Method for reducing Laves phase in nickel-based high-temperature alloy steel ingot

A technology of nickel-based superalloy and superalloy steel, which is applied in the field of metallurgical technology, can solve the problems of difficult homogenization treatment, low diffusion rate and high temperature, and achieves the advantages of reducing the difficulty of homogenization treatment, reducing smelting temperature and reducing the amount of precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

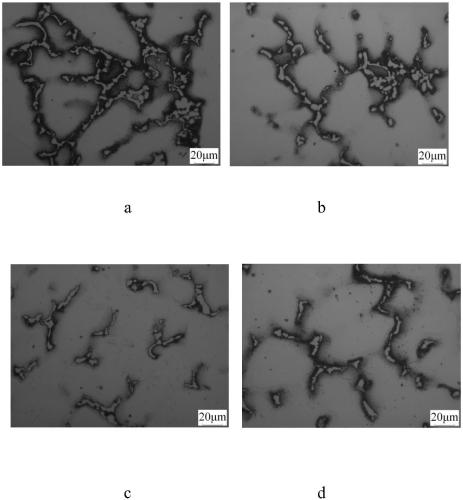

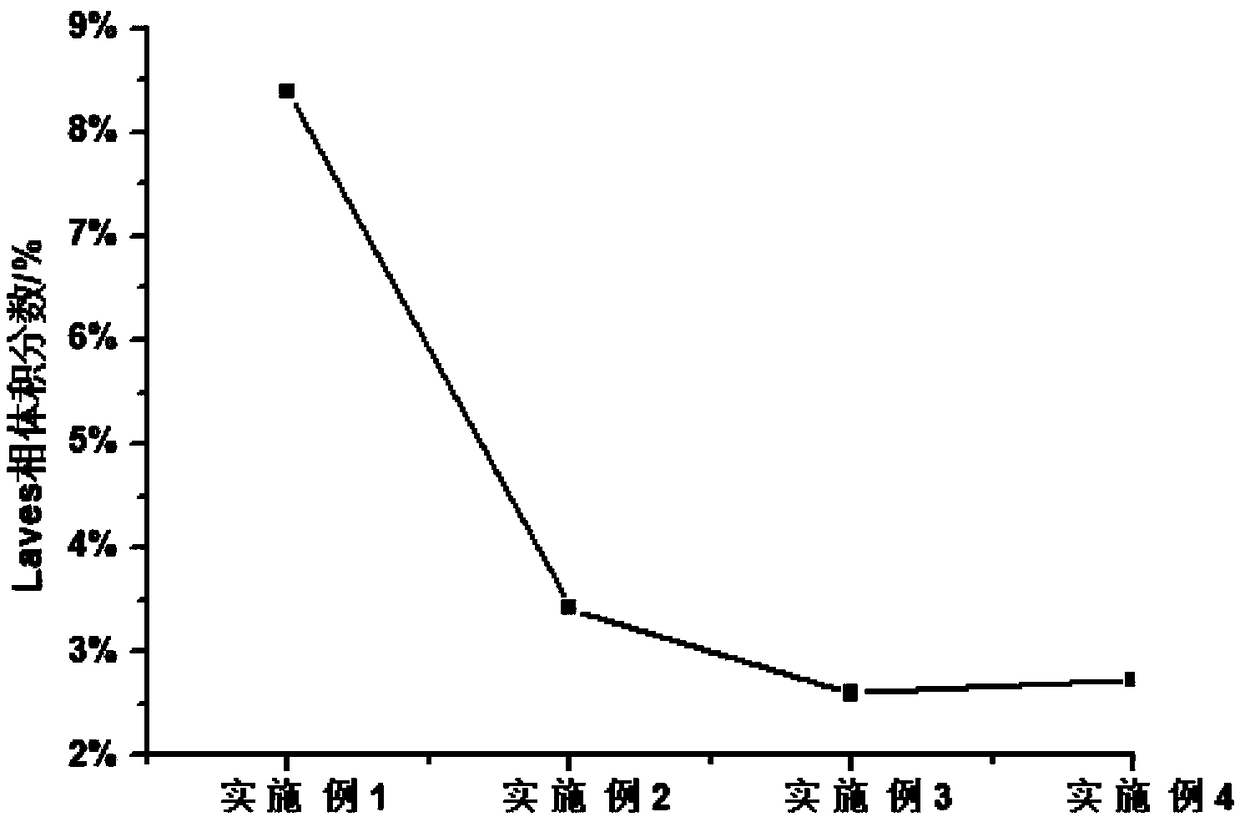

Embodiment 1

[0028] Take 50Kg of the master alloy, carry out vacuum induction melting, and cast to obtain steel ingots. Take metallographic samples for microstructure observation and analysis, and then the master alloy is smelted by electroslag, and the weight percentage of CaF is about 5-7kg. 2 :CaO:Al 2 o 3 : MgO=60:15:20:5 electroslag material, crystallizer diameter is The melting current is 3±1kA, the voltage is 45±5V, and the feeding current is 1-2kA / s. Then carry out homogenization annealing at 1140°C×24h; finally, heat the ingot at 1080±15°C for 120min and start forging, start forging temperature ≥ 1080°C, final forging temperature ≥ 980°C, total forging ratio ≥ 4, then measure its mechanical properties.

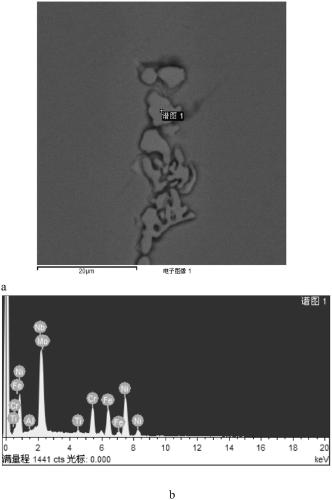

[0029] see figure 1 , figure 1 (a) and (b) respectively represent the scanning electron microscope pictures of the Laves phase in the steel ingot structure of Example 1 and the elemental composition of the Laves phase. It can be seen that a large amount of Nb and Mo element...

Embodiment 2

[0031] Take 50Kg of master alloy, add vanadium-iron master alloy, make the weight percentage of vanadium element be 0.2% of master alloy weight, carry out vacuum induction melting, cast, take metallographic sample and carry out microstructure observation and analysis, and other steps are the same as the embodiment 1. Determination of its mechanical properties.

Embodiment 3

[0033] Take 50Kg of master alloy, add vanadium-iron master alloy, make the weight percentage of vanadium element be 0.5% of master alloy weight, carry out vacuum induction melting, cast, take metallographic sample and carry out microstructure observation and analysis, and other steps are the same as the embodiment 1. Determination of its mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com