Rapid constant temperature high definition dyeing structural unit and high definition dyeing method

A structural unit, high-definition technology, applied in the field of biochemical dyeing, can solve the problems of the centrifugal dyeing machine, such as the trouble of loading and taking the film, and achieve the effect of free and convenient dyeing operation, high heat utilization, stable and reliable temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

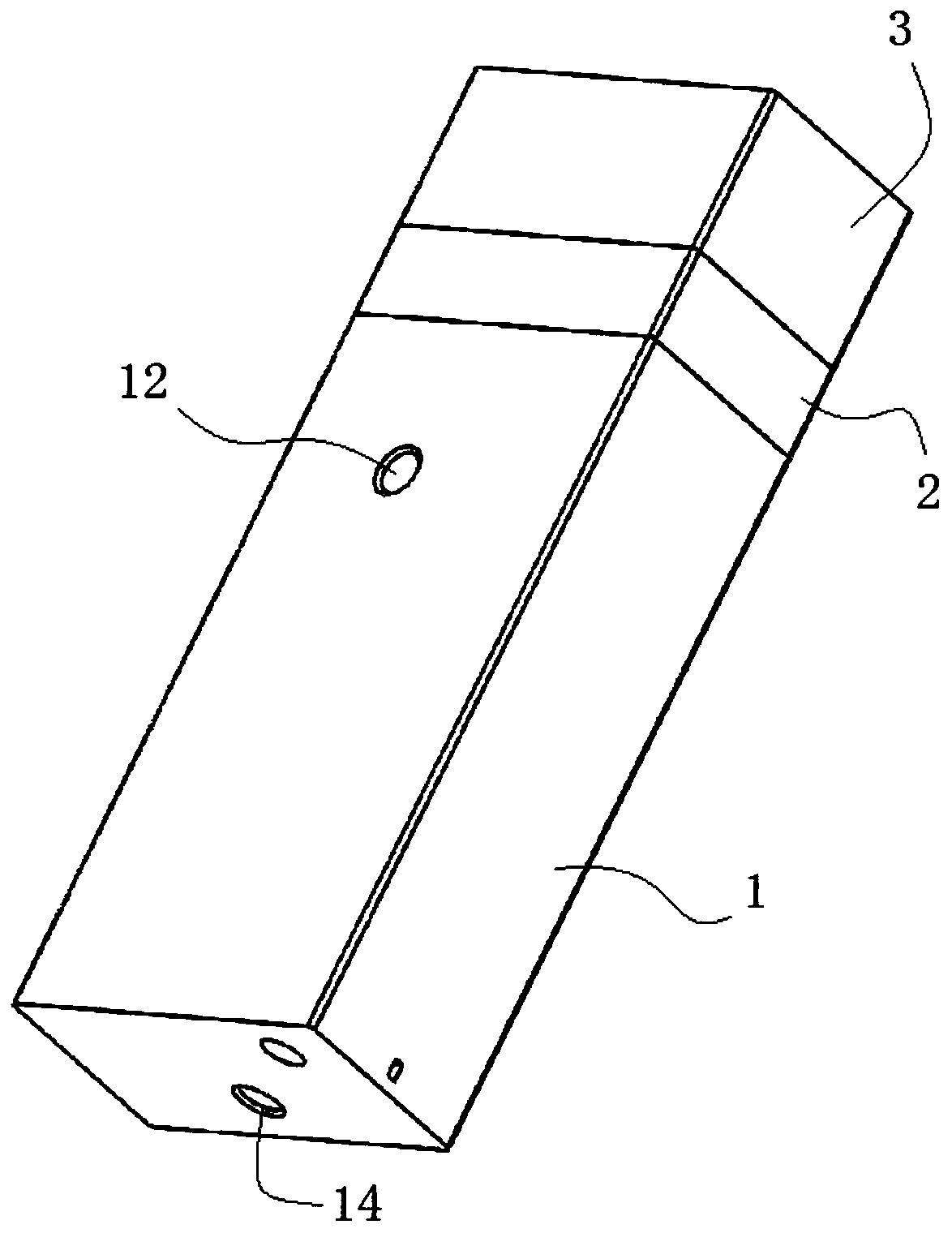

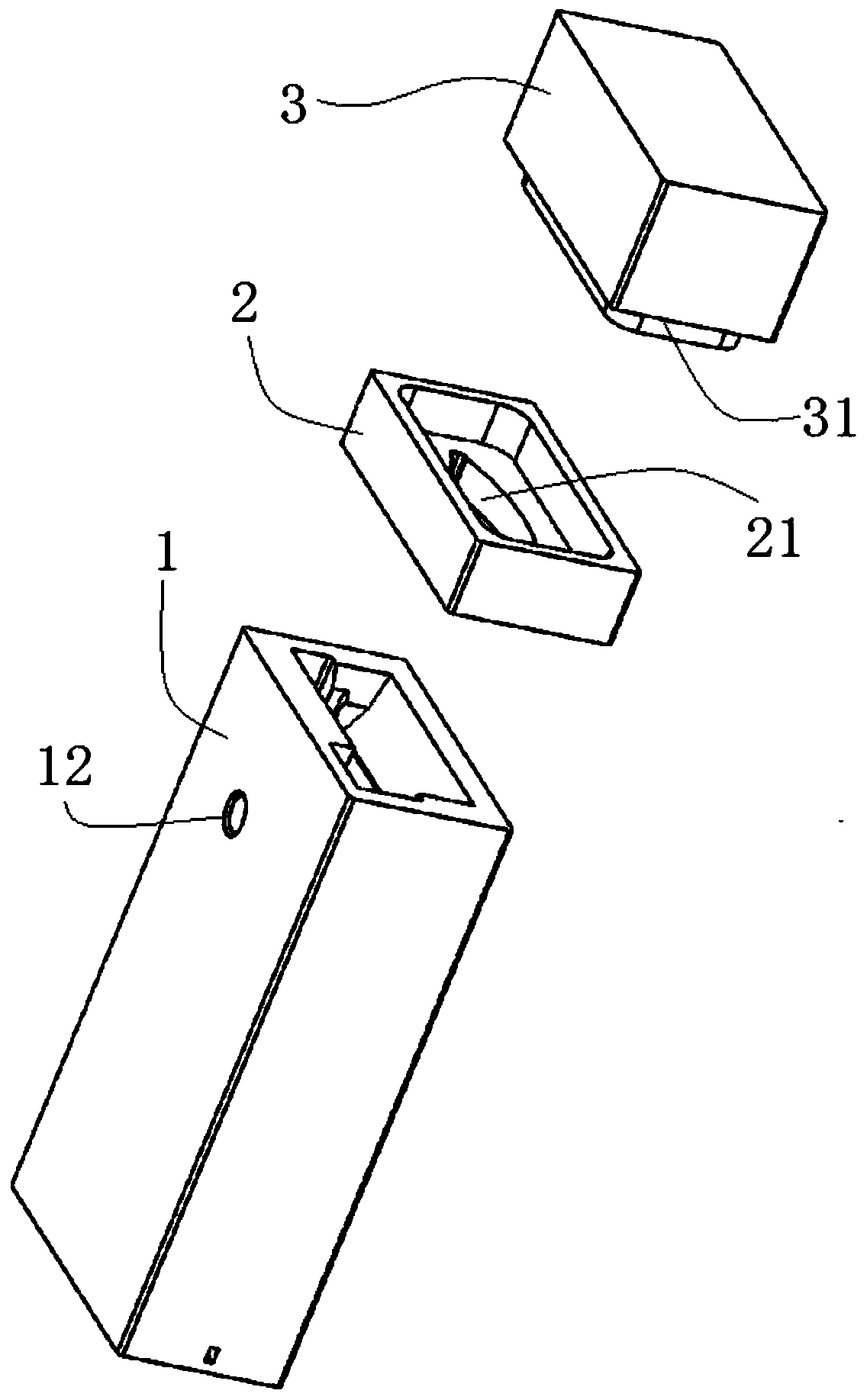

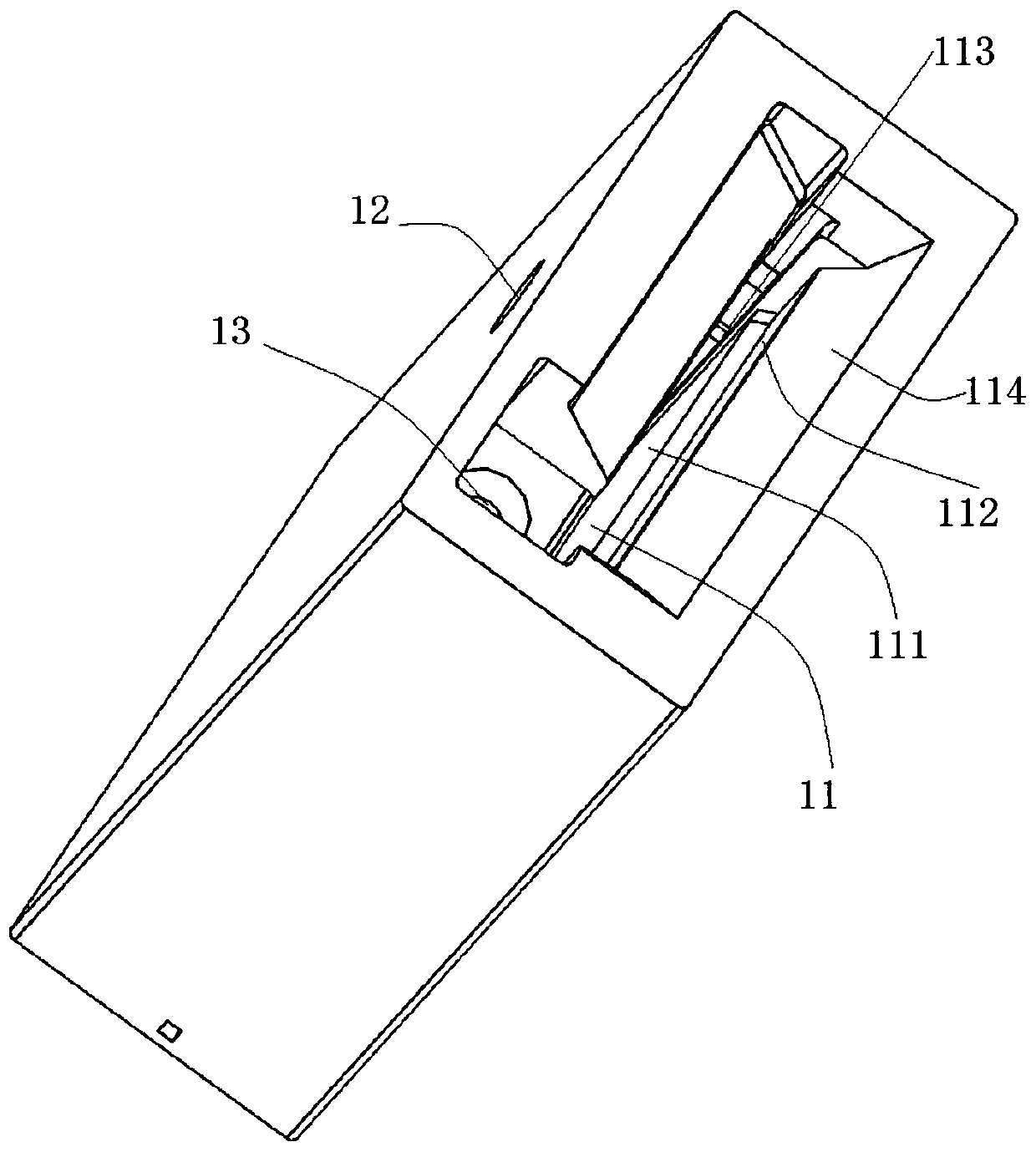

[0053] Such as Figure 1-Figure 5 As shown, the rapid constant temperature high-definition staining structural unit includes an upper cover body 3, a middle cover body 2, and a reaction chamber body 1. The reaction chamber body 1 is provided with an upper opening for placing a staining