Eliminating method for brittle phase in laser-repaired nickel-base high temperature alloy

A nickel-based superalloy, laser repair technology, applied in metal material coating process, coating and other directions, can solve the problems of the influence of material mechanical properties, the inability to completely eliminate the Laves brittle phase, and the limited effect of Laves phase control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Laser repair of nickel-based superalloys

[0030] Mechanically remove and polish the repaired parts of the nickel-based superalloy specimen with alloy grade of GH4169, and clean the repaired parts with alcohol and acetone; fix and clamp the nickel-based superalloy specimen on the CNC workbench, The coaxial powder feeding laser repair method is used to laser repair the area to be repaired to restore the shape and size of the parts and samples.

[0031] (2) Elimination of brittle phases in laser repair of nickel-based superalloys

[0032] δ aging treatment: Put the above-mentioned nickel-based superalloy sample after laser repair into the muffle furnace, heat up to 890°C at 10°C / min, and keep it for 12h;

[0033] δ solution treatment: After the δ aging treatment, the furnace temperature is increased to 1020 ℃ at 10 ℃ / min, and the temperature is kept for 4 hours. After the temperature is finished, the sample is taken out and cooled to room temperature.

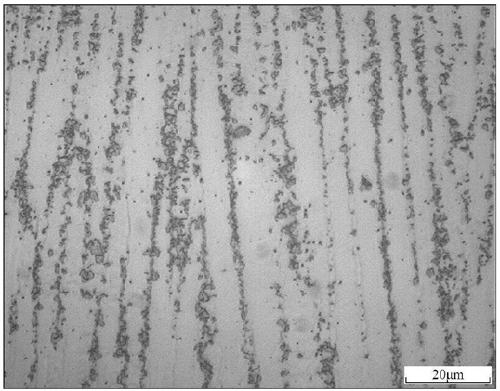

[0034] The metallograph...

Embodiment 2

[0038] (1) Laser repair of nickel-based superalloys

[0039] Mechanically remove and polish the repaired parts of the nickel-base superalloy sample with alloy grade of DZ125, and clean the repaired parts with alcohol and acetone; fix and clamp the nickel-base superalloy sample on the CNC workbench. The coaxial powder feeding laser repair method laser repairs the area to be repaired to restore the shape and size of the parts and specimens.

[0040] (2) Elimination of brittle phases in laser repair of nickel-based superalloys

[0041] δ aging treatment: Put the above-mentioned repaired nickel-based superalloy sample into a muffle furnace, and heat up to 960°C at 20°C / min, and keep it for 10 hours;

[0042] δ solution treatment: After the δ aging treatment, the furnace temperature is increased to 1030°C at 20°C / min, and the temperature is kept for 6 hours. After the heat preservation is completed, the sample is taken out and cooled to room temperature.

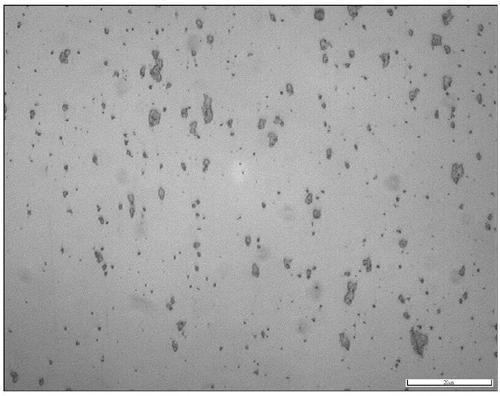

[0043] The metallographic structur...

Embodiment 3

[0045] (1) Laser repair of nickel-based superalloys

[0046] Mechanically remove and polish the repaired parts of the GH3625 nickel-based superalloy sample, and clean the repaired parts with alcohol and acetone; fix and clamp the nickel-based superalloy sample on the CNC workbench. The coaxial powder feeding laser repair method laser repairs the area to be repaired to restore the shape and size of the parts and specimens.

[0047] (2) Elimination of brittle phases in laser repair of nickel-based superalloys

[0048] δ aging treatment: Put the above-mentioned repaired nickel-based superalloy sample into the muffle furnace, heat up to 970°C at 15°C / min, and keep it for 8h;

[0049] δ solution treatment: After the δ aging treatment is completed, the furnace temperature is increased to 1035 ℃ at 15 ℃ / min, and the temperature is kept for 3 hours. After the temperature is finished, the sample is taken out and cooled to room temperature.

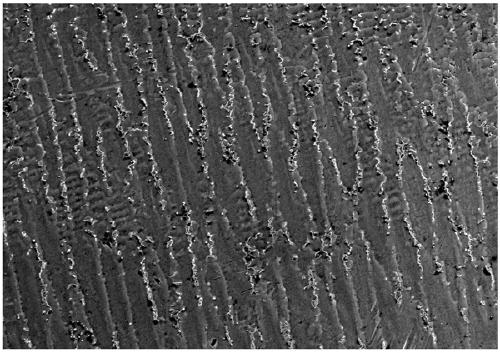

[0050] The metallographic structure observation and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com