Infrared dry-combustion-preventing high-efficient furnace end

An anti-dry burning and infrared technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of ineffectiveness, high heat load and efficiency, failure of anti-dry burning function, etc., and achieve accurate temperature sensing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

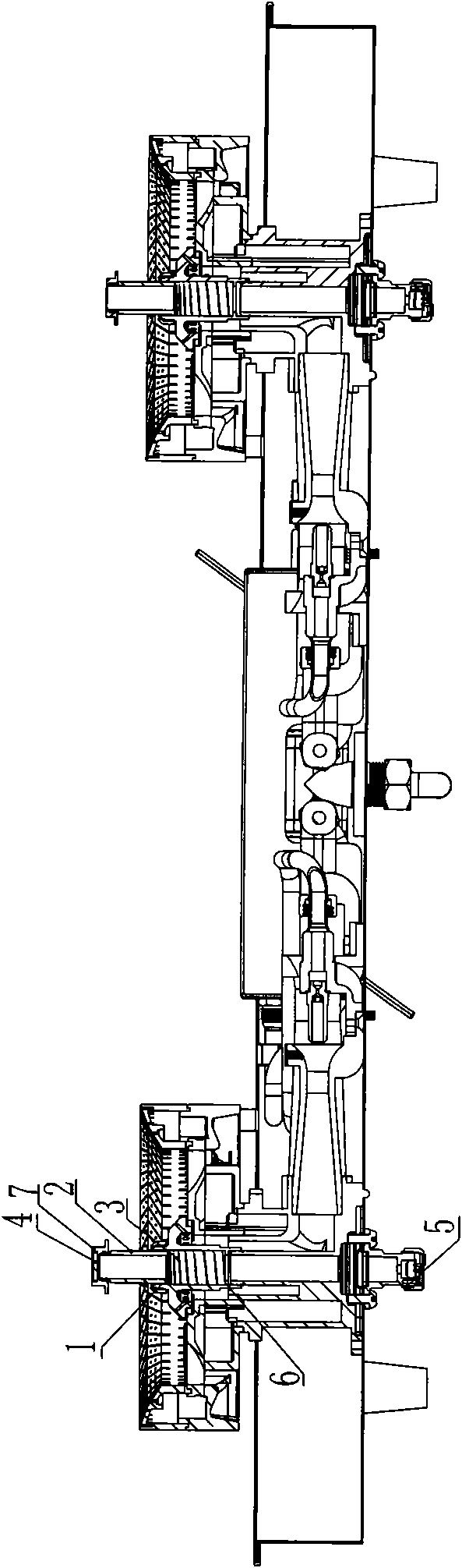

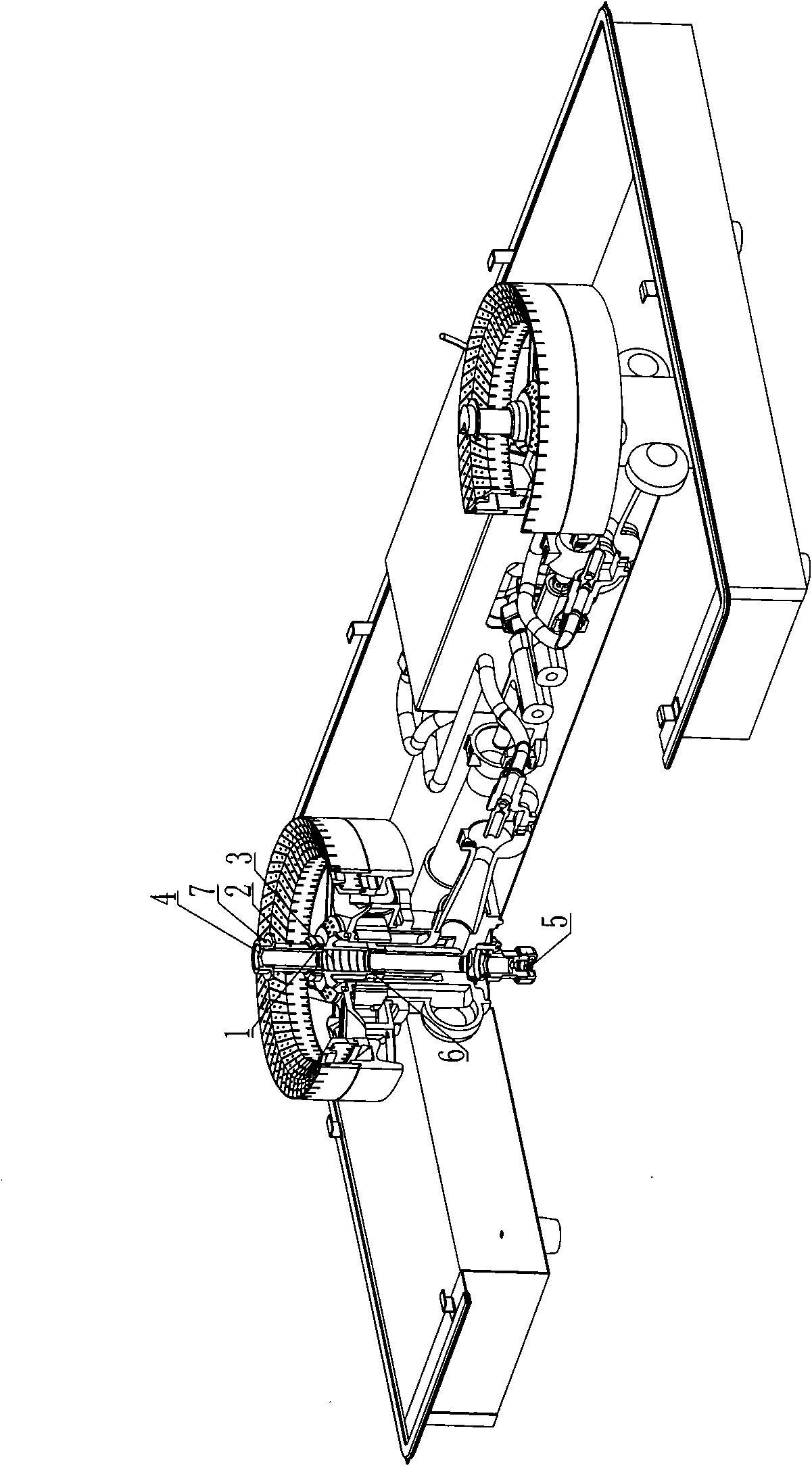

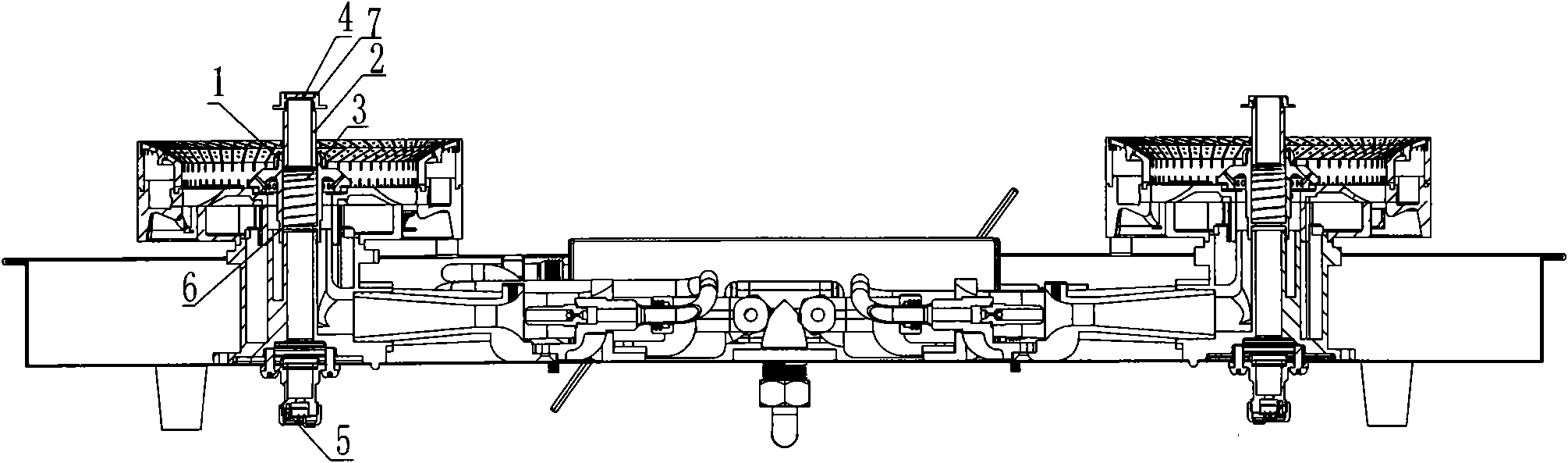

[0012] Embodiment: An infrared anti-dry burning high-efficiency furnace head. Based on the use direction, a longitudinally penetrating conduit 1 is provided in the center of the furnace head, and a telescopic sleeve 2 and an elastic member 3 are sequentially inserted into the conduit 1 from top to bottom. Inside, the lower end of the elastic member 3 is fixedly positioned on the inner wall of the burner duct 1, the upper end of the elastic member 3 is fixedly connected with the telescopic sleeve 2, the center of the elastic member 3 and the telescopic sleeve 2 are provided with through holes, and the upper end of the telescopic sleeve 2 protrudes from the upper end surface of the furnace head The upper end of the telescopic sleeve 2 is inlaid with a high-temperature-resistant optical glass 4. The high-temperature-resistant optical glass 4 is just above the through hole of the telescopic sleeve. When placed on the burner for cooking, the upper end of the telescopic sleeve 2 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com