solution and inserting a glass slide loaded with a sample. The color chamber 11. The distance between the front side wall 115 and the rear side wall 111 of the dyeing chamber 11 is greater than the thickness of the glass slide, and the left and right side walls of the dyeing chamber are provided with a slide guide groove 113 extending up and down, and the slide guide groove 113 is opposite to the glass slide. The insertion guide of the slide 4 is positioned so that there are gaps between the slide 4 and the front and rear side walls of the staining chamber 11 .

[0054] The width of the slide guide groove 113 is preferably slightly larger than the thickness of the slide 4, preferably 1.2-1.5mm;...

Embodiment 2

[0087] Figure 13 As shown, the difference between this embodiment and Embodiment 1 is that no separate liquid inlet hole is provided in this embodiment, but the liquid discharge hole at the bottom in Embodiment 1 is used to set it as the liquid inlet and discharge hole 18, and then The liquid inlet and discharge holes 18 are shared by liquid and discharge. Realize multi-function in one mouthful and save processing cost.

[0088] The inlet and outlet holes 18 are used to connect with the inlet and outlet pipelines. The inlet and outlet pipelines include a liquid inlet branch and a liquid outlet branch. Several reaction solution pipelines for providing different types of reaction solutions, such as reaction solution pipeline A, reaction solution pipeline B, reaction solution pipeline C, and reaction solution corresponding to reaction solutions A, B, C, D, and E respectively Pipeline D, reaction liquid pipeline E. The reaction liquid pipeline is provided with reaction liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com