Arc-shaped heater

A heater and arc-shaped technology, applied in the field of manifold processing machinery, can solve the problems of reducing the production efficiency of manifolds and product quality, and achieve the effects of improving production efficiency and product quality, simple structure, and uniform heating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

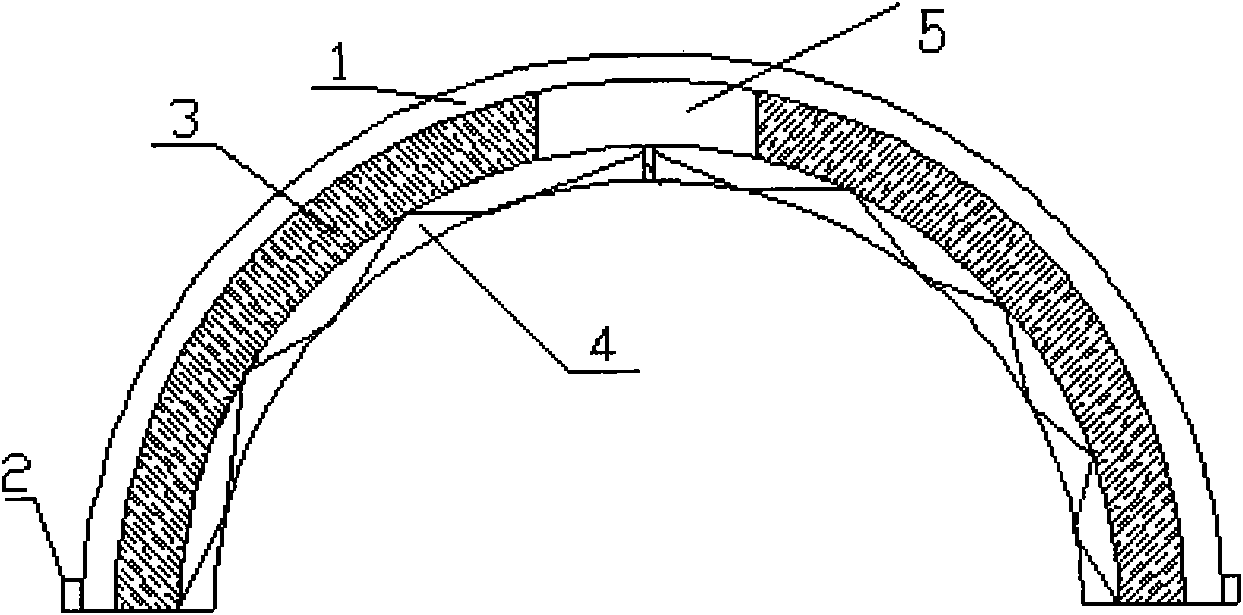

[0012] The arc heater includes a casing 1, and the casing 1 is a metal casing. Flange 2 is installed on the bottom and outer end of shell 1, the shape of the inner wall of shell 1 matches the external shape of the pipe fitting to be processed, and the inner wall of shell 1 is attached with insulation layer 3 and heating layer 4 in turn, and the heat preservation layer 3 is located between shell 1 and heating layer 4 In between, the insulation layer 3 is made of insulation cotton, the heating layer 4 is made of resistance wires arranged on the insulation layer, and the heating layer 4 has a power line drawn out to connect with an external power supply. The top of the shell 1 has a circular hole 5 penetrating through the shell 1 and the insulation layer 3 toward the inside of the shell 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com