Technology for regenerating active carbon by supersonic desorptive activation

An ultrasonic, activated carbon technology, applied in filter regeneration, other chemical processes, combustible gas purification, etc., can solve the problems of high labor intensity, high discharge frequency, and high requirements for regeneration equipment, achieving low cost, low regeneration cost, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

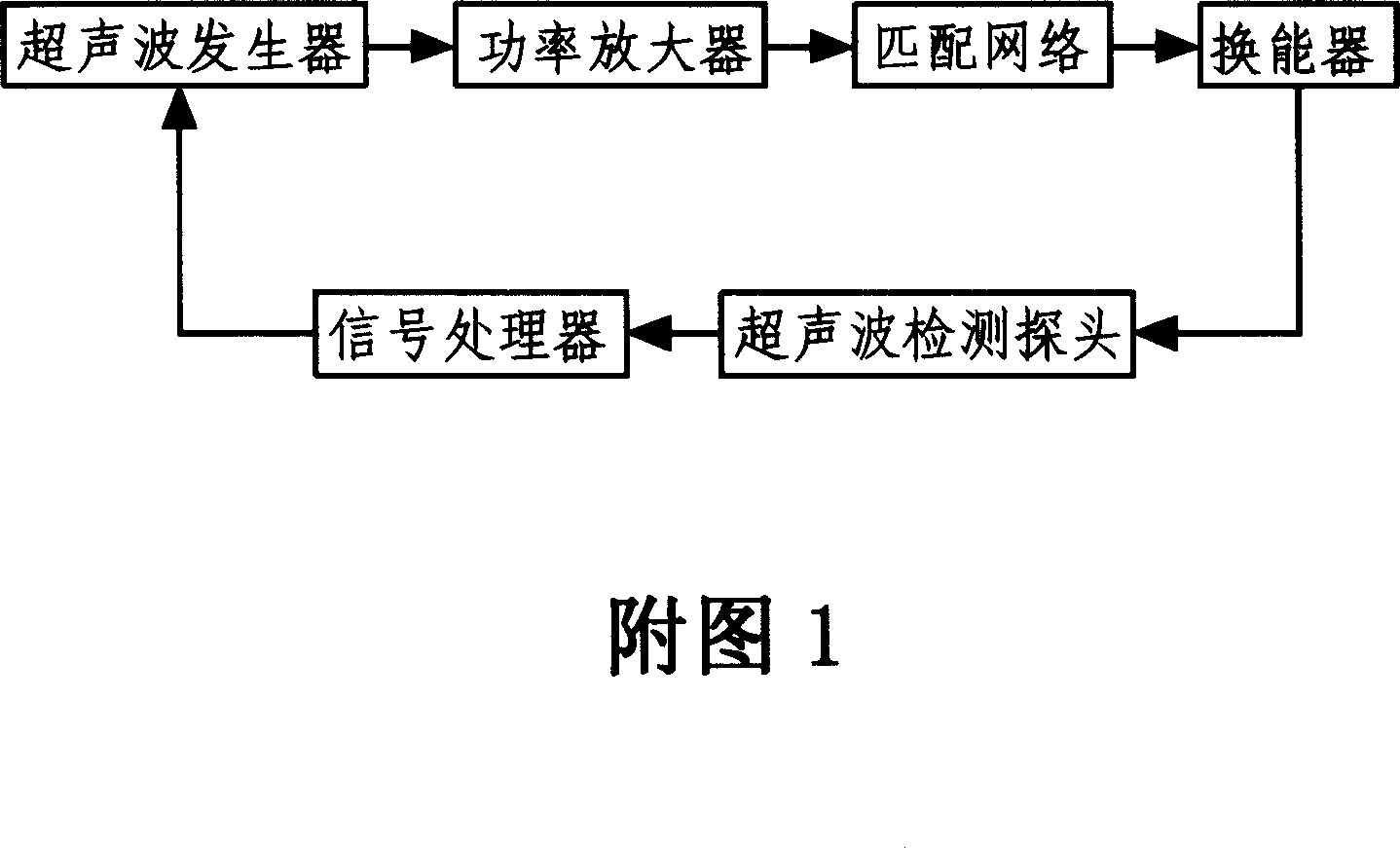

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

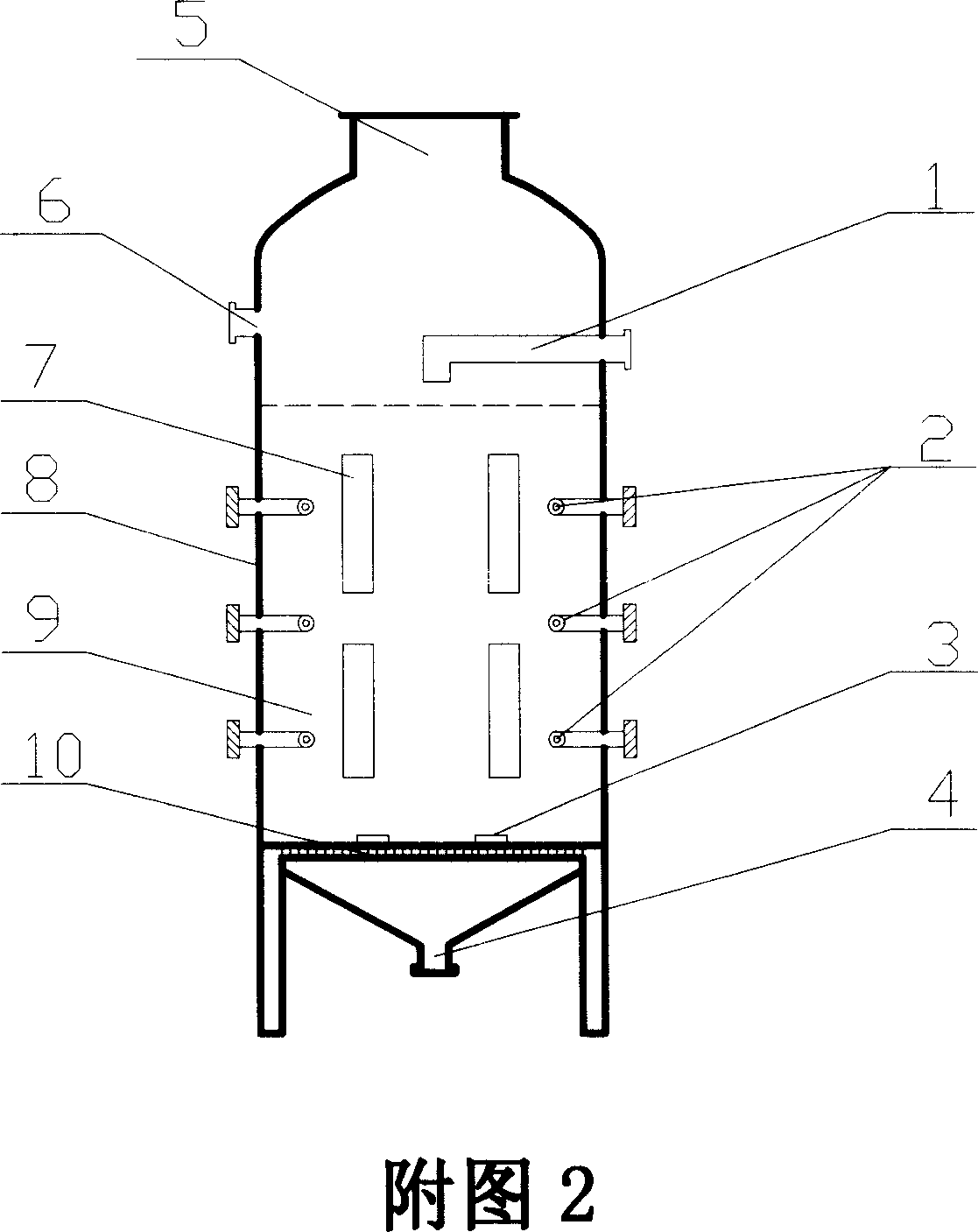

[0031] As shown in accompanying drawing 2, the transduction generator 7 in the industrial ultrasonic device is connected in parallel to multiple groups, and is placed in the activated carbon adsorption tower 8 according to the three-dimensional symmetrical structure of the space network. It is composed of transducing generators, two pairs of which have a distance of 0.6--2 meters, and the ultrasonic power density is greater than 0.6w / cm2. In the attached drawing 2, 1 is the high-pressure water inlet, 2 is the side wall high-pressure water inlet, and 3 is the fabric Water device, 4 is a water outlet, 5 is a manhole, 6 is a water inlet, 7 is an energy conversion generator, 8 is an activated carbon adsorption tower, 9 is an activated carbon layer, and 10 is a bottom sieve plate base.

[0032] Process steps

[0033] A. Adsorb and filter raw water;

[0034] B. Turn on the backwash water after the adsorption is saturated;

[0035] C. Turn on the power supply of the ultrasonic devi...

example 2

[0043] sewage

[0044] Multiple sampling results show that the ultrasonic desorption process meets the needs of this water treatment, occupies a small area, and has low investment and operating costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com