A high-temperature-resistant, stain-resistant and slagging-resistant ceramic coating and its preparation method and application

A ceramic coating and anti-contamination technology, which is applied in the field of special coatings, can solve the problems of reducing the service life of equipment, economic loss, uneven heating, etc., and achieve the effect of improving heat exchange efficiency, obvious application effect, and preventing contamination and slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments, so as to help understand the contents of the present invention.

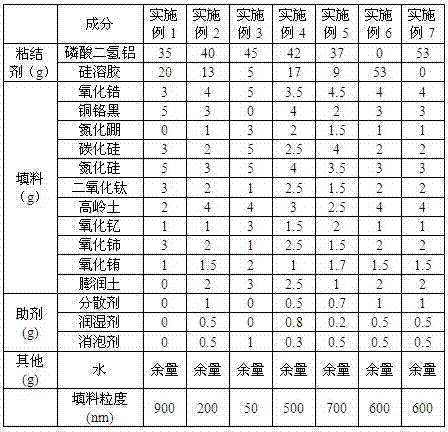

[0024] Mix the binder with water to obtain a binder liquid, then add fillers that have been refined to a particle size of 50-900 nm into the binder liquid, and then add additives as needed, stir evenly, filter and package, and obtain the present invention. The ceramic coating, each raw material of the coating and its consumption are shown in Table 1 below.

[0025] Table 1 Ceramic coatings prepared with different components

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com