Austenitic heat-resistant steel and preparation method thereof

A technology of austenitic heat-resistant steel and steel ingot, which is applied in the field of austenitic heat-resistant steel, can solve the problems of inability to strengthen grain boundaries and reduce high-temperature creep performance, so as to prevent high-temperature creep, improve high-temperature creep strength, The effect of less elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

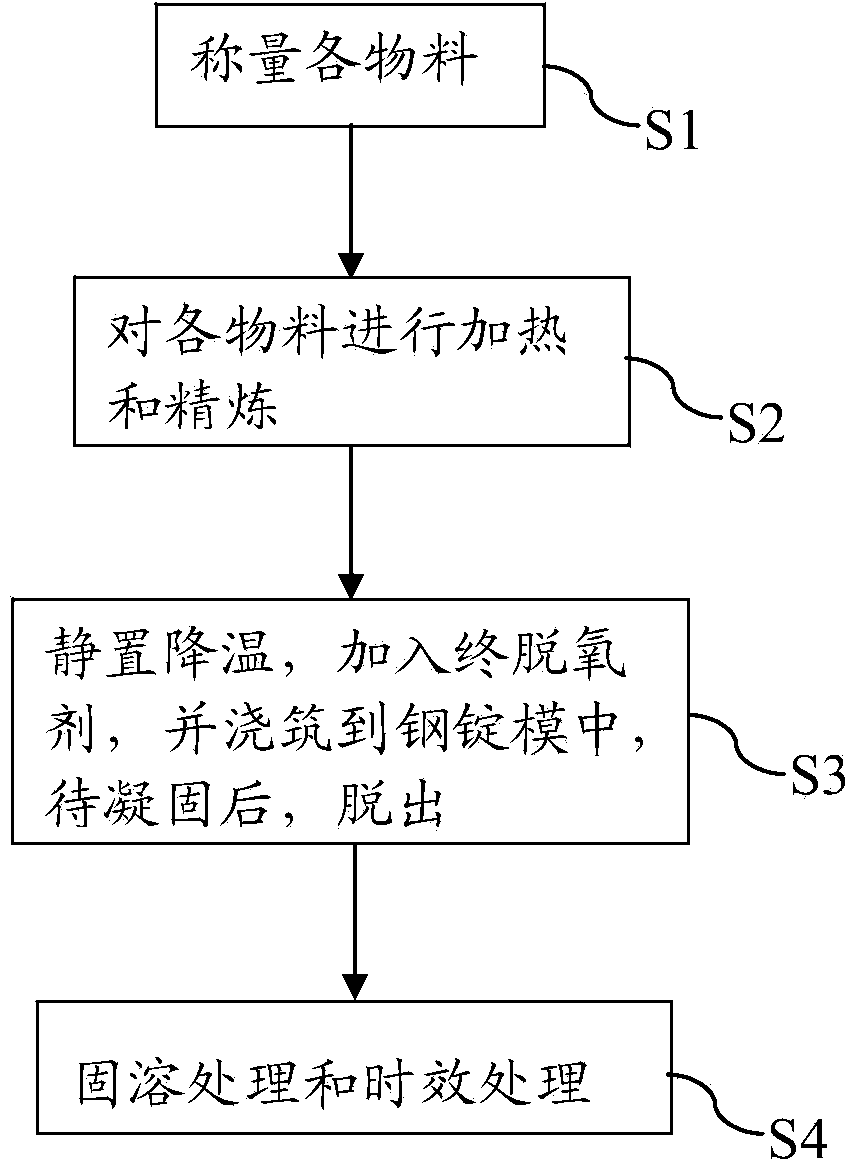

[0030] like figure 1 Shown, the preparation method of austenitic heat-resistant steel of the present invention comprises the steps:

[0031] S1. In terms of mass percentage, according to the alloy composition and burning loss, the raw materials are equipped with carbon 0.01%, chromium 18.6%, nickel 31%, niobium 3.5%, manganese 0.5%, lanthanum 1.6%, boron 0.01% and iron balance. Put the weighed materials into the magnesia crucible;

[0032] S2. Put the magnesia crucible containing various materials into a vacuum furnace, and heat and refine the materials in the magnesia crucible;

[0033] S3. Stand still to cool down, add final deoxidizer to the magnesia crucible, and pour the molten metal into the steel ingot mold at a temperature higher than the melting point, and after solidification, remove the solidified and formed steel ingot from the steel ingot mold;

[0034] S4. Perform solution treatment and aging treatment on the solidified steel ingot.

[0035] Wherein, in step S...

Embodiment 1

[0046] In terms of mass percentage, according to the alloy composition and burning loss, the raw materials are equipped with carbon 0.01%, chromium 18.6%, nickel 31%, niobium 3.5%, manganese 0.5%, lanthanum 1.6%, boron 0.01% and iron balance. Measure each material into a magnesia crucible for later use. Put the magnesia crucible filled with various materials into a vacuum furnace to heat and refine the materials in the magnesia crucible.

