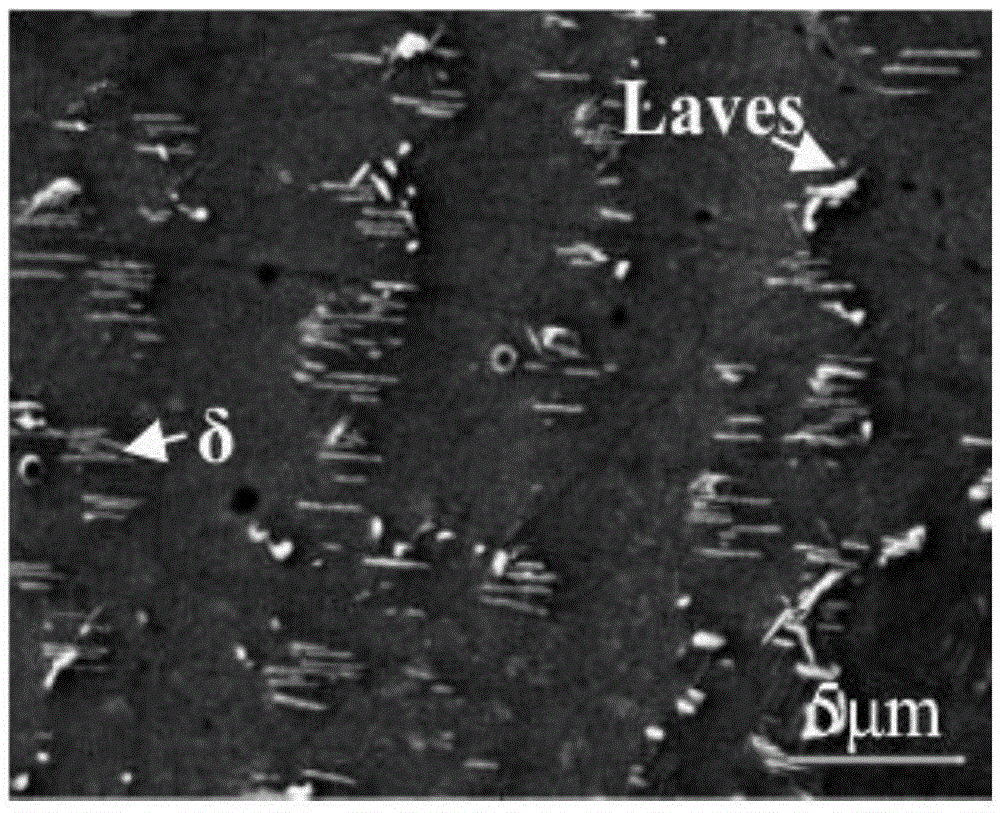

Preparation method of material increase manufactured nickel-based high-temperature alloy reserved with Laves phase

A nickel-based superalloy and additive manufacturing technology, applied in metal material coating process, coating and other directions, can solve the problem that excellent high temperature performance is not fully exerted, achieve excellent room temperature tensile mechanical properties, improve material utilization rate , the effect of excellent high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Described GH4169 superalloy preparation method, its equipment comprises:

[0032] (A) GH4169 superalloy substrate or stainless steel substrate;

[0033] (B) Argon-filled inert atmosphere processing chamber;

[0034] (C) high-energy beam as a heat source;

[0035] (D) Conveying system for synchronously feeding GH4169 superalloy powder;

[0036] (E) CNC system;

[0037] (F) Heat treatment device.

[0038] The specific methods are described in the following examples.

Embodiment 1

[0040] using CO 2 The laser is a high-energy beam additive manufacturing equipment to prepare GH4169 superalloy.

[0041] In the 4kW axis fast-flow continuous CO equipped with five-axis four-linkage CNC machining machine 2 Research on preparation of GH4169 superalloy on laser additive manufacturing equipment. Stainless steel is selected as the substrate, and GH4169 spherical powder with a particle size of -80 to +325 mesh prepared by the plasma rotating electrode method is selected as the raw material for laser additive manufacturing. High-purity argon with a purity of 99.99% is selected as the protective gas and powder conveying gas. The resulting additively manufactured bulk GH4169 superalloy on a stainless steel substrate like Figure 8 shown.

