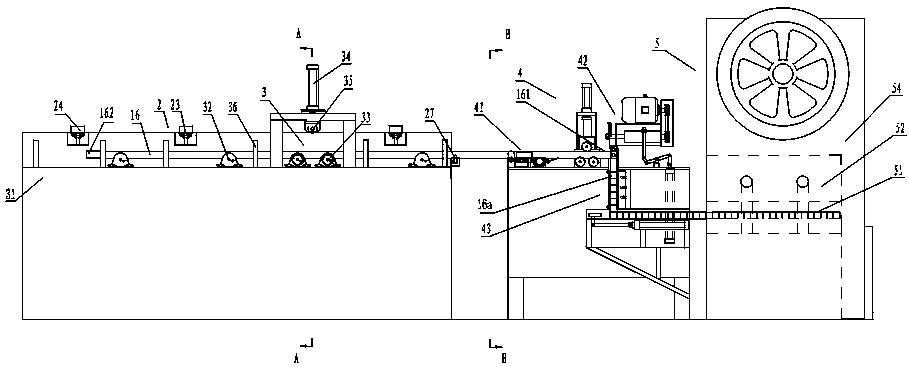

Equipment for automatically lifting, continuously feeding, sawing and heating bars

A technology for heating equipment and bars, which is applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of inability to realize a full set of automatic control, high labor intensity of employees, and low degree of automation, so as to reduce the labor intensity of employees , reduce burns, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

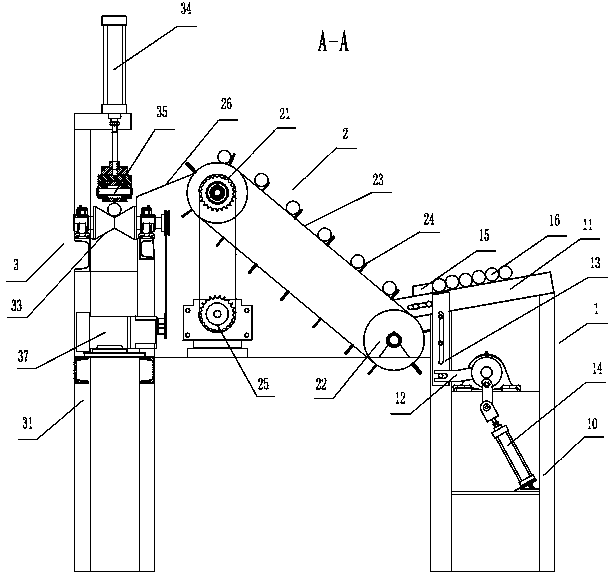

[0028] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

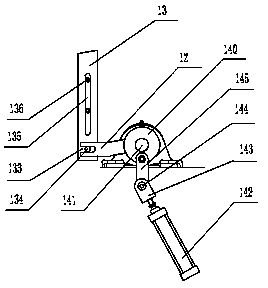

[0029] see Figure 1~3 As shown, the loading device 1 is used to receive and deliver the pre-cut bar 16 , including a loading frame 10 , a loading table 11 , a linkage rod 12 , a lifting rod 13 , a lifting cylinder 14 and a blocking block 15 . The material loading platform 11 rests obliquely on the material loading frame 10, the lower end of the material loading platform 11 is provided with a stop block 15, the material loading platform 11 is an inclined plane inclined to the lifting chain 23, and the upper surface of the material stop block 15 is for lifting material. Chain 23 inclined slope. The jacking cylinder 14 includes a transmission wheel 140 , a transmission wheel shaft 141 , a transmission cylinder 142 , a piston rod 143 , a center pin 144 and a transmission rod 145 . The transmission cylinder 142 is fixedly connected in the carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com