Novel nitride-reinforced martensite heat-resisting steel

A martensitic and heat-resistant steel technology, applied in the field of iron-based heat-resistant steel, can solve the problems of poor high temperature resistance structure stability, and achieve the effect of high structure stability and good high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0044] The martensitic heat-resistant steel in embodiment 1~embodiment 5 is carried out the test of martensitic structure performance:

Embodiment 1

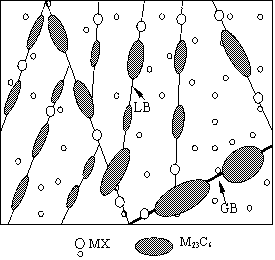

[0045] In Example 1, the Mn content in the martensitic heat-resistant steel does not increase, and is maintained at 0.5%, and its structure is as follows Figure 4 As shown, it can be seen that after the carbon content is reduced, if the Mn content is not increased, δ ferrite will be formed.

Embodiment 2

[0046] The microstructure of martensitic heat-resistant steel in embodiment 2 is as follows Figure 5 As shown, it can be seen that after the carbon content is reduced, increasing the Mn content to 0.8% can inhibit the delta ferrite and obtain the entire martensite structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com