Thermal power plant T/P92 heat-resistant steel aging grade evaluation method based on combination of Brinell hardness, structure and precipitation phase characteristic

A technology of Brinell hardness and precipitated phase, which is applied in the field of heat-resistant steel aging rating of T/P92 supercritical units used in thermal power plants, can solve the problems of large rating error, single evaluation reference standard, unfavorable production and application, etc., and achieve the rating method Accurate, easy to grasp, and the effect of reducing testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

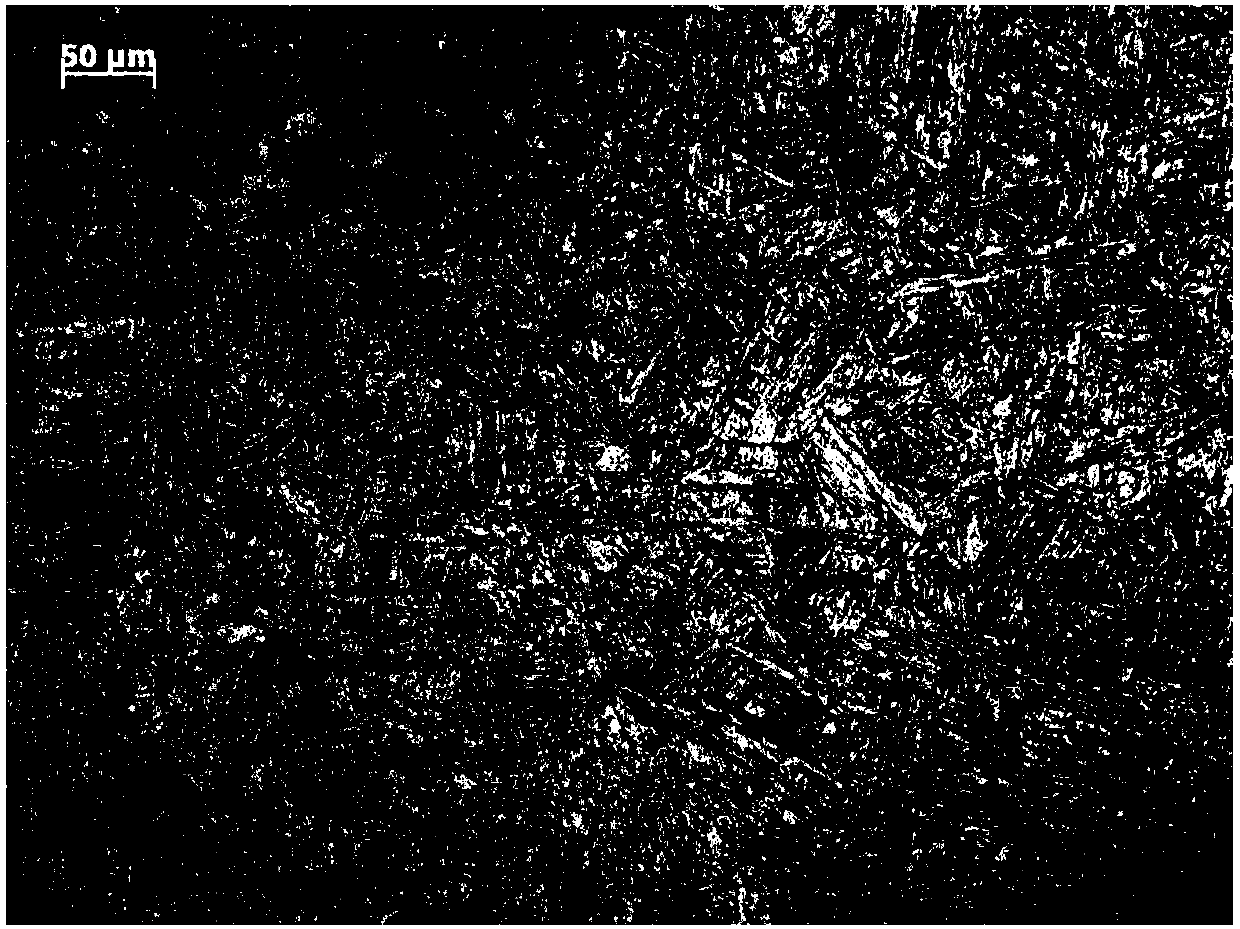

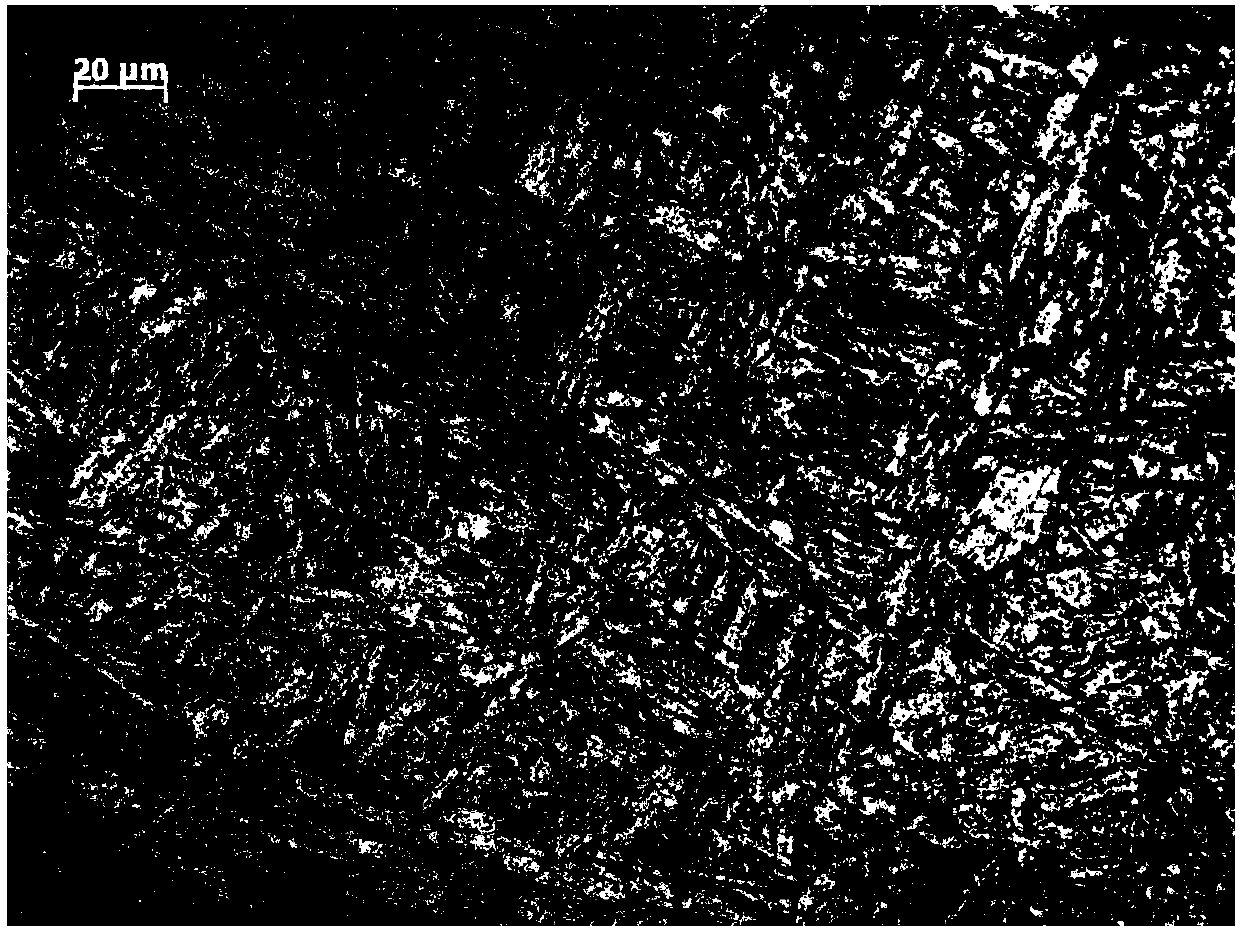

[0043] The samples were taken from the main steam pipeline of a 600MW supercritical generator set in a power plant. The material is P92 steel with full martensitic structure, the steam pressure is 28.1MPa, the outlet steam temperature is 593°C, and the unit has been running for 35841 hours.

[0044] (1) Cut the sample

[0045] Cut the sample from the pipe to be inspected, the sample should include the entire wall thickness section of the inspection part, and consider the difference in horizontal and vertical orientation; for thicker parts, it is allowed to cut several samples, and it is necessary to ensure that the entire inspection is covered Cross-section; the cutting of the sample should be done mechanically, and the sample needs to be cooled during cutting to prevent tissue changes; the sample should not be cut by flame, if flame cutting must be used, the heat-affected zone must be completely removed after cutting.

[0046] (2) Sample flattening and polishing

[0047] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com