Under-measurement Laves phase hydrogen storage alloy and preparation method thereof

A technology for hydrogen storage alloys and alloys, applied in chemical instruments and methods, non-metallic elements, metal hydrides, etc., can solve the problems of poor cycle stability, short platform area, and reduced hydrogen storage capacity, and achieve small hysteresis, The effect of long platform area and large hydrogen storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

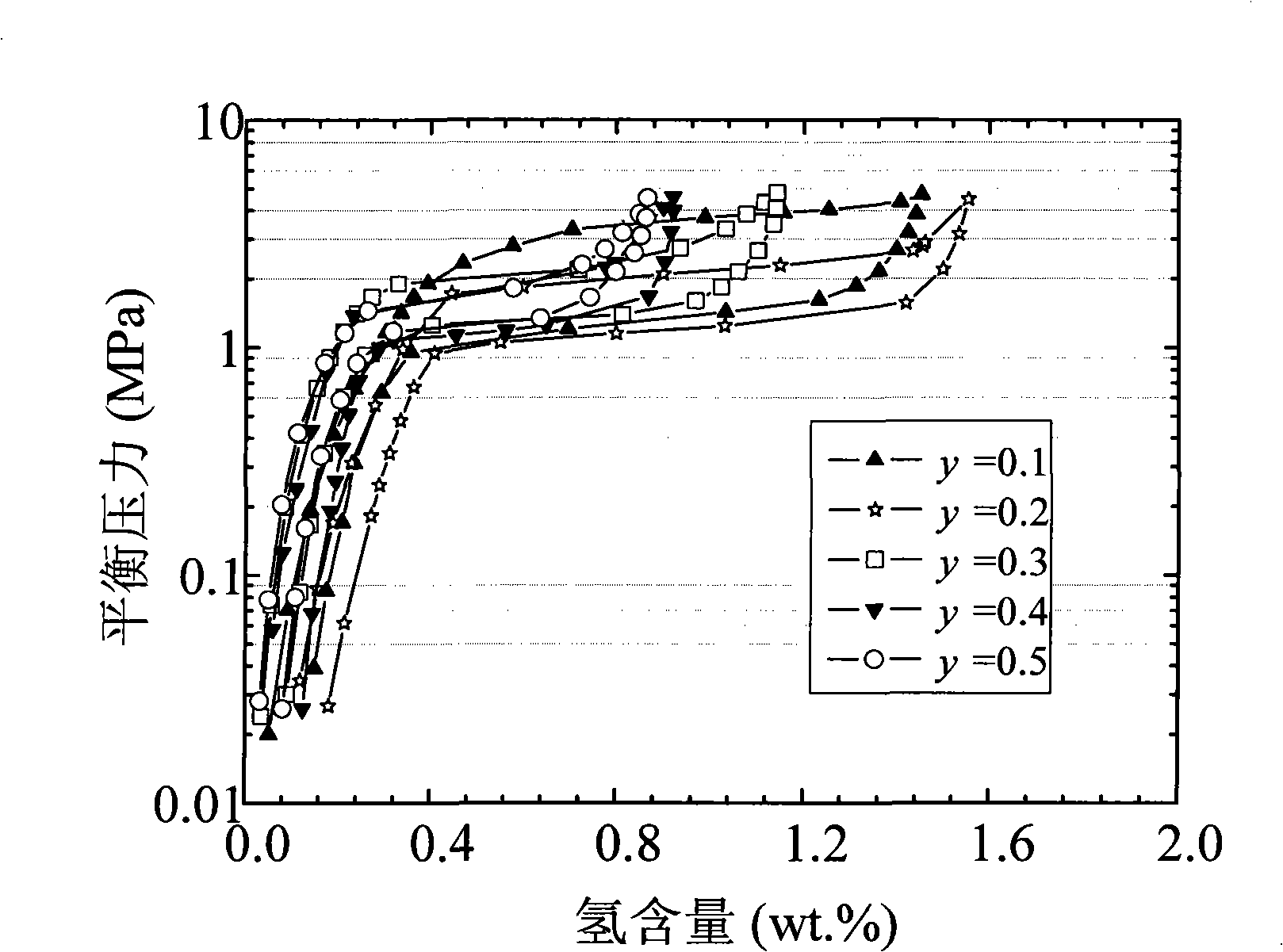

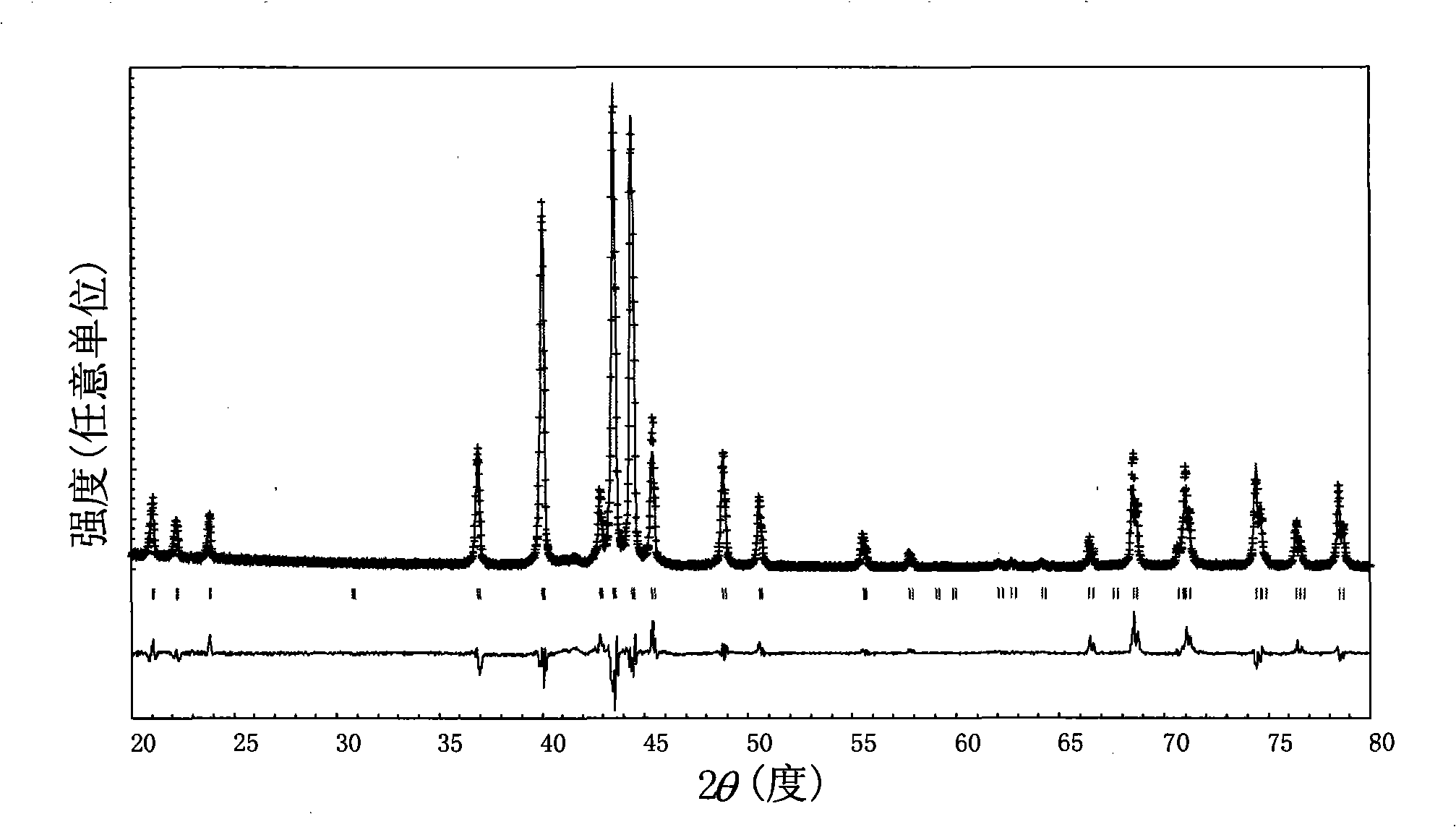

[0044] According to TiMn 1.5 V z (z=0.1~0.5) The chemical composition of the alloy Weigh a total of 30g of Ti, Mn (considering the burning rate of 3wt.%) and V metal blocks with a purity greater than 99% and melt them in a magnetic levitation high-frequency induction furnace for 2 to 3 times; Put the as-cast alloy into a quartz tube and keep it warm for 7 days under the protection of argon at 950°C; finally cool the furnace to room temperature, take out the annealed alloy, grind to remove the scale on the surface of the alloy, then crush it mechanically, and pass through a 300-mesh sieve spare. The alloy consists of a single C14-type Laves phase (attached figure 2 for TiMn 1.5 V 0.2 X-ray diffraction pattern of the alloy). The hydrogen absorption / desorption curves of the alloys were determined by the Sievert method. The test steps are as follows: First, weigh 2g of the above-mentioned alloy powder, put it into the sample chamber, 2 Activated under pressure; then lowere...

