become, form four-bar linkage mechanism, the transverse fixed rod (14) tail end of this cradle mechanism is equipped with telescopic driving device by a support, telescopic gun bar is housed on the cradle upper bar (5).

[0017] The telescopic drive device is mainly composed of a pneumatic push rod (7) and a cylinder (8), and one end of the pneumatic push rod (7) is hinged to the rocker (4) of the cradle mechanism. The telescopic gun rod (3) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com