Polymer alloy for manufacturing plastic pipeline insert

A plastic pipe and polymer technology, which is applied in the field of engineering plastic alloy preparation, can solve the problems that the dimensional stability is difficult to meet the use requirements, it is not suitable for water supply pipe inserts, and the inserts are expensive, etc., and achieve good dimensional stability and weight. Lightweight, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

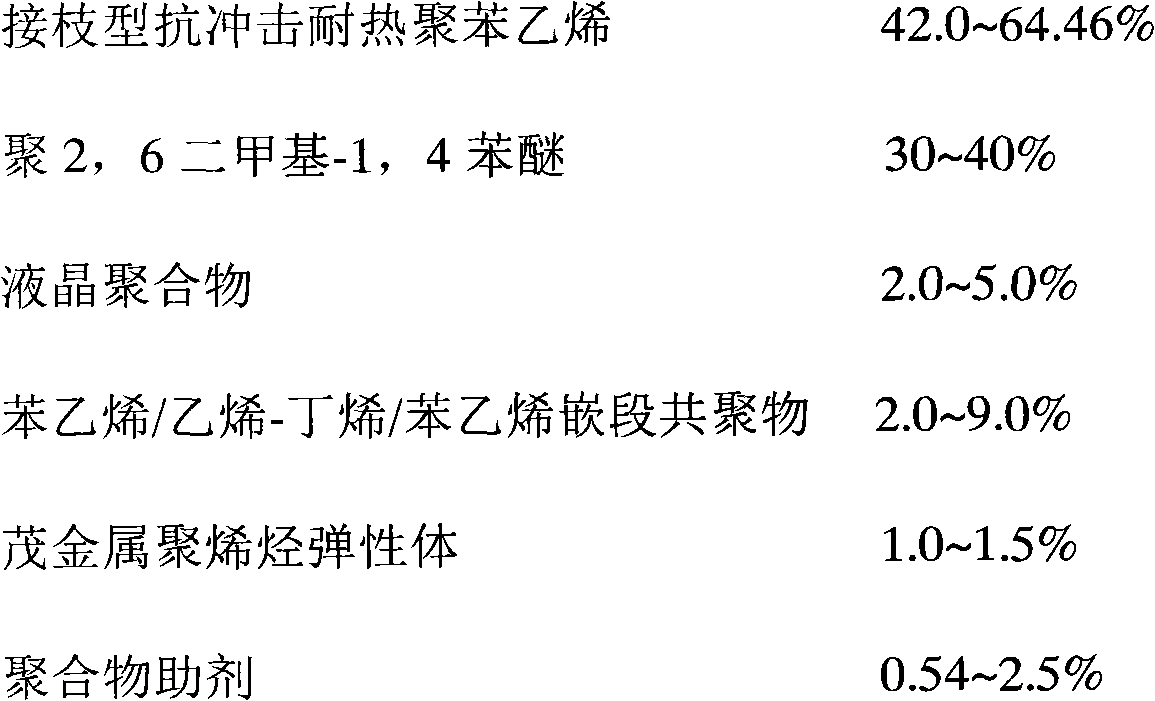

[0021] A kind of polymer alloy composition weight percentage of making plastic pipe insert is:

[0022]

[0023] A method for preparing a polymer alloy for making plastic pipe inserts:

[0024] First add liquid paraffin into styrene / ethylene-butylene / styrene block copolymer separately in advance, and then physically blend with each component, after fully mixing evenly, add to extruder to melt and extrude to granulate, That is, the polymer alloy to be prepared is obtained.

