High-strength martensitic stainless steel with excellent resistances to carbon dioxide gas corrosion and sulfide stress corrosion cracking

A martensitic stainless steel, stress corrosion technology, applied in the field of steel, can solve problems such as inability to obtain strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

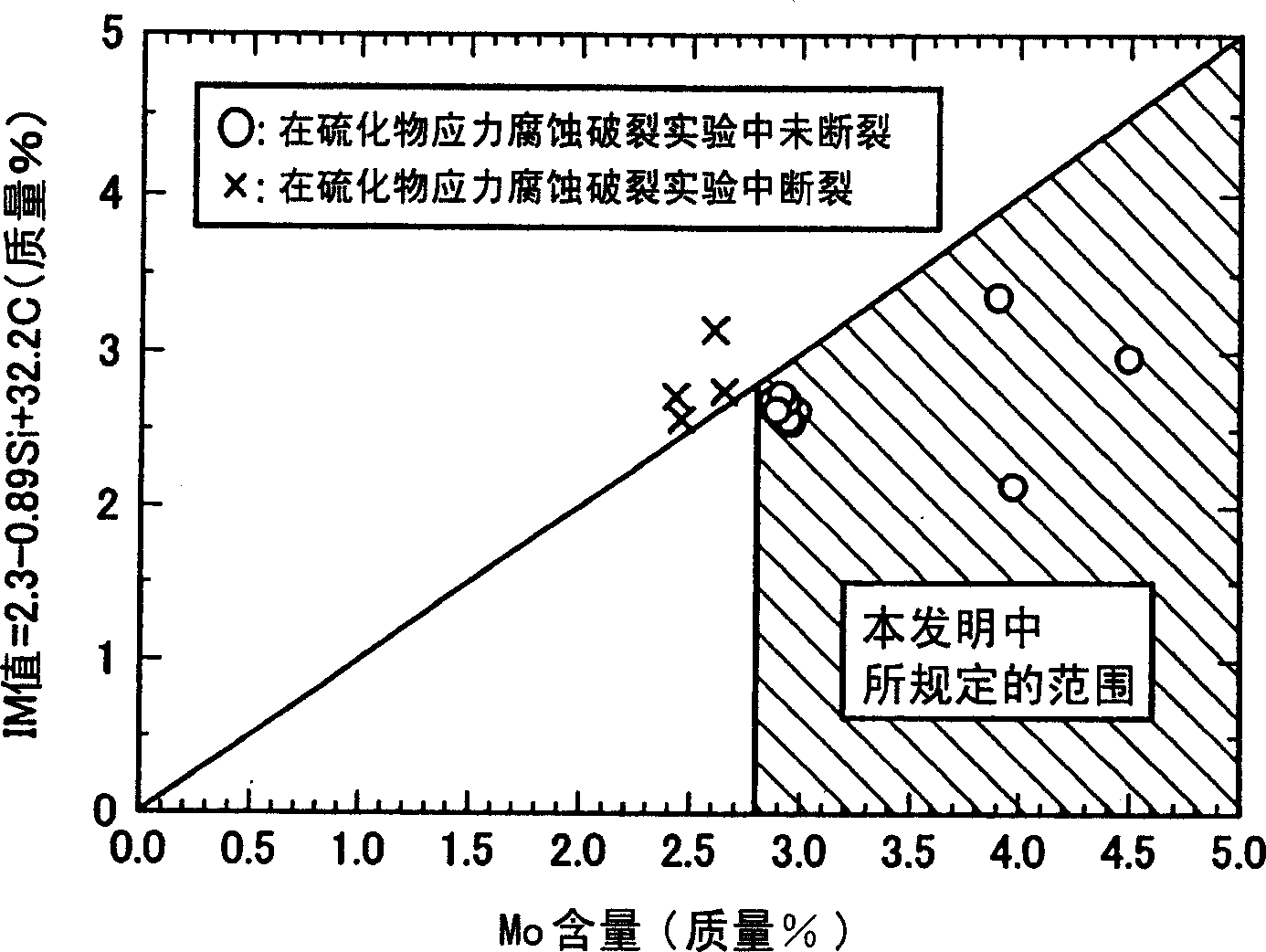

[0018] The reasons for limiting the content of each element specified in the present invention will be described below. In addition,% of each content means mass %.

