High-strength and high-performance special aluminum alloy covered profile for radiator

An aluminum alloy, high-performance technology, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of aluminum alloy castings and aluminum alloy processing materials, such as variety and quality gap, and achieve simple and easy product structure. The effect of simple acquisition and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

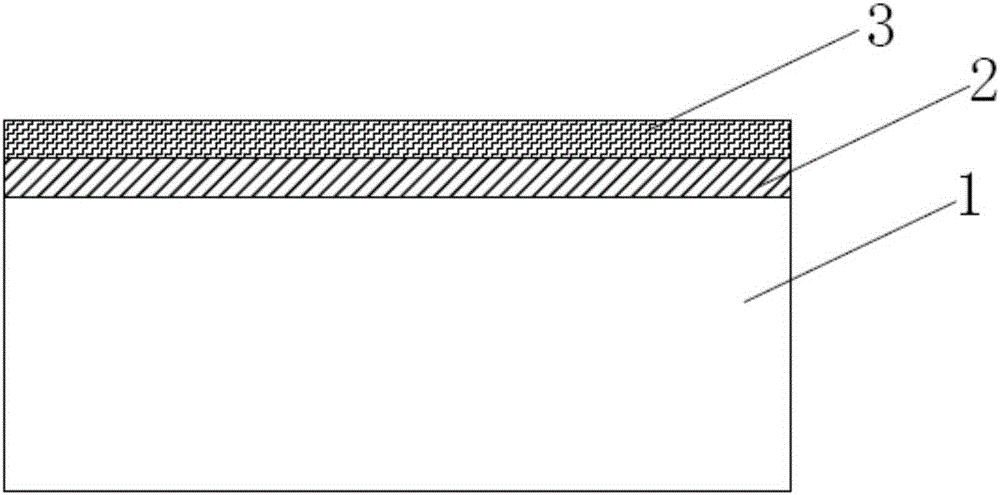

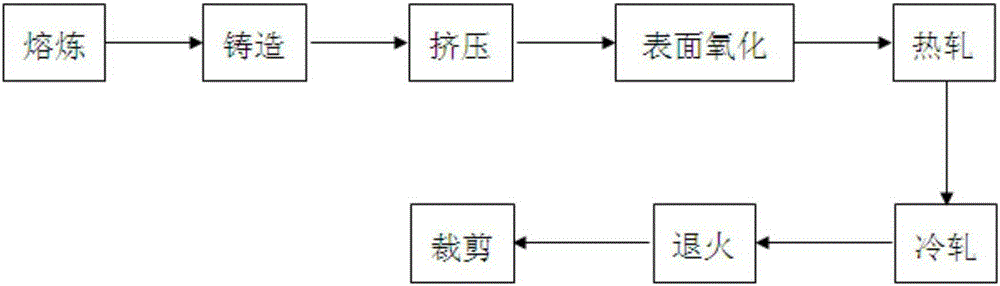

[0034] Such as figure 1 As shown, it is a structural schematic diagram of a high-strength, high-performance radiator special-purpose aluminum alloy clad profile according to the present invention. The inner layer of anti-corrosion aluminum alloy 2 is covered on the top of the base aluminum alloy 1, and the surface brazing material 3 is covered with the inner layer of anti-corrosion aluminum alloy. Above the alloy 2, the base aluminum alloy 1 accounts for 80% of the total thickness, and the inner anti-corrosion aluminum alloy 2 and the surface solder 3 each account for 10% of the total thickness.

[0035] The composition elements and mass percentages of the base aluminum alloy 1 are: Si: 0.6%, Fe: 0.7%, Cu: 0.15%, Mn: 1.3%, Zn: 0.1%, Re: 0.015%, and the balance Al, the base aluminum alloy The melting temperature is 655°C. Adding appropriate Si elements to the base aluminum alloy strengthens the base and enhances its resistance to deformation and support.

[0036] The compositi...

Embodiment 2

[0043] The thickness of the aluminum alloy clad profile is 3mm, the melting temperature is set at 745°C, the melting time is 5 hours, the temperature of the aluminum liquid during casting is 735°C, the annealing temperature is 480°C, and the temperature of the anodizing workshop is set at 50°C. All the other are identical with embodiment 1.

Embodiment 3

[0045] The thickness of the aluminum alloy clad profile is 5mm, the melting temperature is set at 730°C, the melting time is 5.5 hours, the temperature of the molten aluminum during casting is 725°C, the annealing temperature is 460°C, and the temperature of the anodizing workshop is set at 55°C. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com