Automatic spray valve

An automatic spraying and valve cover technology, which is applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of affecting the thrust, maintenance or testing, and cannot manually fine-tune the opening and closing of the valve, so as to improve reliability, installation and maintenance. Ease of valve replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

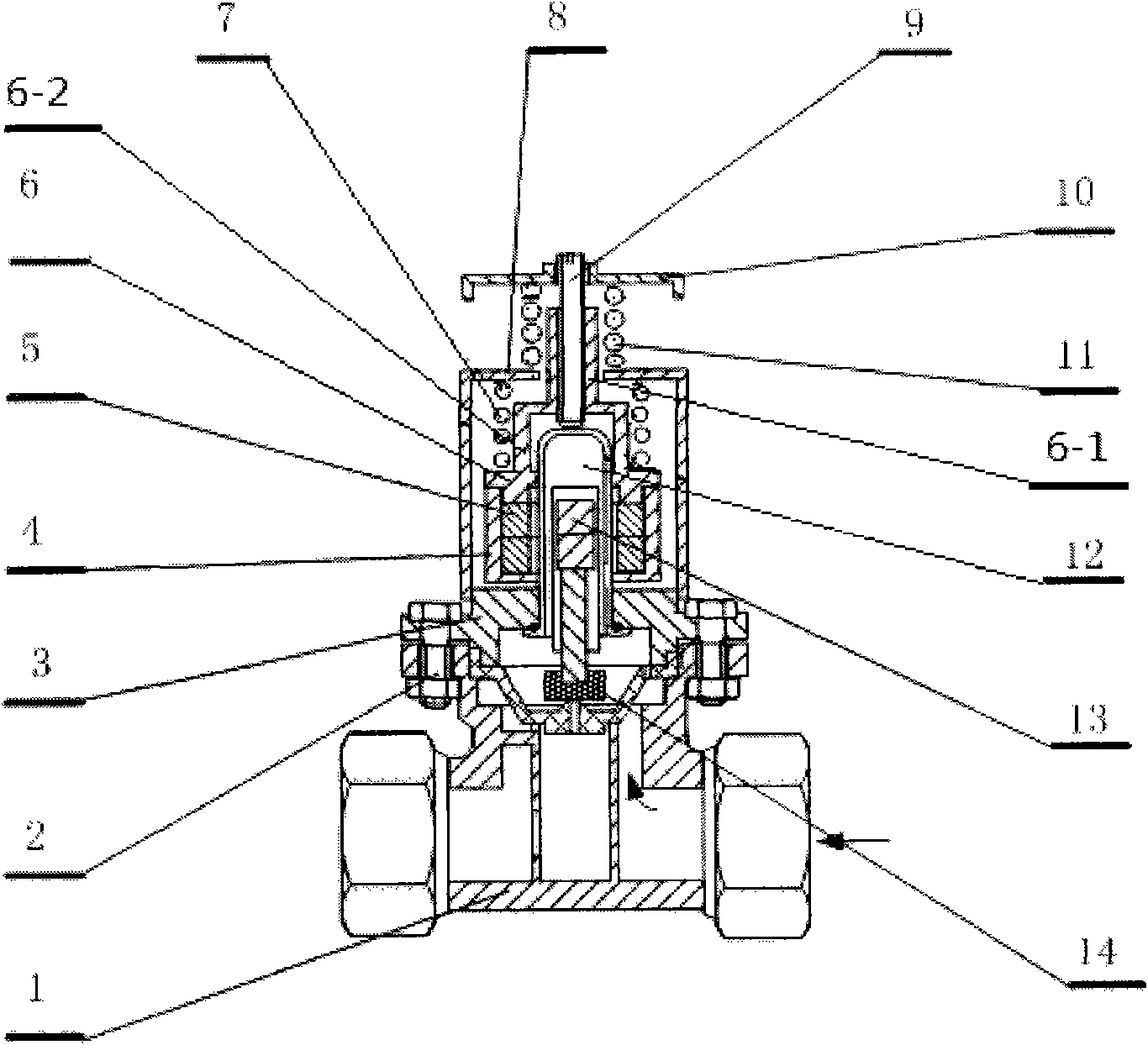

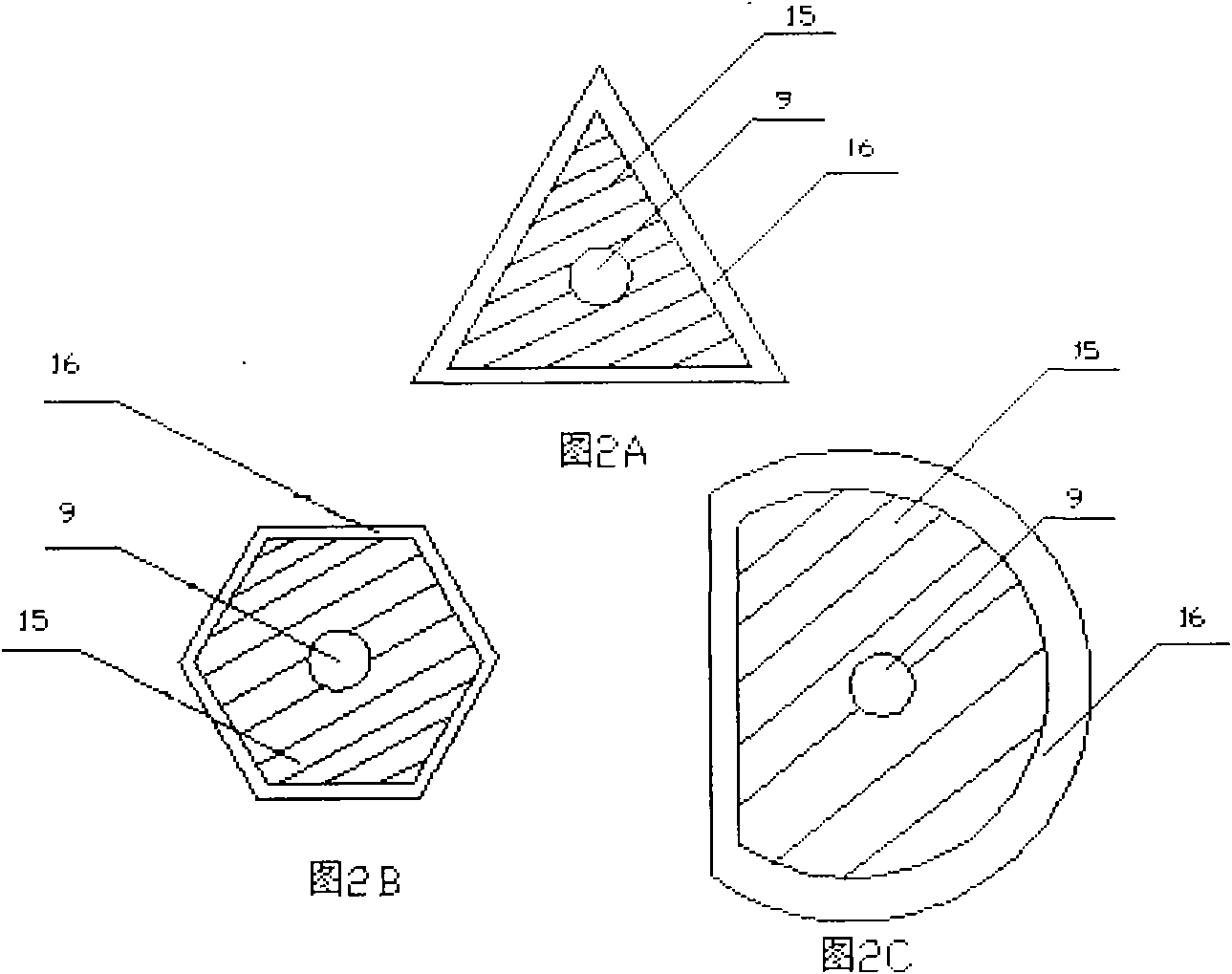

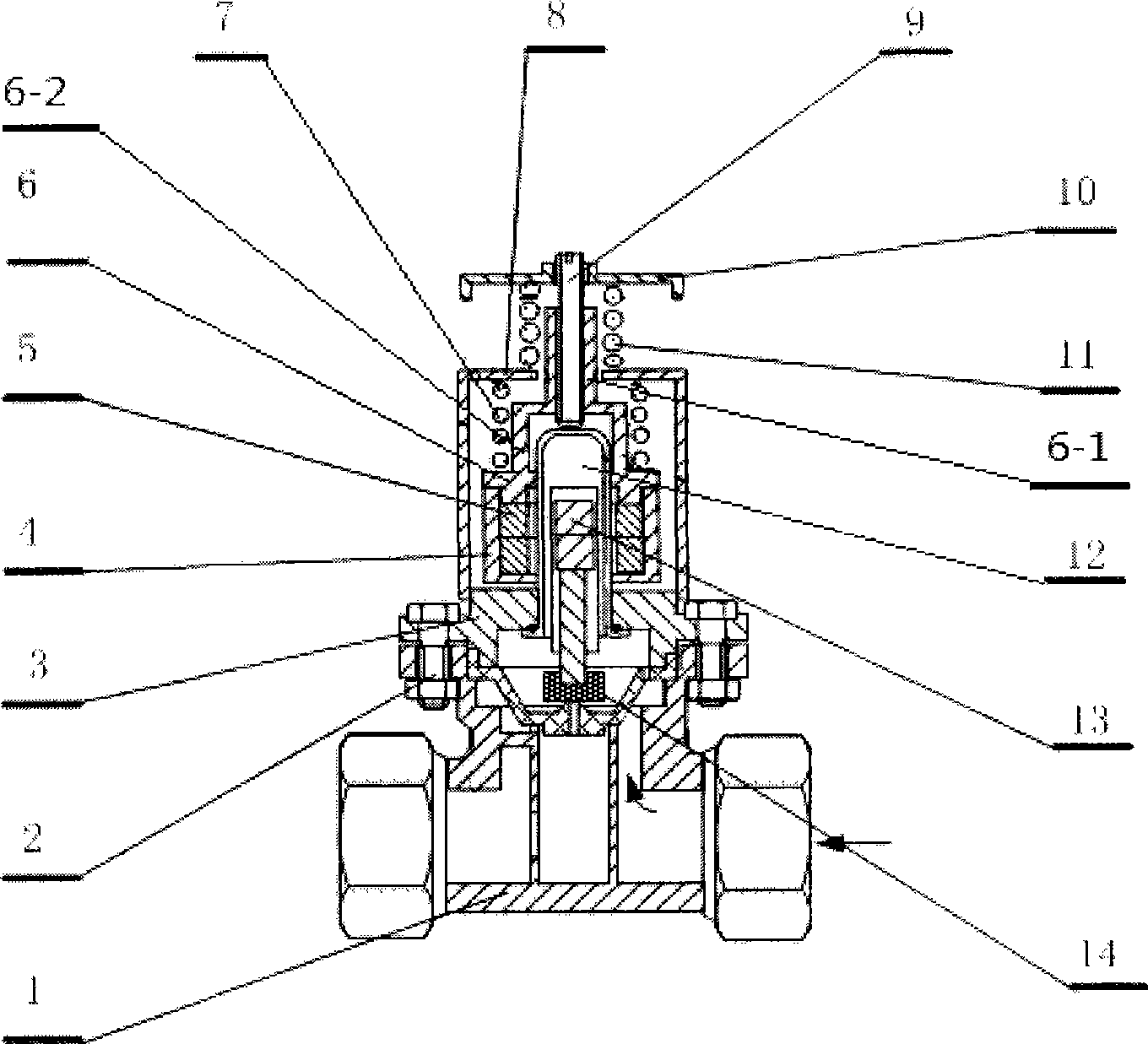

[0016] Such as figure 1 and 2 As shown, an automatic sprinkler valve includes a valve body 1, a valve cover 3, a magnetic ring sleeve 4, a magnetic ring assembly 5, a movable rod 6, a bias spring 7, a valve cover 8, a memory alloy 11, a piston cylinder 12, The magnetic core assembly 13 and the piston 14, the upper part 6-1 of the movable rod 6 passes through the middle hole 8-1 of the valve cover 8, and protrudes outside the valve cover 8; the memory alloy 11 is sleeved on the protruding The upper part 6-1 of the movable rod 6 outside the valve cover 8, the upper end is in contact with the spring cap 10, and the lower end is in contact with the valve cover 8, and the inner diameter of the memory alloy 11 wound into a coil is smaller than the outer diameter of the lower part 6-2 of the movable rod The spring cap 10 is connected with the top of the adjusting rod 9; the outer diameter of the top 6-1 of the movable rod 6 is less than the outer diameter of the lower part 6-2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com