Circuit and method for controlling metal ceramic heating element through bidirectional triode thyristor

A cermet, heating element technology, applied in electric heating devices, electrical components, electronic switches, etc., can solve problems such as failure to work normally, the circuit cannot be triggered normally in both directions, and achieve stable operation, high reliability, and stable and reliable temperature control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

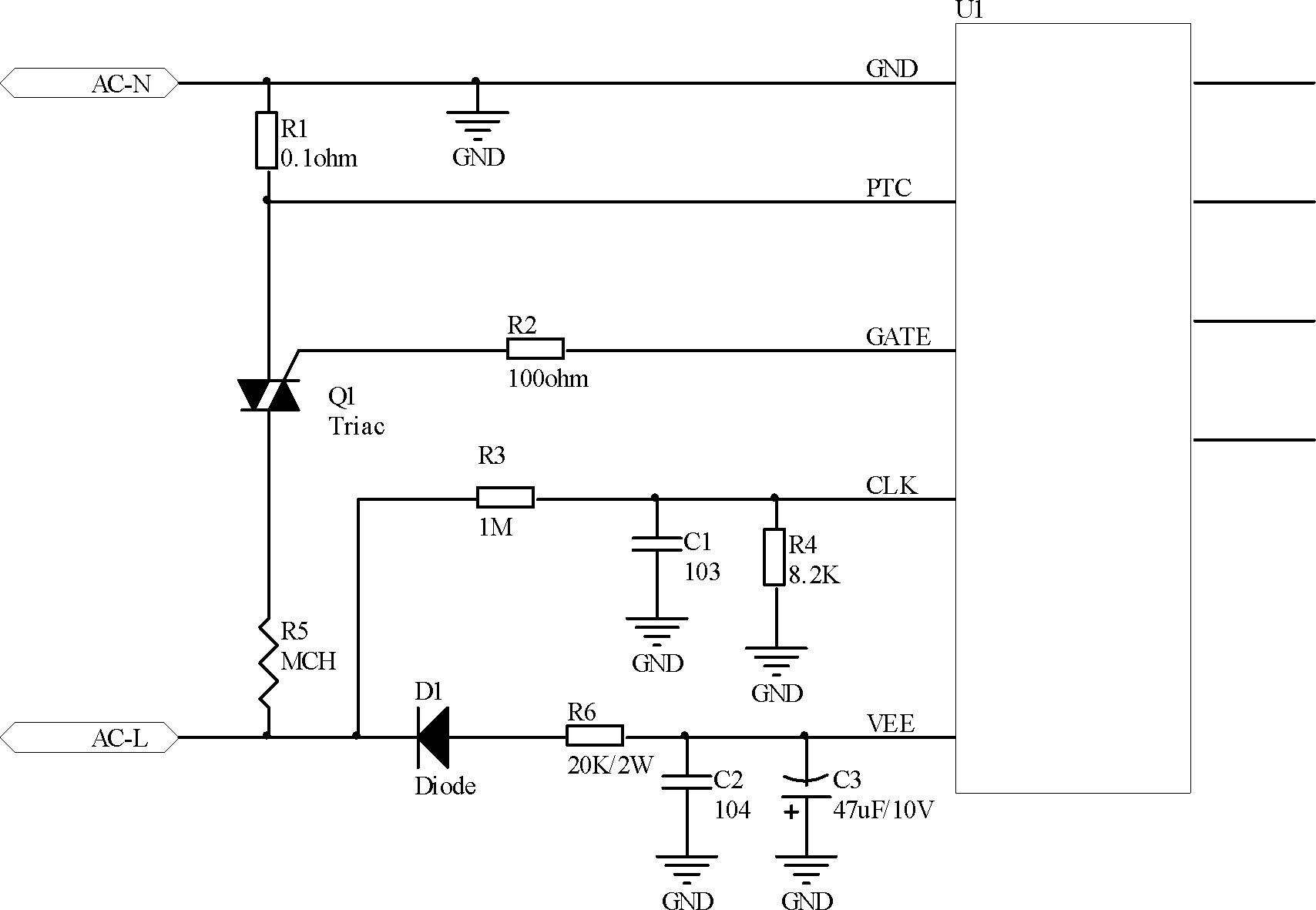

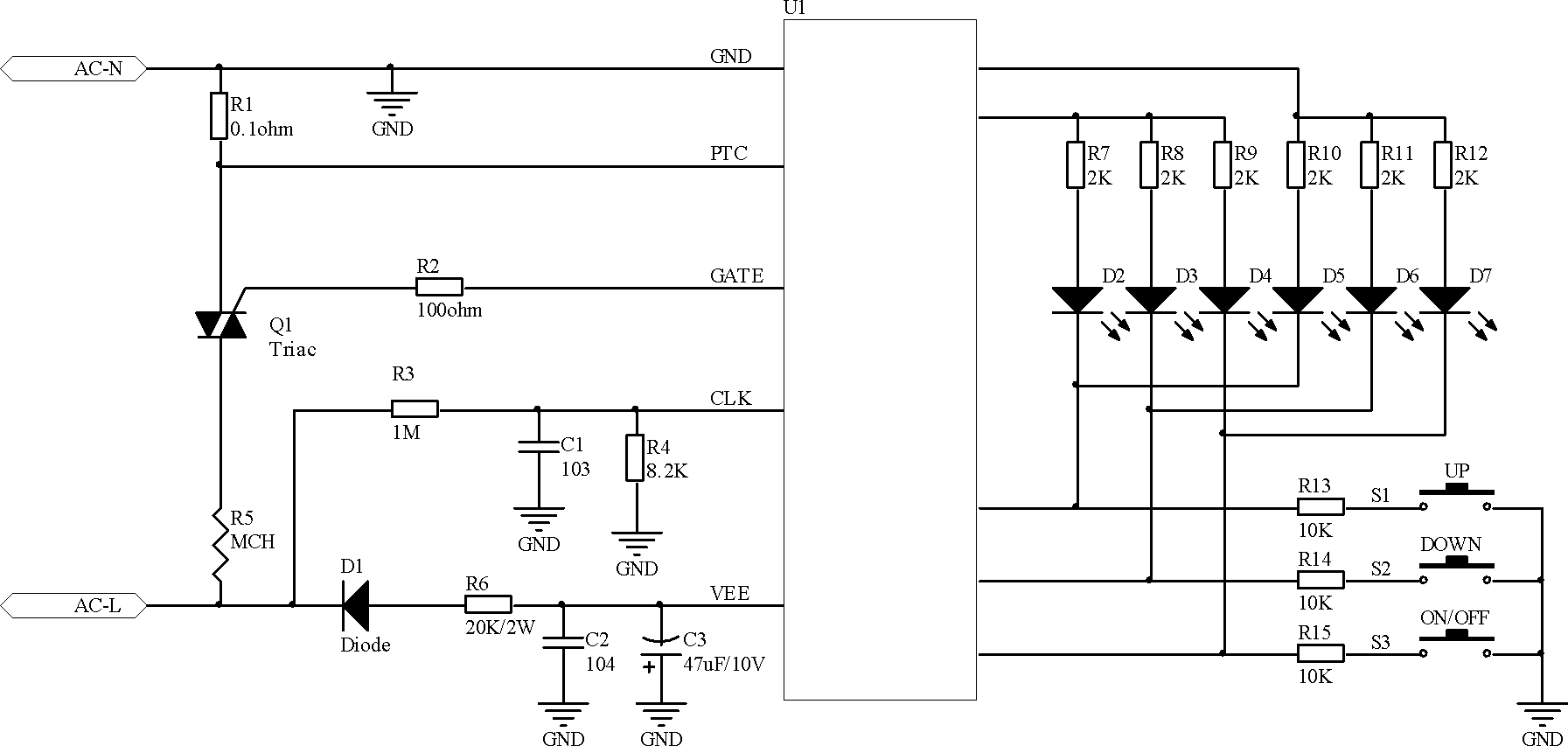

[0020] Such as figure 1 and figure 2 As shown, a temperature control circuit diagram using bidirectional thyristors to realize heating and sensing of ceramic metal heating elements, the circuit includes dedicated control integrated circuits, bidirectional thyristors, sampling resistors, negative power supply circuits, AC clocks and AC Voltage sampling circuit, the circuit collects the external AC voltage zero-crossing point through the CLK pin and the internal digital zero-crossing sampling circuit of U1, the GATE pin outputs a negative pulse at the voltage zero-crossing point to turn on the thyristor, and collects the sampling resistor R1 through the PTC pin during the conduction process The voltage on the CLK pin is used to obtain the current in the sampling resistor. At the same time, the power supply voltage at the same time is obtained according to the voltage on the CLK pin, and the resistance of the ceramic heating element is calculated to obtain its internal temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com