Embodiment 2

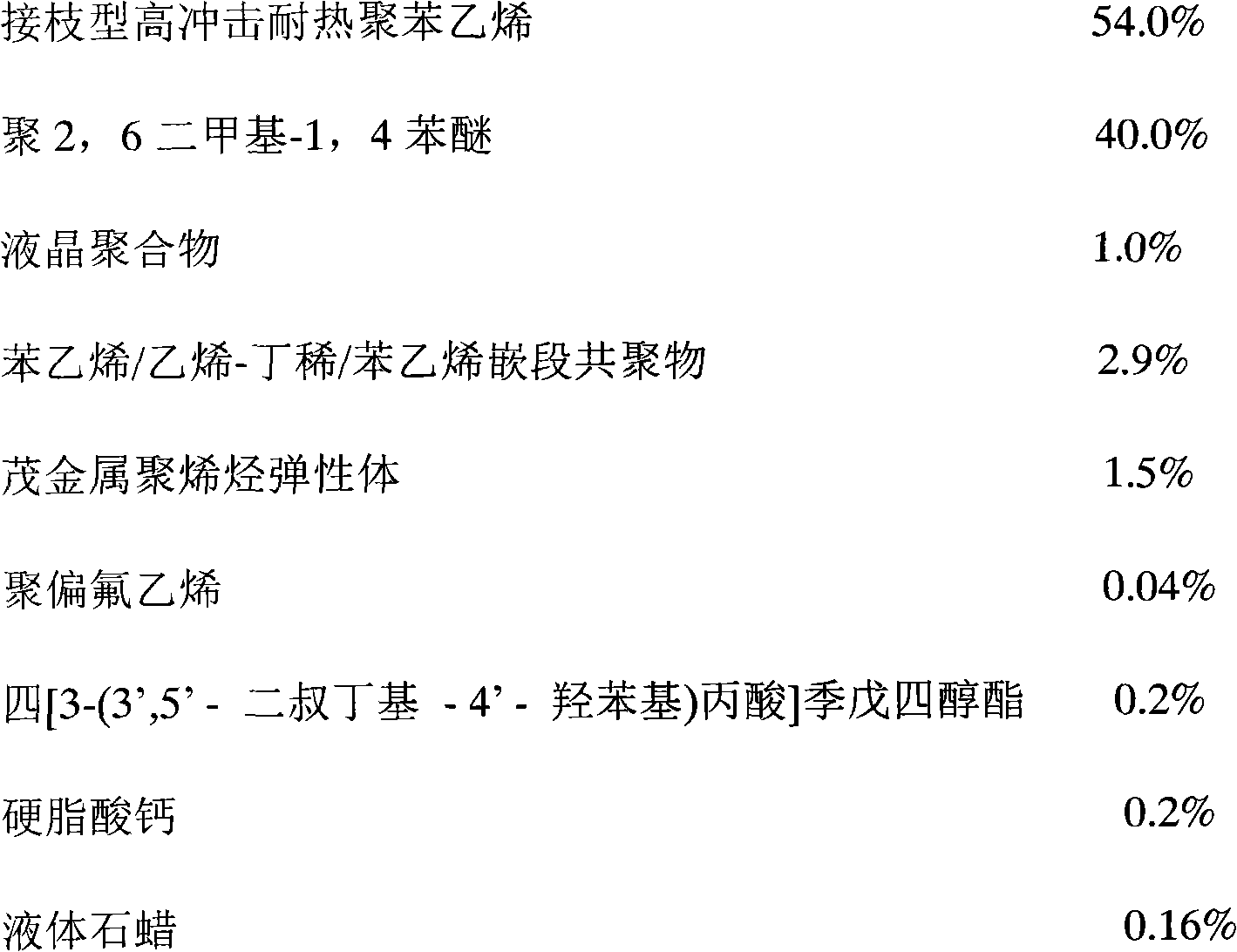

[0026] A kind of polymer alloy composition weight percentage of making plastic pipe insert is:

[0027]

[0028]

[0029] A method for preparing a polymer alloy for making plastic pipe inserts:

[0030] First add liquid paraffin into styrene / ethylene-butylene / styrene block copolymer separately in advance, and then physically blend with other components. After mixing well, add it into an extruder to melt and extrude to granulate. That is, the desired polymer alloy is obtained.