[0042] The first step: put the GH4169 superalloy with a particle size of -80 to +325 mesh into the powder feeder.

[0043] Step 2: Put the stainless steel substrate into the argon-filled inert atmosphere processing chamber an...

Embodiment 2

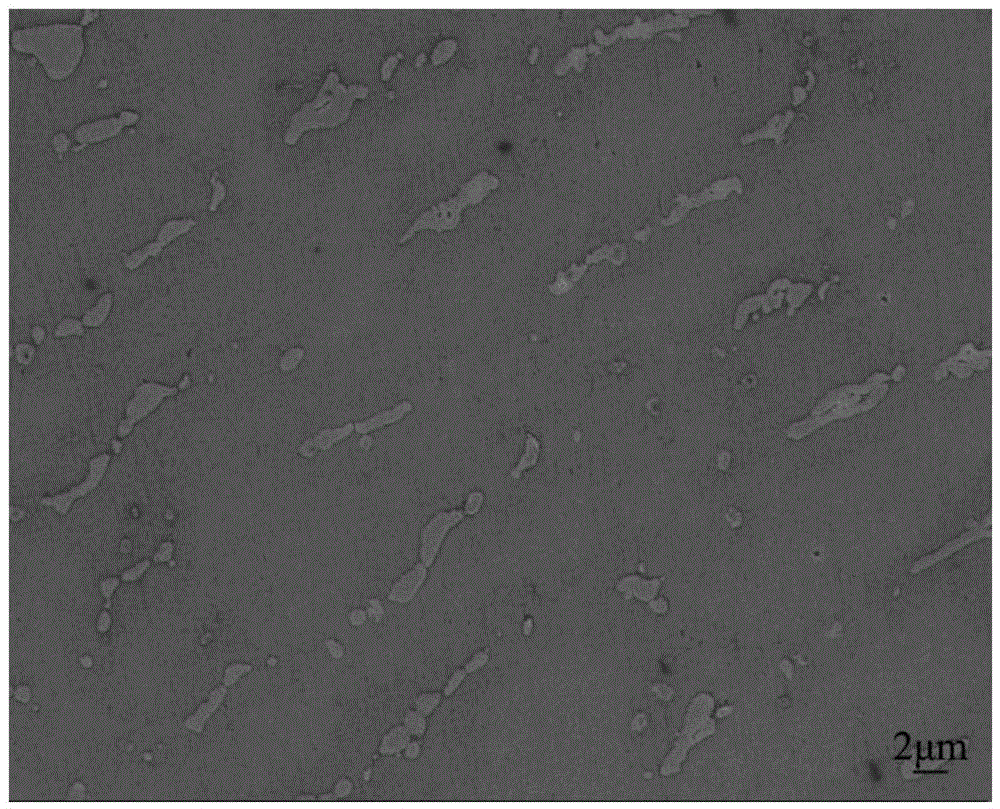

[0065] using CO 2 Laser for high energy beam additive manufacturing equipment to repair GH4169 superalloy. The obtained block GH4169 superalloy is additively manufactured on the GH4169 superalloy substrate like Image 6 shown.

[0066] In the 4kW axis fast-flow continuous CO equipped with five-axis four-linkage CNC machining machine 2 GH4169 superalloy repair research on laser additive manufacturing equipment. The forged GH4169 superalloy was selected as the substrate, and the GH4169 spherical powder with a particle size of -80 to +325 mesh prepared by the plasma rotating electrode method was selected as the raw material for laser additive manufacturing. High-purity argon with a purity of 99.99% is selected as the protective gas and powder conveying gas.

[0067] The first step: put the GH4169 superalloy with a particle size of -80 to +325 mesh into the powder feeder.

[0068] Step 2: Put the forged GH4169 superalloy into the argon-filled inert atmosphere processing roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com