Embodiment 2

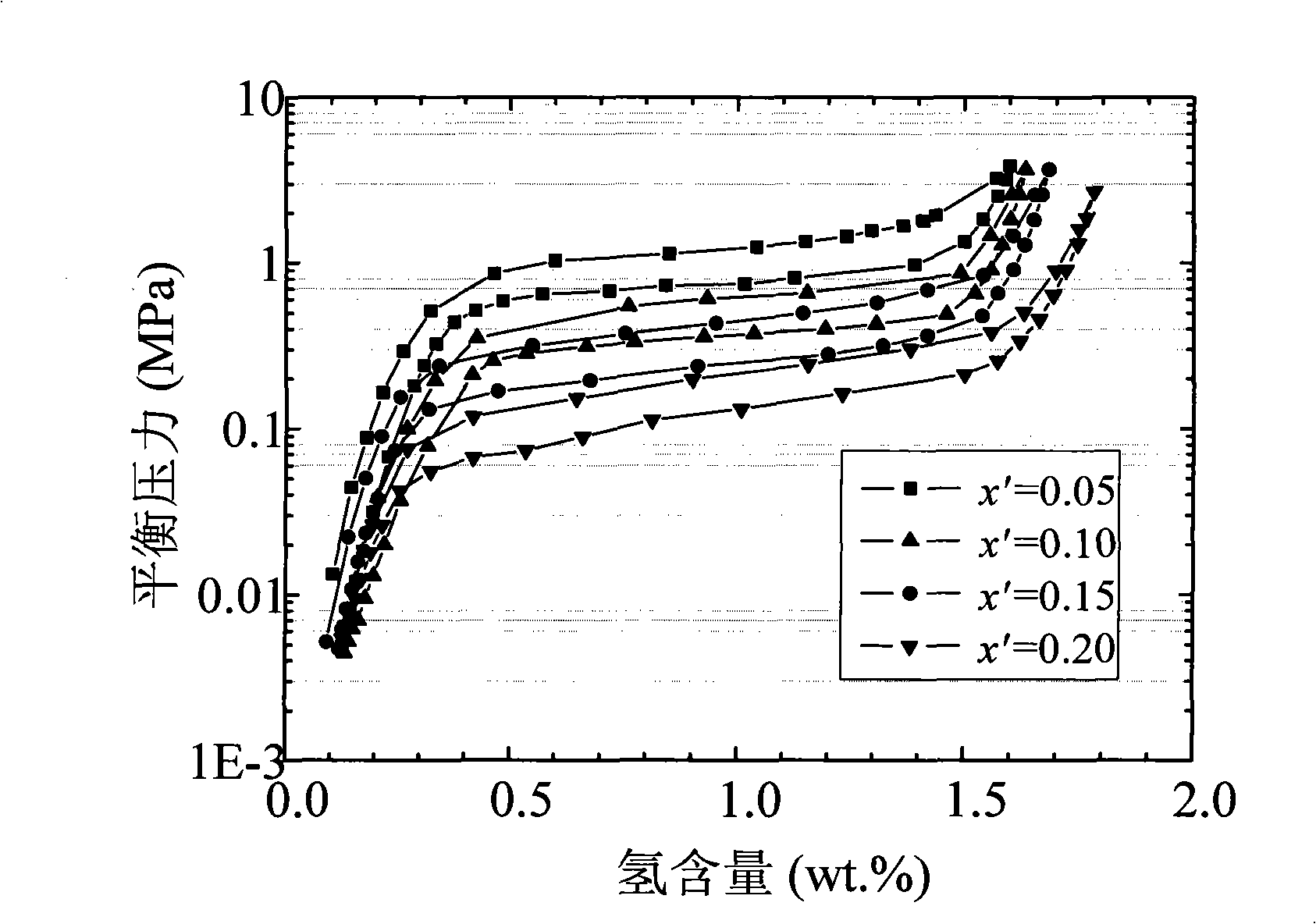

[0046] According to Ti 0.85 Zr 0.15 mn 1.4 Cr 0.1 V 0.2 The chemical composition of the alloy weighs a total of 30g of Ti, Mn (considering the burning rate of 3wt.%) and V metal blocks with a purity greater than 99% and melts them in a magnetic levitation high-frequency induction furnace for 2 to 3 times; put the cast alloy into the quartz In the tube, it was kept under argon protection at 950°C for 7 days; finally, the furnace was cooled to room temperature, and the annealed alloy was taken out, polished to remove the oxide scale on the alloy surface, then mechanically crushed, and passed through a 300-mesh sieve for later use. The resulting alloy consists of a single C14-type Laves phase (attached Figure 5 for Ti 0.85 Zr 0.15 mn 1.4 Cr 0.1 V 0.2 X-ray diffraction pattern of the alloy); through Rietvield software fitting, it can be known that its lattice constant and unit cell volume are the same as those of TiMn 1.5 V 0.2 Alloy is significantly larger. The hydro...

Embodiment 3

[0048] According to Ti 0.85 Zr 0.15 mn 1.3 Cr 0.2 V 0.2 The chemical composition of the alloy weighs a total of 30g of Ti, Mn (considering the burning rate of 3wt.%) and V metal blocks with a purity greater than 99% and melts them in a magnetic levitation high-frequency induction furnace for 2 to 3 times; put the cast alloy into the quartz In the tube, it was kept under argon protection at 950°C for 7 days; finally, the furnace was cooled to room temperature, and the annealed alloy was taken out, polished to remove the oxide scale on the alloy surface, then mechanically crushed, and passed through a 300-mesh sieve for later use. The resulting alloy consists of a single C14-type Laves phase (attached Figure 7 for Ti 0.85 Zr 0.15 mn 1.3 Cr 0.2 V 0.2X-ray diffraction pattern of the alloy). The hydrogen absorption / desorption curves of the alloys were determined by the Sievert method. The test steps are as follows: First, weigh 2g of the above-mentioned alloy powder, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com