Embodiment 3

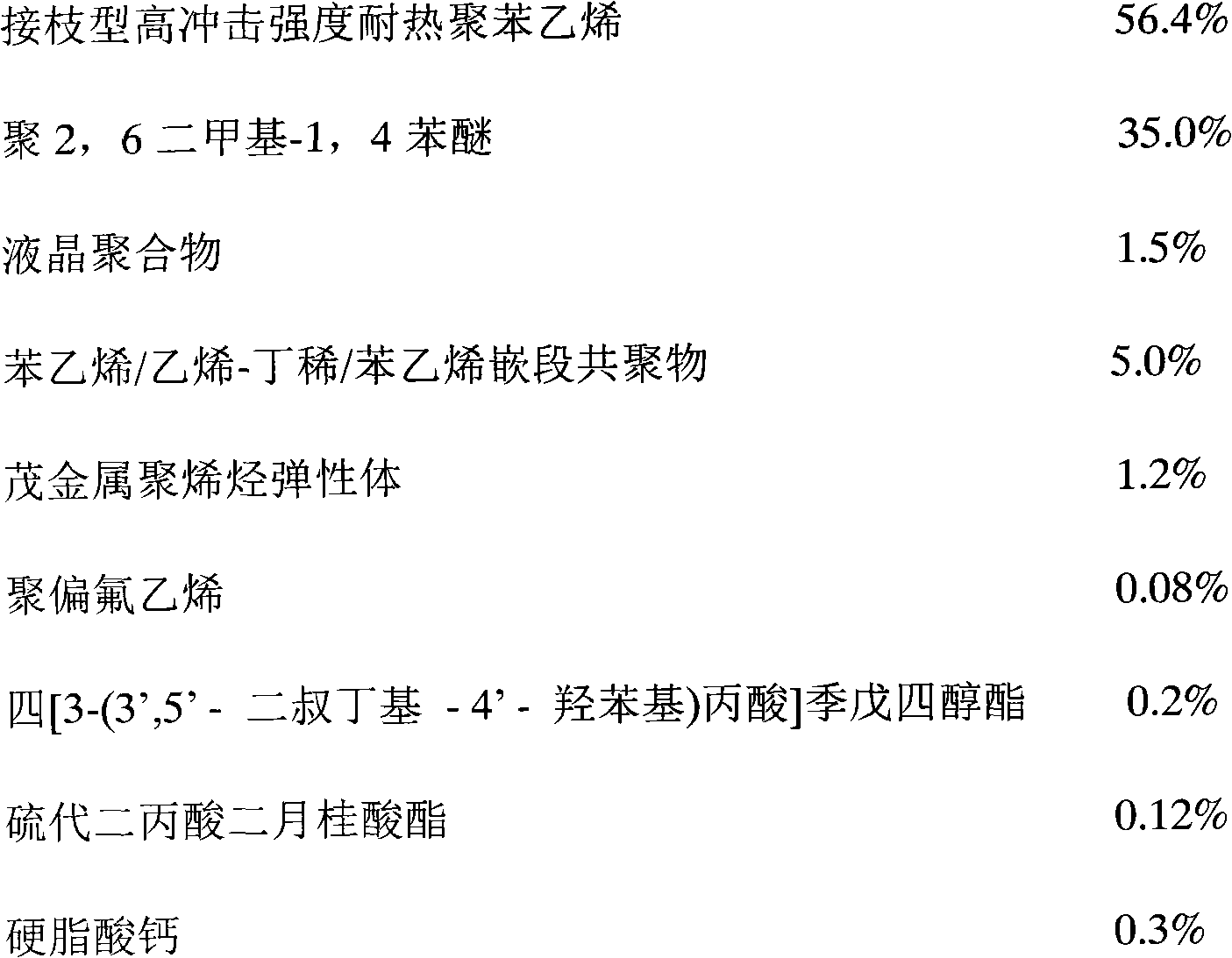

[0032] A kind of polymer alloy composition weight percentage of making plastic pipe insert is:

[0033]

[0034] A method for preparing a polymer alloy for making plastic pipe inserts:

[0035] First add liquid paraffin into styrene / ethylene-butylene / styrene block copolymer separately in advance, and then physically blend with other components. After mixing well, add it into an extruder to melt and extrude to granulate. That is, the desired polymer alloy is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com