Scale inhibition double-flow-channel loop tube electric heater with electric insulating surface as heating surface

An electric heater and heater technology, applied in ohmic resistance heating, immersion heating device, electric heating device, etc., can solve the problems of strength, installation space safety, inconvenient construction cost, corrosion of metal tubes, large volume of high-power tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

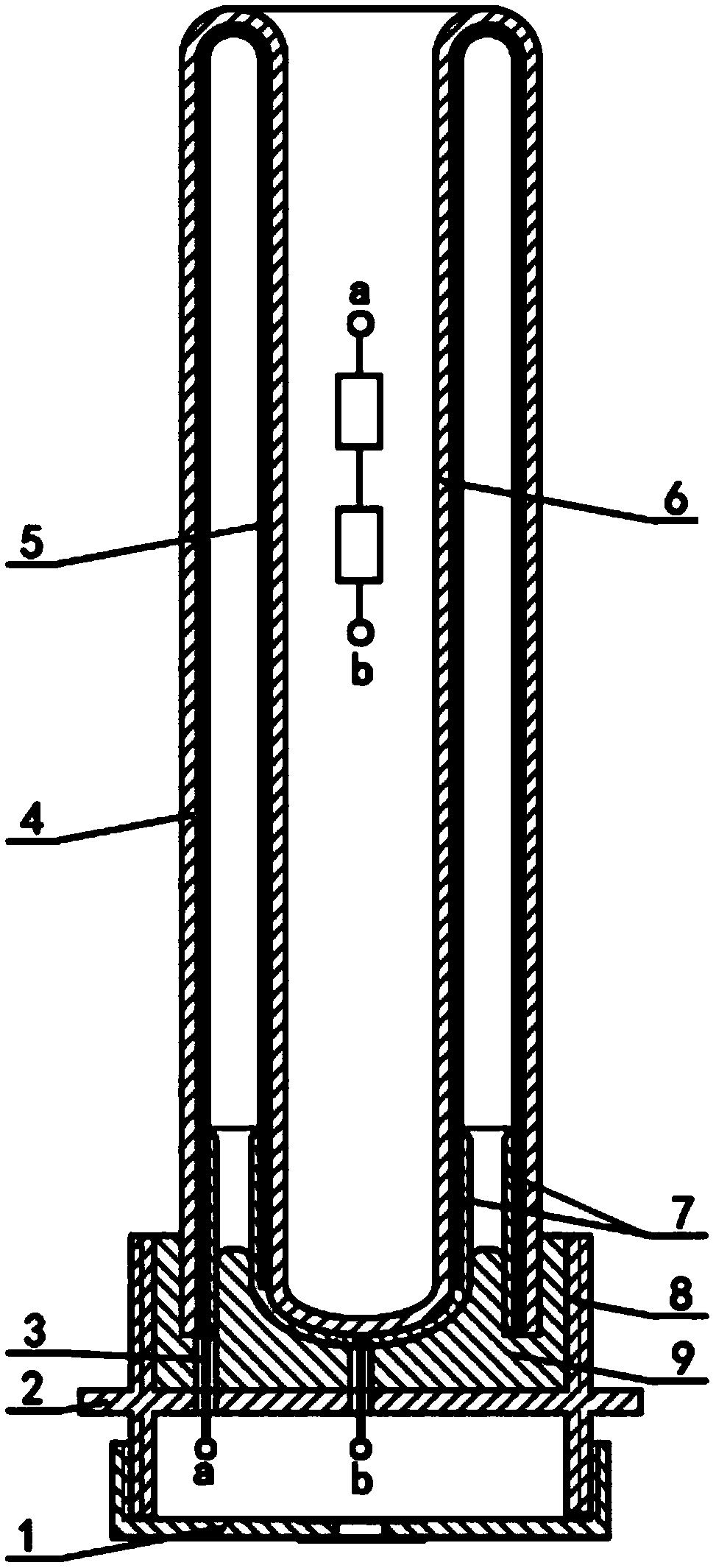

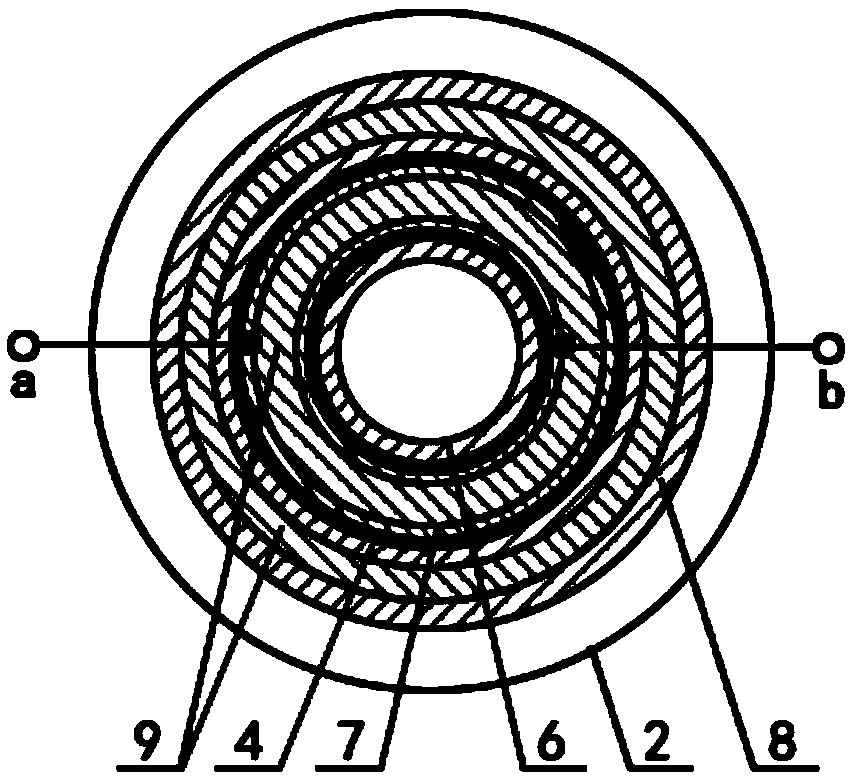

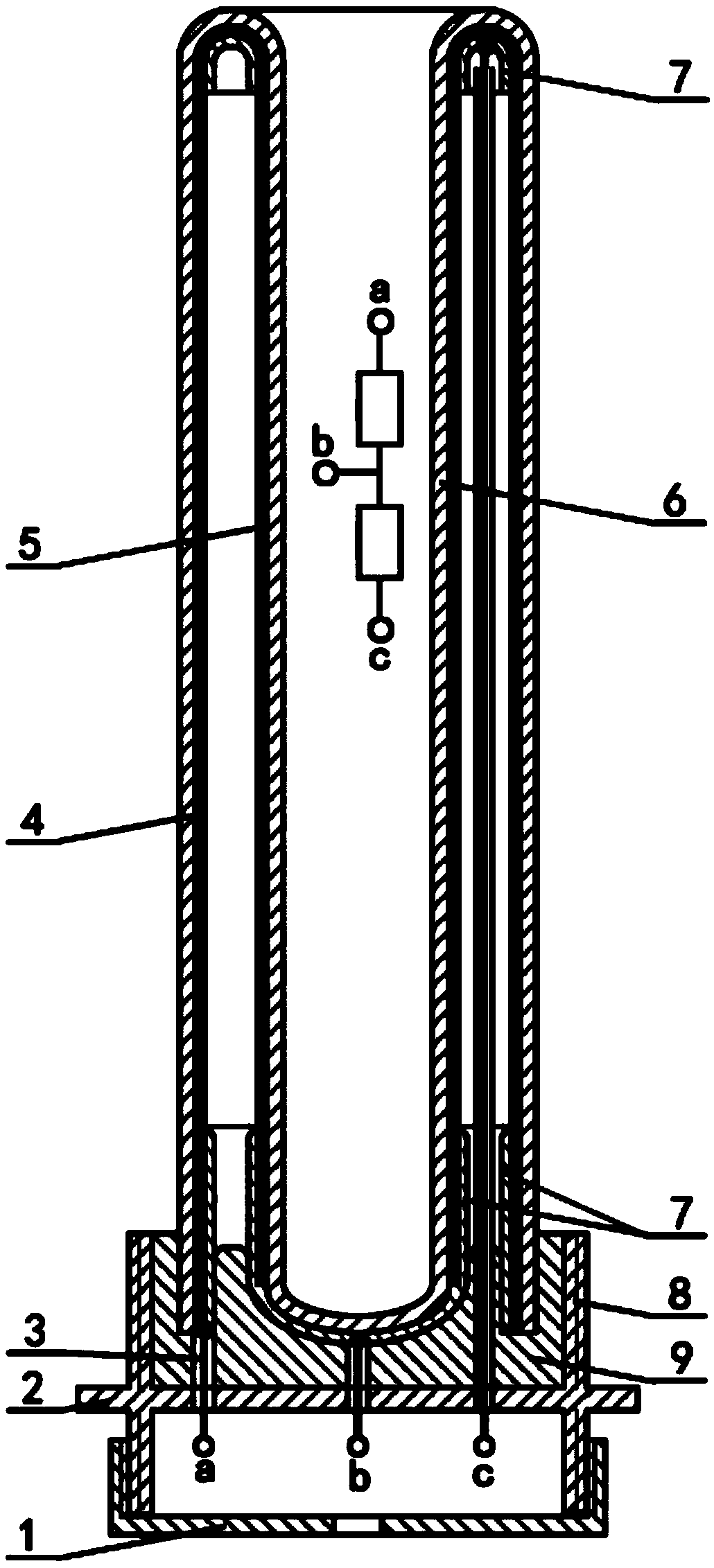

[0045] Such as figure 1 , figure 2Shown in the first embodiment of the present invention: the heat release surface is an electric insulating surface scale-resistant double-channel ring-cavity electric heater, and the ring-cavity electric heater skeleton is composed of one end of the electric heater skeleton outer sleeve 4 and the electric heater. One end of the inner casing 6 of the heater skeleton is glass-welded, and the other end of the inner casing 6 of the electric heater skeleton is glass-welded and closed to form a quartz glass ring cavity tube with an opening at one end of the outer casing 4 of the electric heater skeleton; the ring cavity tube is electrically heated The heat exchange surface of the heater frame and the medium is a smooth surface, and the inner surface of the ring-cavity electric heater frame is a rough surface that has been frosted or halogenated. Coat the inner surface of the inner surface of the ring-cavity tube electric heater skeleton to make a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com