[0019] C: 0.005~0.04%

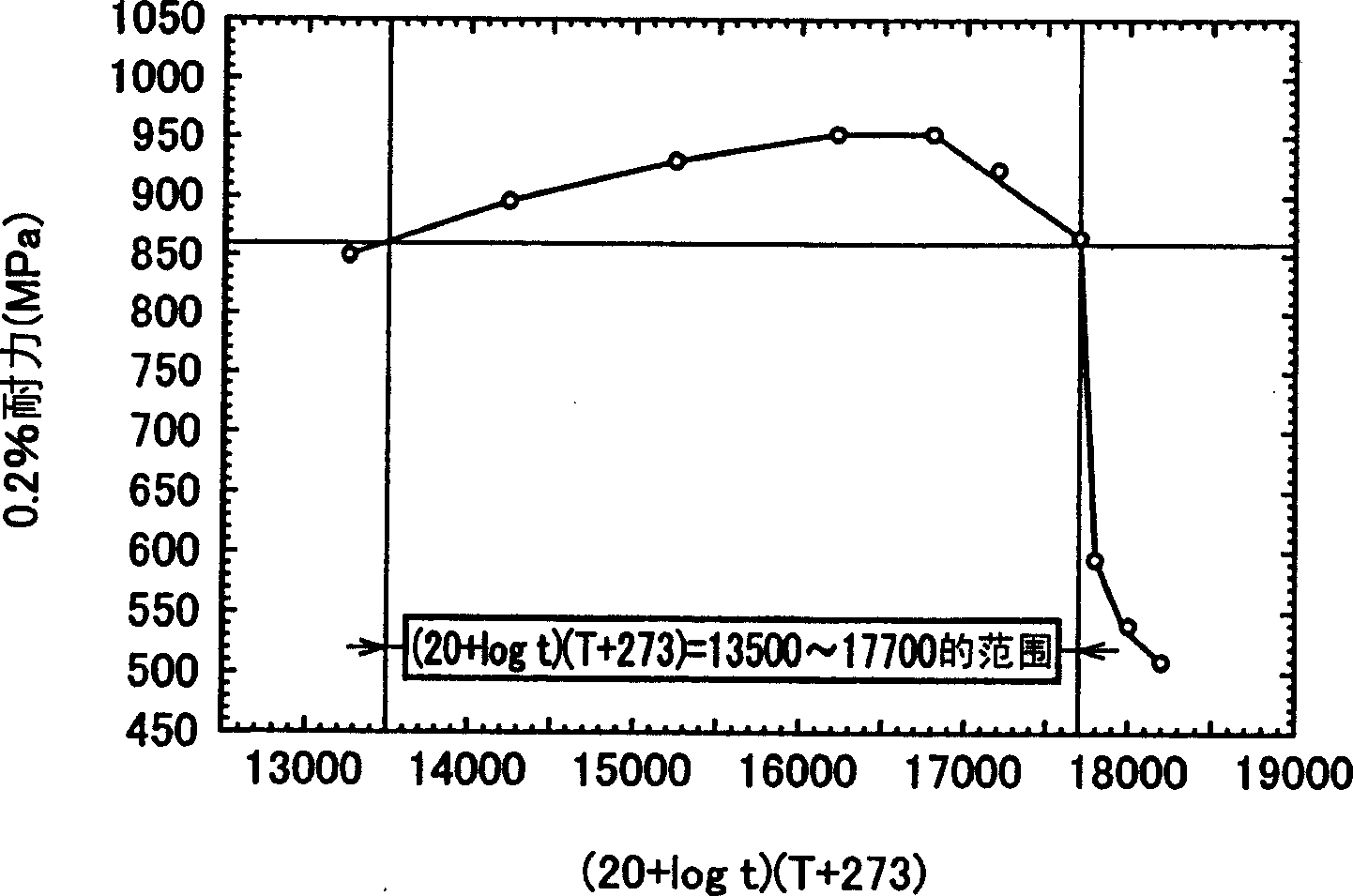

[0020] Although C is an effective element in improving the strength of steel, it is better to have as little as possible in terms of corrosion resistance. However, when it is less than 0.005%, since the endurance does not reach 860 MPa or more, the lower limit of the content is made 0.005%. On the other hand, when its content exceeds 0.04%, the hardness after tempering becomes too high, and the sulfide stress corrosion cracking sensitivity becomes high. Therefore, the content of C is set to 0.005 to 0.04%.

[0021] Si: 0.5% or less

[0022] Si is an essential element as a deoxidizer. The residual amount in steel can also be an impurity level. However, in order to obtain a greater deoxidation effect, it is best to set its content to 0.01% or more. On the other hand, when its content exceeds 0.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com