Filling body-pillar system mechanical effect mechanism test method

A technology of action mechanism and test method, applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve the problem that the bearing law cannot be systematically revealed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

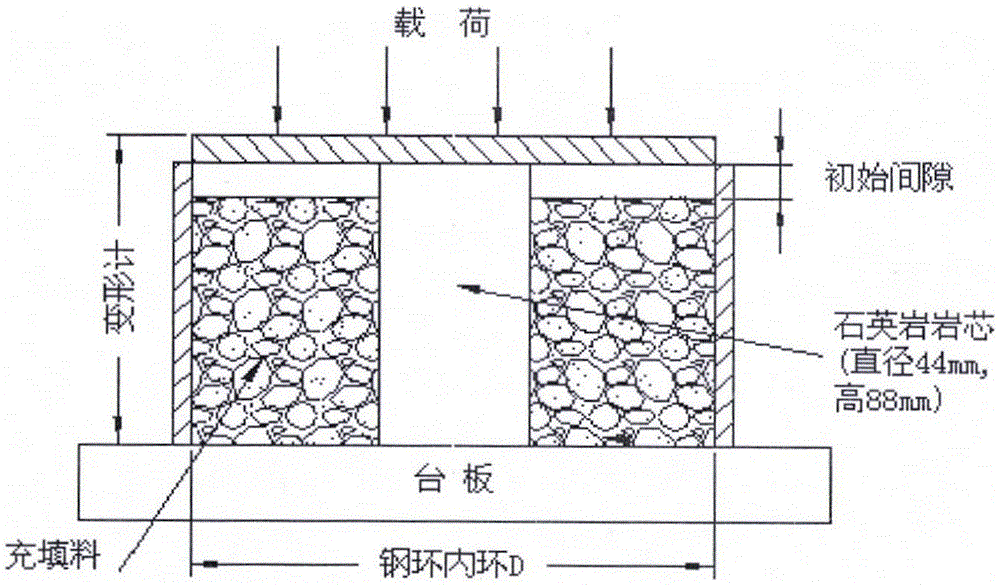

[0032] S1. Preparation of rock pillar specimens: According to the lime-sand ratio shown in Table 1, the preparation specifications are: The limestone specimen with a height of 100 mm was used as a substitute material for the test rock (mine) pillar, and the conventional uniaxial compressive strength test and the uniaxial loading test of the filling body-rock pillar system with confining conditions were carried out; 20 pieces, labeled Y-1, Y-2, ... Y-20 at a time.

[0033] Table 1 Grouping of filling body-rock pillar system test

[0034]

[0035] S2. Processing and preparation of self-made elastic modules: prepare the slurry according to the concentration of the filling slurry and the ratio of lime and sand designed in the experiment, add the filling slurry into a small plastic mold of 20mm×10mm×5mm and scrape the surface, and then keep it under constant temperature and humidity The curing box is cured for 28 days according to the test requirements, and it can be used as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com