Method for discriminating Laves phase and carbide phase in high Nb iron nickel base high temperature alloy

A high-temperature alloy, iron-nickel-based technology, applied in the preparation of test samples, measuring devices, and material analysis by optical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

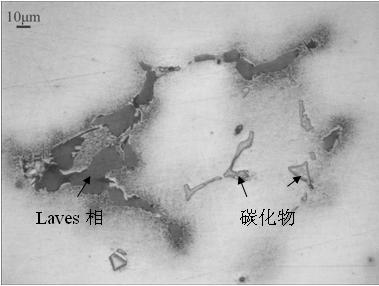

[0024] After grinding and polishing the GH4169 as-cast alloy sample, expose the polished sample surface to a box-type resistance furnace at a furnace temperature of 500°C for 1 hour, and then air-cool to ensure that the polished sample surface is not polluted. After the sample was cooled, it was directly observed under a metallographic microscope. The tissue of the sample after being treated at 500°C for 1 hour is as follows: figure 2 shown. It can be seen that after heat dyeing at 500°C for 1 hour, the Laves phase in the sample has turned reddish brown, and the carbides have a certain luster, surrounded by a coating film.

Embodiment 2

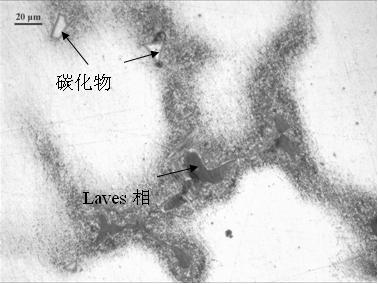

[0028] After the GH4169G alloy as-cast sample was ground and polished, the surface of the polished sample was exposed to a box-type resistance furnace at a furnace temperature of 520 ° C for 60 minutes, and the sample was directly observed under a metallographic microscope after cooling. The tissue of the sample after being treated at 520°C for 60 minutes is as follows: Figure 4 As shown, it can be seen that after heat dyeing at 520°C for 60 minutes, the Laves phase in the sample has turned brown, while the carbides have a certain luster.

Embodiment 3

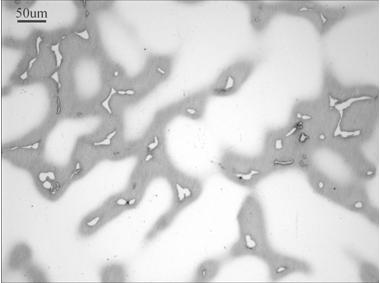

[0032] The Thermo-Span as-cast alloy sample was homogenized at 1120°C for 20 hours. After the sample was ground and polished, the surface of the polished sample was exposed to a box-type resistance furnace at a furnace temperature of 450°C for 80 minutes. After the sample was cooled, Observe directly under a metallographic microscope. The tissue of the sample after being treated at 450°C for 80 minutes is as follows: Figure 6 As shown, it can be seen that after heat dyeing at 450°C for 80 minutes, the Laves phase in the sample has turned reddish brown, and the carbides have a certain luster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com