[0047] In this embodiment, a 50kg vacuum furnace is used. The parameters of the vacuum furnace are a capacity of 0.05T, a rated power of 120 kW, a frequency of 2.5 kHz, and an ultimate vacuum of 6.7×10 -3 mmHg, rated temperature 1700°C, weight 1.5 tons, control voltage 220V.

[0048] Let stand to cool down for 3 minutes, add nickel-magnesium alloy into the magnesia crucible as a final deoxidizer, and then send electricity to the induction coil in the vacuum furnace with a power of 30kw for 1.5 minutes. The molten metal is poured into the s...

Embodiment 2

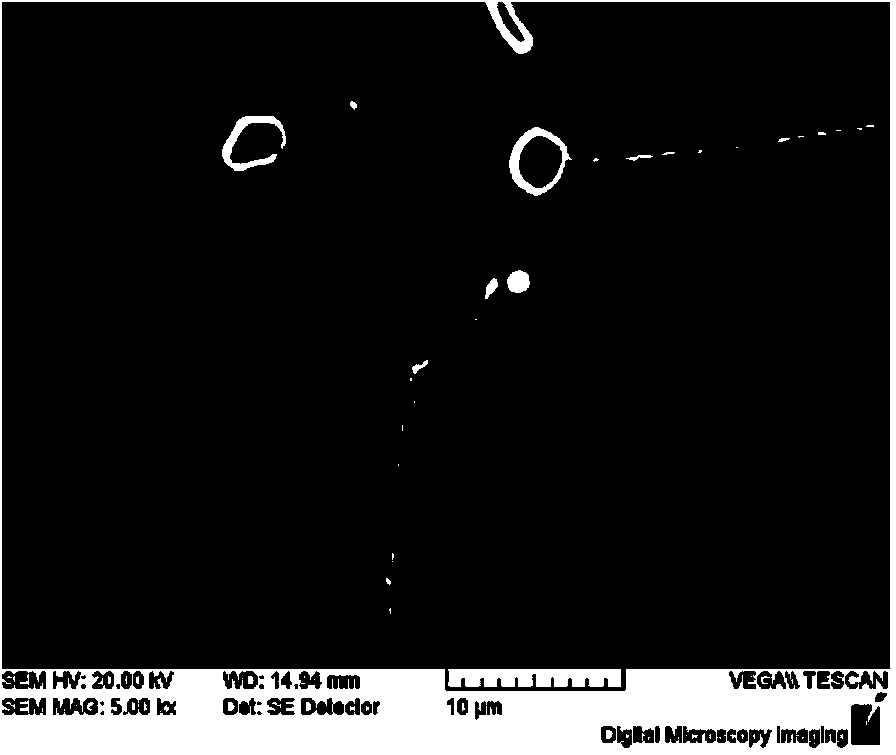

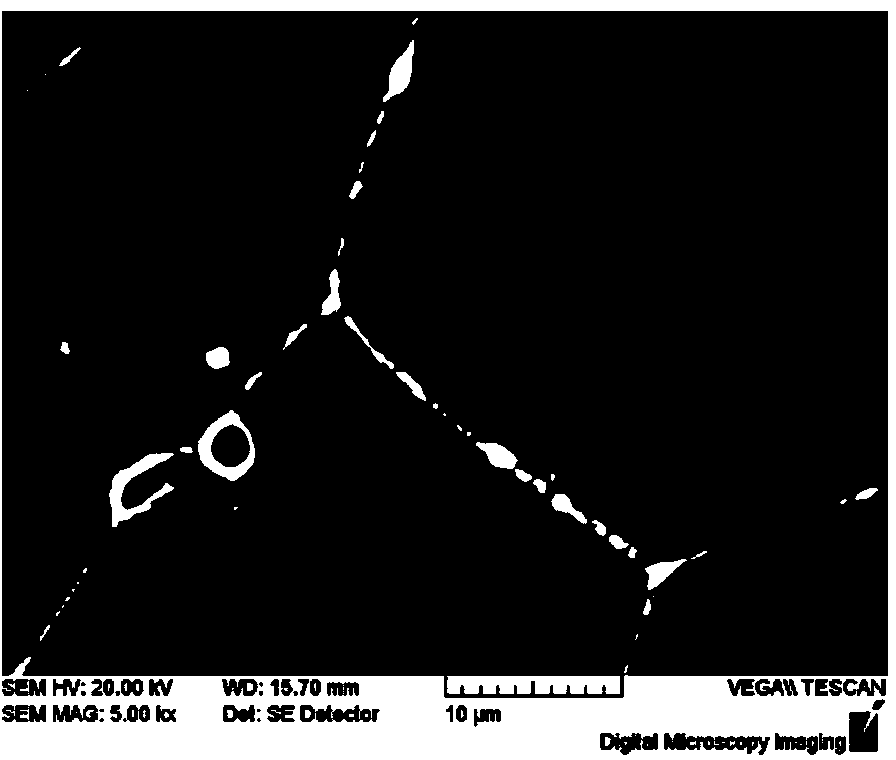

[0052] The difference between this embodiment and the above-mentioned embodiment 1 is that the time for aging treatment is 12 hours. Then, grinding, polishing and corrosion are carried out, and the surface of the sample is observed under a scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com