High strength martensitic stainless steel excellent in carbon dioxide gas corrosion resistance and sulfide stress-corrosion cracking resistance

a martensitic stainless steel, high-performance technology, applied in the field of steel materials, can solve the problems of low carbon-content steel described in these publications not having the strength required for deep well use, sus 420 steel is liable to generate sulfide stress-corrosion cracking (sscc) under, poor corrosion resistance to hydrogen sulfide, etc., to achieve excellent carbon dioxide gas corrosion resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

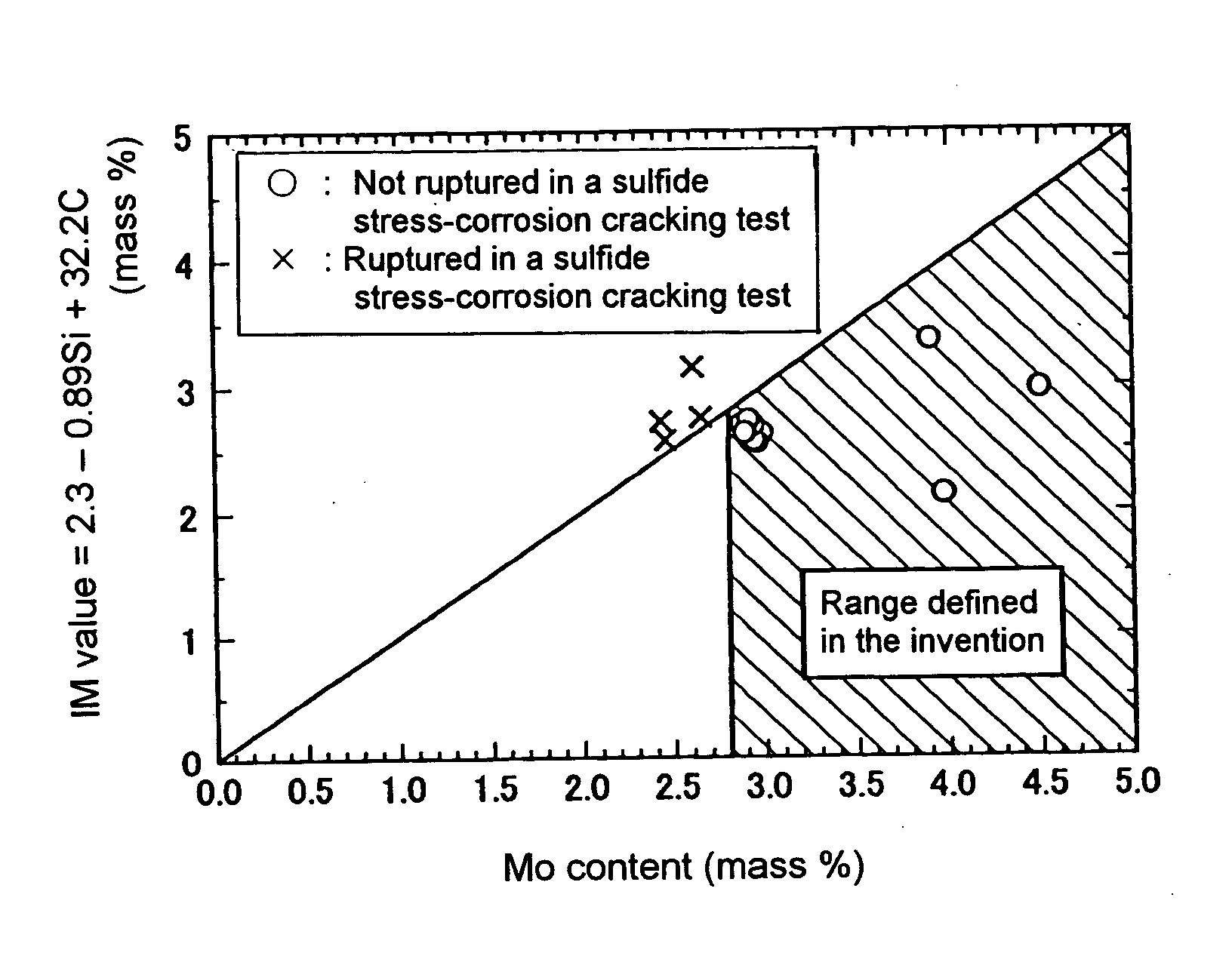

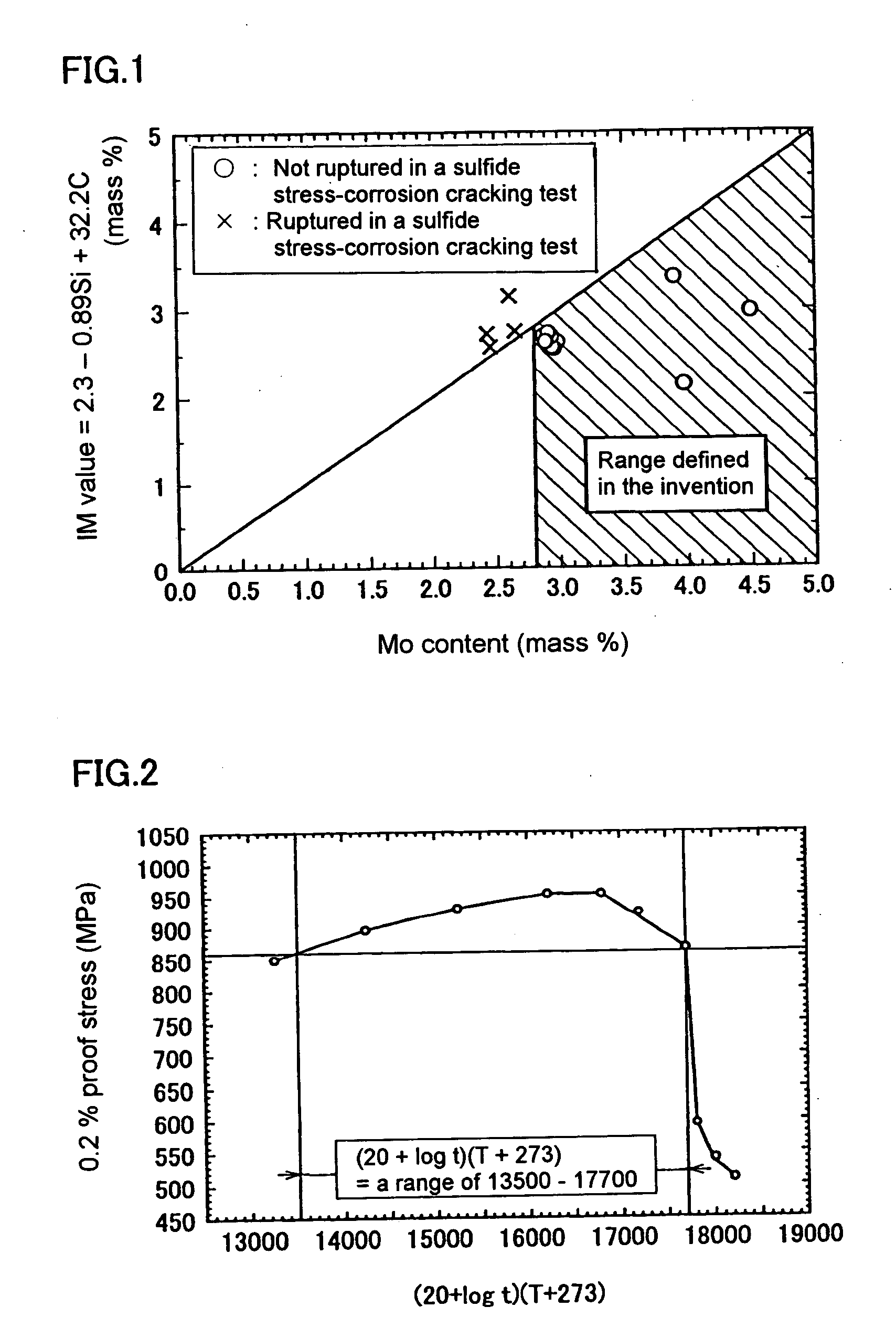

[0063] Steels having chemical compositions shown in Tables 1 (1) and 1 (2) were melted and cast, and the obtained cast ingots were forged and hot rolled to prepare steel plates each having a thickness of 15 mm, a width of 120 mm and a length pf 1,000 mm. These steel plates were subjected to quenching (water cooling at 920° C.) and tempering [air cooling after soaking at 550° C. for 30 min. ((20+log t)(T+273)=16212), and the obtained steel plates were provided in various tests as testing steel plates.

TABLE 1TestChemical composition (mass %)No.CSiMnPSCuCrNiMoAlNSteels of the intention10.0140.170.430.0150.001011.816.852.930.0300.005520.0160.170.460.0150.001012.086.902.930.0300.005530.0260.180.870.0160.00110.0812.027.674.500.0280.005040.0340.040.440.0150.00100.0412.017.393.880.0340.006250.0080.480.410.0110.00100.9811.987.873.980.0240.005060.0150.170.980.0150.001010.114.212.980.0300.005570.0170.171.020.0150.001014.107.922.880.0300.006680.0160.150.230.0130.000912.106.872.860.0250.006590...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com